Introduction

Nitinol, a remarkable nickel-titanium alloy, stands out in the world of materials due to its unique properties such as superelasticity and shape memory effect. These characteristics make it an ideal candidate for various applications across industries, from medical devices to robotics. However, to ensure quality and performance, adherence to standards like ASTM F2063 is crucial.

What Makes Nitinol Unique

What makes Nitinol truly unique is its ability to return to a predetermined shape when heated above a specific temperature, thanks to its shape memory effect. This property not only enhances its functionality but also opens doors for innovative applications in fields like healthcare and aerospace. Moreover, Nitinol's superelasticity allows it to undergo significant deformation under stress without permanent change, making it remarkably resilient.

Overview of ASTM F2063

ASTM F2063 is the standard that governs the specifications for Nitinol used in medical devices and other critical applications. It defines essential parameters such as composition, mechanical properties, and testing methods that ensure reliability and safety in products made from this alloy. Understanding what ASTM F2063 entails is vital for manufacturers aiming to produce high-quality Nitinol components.

Applications of Super Elastic Nickel Titanium

Super elastic nickel titanium has found its niche in numerous applications due to its distinctive qualities—think stents that expand within arteries or guidewires that navigate complex anatomical pathways with ease. The versatility of Nitinol extends beyond medicine; it's also utilized in eyeglass frames that can bend without breaking and actuators in robotics that require precise movements. As industries continue to innovate, the demand for compliant materials under standards like ASTM F2063 will only grow.

What is ASTM F2063?

Definition and Purpose

ASTM F2063 is a standard specification established by ASTM International, aimed specifically at the characteristics of Nitinol used in medical devices. Its primary purpose is to define the chemical composition, mechanical properties, and testing methods for this remarkable shape memory alloy. By adhering to this standard, manufacturers can ensure that their products meet industry expectations for performance and reliability.

Importance in Material Standards

Material standards like ASTM F2063 are vital in maintaining consistency and quality across industries that utilize specialized materials such as Nitinol. They provide a benchmark against which all products can be measured, ensuring safety and efficacy in applications ranging from stents to orthodontic wires. Without such standards, variability could lead to failures or complications in critical devices that rely on Nitinol's unique properties.

Role in Nitinol Applications

The role of ASTM F2063 extends beyond mere compliance; it actively shapes how Nitinol is applied within various sectors. By stipulating essential criteria for shape memory Nickel Titanium alloy wire, the standard helps guide innovation while safeguarding patient health and device functionality. In essence, understanding What is ASTM F2063? not only clarifies its definition but also highlights its importance as a cornerstone of quality assurance in Nitinol applications.

What is the ASTM Standard for Nitinol?

When it comes to ensuring the quality and reliability of materials used in various applications, the ASTM standard plays a pivotal role. Specifically, for Nitinol, which is a nickel-titanium alloy known for its unique properties, the ASTM F2063 standard provides a framework that manufacturers must adhere to. This standard not only defines the key specifications for Nitinol but also serves as a benchmark for compliance and testing procedures.

Key Specifications

The ASTM F2063 standard outlines critical specifications that govern the composition and mechanical properties of Nitinol. These specifications include requirements related to chemical composition, tensile strength, and fatigue resistance, which are essential for ensuring that Nitinol performs reliably in applications ranging from medical devices to aerospace components. By adhering to these specifications, manufacturers can guarantee that their products meet industry standards and customer expectations.

Moreover, the standard also delineates specific temperature ranges for phase transformations in Shape Memory Nickel Titanium Alloy Wire—an essential characteristic that allows Nitinol to remember its original shape after deformation. This unique property is what makes Nitinol particularly valuable in various innovative applications such as self-expanding stents and actuators.

Compliance and Testing Procedures

Compliance with ASTM F2063 involves rigorous testing procedures designed to validate that materials meet specified performance criteria. Manufacturers must conduct tests such as tensile strength assessments and thermal analysis to ensure their Nitinol products align with established standards. These procedures not only help verify material integrity but also provide manufacturers with documented evidence of compliance.

Testing protocols often require samples from production batches to undergo assessments by accredited laboratories, ensuring impartiality and accuracy in results. This commitment to quality assurance builds trust between manufacturers and end-users who rely on the performance of Nitinol in critical applications.

Importance for Manufacturers

For manufacturers, understanding what is the ASTM standard for Nitinol is crucial not just from a compliance standpoint but also from a competitive perspective. Adhering to ASTM F2063 ensures that their products are market-ready while minimizing risks associated with product failures or recalls due to subpar material quality. Compliance can serve as a powerful marketing tool as well—customers often prefer products backed by recognized standards.

Additionally, being compliant with this standard can open doors to new business opportunities across different industries where high-performance materials are required. As demand grows for high-quality Shape Memory Nickel Titanium Alloy Wire in sectors like healthcare and robotics, adherence to established standards like ASTM F2063 will be key in maintaining market relevance.

What are the Different Grades of Nitinol?

Nitinol, a fascinating alloy of nickel and titanium, is categorized into several grades based on its composition and properties. Understanding these grades is crucial for industries that rely on the unique capabilities of Nitinol, especially when considering compliance with standards like ASTM F2063. Each grade serves specific applications, highlighting the versatility and adaptability of this remarkable material.

Overview of Nitinol Grades

The primary grades of Nitinol include medical-grade and industrial-grade variants, each tailored for diverse applications. Medical-grade Nitinol is often used in devices like stents and guidewires due to its biocompatibility and superelastic properties. Industrial-grade Nitinol finds its niche in applications such as actuators and robotics, where performance under stress is paramount.

In addition to these main categories, there are also specialized grades within each type that cater to specific requirements or performance standards. For instance, certain medical-grade variants are engineered for higher fatigue resistance or enhanced shape memory characteristics. This segmentation allows manufacturers to select the most appropriate grade based on their needs while adhering to guidelines set forth by ASTM F2063.

Comparison of Properties

When comparing the properties of different grades of Nitinol, one must consider factors such as transformation temperatures, elasticity limits, and corrosion resistance. Medical-grade Nitinol typically exhibits lower transformation temperatures than industrial-grade options; this makes it more suitable for body temperature applications where superelasticity is crucial. Conversely, industrial grades may prioritize strength over elasticity to withstand harsher environments.

Another significant difference lies in the mechanical properties: medical-grade alloys often have tighter tolerances in terms of composition due to stringent regulations associated with healthcare products. This meticulous control can lead to variations in mechanical performance between different grades; thus understanding what is ASTM F2063 becomes essential for quality assurance in manufacturing processes. These distinctions ultimately influence how each grade can be utilized effectively across various industries.

Applications of Each Grade

The applications for each grade of Nitinol reflect their unique properties and intended uses. Medical-grade Nitinol excels in minimally invasive surgical tools such as stents because it can expand from a compressed state while maintaining flexibility—an essential feature when navigating through blood vessels or other delicate structures within the body. Additionally, its shape memory capability ensures that devices return to their original form after deformation.

On the other hand, industrial-grade Nitinol finds widespread use in sectors like aerospace and automotive engineering where high-performance components are necessary under extreme conditions. Here, you might find it employed in actuators or couplings that require both durability and responsiveness—attributes facilitated by its superelastic nature combined with high tensile strength.

Understanding what are the different grades of Nitinol—and their respective applications—allows manufacturers not only to comply with relevant standards but also to innovate effectively within their fields while keeping costs manageable amidst factors influencing why nitinol so expensive.

Why is Nitinol So Expensive?

Nitinol, a unique nickel-titanium alloy known for its shape memory and superelastic properties, often comes with a hefty price tag. Understanding why this material is so expensive involves delving into several factors that contribute to its high costs, including production complexities, raw material prices, and the specialized processes required to meet standards such as ASTM F2063. Additionally, the demand for Nitinol in various advanced applications further drives up its market value.

Factors Influencing Cost

One of the primary factors influencing the cost of Nitinol is the intricate manufacturing process required to produce it. This includes precise control over composition and temperature during production to ensure compliance with ASTM F2063 standards. Moreover, the need for specialized equipment and skilled labor adds another layer of expense—further inflating costs compared to more conventional materials.

Another significant cost factor is the raw materials themselves; nickel and titanium can be volatile in price due to market fluctuations and geopolitical issues affecting supply chains. The rarity of high-quality titanium also plays a role in driving up costs since not all sources provide material that meets stringent specifications like those outlined in ASTM F2063. Lastly, since Nitinol’s unique properties make it suitable for niche applications—like medical devices or aerospace components—this limited production scale can lead to higher per-unit prices.

Comparison to Other Materials

When comparing Nitinol to other materials commonly used in similar applications, it's clear that Nitinol's advantages come at a premium price. For instance, while stainless steel may be cheaper and widely available for many industrial uses, it lacks the shape memory effect that makes Nitinol so appealing for specific applications like stents or actuators. This inherent value means that manufacturers are often willing to pay more for Nitinol when they require its unique properties.

Additionally, other alloys may not meet rigorous standards like those set by ASTM F2063 without extensive modification or treatment processes that could negate their cost-effectiveness. While alternatives might offer lower upfront costs, they often fall short on performance or longevity when compared to high-grade Nitinol options tailored specifically for demanding environments.

Demand and Supply Dynamics

The demand for Nitinol has been steadily increasing across various industries such as medical technology, automotive engineering, and robotics—which further complicates its pricing dynamics. As innovations continue pushing boundaries in these sectors, manufacturers are increasingly seeking out compliant materials like those governed by ASTM F2063 standards due to their reliability under stress conditions.

On the supply side, fluctuations can occur based on global market conditions affecting nickel and titanium availability—creating a tug-of-war between supply constraints and growing demand that ultimately affects pricing strategies across industries reliant on this alloy's unique characteristics. Consequently, while many manufacturers would love access to affordable Nitinol options compliant with ASTM standards like ASTM F2063 specifications—they often find themselves navigating an ever-changing landscape where scarcity drives up costs even further.

Understanding Shape Memory Nickel Titanium Alloy Wire

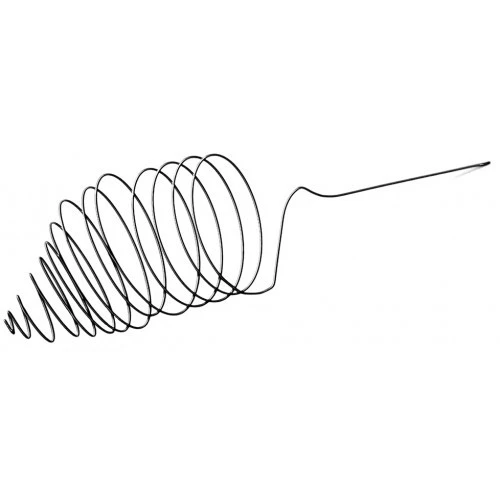

Shape memory nickel titanium alloy wire, commonly referred to as Nitinol wire, is a fascinating material that exhibits unique properties due to its distinct phase transformations. This wire can remember its original shape and return to it when heated above a certain temperature. The exceptional elasticity and shape memory effect make Nitinol wire an intriguing subject of study in materials science, especially in the context of ASTM F2063 standards.

Characteristics and Benefits

The primary characteristic of shape memory nickel titanium alloy wire is its ability to undergo significant deformation while maintaining a relatively lightweight profile. When cooled below a specific temperature, the wire can be bent or twisted into various shapes; however, upon heating, it returns to its pre-deformed state—this is known as the shape memory effect. Additionally, Nitinol exhibits superelasticity, allowing it to absorb large amounts of strain without permanent deformation, making it highly advantageous for applications requiring flexibility and resilience.

The benefits of using Nitinol wire extend beyond mere mechanical properties; its biocompatibility makes it suitable for medical applications such as stents and guidewires. Furthermore, the versatility in manufacturing processes allows for customization in various industries—from aerospace components to consumer electronics—demonstrating how this material aligns with emerging technologies and trends. Understanding these characteristics is essential for manufacturers who seek compliance with standards like ASTM F2063.

Common Uses in Industry

Shape memory nickel titanium alloy wire finds itself at home across diverse industries due to its remarkable properties. In the medical field, for instance, it's widely used in devices like self-expanding stents that adapt seamlessly within the human body—a perfect example of how what is ASTM F2063? plays a pivotal role by ensuring product reliability and safety through standardized testing protocols. Beyond healthcare, Nitinol's unique features are leveraged in robotics for actuators that mimic natural movements or even in eyeglass frames that return to their original shape after being bent.

Moreover, Nitinol's application extends into automotive systems where components require adaptability under varying conditions—think smart actuators or safety features that respond dynamically during operation. The aerospace industry also taps into this technology; lightweight yet strong materials are crucial for enhancing fuel efficiency while maintaining performance standards. As industries continue exploring innovative uses for shape memory alloys under guidelines like what is the ASTM standard for Nitinol?, we can expect an exciting future ahead.

GEE SMA's Role in Nitinol Production

GEE SMA (Shape Memory Alloys) plays an instrumental role in advancing the production of high-quality shape memory nickel titanium alloy wire tailored specifically to meet industry demands and standards such as ASTM F2063. Their expertise ensures that each batch adheres not only to performance specifications but also complies with rigorous testing procedures outlined within established frameworks—what are the different grades of Nitinol? becomes relevant here as GEE SMA produces various grades optimized for specific applications.

By focusing on quality control measures throughout production processes—from raw material selection through final testing—GEE SMA reinforces trust among manufacturers relying on Nitinol components across sectors ranging from healthcare devices to aerospace engineering products. Their commitment ensures end-users receive reliable solutions while navigating factors influencing cost; why is nitinol so expensive? becomes less daunting when quality assurance meets affordability through strategic manufacturing practices.

In summary, understanding shape memory nickel titanium alloy wire opens up new avenues not only within specialized fields but also across broader industrial landscapes where innovation thrives under compliance with standards like nitinol astm f2063.

Conclusion

In wrapping up our exploration of Nitinol, it’s clear that this remarkable material is poised for a bright future in various technological applications. As industries continue to innovate, the demand for Nitinol, particularly under the guidelines of ASTM F2063, will likely increase. With its unique properties and compliance standards, Nitinol is set to redefine what we know about smart materials.

The Future of Nitinol in Technology

The future of Nitinol in technology looks promising as advancements continue in fields like medicine, robotics, and aerospace. With its shape memory capabilities and superelastic properties, this alloy can revolutionize how we design devices that adapt to changing conditions or stressors. As research progresses and new applications emerge, understanding what ASTM F2063 entails will become increasingly important for developers seeking to leverage these advantages.

Benefits of ASTM F2063 Compliance

Compliance with ASTM F2063 not only ensures that manufacturers produce high-quality Nitinol but also guarantees safety and reliability in its applications. This standard provides a framework for testing and evaluating the material's performance under various conditions, making it essential for industries where precision is critical. By adhering to these guidelines, manufacturers can confidently market their products as compliant with rigorous industry standards while enhancing consumer trust.

Key Takeaways on Super Elastic Nickel Titanium

Super elastic nickel titanium represents a breakthrough in material science due to its exceptional properties and versatility across different grades of Nitinol. Understanding what the ASTM standard for Nitinol entails helps businesses navigate compliance while exploring innovative uses ranging from medical devices to actuators in robotics. Ultimately, recognizing why Nitinol is so expensive underscores its value—this alloy isn't just a material; it's a gateway to advanced technology that shapes our future.