Introduction

When it comes to orthodontic treatment, the benefits of heat activated nitinol wire cannot be overstated. This innovative material offers unparalleled flexibility and shape memory capabilities, making it a top choice for modern orthodontics. As orthodontists explore the best options for treatment, heat activated nitinol wire continues to stand out as a game-changer in the industry. Leading the way in nitinol wire production is GEE SMA, a trusted name known for its commitment to quality and innovation.

Benefits of Heat Activated Nitinol Wire

Heat-activated Nitinol wire has become a valuable tool in orthodontics, offering several key benefits for both orthodontists and patients:

- Gentle and Continuous Force: Heat-activated Nitinol applies a more gentle yet consistent force for tooth movement compared to traditional wires. This translates to increased patient comfort and potentially shorter treatment times.

- Enhanced Control and Efficiency: The heat activation process allows orthodontists to precisely control the force exerted by the wire at different stages of treatment. This level of control can lead to more efficient tooth movement and predictable results.

- Improved Shape Memory: Heat activation enhances Nitinol's shape memory capabilities. When warmed to body temperature, the wire exerts a gentle but persistent force to guide teeth back to their desired positions.

- Flexibility for Easier Placement: In its inactive state (at room temperature), heat-activated Nitinol wire is more flexible, allowing for easier placement and manipulation during orthodontic procedures.

Heat-activated Nitinol wire offers a combination of gentle force, precise control, and improved efficiency, making it a valuable advancement in orthodontic treatment for both orthodontists and patients.

Exploring the Best Options for Orthodontic Treatment

As orthodontists seek out the best materials for their patients, heat-activated nitinol wires continue to be at the forefront of modern orthodontic treatment options. Their ability to deliver consistent and controlled forces makes them ideal for a wide range of cases, from mild misalignments to more complex orthodontic issues.

How GEE SMA Leads the Industry in Nitinol Wire Production

GEE SMA has earned a well-deserved reputation as a leading manufacturer of nitinol wire for orthodontic applications. Their commitment to quality and innovation sets them apart in the industry. Here's what makes GEE SMA stand out:

- Consistent Quality: Their focus on high-precision manufacturing ensures Nitinol wire meets rigorous standards for performance and reliability. This translates to predictable results for orthodontists and a positive experience for patients.

- Advanced Research and Development: GEE SMA prioritizes ongoing research and development to refine its Nitinol technology. This dedication to innovation allows them to stay at the forefront of the industry, offering orthodontists access to the latest advancements in Nitinol wire properties and functionalities.

- Meeting Orthodontic Needs: By understanding orthodontists' specific needs, GEE SMA tailors its Nitinol wire offerings to deliver optimal performance in various clinical scenarios. This ensures orthodontists have the right tools to achieve the best possible outcomes for their patients.

Beyond the Basics

While other manufacturers might focus solely on producing nitinol wire, GEE SMA goes a step further. Their commitment to quality, innovation, and understanding the specific needs of orthodontics positions them as a valuable partner for dental professionals seeking the best possible materials for their practice.

What is Heat Activated Nitinol Wire?

Heat activated nitinol wire is a specialized nickel-titanium alloy with unique shape memory and superelastic properties. This innovative material can return to its pre-determined shape when subjected to heat, making it an ideal choice for orthodontic applications.

Characteristics and Properties of Nitinol Alloy

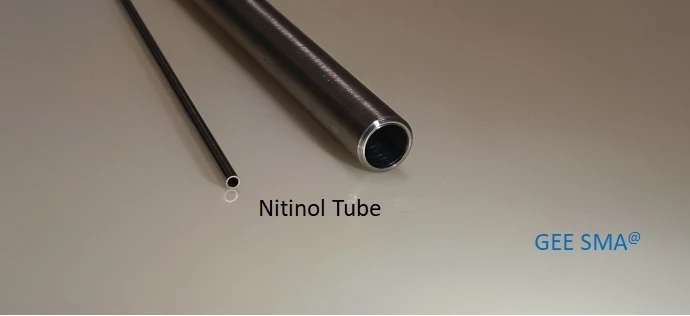

Nitinol alloy combines nickel and titanium, displaying remarkable flexibility, resilience, and biocompatibility. Its shape memory capabilities allow it to be easily manipulated into various forms, providing orthodontists with versatile options for creating customized dental appliances.

Advantages of Using Nitinol Wire in Orthodontic Treatment

Nitinol wire, a nickel-titanium alloy with unique properties, has revolutionized orthodontic treatment. Here's how it benefits both orthodontists and patients:

For Patients:

- Reduced Treatment Times: Nitinol's ability to apply gentle yet consistent force can potentially shorten treatment times compared to traditional wires. This translates to faster results and a shorter time spent wearing braces.

- Enhanced Comfort: The gentle and continuous pressure exerted by Nitinol wire minimizes discomfort compared to traditional wires, which can significantly improve patients' overall orthodontic experience.

- Precise Tooth Movement: Nitinol's shape memory and responsiveness to heat activation allow orthodontists to control tooth movement throughout treatment precisely. This leads to more predictable outcomes and a higher chance of achieving a perfect smile.

For Orthodontists:

- Improved Efficiency: Nitinol's durability reduces the need for frequent adjustments as it maintains its shape and applies consistent pressure. This frees up valuable chair time for orthodontists.

- Reduced Risk of Breakage: Nitinol's high resistance to deformation minimizes the risk of broken wires, leading to fewer disruptions in treatment and improved patient satisfaction.

- Biocompatible Material: Nitinol's biocompatibility minimizes the risk of allergic reactions or discomfort in patients. This allows orthodontists to focus on treatment planning and achieving optimal results with minimal complications.

Nitinol wire offers a significant advancement in orthodontic care. Its benefits for both patients and orthodontists contribute to a more comfortable, efficient, and predictable path to achieving a beautiful and healthy smile.

Applications in Modern Orthodontics

In modern orthodontics, heat-activated nitinol wires are commonly used to fabricate archwires, springs, and other orthodontic devices due to their exceptional mechanical properties. These advanced materials have revolutionized the field by allowing for more efficient tooth alignment and faster treatment progress. Additionally, nitinol wires offer superior flexibility and shape memory, allowing them to adapt to the changing positions of teeth throughout treatment. This means patients experience less discomfort and fewer adjustments during their orthodontic journey.

Top Features to Look for in Nitinol Wire

1. Flexibility and Shape Memory Capabilities

When considering nitinol wires for orthodontic treatment, it's crucial to prioritize flexibility and shape memory capabilities. Heat activated nitinol wire, also known as heat activated nickel titanium wires, offers the unique ability to return to its original shape when heated, allowing for precise positioning of teeth. This feature ensures that the wire can effectively apply consistent pressure to move teeth into the desired alignment, making it an ideal choice for orthodontic appliances.

2. Biocompatibility and Corrosion Resistance

Another essential feature of nitinol wires is their biocompatibility and corrosion resistance. These wires are used within the oral cavity, so they must be safe for prolonged contact with bodily tissues. Heat activated niti wires are known for their excellent biocompatibility, minimizing the risk of adverse reactions or tissue irritation. Additionally, their corrosion resistance ensures longevity and reliability in orthodontic appliances.

In addition to biocompatibility and corrosion resistance, nitinol wires also offer exceptional durability and longevity in orthodontic appliances. This means that orthodontic devices made with nitinol wires can withstand the wear and tear of everyday use, providing patients with reliable and long-lasting treatment. The ability of these wires to maintain their shape and function over time is crucial for ensuring the effectiveness of orthodontic treatment, giving both patients and orthodontists peace of mind.

Durability and Longevity in Orthodontic Appliances

Durability and longevity are key factors when selecting nitinol wire for orthodontic treatment. Heat activated nitinol wires offer exceptional durability, capable of withstanding repeated bending and flexing without compromising their structural integrity. This longevity translates to fewer wire replacements during treatment, reducing overall maintenance costs and ensuring consistent performance throughout the orthodontic process.

Comparing the Best Nitinol Wire Options

When choosing the best nitinol wire for orthodontic treatment, GEE SMA stands out with its premium products. Their heat activated nitinol wires are known for their exceptional flexibility, shape memory capabilities, and biocompatibility, making them a top choice for orthodontic appliances.

GEE SMA's Premium Nitinol Wire Products

GEE SMA offers a wide range of heat-activated nitinol wires designed to meet the diverse needs of orthodontic practices. From round to rectangular wires, their products boast superior flexibility and shape memory properties, ensuring optimal performance and patient comfort during treatment.

Other Leading Manufacturers in the Industry

While other leading manufacturers in the industry offer nitinol wires, GEE SMA's commitment to quality and innovation sets them apart. Their continuous advancements in nitinol technology make them a preferred choice for orthodontic professionals seeking reliable, high-quality materials for their patients.

While GEE SMA stands out for its commitment to quality and innovation, other factors should be considered when choosing the right nitinol wire for orthodontic treatment. For example, the cost of the materials may be a significant consideration for orthodontic professionals working within a budget. Additionally, the availability of nitinol wires of different sizes and shapes from various manufacturers can impact the decision-making process.

Factors to Consider When Choosing the Right Nitinol Wire for Orthodontic Treatment

Selecting the optimal Nitinol wire for orthodontic applications requires careful consideration of several key factors:

Mechanical Properties

- Force Delivery: Evaluate the wire's ability to deliver the desired level of force for specific tooth movement needs. Consider factors like wire diameter and material properties.

- Shape Memory: Consistent shape memory ensures the wire maintains its corrective force throughout treatment.

- Superelasticity: The wire's ability to return to its original shape after bending is crucial for maintaining pressure and reducing the need for adjustments.

Clinical Characteristics

- Biocompatibility: Choose Nitinol wire with high biocompatibility to minimize the risk of allergic reactions or tissue irritation in patients.

- Surface Finish: A smooth surface finish reduces friction and discomfort while the wire is in contact with the teeth and gums.

Supplier Considerations

- Quality Control: Reputable suppliers prioritize strict quality control measures to ensure consistent material properties and reliable performance in the Nitinol wire.

- Product Range: Access to various wire diameters, lengths, and temperaments allows orthodontists to select the most suitable option for each treatment stage.

Making an Informed Decision

By carefully evaluating these factors and considering the specific requirements of each patient's case, orthodontists can select Nitinol wire that delivers optimal performance, patient comfort, and predictable treatment outcomes. Consulting with experienced Nitinol wire suppliers can also provide valuable insights to help orthodontists make informed decisions based on their practice needs.

The Future of Nitinol Wire in Orthodontics

Innovations and Developments in Nitinol Technology

As the demand for advanced orthodontic treatment options continues to grow, so does the need for innovative materials like heat-activated nitinol wire. In recent years, significant advancements have been made in the development of nitinol wires, including improvements in flexibility, shape memory capabilities, and biocompatibility. These innovations have paved the way for more efficient and effective orthodontic treatments.

Potential Advancements in Orthodontic Treatment with Nitinol Wire

Potential advancements in orthodontic treatment with heat-activated nitinol wire are vast and promising. With ongoing research and development, we can expect to see further improvements in the performance and durability of nitinol wires, leading to enhanced patient comfort and shorter treatment times. Additionally, advancements in manufacturing processes may result in more cost-effective options for orthodontic practices.

GEE SMA's Ongoing Commitment to Advancing Nitinol Functional Materials

GEE SMA is at the forefront of advancing nitinol functional materials for orthodontic applications. With a strong commitment to research and development, GEE SMA continues to push the boundaries of nitinol technology, striving to create cutting-edge products that meet the evolving needs of orthodontic professionals and their patients. Their dedication to innovation ensures that practitioners have access to high-quality nitinol wires that deliver superior results.

Ensuring Quality and Satisfaction with Nitinol Wire

Customer testimonials play a crucial role in showcasing the effectiveness of GEE SMA's products when it comes to ensuring quality and satisfaction with nitinol wire. Many orthodontic professionals have expressed their satisfaction with the performance and reliability of heat-activated nitinol wires from GEE SMA, highlighting the superior results achieved in orthodontic treatment.

Customer Testimonials and Satisfaction with GEE SMA Products

Several orthodontists have shared their positive experiences using GEE SMA's heat activated nitinol wires, praising the exceptional flexibility, shape memory capabilities, and long-lasting performance of these innovative products. With glowing reviews from satisfied customers, it's clear that GEE SMA is a trusted provider of high-quality nitinol wires for orthodontic applications.

Importance of Quality Assurance in Orthodontic Appliances

Orthodontic appliances play a critical role in tooth movement and achieving optimal results. Heat-activated Nitinol wires are particularly crucial as they exert gentle yet persistent forces for tooth alignment. Therefore, ensuring their quality and consistency is paramount.

Here's why quality assurance is essential in orthodontic appliances:

- Patient Safety and Comfort: High-quality materials minimize the risk of allergic reactions, irritation, or breakage that can compromise patient comfort and potentially prolong treatment.

- Predictable Treatment Outcomes: Consistent material properties ensure the wires deliver the planned force levels throughout treatment, leading to more predictable tooth movement and reduced treatment times.

- Reduced Risk of Complications: Durable and reliable materials minimize the risk of wire breakage or malfunction, leading to fewer complications and disruptions in treatment.

- Trust and Confidence for Orthodontists: When orthodontists use appliances backed by rigorous quality control, they can have greater confidence in their chosen materials and focus on delivering optimal care to their patients.

Choosing Reliable Suppliers

Selecting orthodontic appliance suppliers with a strong commitment to quality assurance is crucial. Look for suppliers who prioritize:

- Strict Quality Control Measures: These ensure consistent material properties and reliable performance throughout the manufacturing process.

- Biocompatible Materials: Materials used should minimize the risk of adverse patient reactions.

- Rigorous Testing: Regular testing verifies that the appliances meet all safety and performance standards.

By prioritizing quality assurance, orthodontists and patients can benefit from safe, reliable, and predictable orthodontic treatment.

Choosing the Right Supplier for Nitinol Wire in Orthodontic Practices

Selecting the right supplier for heat-activated nitinol wire is a critical decision for orthodontic practices seeking optimal patient results. With a proven track record of excellence in nitinol technology and a commitment to advancing functional materials, GEE SMA stands out as the premier choice for orthodontists looking to partner with a reliable and innovative supplier.

GEE SMA's dedication to quality assurance sets them apart from other suppliers in the industry. Their rigorous testing protocols ensure that every batch of nitinol wire meets the highest standards for performance and reliability. Orthodontic practices can trust that they receive a consistent and top-quality product with GEE SMA, giving them peace of mind in their treatment plans.

Embrace the Future of Orthodontics with Nitinol Technology

When making informed decisions for orthodontic treatment with heat activated nitinol wire, it's essential to consider the benefits and advantages of this innovative material. With its unique properties and applications in modern orthodontics, nitinol wires offer a superior option for patients seeking effective and comfortable treatment. By choosing GEE SMA as your trusted partner for high-quality nitinol wire, you can get the best products on the market. Embrace the future of orthodontics with nitinol technology and experience the difference it can make in your practice.

Making Informed Decisions for Orthodontic Treatment with Nitinol Wire

Understanding how to use heat activated nitinol wire is crucial in making informed decisions for orthodontic treatment. With its flexibility, shape memory capabilities, and biocompatibility, nitinol wires provide a reliable and effective solution for patients seeking comfortable orthodontic appliances. By exploring the top features in nitinol wire and comparing the best options available, orthodontists can ensure that they provide their patients with the highest quality treatment.

When selecting nitinol wire for orthodontic treatment, orthodontists should consider the wire's superelasticity, allowing it to return to its original shape after deforming. This feature ensures that the wire can withstand the forces exerted during orthodontic treatment without permanently bending or breaking. Additionally, orthodontists should look for nitinol wire that offers a smooth surface finish to minimize friction and discomfort for the patient. By prioritizing these features, orthodontists can confidently provide their patients with comfortable and effective orthodontic appliances.

GEE SMA: Your Trusted Partner for High-Quality Nitinol Wire

GEE SMA leads the industry in nitinol wire production, offering premium products that meet the highest quality and performance standards. With a commitment to innovation and excellence, GEE SMA provides orthodontic professionals with reliable solutions for their patients' needs. By choosing GEE SMA as your supplier of heat activated nickel titanium wires, you can trust that you're getting top-notch products backed by years of expertise and dedication to advancement in nitinol functional materials.

As advancements continue in nitinol technology, the future of orthodontics looks promising, with new opportunities for improved treatment options. Innovations and developments in heat-activated niti wires are paving the way for enhanced patient experiences and more efficient orthodontic appliances. With GEE SMA's ongoing commitment to advancing nitinol functional materials, orthodontists can look forward to embracing these exciting developments and providing their patients with cutting-edge solutions.