Introduction

Nitinol, a remarkable alloy of nickel and titanium, has gained widespread attention for its exceptional tensile strength and unique wire properties. From medical devices to consumer electronics, the applications of nitinol in various industries continue to expand, making it a material of great interest and potential.

Understanding Nitinol Tensile Strength

Nitinol's impressive tensile strength is what sets it apart from other materials. This allows it to withstand high levels of stress and deformation, making it ideal for applications that require durability and reliability. In addition to its remarkable tensile strength, Nitinol exhibits superelasticity, meaning it can undergo large deformations and return to its original shape. This unique property makes Nitinol an excellent choice for medical devices such as stents and guidewires, where the material needs to maintain its shape while navigating through the body's intricate pathways.

Exploring Nitinol Wire Properties

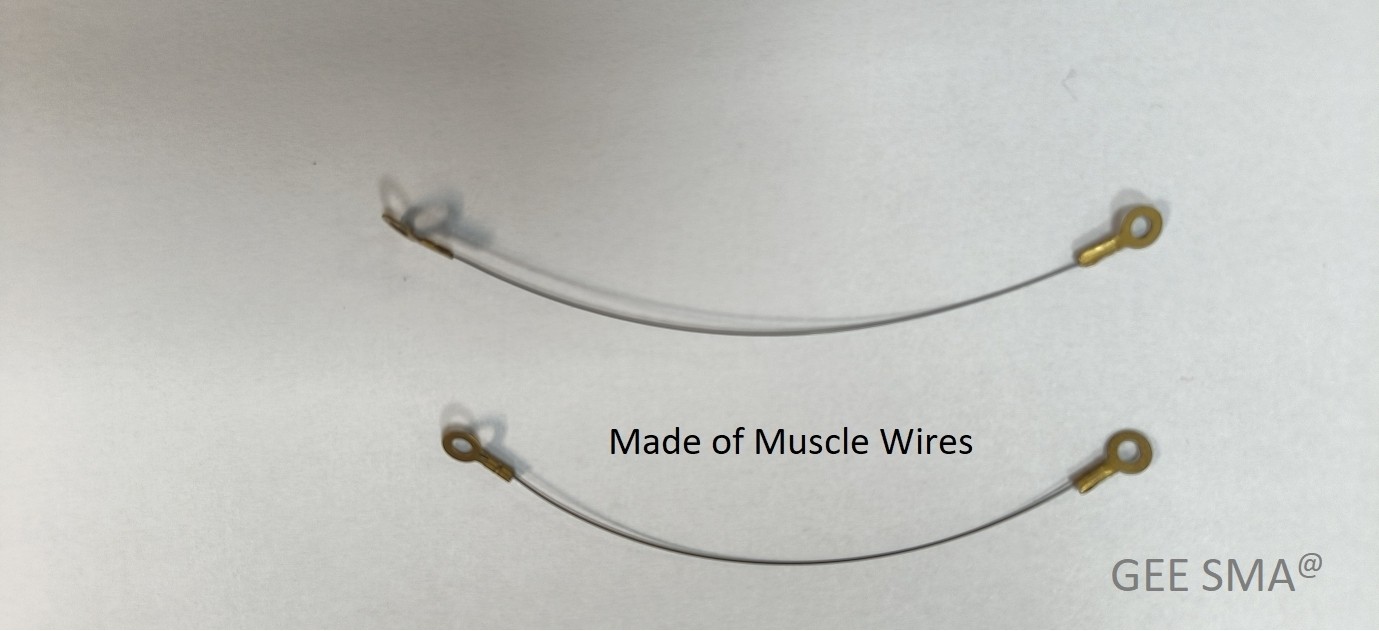

Nitinol wire is truly a marvel of modern materials science. Its most astonishing property is the shape memory effect: the ability to return to its original shape after deforming. This unique characteristic, among others, has made nitinol a prized material across various industries.

Nitinol's exceptional qualities have led to its widespread adoption in various sectors, and its applications are vast and varied.

- Medical Devices: Nitinol's biocompatibility and shape memory effect make it ideal for medical implants like stents and guidewires.

- Aerospace: This material's resistance to extreme temperatures and conditions makes it suitable for actuators and sensors in the aerospace industry.

- Automotive: Nitinol's durability and reliability are leveraged in components such as valves and sensors within the automotive sector.

Nitinol wire is a testament to human ingenuity. Its potential applications are still being explored, and its remarkable properties continue to shape innovation across multiple fields.

Applications of Nitinol in Various Industries

Nitinol's versatility has led to its widespread use across different industries, from medical devices like stents and orthodontic wires to aerospace components and consumer electronics. Its unique properties make it an invaluable material for innovative solutions.

Nitinol's shape memory and superelasticity properties have made it an ideal material for minimally invasive medical devices, such as guidewires and catheter components. Its ability to return to its original shape after being deformed allows for precise navigation through the body's intricate pathways, while its superelasticity ensures durability and resistance to fatigue. As a result, nitinol has revolutionized interventional medicine, enabling safer and more effective treatments for patients.

Unveiling the Fascinating Properties of Nitinol

Nitinol, a unique alloy of nickel and titanium, boasts an exceptional nitinol tensile strength that sets it apart from other materials. This remarkable property allows nitinol to return to its original shape even after being bent or deformed, making it a popular choice for various applications in different industries.

Nitinol's unique combination of nickel and titanium gives it a distinctive advantage in nitinol tensile strength. This exceptional property allows the alloy to withstand significant amounts of force without permanently deforming, making it an ideal choice for applications where resilience and durability are essential. Whether used in medical devices, aerospace components, or consumer products, nitinol's ability to maintain its original shape even under extreme conditions has made it a sought-after material in various industries.

Nitinol Tensile Strength: What Makes it Unique?

Nitinol's exceptional tensile strength makes it stand out among other materials. This property enables nitinol to withstand high levels of stress and deformation without permanently altering its shape, making it ideal for medical devices, aerospace components, and consumer electronics.

Nitinol's exceptional tensile strength is not only impressive, but it also allows for greater design flexibility in various applications. This means that nitinol components can be made thinner and lighter without sacrificing strength, making it an attractive choice for industries with critical weight and space. Additionally, its ability to return to its original shape after deformation makes it highly reliable for use in intricate and precise medical devices, where consistency and accuracy are paramount.

Nitinol Memory Metal: The Science Behind it

Nitinol's unique memory metal properties are derived from its ability to undergo a phase transformation at specific temperatures. When heated above its transition temperature, nitinol can revert to its original shape, exhibiting remarkable shape memory capabilities that have revolutionized various industries.

Exploring the Nitinol Melting Point

Nitinol's melting point is another intriguing aspect of this exceptional material. With a melting point of around 1310°C (2390°F), nitinol exhibits excellent stability at high temperatures, making it suitable for applications where heat resistance is crucial.

Nitinol's impressive stability at high temperatures makes it an ideal material for use in harsh environments, such as aerospace and automotive applications. Its ability to maintain its shape and mechanical properties at extreme temperatures ensures reliability and longevity in these demanding settings. This characteristic sets nitinol apart from other materials and contributes to its widespread use in critical components for industries where heat resistance is a top priority.

Stay tuned for the next section as we delve deeper into the versatile applications of nitinol in various industries!

The Versatile Applications of Nitinol

Nitinol is a remarkable material with various applications across various industries. From medical devices to aerospace components and consumer electronics, its unique properties make it an invaluable resource in modern technology.

Medical Applications of Nitinol

Nitinol's exceptional flexibility and shape memory properties make it a prized material in medicine. Its unique characteristics enable it to be used in various medical applications.

- Stents: Nitinol's ability to expand and retain its shape is crucial for stents, which are used to open blocked arteries.

- Orthodontic wires: The material's flexibility allows gentle tooth movement during orthodontic treatment.

- Surgical tools: Nitinol's shape memory property benefits surgical instruments requiring precise manipulation.

- Catheters and guidewires: The material's flexibility and shape memory allow smooth navigation through the body's complex systems.

Nitinol's applications have significantly advanced minimally invasive procedures, improving patient outcomes and increasing procedure success rates.

The combination of these factors underscores nitinol's invaluable role in modern medicine.

Nitinol in

the Aerospace Industry

Nitinol's high strength-to-weight ratio and superelasticity benefit the aerospace industry, making it suitable for components such as actuators, valves, and landing gear systems. Its resistance to corrosion and high-temperature stability also make it an excellent choice for critical aircraft applications.

Nitinol's unique properties also make it an ideal material for aerospace applications due to its ability to withstand extreme conditions and high-stress environments. Its shape memory allows it to return to its original shape after deformation, making it perfect for components that experience repeated stress during flight. Additionally, nitinol's fatigue resistance ensures the reliability and longevity of critical aircraft systems, providing a level of safety and performance that is essential in the aerospace industry.

Nitinol in Consumer Electronics

Nitinol's unique properties are harnessed in consumer electronics products such as eyeglass frames, cellular antennas, and headphone wires. Its durability and ability to withstand repeated bending without deformation make it an ideal material for everyday use.

In addition to eyeglass frames, cellular antennas, and headphone wires, nitinol is also used to produce smartphone components such as vibration motors and hinges. Its ability to maintain its shape memory allows for seamless operation and longevity in these devices, making nitinol a preferred material for consumer electronics manufacturers looking to enhance the performance and durability of their products.

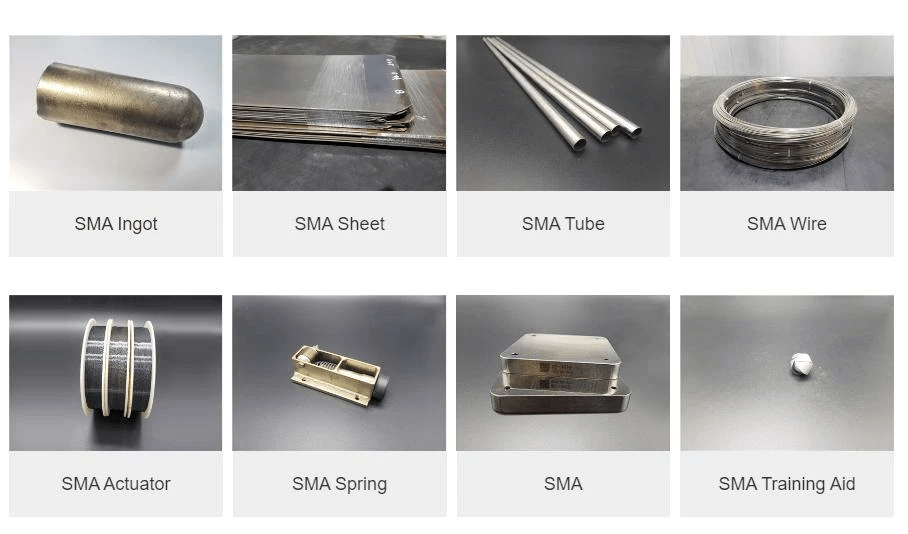

Crafting High-Quality Nitinol Materials and Components at GEE SMA

At GEE SMA, we take pride in our ability to tailor nitinol functional materials to meet our customers' specific needs. Whether it's a unique shape, size, or property requirement, our team of experts can customize nitinol materials to ensure they perform optimally in any application.

Tailoring Nitinol Functional Materials to Customer Needs

Our experienced engineers work closely with clients to understand their exact specifications and develop nitinol materials that align with their requirements. From medical devices to aerospace components, we have the expertise to create customized solutions that deliver exceptional performance and reliability.

Our team at GEE SMA is dedicated to staying at the forefront of nitinol material development, constantly seeking new ways to tailor our products to the specific needs of our customers. By collaborating closely with clients, we ensure that every aspect of their requirements is considered, resulting in nitinol materials that meet and exceed expectations. Whether a complex medical device or a critical aerospace component, our customized solutions are designed to deliver exceptional performance and reliability in any application.

Enhancing Product Quality at GEE SMA

Quality is at the core of everything we do at GEE SMA. We adhere to stringent quality control measures throughout manufacturing to ensure that every nitinol material and component meets the highest industry standards. Our commitment to excellence is reflected in the superior quality of our products.

In addition to our rigorous quality control measures, we prioritize swiftly and efficiently addressing customer requirements. Our customer service team is dedicated to providing prompt and personalized support to ensure our client's needs are met promptly. Whether a custom order or a specific request, we strive to exceed expectations and deliver exceptional service at every touchpoint.

Addressing Customer Requirements Swiftly

We understand that time is of the essence in today's fast-paced industries. That's why we prioritize swift response times and efficient customer communication. Whether it's a new project inquiry or an urgent request for technical support, our team is dedicated to addressing customer requirements promptly and effectively.

In addition to our swift response times, we also strongly emphasize proactive communication with our customers. Our team takes the initiative to keep clients informed every step of the way, ensuring that they are always in the loop regarding the progress of their projects or the resolution of their technical issues. This level of transparency and engagement helps build trust and strengthens our relationships with valued customers.

With a focus on customization, quality, and responsiveness, GEE SMA is a trusted partner for all nitinol solutions.

GEE SMA: Your Trusted Partner for Nitinol Solutions

The remarkable impact of nitinol in various industries cannot be overstated. Its exceptional tensile strength, unique memory metal properties, and high melting point make it a sought-after material in medical devices, aerospace engineering, and consumer electronics. The limitless potential of nitinol continues to be explored, with new applications emerging regularly. GEE SMA is your trusted partner for custom nitinol solutions, providing tailored materials and components to meet your needs.

The Remarkable Impact of Nitinol in Various Industries

Nitinol, a remarkable alloy with unique properties, has significantly impacted various industries. Its exceptional flexibility and ability to return to its original shape after deformation, known as shape memory, have made it an invaluable material for numerous applications.

Nitinol's versatility is evident in its widespread use across multiple sectors:

- Medical Devices: Its biocompatibility and flexibility have made it a staple in medical devices such as stents, guidewires, and orthodontic wires, revolutionizing minimally invasive procedures.

- Aerospace Industry: Nitinol's high fatigue resistance and lightweight nature make it ideal for critical aircraft components like actuators and landing gear systems.

- Consumer Electronics: Designers are increasingly harnessing the material's unique properties to create innovative and functional electronic products.

- Sports Equipment: Nitinol's shape memory effect enhances the performance and durability of sports equipment, such as golf clubs and bicycle frames.

- Automotive Industry: Its ability to return to its original shape is utilized in actuators for various vehicle components, improving efficiency and reliability.

As research and development continue to explore new applications, nitinol's potential to shape the future of technology and industries is immense.

The versatility and performance benefits offered by nitinol solidify its position as a groundbreaking material with a promising future.

Exploring the Limitless Potential of Nitinol

Nitinol's limitless potential is still being discovered as researchers uncover new ways to harness its unique properties. The possibilities are endless, from self-expanding stents that adjust to the body's natural movements to adaptive eyeglass frames that remember their shape. As technology advances, so does our understanding of how to utilize this remarkable material in groundbreaking ways.

As technology continues to evolve, the potential applications of nitinol are expanding rapidly. From innovative medical devices to cutting-edge consumer products, the versatility of this shape memory alloy is being leveraged in ways that were once thought impossible. As researchers delve deeper into the properties of nitinol, new opportunities for advancement and innovation are constantly emerging, paving the way for a future where this remarkable material plays an even more integral role in our daily lives.

GEE SMA is committed to providing high-quality nitinol materials and components tailored to your requirements. With a focus on enhancing product quality and swiftly addressing customer needs, GEE SMA stands out as a trusted partner for custom nitinol solutions. Whether you're looking for specialized medical devices or cutting-edge aerospace components, GEE SMA has the expertise and resources to deliver top-notch results.

Furthermore, GEE SMA prides itself on its ability to collaborate closely with clients to understand their unique needs and challenges. GEE SMA ensures that every nitinol solution is tailored to perfection by fostering open communication and a spirit of partnership. This personalized approach sets GEE SMA apart as a reliable and innovative partner in nitinol materials and components.