Introduction

In the realm of modern technology, the spotlight is increasingly shining on innovative materials that can transform how we interact with machines. Among these, Shape Memory Alloys (SMAs) stand out for their remarkable ability to return to a predetermined shape when subjected to specific temperature changes. This unique property forms the backbone of SMA wire actuators, which are revolutionizing various industries by offering unprecedented control and efficiency.

Understanding Shape Memory Alloys

Shape Memory Alloys are a class of metallic materials that exhibit an extraordinary phenomenon known as the shape memory effect. When deformed at lower temperatures, these alloys remember their original shape and can return to it upon heating. This fascinating behavior raises questions such as What is an SMA actuator?—a device that utilizes this principle to perform mechanical work in response to thermal stimuli.

Overview of SMA Wire Actuators

SMA wire actuators harness the power of Shape Memory Alloys, converting thermal energy into mechanical motion with impressive precision. These actuators typically consist of thin wires made from SMAs like Nitinol, which expand and contract based on temperature changes. The versatility and compactness of SMA wire actuators make them ideal for applications ranging from robotics to medical devices.

Importance of SMA Actuators in Modern Technology

The significance of Shape Memory Alloy (SMA)-enabled actuators cannot be overstated; they are paving the way for advancements across various sectors by providing solutions that traditional actuators simply cannot match. Their ability to operate without complex electrical systems makes them particularly valuable in environments where space or power is limited. As we explore further into how does SMA wire work and its applications, it becomes clear that these remarkable devices are not just a novelty but a vital component in the future landscape of technology.

What is an SMA Actuator?

When diving into the world of actuators, one might stumble upon the term SMA actuator. But what is an SMA actuator, you ask? Well, it's a fascinating device that utilizes Shape Memory Alloys (SMAs) to convert thermal energy into mechanical work. This transformation allows for precise movements and has garnered attention in various fields such as robotics, medical devices, and aerospace technology.

Defining Shape Memory Alloys

Shape Memory Alloys (SMAs) are unique materials that can return to a predefined shape when subjected to specific temperature changes. These alloys have the remarkable ability to remember their original form after being deformed. The most common type of SMA used in actuators is Nitinol, an alloy composed primarily of nickel and titanium.

Key Characteristics of SMA Actuators

SMA wire actuators exhibit several key characteristics that set them apart from traditional actuators. Firstly, they are lightweight and compact, making them ideal for applications where space is at a premium. Secondly, their ability to operate without external power sources means they can be deployed in environments where electricity may not be readily available.

Advantages Over Traditional Actuators

The advantages of Shape Memory Alloy (SMA)-enabled actuators over traditional systems are numerous and compelling. For starters, they offer high force-to-weight ratios, which is essential in applications like robotics where weight savings can lead to enhanced performance. Additionally, SMA actuators have fewer moving parts compared to conventional electromechanical systems; this simplicity translates into lower maintenance requirements and increased reliability.

How Does SMA Wire Work?

Understanding how SMA wire works is essential for grasping the full potential of Shape Memory Alloy (SMA)-enabled actuators. The unique properties of these materials allow them to change shape and exert force in response to temperature changes, making them invaluable in various applications. But what exactly happens at the molecular level when we talk about SMA wire actuators?

The Science Behind Shape Memory

At the heart of every SMA actuator lies the fascinating science of shape memory. Essentially, these materials can remember a specific shape that they can revert to when heated above a certain temperature. This phenomenon occurs due to the arrangement of atoms within the alloy, which can shift between two different crystalline structures—one at lower temperatures and another at higher temperatures—allowing for remarkable versatility in applications.

When we ask, What is an SMA actuator? it’s crucial to recognize this transformative capability as its defining feature. As heat is applied, the SMA wire actuator undergoes a physical change that allows it to expand or contract dramatically, performing mechanical work without needing complex machinery. This simplicity and efficiency are precisely why SMAs are gaining traction in modern engineering solutions.

Phase Transformation Process Explained

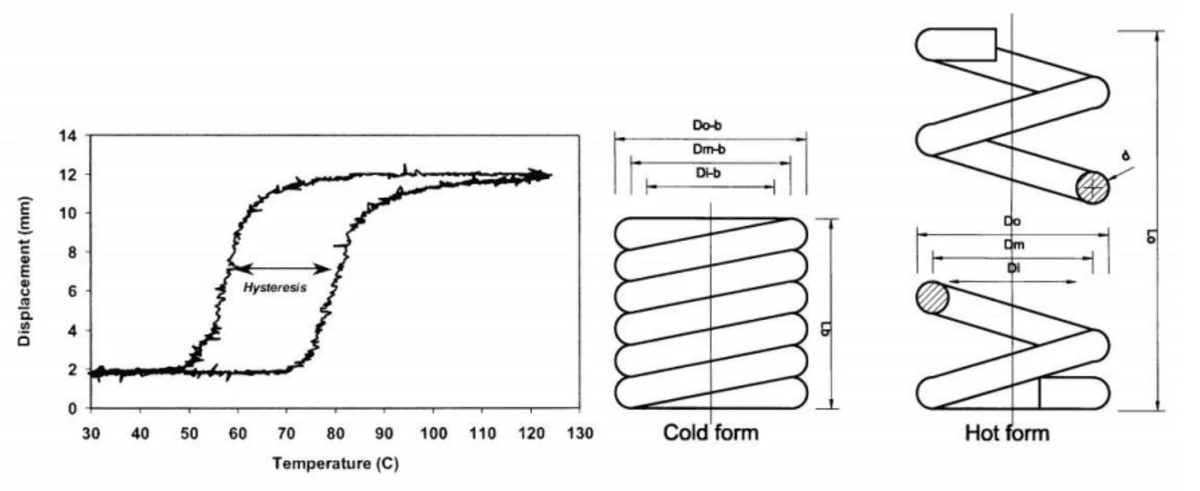

The phase transformation process is fundamental in understanding how does SMA wire work? When an SMA wire is heated above its transformation temperature, it transitions from a martensitic phase (a softer structure) to an austenitic phase (a stronger structure). This switch not only alters its shape but also enables it to exert considerable force, making SMAs particularly effective for actuation purposes.

During cooling, the process reverses; when cooled below its transformation temperature, the material returns to its original martensitic form. This cyclical behavior allows for repeated actuation without significant wear or tear on the material itself—a key advantage over traditional actuators that may require more maintenance and have shorter lifespans. With this understanding of phase transformation, it's clear why many industries are exploring what can SMAs be used for.

Temperature Sensitivity of SMA Materials

Temperature sensitivity is another vital aspect of how SMA wire actuators function effectively across various applications. Each type of Shape Memory Alloy has specific transition temperatures that dictate when it will activate or return to its original shape; thus, selecting the right material for each application is crucial. For instance, Nitinol—a popular type of SMA—exhibits notable thermal responsiveness that makes it ideal for medical devices and robotics alike.

This sensitivity means that engineers must carefully calibrate their systems based on environmental conditions and desired performance outcomes when integrating these materials into their designs—the essential components of SMA actuators need precise control mechanisms as well as appropriate thermal management strategies. Ultimately, understanding temperature sensitivity not only enhances performance but also opens doors for innovative uses across different sectors.

Applications of SMA Wire Actuators

Shape Memory Alloy (SMA)-enabled actuators are making waves across various industries, showcasing their versatility and efficiency. From robotics to medical devices, the applications of SMA wire actuators are both innovative and transformative. Let’s dive into some exciting areas where these remarkable materials are changing the game.

Robotics and Automation Innovations

In the realm of robotics, SMA wire actuators are revolutionizing how machines operate with their unique properties. What is an SMA actuator? Essentially, it’s a device that utilizes shape memory alloys to create movement in response to temperature changes, allowing for precise control in robotic systems. These actuators can be found in robotic arms, grippers, and even soft robots that mimic natural movements—an impressive feat made possible by the flexibility of SMAs.

How does SMA wire work? The phase transformation process enables these wires to contract or expand based on thermal input, providing a lightweight and compact solution for actuation needs in automation. This capability opens up new possibilities for creating more efficient robots that can perform tasks previously deemed too complex or delicate for traditional mechanisms.

Medical Devices Utilizing SMA Technology

The medical field is another area where shape memory actuators shine brightly. From stents that expand within blood vessels to minimally invasive surgical tools, SMA wire actuators offer solutions that enhance patient care while minimizing risk. What can SMAs be used for? Their ability to respond dynamically to body temperature makes them ideal candidates for devices requiring precise movements inside the human body.

For instance, nitinol—a nickel-titanium alloy—is frequently employed due to its biocompatibility and excellent mechanical properties when used as an actuator material in medical applications. How is nitinol used in actuators? Its unique phase transformation allows it to revert back to its original shape at specific temperatures, enabling effective operation within various medical devices without external power sources.

Aerospace Advancements with SMA Actuators

Aerospace technology has also embraced the potential of shape memory alloys with open arms—or wings! The lightweight nature of SMA wire actuators makes them perfect candidates for applications where every gram counts; think aircraft wing flaps or satellite deployment mechanisms. These Shape Memory Alloy (SMA)-enabled actuators provide reliable performance under extreme conditions while ensuring energy efficiency during operation.

The essential components of SMA actuators play a crucial role here—integrating sensors and control systems allows engineers to fine-tune their performance based on real-time data from flight conditions or structural stressors. This adaptability not only enhances safety but also improves overall flight efficiency by optimizing control surfaces during flight maneuvers.

How is Nitinol Used in Actuators?

Nitinol, a unique alloy of nickel and titanium, represents a fascinating application of Shape Memory Alloys (SMAs) in actuators. This remarkable material exhibits the ability to return to a predetermined shape when heated, making it an ideal candidate for various actuation systems. Understanding how Nitinol functions within SMA wire actuators opens the door to innovative solutions across multiple industries.

Introduction to Nitinol as SMA

Nitinol stands out among Shape Memory Alloys (SMAs) due to its distinctive properties that make it particularly effective in actuation applications. The alloy’s ability to undergo phase transformations between austenite and martensite allows for significant movement with minimal energy input. When discussing What is an SMA actuator?, Nitinol’s role becomes clear; it provides a reliable mechanism for converting thermal energy into mechanical motion.

Benefits of Nitinol in Actuation Systems

One of the key benefits of using Nitinol in actuation systems is its high strength-to-weight ratio, which allows for compact designs without sacrificing performance. Additionally, the temperature sensitivity inherent in SMA wire actuators enables precise control over movement, making them suitable for applications requiring fine adjustments. Furthermore, the durability and corrosion resistance of Nitinol enhance the longevity and reliability of Shape Memory Actuators across various environments.

Real-World Applications of Nitinol Actuators

Nitinol actuators are making waves in several fields due to their versatility and effectiveness. In robotics, they are used for creating lightweight yet powerful joints that mimic human motion, showcasing what SMAs can be used for beyond traditional applications. Moreover, medical devices benefit from Shape Memory Alloy (SMA)-enabled actuators; examples include stents that expand within blood vessels or surgical tools that require precise manipulation during procedures.

The Essential Components of SMA Actuators

Shape Memory Alloy (SMA)-enabled actuators are fascinating devices that rely on the unique properties of SMA wire to perform a variety of functions. To appreciate the full potential of these actuators, it's essential to delve into their design, control systems, and how they integrate with other technologies. Understanding these components not only answers the question, What is an SMA actuator? but also highlights their significance in modern applications.

Overview of SMA Wire and its Design

SMA wire is the heart and soul of an SMA actuator, crafted from materials like Nitinol that exhibit remarkable shape memory effects. The design of this wire involves precise engineering to ensure it can effectively transition between different shapes when subjected to temperature changes. With its ability to return to a predetermined shape upon heating, SMA wire is integral in answering How does SMA wire work? while providing reliable actuation in various environments.

The versatility of SMA wire allows for a range of designs tailored for specific applications—think small diameters for delicate tasks or thicker wires for heavier loads. This adaptability makes it possible for SMAs to be used in everything from robotics to medical devices, demonstrating their wide-ranging utility. As we explore these essential components further, it becomes clear that the design intricacies play a crucial role in determining performance and efficiency.

Role of Control Systems in Actuation

Control systems are vital for harnessing the capabilities of Shape Memory Actuators effectively; they dictate how and when the actuator responds based on input signals. These systems manage temperature changes within the actuator by regulating current flow through the SMA wire, allowing precise control over its movements. Without robust control systems, even the best-designed SMA actuators would struggle to deliver consistent performance or respond accurately to varying conditions.

Moreover, modern control systems can incorporate feedback mechanisms that enhance responsiveness and accuracy—essential features when deploying these actuators in dynamic environments such as robotics or aerospace applications. By integrating sensors with SMAs, engineers can create sophisticated actuation solutions capable of adapting on-the-fly based on real-time data analysis. This synergy between control systems and Shape Memory Alloy technology elevates what can SMAs be used for? beyond simple tasks into realms requiring precision and adaptability.

Integration with Other Technologies

The integration capabilities offered by SMA actuators make them standout components across various technological landscapes; they can seamlessly work alongside other electronic and mechanical systems. For instance, coupling an SMA actuator with microcontrollers enables smart automation solutions that enhance efficiency across industries—from manufacturing lines to healthcare devices like surgical tools utilizing Nitinol technology. This collaborative approach expands possibilities significantly as we look at How is nitinol used in actuators?—demonstrating its role not just as a material but as part of an intricate system.

Furthermore, combining SMAs with advanced materials such as composites or smart sensors opens up new avenues for innovation; this allows engineers to develop lightweight yet strong structures capable of performing complex tasks without compromising functionality or safety standards. As we continue exploring how Shape Memory Actuators fit into broader technological frameworks, it's clear their potential reaches far beyond standalone applications—they're paving pathways toward smarter designs across multiple sectors.

Conclusion

In the world of engineering and technology, Shape Memory Alloys (SMAs) have emerged as innovative solutions that redefine the capabilities of actuators. The unique properties of SMA wire actuators allow them to respond dynamically to changes in temperature, making them a versatile choice for various applications. Whether it's in robotics, medical devices, or aerospace systems, the flexibility and efficiency offered by SMA-enabled actuators are paving the way for smarter designs and enhanced performance.

Innovative Solutions with Shape Memory Alloys

The question What is an SMA actuator? often leads to discussions about their transformative potential across industries. These shape memory actuators can be programmed to remember specific shapes, allowing them to perform tasks that traditional actuators simply cannot achieve. With their compact size and lightweight nature, SMA wire actuators are becoming indispensable in developing innovative solutions that require precise movement and control.

Future Prospects of SMA Wire Actuators

Looking ahead, the future prospects of SMA wire actuators seem incredibly bright as advancements in materials science continue to evolve. As researchers delve deeper into understanding How does SMA wire work? we can expect even more efficient designs that enhance performance and reduce energy consumption. Additionally, with growing interest in sustainable technologies, SMAs offer environmentally friendly alternatives that could revolutionize various sectors by minimizing waste while maximizing functionality.

GEE SMA: Leaders in Nitinol Production

When discussing how nitinol is used in actuators, one name stands out: GEE SMA. Renowned for their expertise in producing high-quality shape memory alloys, GEE SMA has positioned itself at the forefront of innovation within this field. Their commitment to excellence ensures that their shape memory actuator products remain reliable and effective across numerous applications—solidifying their place as leaders in nitinol production.