Introduction

When understanding nitinol cost, there's a lot more than meets the eye. Is nitinol expensive? What are the factors that impact its price? And most importantly, are there affordable solutions out there? Let's delve into nitinol pricing and explore the options available for those seeking cost-effective solutions.

Understanding Nitinol Cost

Nitinol, a shape memory alloy with unique properties, has gained popularity in various industries. Understanding its cost is crucial for businesses looking to incorporate it into their products. From nitinol sheet price to nitinol price per kg, there are different aspects to consider when evaluating its overall cost.

Nitinol is known for its unique shape memory properties, allowing it to return to its original shape after deforming. This makes it an ideal material for applications in industries such as medical devices, aerospace, and automotive. However, the cost of nitinol can vary depending on factors such as purity, size, and shape. When evaluating the cost of nitinol, businesses should consider not only the initial purchase price but also the long-term benefits it can provide in terms of performance and durability.

Is Nitinol Expensive?

The perception of nitinol as an expensive material often deters companies from exploring its potential benefits. However, a closer look at the accurate nitinol metal price and nitinol alloy price might reveal surprising insights about its affordability.

It's essential to consider the long-term benefits of using nitinol in various applications. While the initial cost may seem higher than other materials, nitinol's unique properties, such as shape memory and superelasticity, can lead to cost savings over time. For example, in the medical field, nitinol medical devices may reduce the need for additional surgeries or interventions, ultimately saving money for patients and healthcare providers.

Exploring Affordable Solutions

Nitinol's unique properties make it valuable for many applications, but affordability is crucial in a competitive market. Here's how businesses can find cost-effective nitinol solutions:

- Explore Material Options: Consider cost-effective nitinol alloys and tailored functional materials to find the best fit for your needs.

- Partner with Suppliers: Negotiate volume discounts or customized pricing based on your requirements.

- Invest in R&D: Explore innovative applications for nitinol that can lead to cost savings and a competitive edge.

By implementing these strategies and continuously seeking affordable solutions, businesses can leverage the power of nitinol while maintaining financial viability and a strong market position.

The True Nitinol Cost

When considering the true cost of nitinol, it's essential to look at the price per kg, as this provides a clear understanding of the metal's value. Nitinol is priced based on its unique properties and uses, making it a valuable investment for various industries. Understanding the price per kg can help businesses make informed decisions about incorporating nitinol into their products.

Nitinol Price Per Kg

Nitinol, a unique alloy prized for its shape memory and superelasticity, comes at a premium compared to other metals. Here's what businesses need to consider when navigating nitinol pricing:

- Price Variation: Nitinol per kilogram (kg) can fluctuate based on purity, quality, and market demand. Due to its specialized properties, nitinol inherently costs more than common metals.

- Cost per Kg vs. Budget: Businesses must carefully evaluate the price per kg against their budget and product requirements. This ensures they select nitinol that aligns with their financial constraints and project needs.

- Imperial System Considerations: While the price per kg offers a baseline, some regions might utilize the imperial system. Understanding the nitinol price per pound is crucial for practical budgeting and procurement decisions for these businesses.

By understanding these factors, businesses can make informed purchasing decisions about nitinol, optimize their budgets, and acquire the ideal material for their needs.

Nitinol Price Per Pound

When exploring the nitinol cost, examining the price per pound is also important for businesses operating in regions where this unit of measurement is commonly used. The price per pound may differ slightly from the cost per kg due to market fluctuations and manufacturing processes. Companies must compare both metrics to determine the most cost-effective option for their specific needs. Additionally, considering the price per pound allows businesses to accurately estimate their material costs and make informed decisions about production and pricing strategies. This level of detail can give companies a competitive edge in their respective markets, ensuring they are maximizing their resources and profitability.

Nitinol Sheet Price

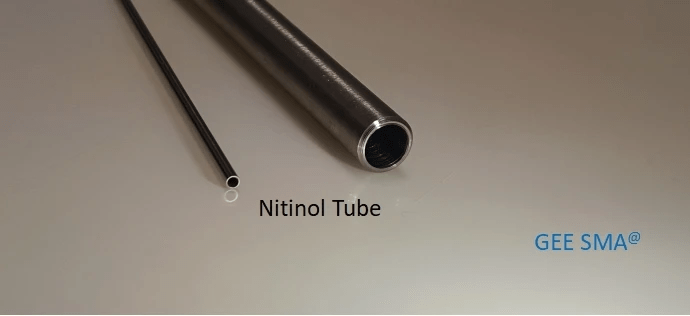

The nitinol sheet price is another key consideration when evaluating overall costs. Sheets are commonly used in various applications, such as medical devices, actuators, and aerospace components. Understanding the sheet price allows businesses to estimate expenses related to fabrication, machining, and finishing processes when incorporating nitinol into their products.

Additionally, the price of nitinol sheets can impact a business's overall competitiveness within its industry. Understanding the cost of these sheets allows companies to make informed decisions about pricing their products, ensuring they remain attractive to customers while generating a profit. This consideration is critical in industries with high competition, where even slight differences in material costs can significantly impact market positioning.

Now that we've delved into the true cost of nitinol by examining its price per kg, pound, and sheet, let's explore how various factors impact these prices in more detail in the following section.

Factors Impacting Nitinol Price

Manufacturing Processes

The manufacturing processes involved in producing nitinol significantly impact its cost. The intricate and precise methods required to create this shape memory alloy contribute to its price. From the initial melting of the nickel and titanium to the complex shaping and heat treatment, each step requires specialized equipment and skilled labor, adding to the overall nitinol cost.

The demand for nitinol in various industries also plays a significant role in its cost. As the market demand for shape memory alloys grows, competition for resources and skilled labor intensifies, further driving up production costs. This increased demand also leads to fluctuations in the price of raw materials, impacting the overall cost of nitinol. Furthermore, as more industries recognize nitinol's unique properties and benefits, the demand for customized shapes and sizes also adds complexity to the manufacturing processes, contributing to its cost.

Market Demand

The market demand for nitinol also plays a significant role in determining its price. As a highly sought-after material in industries such as medical devices, aerospace, and automotive, fluctuations in demand can directly affect nitinol pricing. When demand is high, prices tend to rise due to limited supply, making it essential for businesses to monitor market trends when planning their nitinol purchases closely.

The quality and purity of nitinol also significantly impact its price. High-quality nitinol that meets industry standards and specifications is often priced higher due to the cost of production and manufacturing processes. Additionally, the purity of nitinol, which refers to the absence of impurities or defects in the material, can affect its overall performance and functionality in various applications. As a result, businesses must carefully consider the quality and purity of nitinol when making purchasing decisions to ensure that they obtain the most suitable material for their specific needs.

Quality and Purity of Nitinol

Nitinol, a unique metal alloy, offers valuable properties like shape memory and superelasticity. However, navigating its cost requires understanding the quality-price relationship. Here's how to find affordable, high-quality nitinol:

- Quality Matters: High-purity nitinol with superior shape memory and durability comes at a premium due to its precise manufacturing. Lower-grade materials may be cheaper but compromise performance and lifespan.

- Supplier Comparison: Research and compare different nitinol suppliers. Some may offer competitive pricing for high-quality products.

- Direct Communication: Contacting suppliers directly lets you discuss your needs and budget. This can lead to customized solutions that meet both quality and cost requirements.

By understanding the quality-price dynamic and exploring various suppliers, you can find affordable solutions for high-performance nitinol. Remember, compromising on quality can lead to hidden costs down the line.

Finding Affordable Nitinol Solutions

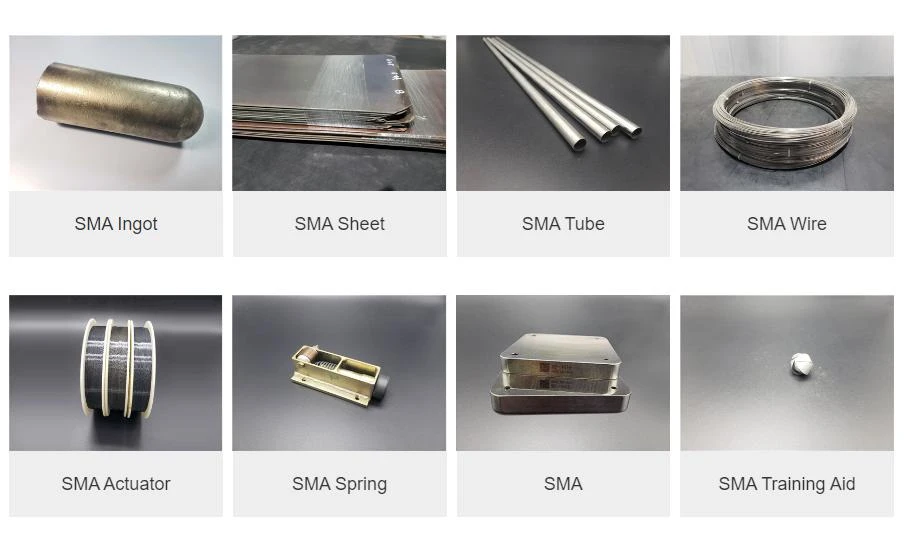

Regarding nitinol cost, GEE SMA offers competitive pricing that ensures high-quality nitinol without breaking the bank. With our cost-effective solutions, customers can access the benefits of nitinol without overspending on their budgets.

GEE SMA's Competitive Pricing

At GEE SMA, we understand the importance of providing affordable nitinol solutions without compromising quality. Our competitive pricing model allows businesses to invest in nitinol materials at a reasonable cost, making it accessible for various applications and industries.

Tailoring Nitinol Functional Materials

In addition to competitive pricing, GEE SMA specializes in tailoring functional materials for nitinol to meet specific project requirements. By customizing nitinol's shape memory properties and characteristics, we ensure that our customers receive tailored solutions that are both effective and affordable.

Cost-Effective Nitinol Alloys

GEE SMA also offers a range of cost-effective nitinol alloys that provide superior performance at a reasonable price point. Our expertise in alloy development allows us to create innovative solutions that deliver exceptional value without inflating the overall nitinol cost.

GEE SMA is committed to providing affordable nitinol solutions for businesses seeking high-quality shape memory materials by offering competitive pricing, tailored functional materials, and cost-effective alloys.

Benefits of Investing in Affordable Nitinol

Long-Term Cost Savings

Investing in affordable nitinol can lead to significant long-term cost savings for businesses. By choosing cost-effective nitinol solutions, companies can reduce production expenses and improve their profit margins over time. This allows for greater financial stability and the ability to invest in other business areas.

Enhanced Product Quality

Affordable nitinol does not equate to lower quality. In fact, by carefully selecting a reliable supplier that offers competitive pricing, businesses can still access high-quality nitinol materials that meet industry standards and deliver exceptional performance. This ensures that products manufactured with nitinol maintain their integrity and reliability.

Meeting Customer Budgets

Affordable nitinol solutions enable businesses to meet customer budgets without compromising on product quality. By keeping production costs down through cost-effective nitinol materials, companies can offer competitive pricing to their customers while still delivering superior products that meet or exceed expectations.

Securing Quality Nitinol at a Fair Price

In the search for high-quality nitinol at a fair price, GEE SMA stands out with its unwavering commitment to meeting customer requirements. With extensive experience in the industry, GEE SMA understands the importance of delivering cost-effective solutions without compromising on quality. By prioritizing customer needs and offering competitive pricing, GEE SMA ensures that clients can secure top-notch nitinol without breaking the bank.

GEE SMA's Commitment to Customer Requirements

GEE SMA goes above and beyond to understand each customer's specific needs, tailoring their nitinol solutions accordingly. Whether it's a custom alloy or a particular shape or size requirement, GEE SMA is dedicated to meeting and exceeding customer expectations. This commitment translates into providing high-quality nitinol and ensuring that it is offered at a fair and competitive price point.

Craftsmanship of High-Quality Nitinol

Craftsmanship plays a pivotal role in producing high-quality nitinol, and GEE SMA takes great pride in its meticulous approach to crafting superior nitinol components. Focusing on precision and attention to detail, GEE SMA's craftsmanship ensures that every piece of nitinol meets stringent quality standards while remaining cost-effective for customers.

Ensuring Cost-Effective Nitinol Components

GEE SMA understands that cost-effectiveness is crucial for businesses investing in nitinol components. By leveraging advanced manufacturing techniques and efficient processes, GEE SMA ensures that its nitinol components are top-notch in quality and affordable for customers across various industries.

GEE SMA's Affordable Nitinol Solutions

Regarding nitinol cost, GEE SMA offers affordable solutions that don't compromise quality. With competitive pricing for nitinol alloys and functional materials, customers can make informed purchasing decisions that maximize the value of their investments. By choosing GEE SMA, businesses can secure high-quality nitinol at a fair price, ensuring long-term cost savings and meeting customer budgets.

GEE SMA provides cost-effective nitinol options without sacrificing performance or reliability. With a commitment to meeting customer requirements, businesses can rely on GEE SMA for high-quality nitinol components at an affordable price point.

Making Informed Nitinol Purchasing Decisions

Businesses can make informed decisions when purchasing nitinol materials by understanding the factors impacting nitinol price and exploring competitive pricing options. Considering the long-term benefits of investing in affordable nitinol solutions is essential to maximize value.

Maximizing Value in Nitinol Investments

Choosing GEE SMA for nitinol needs allows businesses to maximize the value of their investments by securing top-notch materials at a fair price. This ensures enhanced product quality while staying within budget constraints, ultimately leading to long-term cost savings and customer satisfaction.