- Our Products

- Our Products

- Material

- Components

- About Us

- …

- Our Products

- Our Products

- Material

- Components

- About Us

- Our Products

- Our Products

- Material

- Components

- About Us

- …

- Our Products

- Our Products

- Material

- Components

- About Us

Your trusted partner in innovative nitinol solutions

Our Products

Shape Memory Alloys:

Metals That Remember Their Shape

Shape Memory Alloys (SMA) are a class of metallic materials that have the unique ability to "remember" their original shape.

What are Shape Memory Alloys?

1. Atomic - level mechanism

The shape - memory effect is based on a reversible phase transformation between two different crystal structures. At a lower temperature, the alloy is in a martensitic phase, which is relatively soft and can be easily deformed. When the alloy is heated above a certain temperature (the transformation temperature), it reverts to an austenitic phase, and it returns to its original shape. This phase transformation is a diffusion - less transformation that involves the rearrangement of atoms. For example, in nickel - titanium (Ni - Ti) alloys, the atoms shift their positions during the phase change, enabling the material to recover its shape.

2. Properties

Superelasticity: In addition to the shape - memory effect, SMAs also exhibit superelasticity. This means that the material can undergo large deformations (up to about 8 - 10%) and still return to its original shape when the applied stress is removed. This property is due to the stress - induced martensitic transformation.

Good biocompatibility: Many SMAs, especially Ni - Ti alloys, have excellent biocompatibility. They are corrosion - resistant and do not cause significant immune responses in the body.

Applications of Shape Memory Alloys

1. Medical field

Stents: As mentioned earlier, SMA - based stents are widely used in cardiovascular medicine. They can be inserted into narrowed blood vessels in a compressed state and then expand to their original shape as they reach body temperature. This helps to keep the blood vessels open and improve blood flow.

Orthodontic wires: Ni - Ti wires are used in orthodontics. They can exert a constant, gentle force on teeth over a long period. Their superelastic property allows them to provide the necessary corrective force as the teeth gradually move to their desired positions.

Surgical tools: Some surgical instruments are made using SMAs. For example, endoscopic graspers can be designed to have a shape - memory effect. They can be inserted through a small incision in a deformed state and then regain their original shape to perform the intended function inside the body.

2. Aerospace and automotive industries

Aerospace: In aerospace applications, SMAs can be used for morphing structures. For example, the shape of an aircraft wing could potentially be adjusted using SMA components to optimize aerodynamic performance during different flight conditions such as take - off, cruise, and landing.

Automotive: They can be used in actuators for various functions. For example, in engine components, SMA - based actuators could help control the flow of fuel or air by changing their shape in response to temperature changes.

3. Consumer products

Eyeglass frames: Some eyeglass frames are made from SMAs. They can be bent and deformed without breaking and will return to their original shape.

Smart textiles: There is research into incorporating SMAs into textiles to create clothing that can change its shape or fit according to the wearer's body temperature or other environmental factors.

Ingot Product

SMA Ingot

SMA Sheet

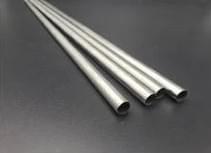

SMA Tube

SMA Wire

SMA Actuator

SMA Spring

SMA

Other Surfaces

Ni-Ti Alloy Code, Active Af,

Chemical Compositions and Typical Uses

Serial Number

Alloy Code

Typical Active Af

Composition at%

Typical Uses

1

SE 510

-15 to 0° C

51.0Ni

industrial and medical applications, such as antennas,fishing wires,guidewires

2

SE 508

-5 to 10° C

50.8Ni

Widely used in industrial and

medical fields

3

SE 508 ELI

0 to 15°C

55.8Ni

Batch weight greater than 250kg especially used in biomedical fields Ideal for high fatigue applications

4

SE NTC

-40 to -25° C

50.8 Ni ,0.30 Cr

Industrial, such as antennas,fishing wires

5

LSE 5065

22 to 37° C

50.65Ni

relatively low superelastic & high toughnes for fishing wire or medical wires applications.

6

LSE 507 ELI

22 to 37° C

50.7Ni

Binary Ni-Ti for

in-body medical applications

Batch weight greater than 250kg higher fatigue life

7

SM 499

90° C +/-2 ° C

49.9Ni

muscle wires

8

SM 500

80° C +/-2 ° C

50.0Ni

shape memory applications,actuators,robotics

9

SM 501

70° C +/-2 ° C

50.1Ni

muscle wires

10

SM 502

60° C +/-2 ° C

50.2Ni

shape memory form

11

SM NTC

55 to 70° C,

Hysteresis

(As-Ms)≤ 5° C

Ti50Ni45-41Cu5-9

narrow hysteresis, fast response speed for actuators

12

SM NTCC

20 to 35° C

Ti50Ni44.8-44.6

Cu5Cr0.2-0.4

medical application,ideal

for the field of orthopedics

13

NiTiNb

As'=60°C, Af’=80°C

Hysteresis

(As-Ms)-> 110° C

Ni44Ti47Nb9

mechanical and aerospace engineering components,such as NiTiNb ring

14

NiTiFe

Ms≤-130°C, As:≤-70°C

Ni47Ti50Fe3

Pipe-joint /Tube Coupling

15

NiTiHf

90 to 350° C

Ni38Ti50Hf12

High temperature actuators

NOTE:

- SE are typically used for their superelastic properties.

- SM are typically used for their shape memory properties.

- Typical tolerance for custom products is ±2 ° C

Materials Surface finishes

Black or brown Oxide

Polished

Centerless Ground

Other Surfaces

Contact Us

Don't be afraid to reach out. You + us = awesome