Introduction

In the ever-evolving landscape of medical technology, wire nitinol has emerged as a game-changer, captivating the attention of healthcare professionals and engineers alike. This remarkable material, composed primarily of nickel and titanium, boasts a unique set of properties that make it ideal for various medical applications. As we delve deeper into the world of Nitinol components, we will explore not only what Nitinol wire is but also its transformative role in modern medicine.

Understanding Wire Nitinol for Medical Devices

Wire nitinol is a specialized alloy known for its shape memory and superelastic properties, making it a favorite in the realm of medical devices. Its ability to return to a predetermined shape when heated allows for innovative solutions in minimally invasive surgeries and other applications where flexibility is paramount. By understanding wire nitinol's composition and behavior, we can appreciate why it's become an essential tool in healthcare.

The Unique Properties of Nitinol

What sets Nitinol apart from other materials? Its exceptional flexibility and strength are just the beginning; this alloy also exhibits remarkable resistance to corrosion and fatigue, which are crucial attributes for devices that must endure harsh bodily environments over time. Additionally, researchers have discovered that wire nitinol can undergo transformation phases that enhance its functionality—making it not just durable but versatile in various medical scenarios.

Why the Medical Field Chooses Nitinol

The medical field's preference for wire nitinol stems from its biocompatibility and safety profile when used within the human body. Surgeons rely on what does NiTi wire do? It facilitates procedures like stent placements or guidewire navigation through complex vascular systems with ease and precision. As we continue to innovate within healthcare, understanding how to train Nitinol wire effectively will be crucial to unlocking even more potential applications in this exciting field.

What is Nitinol Wire?

Nitinol wire is a fascinating material that has revolutionized various fields, particularly in medicine. Known for its unique properties, wire nitinol is a nickel-titanium alloy that exhibits remarkable flexibility and shape memory capabilities. This combination of traits makes it an ideal choice for many applications within the medical industry.

Defining Nitinol and Its Composition

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, consists primarily of nickel and titanium in varying proportions, typically around 55% nickel and 45% titanium. This specific composition grants wire nitinol its extraordinary qualities, such as superelasticity and the ability to return to a predetermined shape when heated above a certain temperature. Understanding what is Nitinol wire goes beyond its basic definition; it encompasses the science behind its unique atomic structure that allows it to undergo significant deformation while maintaining strength.

The Transformation Phase of Nitinol

One of the most intriguing aspects of wire nitinol is its transformation phase, which refers to how this material can change between two distinct crystalline forms: martensite and austenite. In its martensitic state, Nitinol can be easily deformed at lower temperatures; however, when heated above its transformation temperature, it reverts to the stronger austenitic phase. This property not only enhances the versatility of what does NiTi wire do but also allows for innovative applications in minimally invasive surgical procedures where precise movement and deployment are crucial.

Applications in Modern Medicine

Wire nitinol has found numerous applications across modern medicine due to its unique characteristics. For instance, it's widely used in stents and guidewires because of their flexibility and ability to navigate through complex vascular systems without causing damage. Additionally, orthopedic tools made from Nitinol components are designed to adapt seamlessly to the body's movements while providing support—demonstrating how integral this material has become in enhancing patient care.

Advantages of Nitinol Components

Nitinol components have garnered significant attention in the medical field due to their unique properties that enhance performance and patient safety. Among these advantages are exceptional flexibility and strength, biocompatibility, and impressive resistance to corrosion and fatigue. Understanding these benefits helps explain why wire nitinol is a preferred choice for various medical applications.

Exceptional Flexibility and Strength

One of the standout features of wire nitinol is its remarkable flexibility combined with high strength, making it an ideal material for numerous medical devices. This exceptional flexibility allows Nitinol components to navigate complex anatomical pathways during procedures with ease, reducing trauma to surrounding tissues. When we ask, What is Nitinol wire? we discover that its ability to return to its original shape after deformation—thanks to its shape memory effect—enables it to withstand significant stress without compromising structural integrity.

Biocompatibility and Safety in Patients

Another compelling advantage of Nitinol components lies in their biocompatibility, which ensures that they can safely interact with human tissue without eliciting adverse reactions. This property makes wire nitinol particularly suitable for implants and devices used within the body, as it minimizes risks associated with foreign materials. As healthcare professionals prioritize patient safety, understanding What does a NiTi wire do? reveals that its use can significantly reduce complications related to allergies or rejections.

Resistance to Corrosion and Fatigue

Nitinol's resistance to corrosion and fatigue further solidifies its position as a go-to material in the medical industry. Wire nitinol exhibits excellent durability when exposed to bodily fluids or environmental factors within the body, ensuring long-lasting performance of medical devices like stents or guidewires. Additionally, this resilience means that healthcare providers can rely on Nitinol components over extended periods without worrying about degradation or failure—an essential aspect when considering how to train Nitinol wire for specific applications.

What Does NiTi Wire Do?

Wire nitinol plays a crucial role in various medical applications, especially due to its unique properties. Its ability to undergo phase transformation allows it to return to a predetermined shape when heated, making it an ideal choice for devices that require flexibility and reliability. Understanding what Nitinol wire does can greatly enhance our appreciation of its contributions to modern medicine.

Functionality in Minimally Invasive Surgery

In the realm of minimally invasive surgery, wire nitinol is a game changer. Surgeons utilize Nitinol components for tools such as catheters and surgical instruments that navigate through the body with minimal disruption to tissues. The flexibility and strength of Nitinol wire allow these instruments to bend and maneuver around delicate structures, ultimately leading to quicker recovery times for patients.

Moreover, the shape memory effect of Nitinol wire means that once deployed, these tools can revert to their original form, enhancing operational efficiency during procedures. This functionality not only reduces patient trauma but also improves surgical precision by allowing access to hard-to-reach areas without extensive incisions. As healthcare continues evolving toward less invasive methods, the role of Nitinol in these advancements is increasingly vital.

Role in Stents and Guidewires

Guidewires crafted from Nitinol wire provide unmatched navigational capabilities during complex surgeries by offering both stiffness for pushing through blockages and flexibility for navigating curves within the body’s anatomy. The combination of these features enhances the effectiveness of interventional procedures while minimizing risks associated with traditional materials that may lack such versatility. With ongoing innovations in stent designs using wire nitinol, we can expect even more effective solutions for vascular diseases.

Enhancing Tools for Orthopedic Uses

Nitinol's unique characteristics extend well into orthopedics where it enhances various surgical tools and implants. For instance, orthopedic devices made from NiTi wire exhibit exceptional strength combined with lightweight properties; this is crucial when considering patient comfort post-surgery. Additionally, the ability of Nitinol components to adapt under stress makes them ideal for applications such as bone fixation devices or spinal implants.

The use of wire nitinol in orthopedic applications also benefits from its biocompatibility—a key factor when developing long-lasting implants that integrate well with human tissue without causing adverse reactions. Moreover, training methods on how to train Nitinol wire can optimize these devices' performance further by ensuring they meet specific mechanical requirements essential for successful surgeries. As orthopedic technology continues advancing, we can anticipate even more innovative uses of NiTi wire enhancing patient care.

Is Nitinol Electrically Conductive?

When discussing Nitinol, a common question arises: is Nitinol electrically conductive? The answer is yes, but the level of conductivity is relatively low compared to traditional metals like copper or aluminum. Understanding the conductivity of wire Nitinol is crucial, especially when considering its applications in modern medical devices and technologies.

Understanding Nitinol's Conductivity

Nitinol consists primarily of nickel and titanium, which gives it unique properties, including shape memory and superelasticity. While it does conduct electricity, its resistivity means it isn't suitable for high-current applications like some other metals. The conductivity of wire Nitinol can be advantageous in specific contexts, such as in sensors where moderate electrical properties are beneficial without compromising flexibility or strength.

Applications in Sensors and Actuators

The unique combination of properties found in wire Nitinol makes it an excellent candidate for various applications in sensors and actuators. For example, its ability to undergo phase transformations allows for innovative designs that can respond dynamically to environmental changes. This responsiveness makes NiTi wire particularly useful in medical devices that require precise movements or adjustments based on real-time data.

Implications for Future Medical Technologies

As we look towards the future of medical technologies, the implications of using electrically conductive wire Nitinol are vast and exciting. The integration of this material into new devices could lead to breakthroughs in minimally invasive surgeries and smart implants that adapt to patient needs over time. Additionally, ongoing research into how to train Nitinol wire could enhance its functionality even further, paving the way for more advanced applications that blend mechanical performance with electrical capabilities.

How to Train Nitinol Wire?

Training wire Nitinol is a crucial process that enhances its shape memory properties, allowing it to adapt and perform as intended in medical applications. This involves specific techniques that mold the Nitinol components into desired shapes while retaining their unique characteristics. Understanding how to train Nitinol wire effectively can lead to better performance in various medical devices.

Methods for Shaping Nitinol Components

There are several methods used for shaping Nitinol components, each tailored to achieve optimal results based on the intended application of the wire nitinol. One common technique involves heating the wire nitinol above its transformation temperature, where it becomes malleable and can be formed into specific shapes through mechanical manipulation or specialized tooling. Another method is cold working, which allows for precise adjustments without compromising the material's inherent properties, ensuring that what does a NiTi wire do remains effective in its role.

In addition to these methods, controlled cooling processes play a significant role in solidifying the shape of trained wire nitinol. By carefully managing the cooling rate and environment, manufacturers can enhance the stability of the trained shape, ensuring that when deployed within a patient’s body, it performs reliably under various conditions. This meticulous approach ensures that every aspect of how to train Nitinol wire is considered for maximum efficacy.

Importance of Training for Performance

The importance of training Nitinol components cannot be overstated; it directly impacts their functionality and reliability in medical applications. Properly trained wire nitinol exhibits predictable behavior when subjected to temperature changes or mechanical stress, which is vital for devices like stents and guidewires that must navigate complex bodily environments safely. Without effective training methods, there could be unpredictable performance issues—something no surgeon wants during a delicate procedure.

Moreover, training enhances the biocompatibility of NiTi wire by ensuring that it closely aligns with physiological conditions encountered within human anatomy. This alignment minimizes potential complications while maximizing patient safety—essential factors when considering what does a NiTi wire do during surgical interventions. In essence, well-trained Nitinol components are not just about aesthetics; they are about functionality and effectiveness in life-saving scenarios.

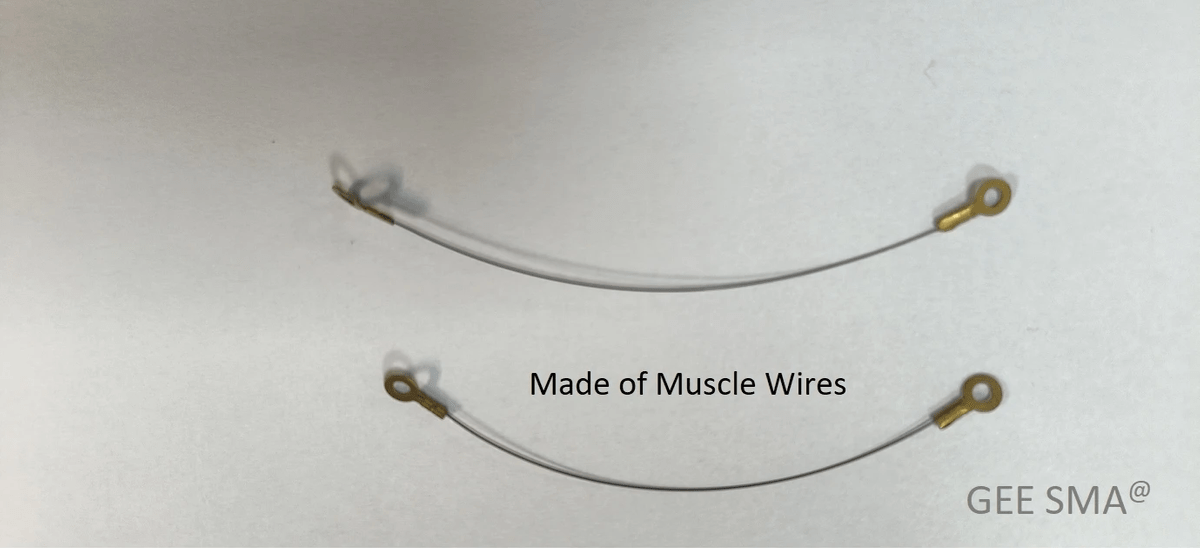

GEE SMA's Expertise in Nitinol Training

When it comes to expertise in how to train Nitinol wire effectively, GEE SMA stands out as a leader in this specialized field. With years of experience and cutting-edge technology at their disposal, they employ advanced techniques tailored specifically for shaping and training wire nitinol components with precision and consistency. Their commitment ensures that every piece meets rigorous standards required for critical medical applications.

GEE SMA also understands that innovation doesn’t stop at production; they continuously explore new methods and materials aimed at improving how NiTi wires perform under varying conditions—especially regarding whether or not is Nitinol electrically conductive? Their research initiatives focus on enhancing both mechanical properties and electrical conductivity where applicable, paving the way for future advancements in medical technology using trained Nitinol wires.

In summary, choosing GEE SMA means opting for expertise backed by innovation when considering your needs related to training wire nitinol components effectively—a decision that ultimately benefits both healthcare providers and patients alike.

Conclusion

In wrapping up our exploration of wire Nitinol, it's clear that this remarkable material has revolutionized the medical field in numerous ways. From its unique properties to its versatile applications, Nitinol components have become indispensable in modern medicine. As we look ahead, the potential for wire Nitinol only seems to grow, promising even more innovative solutions for healthcare challenges.

Key Benefits of Wire Nitinol in Medicine

Wire Nitinol offers a plethora of benefits that make it a preferred choice for medical devices. Its exceptional flexibility and strength allow for designs that can navigate complex anatomical structures with ease. Additionally, the biocompatibility of Nitinol components ensures patient safety, minimizing adverse reactions during procedures.

The Future of Nitinol in Healthcare Innovation

The future looks bright for wire Nitinol as advancements continue to unfold within the healthcare landscape. Researchers are exploring new applications and technologies that leverage what is Nitinol wire? to create smarter medical devices capable of real-time monitoring and treatment adjustments. With ongoing innovation, we can expect wire nitinol to play an even more significant role in enhancing patient outcomes.

Why Choose GEE SMA for Nitinol Needs

When it comes to sourcing high-quality wire nitinol products, GEE SMA stands out as a trusted partner in the industry. With extensive expertise in how to train Nitinol wire?, they ensure optimal performance tailored to specific medical applications. By choosing GEE SMA for your nitinol needs, you’re not just selecting a product; you’re investing in cutting-edge technology designed with both efficacy and safety in mind.