Introduction

When it comes to cutting-edge technology and innovation, heat activated nitinol wire stands out as a game-changer in various industries. Its unique properties and versatility make it an indispensable material for countless applications. From medical devices to industrial machinery, the possibilities with nitinol wires are endless. And when it comes to sourcing top-quality nitinol shape memory alloys, GEE SMA is the trusted name you can rely on for all your needs.

Understanding the Benefits of Heat Activated Nitinol Wire

The benefits of heat activated nitinol wire are truly remarkable. Its ability to return to a predetermined shape after being deformed at a specific temperature makes it ideal for use in medical implants, actuators, and other precision instruments. This remarkable property sets it apart from traditional materials and opens up new possibilities for innovation and design.

The versatility of nitinol wires goes beyond just their ability to return to a predetermined shape. These wires can also be designed to respond to different temperatures, making them suitable for a wide range of applications. From medical stents that can expand and contract with changes in body temperature to self-regulating valves that adjust based on environmental conditions, the potential uses for nitinol wire are vast and varied. This adaptability makes it an exciting material for engineers and designers looking to create innovative solutions.

Exploring the Versatility of Nitinol Wires

Nitinol wires have found their way into an array of applications across different industries due to their exceptional properties. From aerospace engineering to consumer electronics, these wires offer a level of flexibility and durability that is unmatched by other materials. The versatility of nitinol wires makes them an attractive choice for engineers and designers looking to push the boundaries of what's possible.

Nitinol wires are not only known for their flexibility and durability but also for their unique shape memory properties. This means that they can be deformed at one temperature and then return to their original shape when heated. This makes them ideal for applications such as medical devices, where they can be used in minimally invasive procedures. The ability of nitinol wires to "remember" their original form adds another layer of versatility to their already impressive list of properties.

GEE SMA: Your Trusted Source for Nitinol Shape Memory Alloys

When it comes to sourcing high-quality nitinol shape memory alloys, GEE SMA is the go-to supplier for industry professionals around the world. With a proven track record of delivering top-notch products and exceptional customer service, GEE SMA has earned its reputation as a reliable partner for all your nitinol wire needs.

GEE SMA understands the critical nature of nitinol wire in various industries, and that's why we are committed to providing a wide range of high-quality products to meet your specific needs. Our team of experts is dedicated to ensuring that you receive the best possible solution for your application, whether it's for medical devices, aerospace components, or any other industry where nitinol shape memory alloys are essential.

What is Nitinol Wire?

Nitinol wire, short for Nickel Titanium Naval Ordnance Laboratory, is a shape memory alloy known for its unique properties. When heated, it returns to its original shape, making it an ideal material for various applications in different industries. Its superelasticity and biocompatibility make it a popular choice for medical devices and instruments.

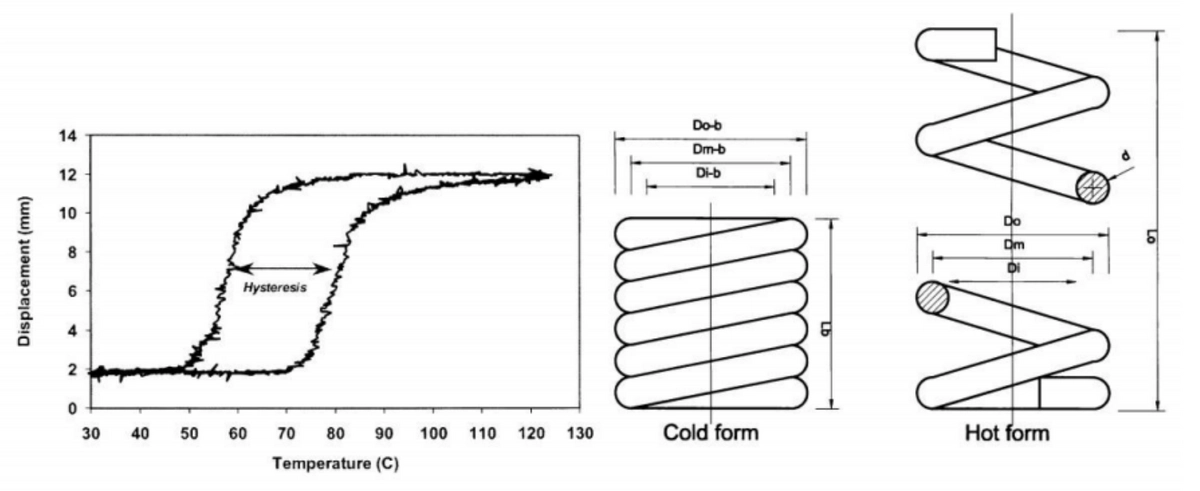

The Science Behind Nitinol's Unique Properties

Nitinol wire exhibits shape memory and superelasticity due to its phase transformation behavior at specific temperatures. This unique property allows the wire to remember its original shape and return to it when heated, making it highly versatile in engineering and manufacturing applications.

Nitinol wire's unique properties make it an ideal material for a wide range of industries. Its shape memory and superelasticity allow for the creation of intricate and precise components in fields such as medical devices, aerospace, and automotive engineering. This versatility has led to the development of innovative products such as stents that can expand and contract within the body, or actuators that provide precise control in complex machinery.

Applications of Nitinol Wire in Various Industries

The versatility of nitinol wire has led to its widespread use across industries such as aerospace, automotive, robotics, and consumer electronics. In the medical field, it is utilized in stents, guidewires, orthodontic wires, and minimally invasive surgical instruments due to its biocompatibility and flexibility.

Nitinol wire's unique properties also make it ideal for use in actuators and sensors in the aerospace and robotics industries. Its shape memory and superelasticity allow for precise control and movement, making it a valuable component in these high-tech applications. Additionally, nitinol wire's ability to withstand high temperatures and harsh environments makes it a reliable choice for use in automotive sensors and components, further expanding its role in various industries.

Advantages of Using Heat Activated Nitinol Wire

Heat activated nitinol wires offer several advantages over traditional materials such as steel or copper. They provide precise control over movement due to their ability to return to a specific shape when heated, making them ideal for actuators and other precision applications.

Heat activated nitinol wires also offer a lightweight and compact solution for applications where space is limited. This makes them highly versatile and suitable for use in medical devices, robotics, aerospace, and automotive industries. The ability of nitinol wires to deliver high force in a small package makes them an attractive choice for designers and engineers looking to optimize performance without sacrificing space or weight.

Heat Activation Process

When it comes to heat activated nitinol wire, the process of heat activation is crucial to unlocking its shape memory properties. By subjecting the nitinol wire to a specific temperature, it can be trained to return to its original shape after deformation. This process involves carefully heating the wire and then cooling it in the desired shape, effectively programming it for future use.

Explaining the Process of Heat Activation

The process of heat activation involves carefully heating the nitinol wire to a specific temperature known as its transformation temperature. This temperature is unique to each nitinol alloy and determines when the wire will undergo a phase change, returning to its original shape. Once heated, the wire is then cooled in the desired shape, effectively locking in this new form until it is subjected to heat again.

After the nitinol wire has been cooled in the desired shape, it becomes a highly flexible and durable material that can be used in a variety of applications. This unique property makes it ideal for medical devices such as stents and guidewires, where it can adapt to the body's natural movements without losing its structural integrity. In addition to medical uses, nitinol wire is also utilized in industries such as aerospace and robotics, where its shape memory and superelasticity are valuable assets.

Factors Affecting the Activation Temperature

Several factors can affect the activation temperature of heat activated nitinol wires, including alloy composition, manufacturing processes, and any previous deformation or training undergone by the wire. Understanding these factors is crucial for achieving precise control over the activation process and ensuring that the nitinol wire performs as intended in its application.

Understanding the alloy composition is essential in determining the activation temperature of heat activated nitinol wires. Different alloys have different phase transformation temperatures, which directly impact the activation temperature. Additionally, variations in manufacturing processes can also lead to differences in the activation temperature, making it crucial to have a clear understanding of these processes. Furthermore, any previous deformation or training undergone by the wire can alter its properties and affect the activation temperature, highlighting the need for precise control over these factors.

Achieving Precision with Heat Activated Nitinol Wire

Achieving precision with heat activated nitinol wires requires careful consideration of factors such as transformation temperatures, training methods, and environmental conditions where they will be used. By working with a trusted supplier like GEE SMA, you can ensure that your nitinol wires are precisely engineered for your specific application needs.

Industrial and Medical Applications

Nitinol Wires in Engineering and Manufacturing

Nitinol wires are revolutionizing the engineering and manufacturing industries with their unique properties. These versatile wires are being used in robotics, aerospace, and automotive applications due to their shape memory and superelasticity. The heat activated nitinol wire is particularly beneficial for its ability to return to a predetermined shape when heated, making it an ideal choice for precise and complex engineering designs.

Nitinol wires are also finding a wide range of applications in the manufacturing industry, particularly in the production of intricate and precise components. The unique properties of nitinol, including its shape memory and superelasticity, make it an ideal material for creating complex parts with tight tolerances. This has led to advancements in the manufacturing of medical devices, microelectronics, and even consumer products, as engineers can rely on nitinol wires to deliver consistent performance in demanding applications.

Nitinol Heat in Medical Devices and Instruments

In the medical field, nitinol heat has proven to be invaluable for developing cutting-edge medical devices and instruments. From stents that can expand within the body to orthodontic wires that apply gentle pressure on teeth, the heat activated nitinol wire has transformed the way medical procedures are conducted. Its biocompatibility and corrosion resistance make it a safe and reliable material for various medical applications.

Innovations in Heat Activated Nickel Titanium Wires

As technology continues to advance, so do the innovations in heat activated nickel titanium wires. Researchers and engineers are constantly exploring new ways to enhance the properties of nitinol wires, leading to breakthroughs in fields such as nanotechnology, energy harvesting, and smart materials. These innovations open up endless possibilities for utilizing nitinol wires in cutting-edge industrial and medical applications.

Nitinol Wire Actuator

Nitinol wire actuators are smart materials that respond to changes in temperature, making them ideal for a wide range of applications. When exposed to heat, these actuators undergo a phase transformation, allowing them to change shape or exert force. This unique functionality has made nitinol wire actuators indispensable in fields like robotics, aerospace, and medical devices.

Understanding the Functionality of Nitinol Wire Actuators

Nitinol wire actuators operate based on the shape memory effect and superelasticity properties of nitinol wires. When heated, the material returns to its predetermined shape, making it an excellent choice for applications requiring precise movement or force generation. This functionality has paved the way for innovative solutions in industries where traditional actuators fall short.

Real-World Examples of Nitinol Wire Actuator Applications

One notable application of nitinol wire actuators is in minimally invasive medical devices, such as stents and catheters. These devices utilize the heat-activated properties of nitinol wires to expand or contract within the body, providing targeted treatment without invasive procedures. Additionally, nitinol wire actuators are used in robotics for intricate movements and in aerospace for deployable structures.

Advancements in Nitinol Actuator Technology

Recent advancements in nitinol actuator technology have focused on enhancing response times and durability while reducing power consumption. Researchers and engineers continue to explore new alloys and manufacturing techniques to further improve the performance of nitinol wire actuators across various applications. These developments underscore the ongoing potential and versatility of heat-activated nitinol wire technology.

Maintaining Quality and Performance

Tips for Ensuring Longevity of Nitinol Wires

To ensure the longevity of heat activated nitinol wires, proper handling and storage are crucial. Avoid bending or kinking the wires excessively, as this can lead to premature fatigue. Additionally, storing the wires in a clean, dry environment can prevent corrosion and maintain their functionality over time.

Quality Control Measures for Heat Activated Niti Wires

Quality control measures for heat activated niti wires involve rigorous testing to ensure consistency and reliability. At GEE SMA, our nitinol wires undergo strict quality checks at every stage of production to guarantee that they meet the highest industry standards. This meticulous approach allows us to deliver superior products that exceed customer expectations.

Customization Options for Nitinol Functional Materials

When it comes to customization options for nitinol functional materials, GEE SMA offers a range of tailored solutions to meet specific application requirements. From wire diameter and shape to surface finish and thermal properties, our team works closely with clients to develop customized nitinol products that align with their unique needs and performance objectives.

Conclusion

Choosing the Right Nitinol Wire for Your Application

When it comes to selecting the right nitinol wire for your application, it's essential to consider factors such as temperature requirements, durability, and shape memory properties. Whether you need heat activated nitinol wire for medical devices or industrial actuators, GEE SMA offers a wide range of options to suit your specific needs.

Harnessing the Potential of Nitinol Heat

Nitinol heat has revolutionized various industries with its unique ability to remember and return to its original shape when heated. From minimally invasive medical procedures to precision engineering applications, the potential of heat activated nitinol wire is truly remarkable. Embracing this technology can lead to innovative solutions and improved performance in your projects.

Partnering with GEE SMA for Your Nitinol Wire Needs

When it comes to sourcing high-quality heat activated niti wires, partnering with GEE SMA ensures reliability, precision, and exceptional customer service. With their expertise in manufacturing and supplying heat activated nickel titanium wires, you can trust that your nitinol wire needs will be met with the highest standards of quality and performance.