Introduction

When it comes to medical procedures, the use of NiTi wire has revolutionized the field of minimally invasive techniques. Also known as Nitinol, this unique alloy offers exceptional properties that make it an invaluable component in various medical devices. From guidewires to braided components, the versatility and reliability of NiTi wire have significantly improved patient outcomes and recovery.

Understanding NiTi Wire

Nitinol wire, a combination of nickel and titanium, possesses shape memory and superelasticity properties that allow it to return to its original shape when heated. This makes it ideal for medical applications where flexibility and precision are crucial.

In addition, NiTi wire is biocompatible, meaning it is well-tolerated by the human body and does not cause adverse reactions. This makes it a safe and reliable material for use in medical procedures such as minimally invasive surgeries, stent deployment, and orthodontic treatments. The ability of NiTi wire to maintain its shape and elasticity even after repeated use further enhances its suitability for long-term medical applications.

Advantages of NiTi Wire in Medical Procedures

The medical use of nitinol wire offers numerous advantages such as its biocompatibility, durability, and enhanced patient comfort during procedures. Its ability to withstand repetitive bending without deformation makes it a preferred material for various medical devices.

Furthermore, nitinol wire's superelasticity and shape memory properties make it an ideal material for minimally invasive procedures. Its ability to return to its original shape after being deformed allows for the creation of medical devices such as stents and guidewires that can be inserted into the body through small incisions. This reduces the need for large surgical openings, leading to faster recovery times and reduced scarring for patients.

Applications of NiTi Wire in Minimally Invasive Procedures

From stents to catheters, nitinol wire plays a vital role in minimally invasive procedures by providing the necessary strength, flexibility, and control required for successful outcomes. Its unique properties have made it indispensable in advancing medical technology.

The Versatility of NiTi Wire

Nitinol wire, also known as NiTi wire, is a unique alloy that exhibits remarkable flexibility and shape memory, making it an ideal material for medical devices. Its ability to return to its original shape after deformation allows for the creation of intricate medical components, such as stents and guidewires, that can navigate through the body's complex pathways with ease.

Flexibility and Shape Memory

NiTi wire's exceptional flexibility and shape memory properties enable it to bend and conform to the body's anatomy without losing its structural integrity. This makes it an invaluable material for medical devices used in minimally invasive procedures, where precision and maneuverability are crucial for successful outcomes.

Biocompatibility in Medical Devices

One of the key advantages of using NiTi wire in medical devices is its biocompatibility, meaning it is well-tolerated by the human body without causing adverse reactions. This makes it suitable for long-term implantation or use in various medical applications, ensuring patient safety and reducing the risk of complications.

Improved Patient Comfort and Recovery

The use of NiTi wire in medical devices contributes to improved patient comfort and faster recovery times. Its flexibility allows for less invasive procedures, leading to reduced trauma to surrounding tissues and organs. Additionally, its biocompatibility minimizes the risk of rejection or inflammation, promoting better overall patient outcomes.

By leveraging the versatility of NiTi wire in medical devices, healthcare professionals can enhance their ability to perform complex procedures with greater precision while prioritizing patient safety and comfort.

Precision and Reliability in Medical Guidewires

Enhanced Control and Navigation

When it comes to medical procedures, precision is key. NiTi wire provides enhanced control and navigation during minimally invasive surgeries, allowing for more accurate placement of medical devices within the body. This level of precision is crucial in ensuring successful outcomes for patients undergoing these procedures.

Durability and Longevity

Medical guidewires made from NiTi wire are known for their durability and longevity, making them reliable tools for healthcare professionals. The exceptional strength of nitinol wire ensures that these guidewires can withstand the rigors of medical procedures without compromising their performance, providing peace of mind to both patients and medical practitioners.

Minimizing Risks and Complications

One of the most significant advantages of using NiTi wire in medical guidewires is its ability to minimize risks and complications during procedures. The flexibility and shape memory properties of nitinol allow for smoother navigation through the body's intricate pathways, reducing the likelihood of tissue damage or other adverse effects often associated with traditional surgical methods.

Nitinol Wire Braided Components

Nitinol Wire Braided Components are essential in medical devices due to their strength and flexibility, allowing for precise control and maneuverability during minimally invasive procedures. The unique properties of nitinol wire make it ideal for crafting braided components that can withstand the rigors of medical applications while maintaining their shape and integrity.

Strength and Flexibility

Nitinol wire braided components offer exceptional strength and flexibility, providing the necessary support and maneuverability required for medical guidewires used in intricate procedures. This enables healthcare professionals to navigate through complex anatomical structures with ease, ensuring accurate placement and delivery of medical devices within the body.

Customization for Specific Medical Devices

The versatility of nitinol wire allows for customization to meet the specific requirements of various medical devices. Whether it's designing intricate stent delivery systems or crafting specialized catheters, nitinol wire braided components can be tailored to fit the exact specifications needed for optimal performance in a wide range of minimally invasive techniques.

Optimizing Performance in Minimally Invasive Techniques

The use of nitinol wire braided components significantly enhances the performance of minimally invasive procedures by providing superior pushability, torque transmission, and kink resistance. This ultimately leads to improved patient outcomes, reduced procedure times, and enhanced overall efficiency in delivering advanced medical care.

The Difference Between TMA Wire and NiTi Wire

Properties and Characteristics

TMA wire is known for its high tensile strength and excellent fatigue resistance, making it ideal for applications in orthodontic braces and other medical devices where flexibility and durability are essential. On the other hand, NiTi wire is valued for its biocompatibility and corrosion resistance, making it suitable for use in cardiovascular stents and other implantable medical devices. These distinct properties and characteristics make TMA and NiTi wires valuable materials in the field of medical engineering, each serving specific purposes based on their unique traits.

Medical Applications and Utilization

TMA wire is commonly used in orthodontic applications due to its superelasticity, while NiTi wire is extensively utilized in medical devices such as stents, guidewires, and orthopedic implants. The unique properties of NiTi wire make it ideal for minimally invasive procedures where flexibility and biocompatibility are essential.

TMA wire's superelasticity allows it to exert continuous, gentle force on teeth, making it an excellent choice for orthodontic applications. On the other hand, NiTi wire's biocompatibility and flexibility make it a top choice for medical devices like stents and guidewires. Its ability to adapt to the body's natural movements makes it perfect for minimally invasive procedures, where precision and ease of use are crucial.

Advantages in Minimally Invasive Procedures

The difference between TMA wire and NiTi wire lies in their advantages for minimally invasive procedures. While TMA wire provides flexibility under stress, NiTi wire's shape memory allows it to navigate through complex anatomical structures with precision, making it a preferred choice for medical guidewires in intricate procedures.

In addition to their advantages in minimally invasive procedures, NiTi wire also offers the benefit of enhanced durability and resistance to corrosion, making it a reliable choice for medical guidewires that need to withstand prolonged use in various bodily environments. This durability ensures that the wire maintains its shape memory and navigational precision over time, reducing the need for frequent replacements and enhancing overall cost-effectiveness in medical procedures. As a result, medical professionals can trust in the longevity and performance of NiTi wire for intricate interventions.

GEE SMA: Crafting High-Quality Medical Nitinol Components

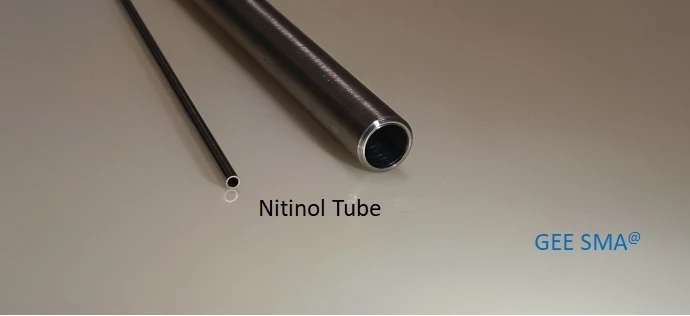

GEE SMA is a leading manufacturer of medical nitinol components, specializing in NT0401 Nitinol Wire & Nitinol Rod. Our commitment to consistent product quality ensures that our nitinol materials meet the highest standards for medical applications. With a focus on addressing customer requirements swiftly, we work closely with our clients to deliver tailored nitinol materials that meet their unique needs and specifications.

Consistent Product Quality

At GEE SMA, we prioritize the quality of our medical nitinol components, including NT0401 Nitinol Wire & Nitinol Rod, to ensure optimal performance and reliability in minimally invasive procedures. Our rigorous quality control processes guarantee that each component meets the highest industry standards for biocompatibility and precision, providing peace of mind for medical professionals and patients alike.

In addition to prioritizing the quality of our medical nitinol components, we also place a strong emphasis on addressing customer requirements swiftly. Our responsive and attentive customer service team is dedicated to understanding the unique needs of each client and providing tailored solutions in a timely manner. Whether it's customizing orders, accommodating specific delivery schedules, or offering technical support, we are committed to going above and beyond to ensure customer satisfaction.

Addressing Customer Requirements Swiftly

We understand the urgency and specificity of our customers' needs in the medical field. That's why at GEE SMA, we prioritize swift communication and efficient problem-solving to address any customer requirements promptly. Our dedicated team is committed to providing personalized support throughout the entire process, from initial consultation to final product delivery.

Tailoring Nitinol Materials to Unique Customer Needs

One of our key strengths at GEE SMA is our ability to customize nitinol materials for specific medical devices and applications. Whether it's shaping NT0401 Nitinol Wire or creating specialized nitinol braided components, we work closely with our clients to tailor materials that meet their unique requirements. This level of customization ensures that our nitinol components optimize performance in minimally invasive techniques while meeting the highest standards for safety and reliability.

Furthermore, our team of experts is dedicated to staying at the forefront of nitinol material advancements, allowing us to offer the latest innovations to our clients. By continuously researching and developing new techniques and technologies, we ensure that our customized nitinol materials are always on the cutting edge. This commitment to innovation enables us to provide our customers with materials that not only meet their current needs but also anticipate future requirements in the rapidly evolving field of medical device technology.

Conclusion

Nitinol Wire: Revolutionizing Minimally Invasive Procedures

Nitinol wire, also known as NiTi wire, has revolutionized minimally invasive procedures with its flexibility, shape memory, and biocompatibility. Its unique properties have made it an invaluable tool in the medical field, allowing for precise and reliable navigation during complex procedures.

Advancing Precision and Reliability in Medical Devices

The medical use of nitinol wire extends beyond just guidewires. It has been instrumental in the development of various medical devices, offering strength, flexibility, and customization for specific applications. From stents to catheters, nitinol components have enhanced the precision and reliability of these devices.

Nitinol components have revolutionized the field of interventional cardiology, allowing for the creation of stents that can be compressed and then expand to fit the precise dimensions of a patient's blood vessel. This level of customization has greatly improved patient outcomes and reduced the need for repeat procedures. Additionally, nitinol wire has enabled the development of advanced catheters that can navigate through complex vascular systems with ease, providing physicians with greater control and accuracy during minimally invasive procedures. The versatility and reliability of nitinol components continue to drive innovation in the medical device industry, leading to improved patient care and treatment options.

GEE SMA: Your Partner for High-Quality Nitinol Components

When it comes to sourcing high-quality nitinol components such as NT0401 nitinol wire & nitinol rod, GEE SMA is your trusted partner. With a focus on consistent product quality and swift response to customer requirements, GEE SMA tailors nitinol materials to meet unique needs in the medical industry.

In conclusion, the versatility and reliability of nitinol wire have significantly advanced minimally invasive procedures and precision in medical devices. As technology continues to evolve, GEE SMA remains committed to providing high-quality nitinol components that meet the ever-changing demands of the medical industry.