Introduction

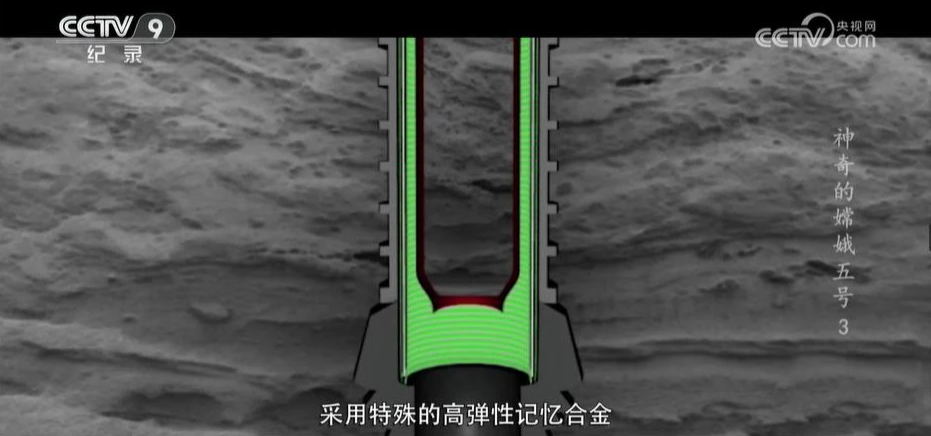

In robotics, the use of Nitinol technology has revolutionized the way we think about movement and actuation. Nitinol muscles, also known as shape memory alloys, offer a unique combination of flexibility and durability that makes them ideal for a wide range of applications. From delicate robotic fingers to powerful industrial machinery, Nitinol muscles have proven indispensable in the field of robotics.

Understanding Nitinol Muscles

Nitinol muscles are made from a unique alloy that exhibits shape memory properties, allowing them to return to their original shape after deforming. This remarkable ability makes them perfect for mimicking human muscle movements in robotic systems. Whether gripping objects or performing intricate tasks, Nitinol muscles provide unparalleled precision and control.

Exploring Nitinol Springs and Wires

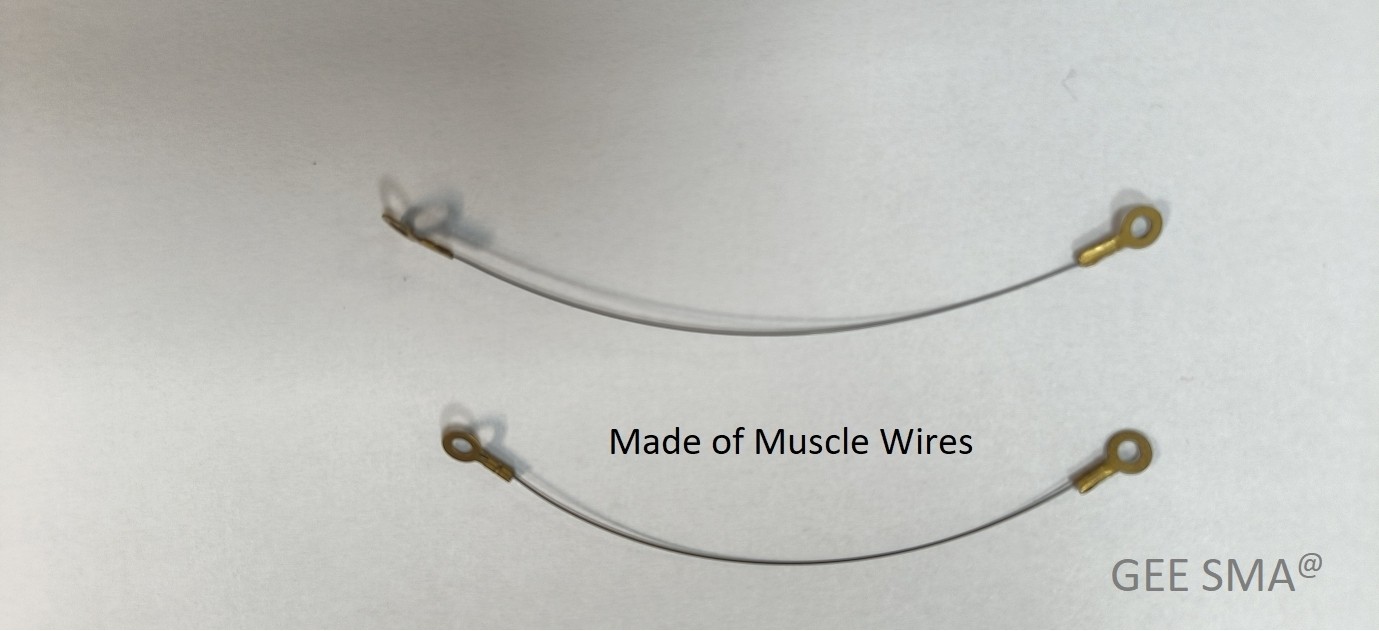

Nitinol springs and wires are another key component in robotics. Their versatility in design allows for complex movements and adjustments, while their reliability and consistency ensure seamless integration into robotic projects. From simple linear actuators to advanced robotic limbs, Nitinol springs and wires are crucial in bringing robots to life.

Benefits of Nitinol Alloy Foil

Nitinol alloy foil offers a wide range of benefits for robotic applications. Its high strength-to-weight ratio makes it an ideal material for creating lightweight yet durable components. Its shape memory properties also allow for precise movement control, making it an invaluable resource for advancing robotic projects.

The Power of Nitinol Muscles

Nitinol muscles are at the forefront of innovative robotics technology, offering unparalleled flexibility and durability. These intelligent materials can withstand thousands of cycles without degradation, making them ideal for long-term robotic applications. Their ability to bend and twist without losing strength makes them a top choice for intricate robotic movements.

Flexibility and Durability

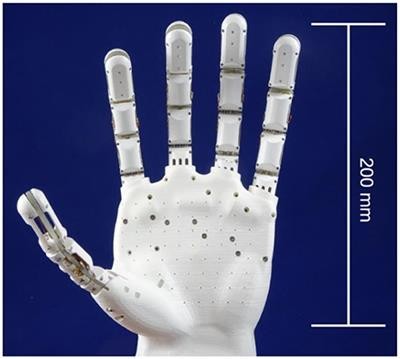

Nitinol muscles boast exceptional flexibility, allowing them to mimic human muscle movements with remarkable precision. This unique property enables robots to perform delicate tasks accurately, such as surgical procedures or intricate assembly work. Their durability ensures these muscles can withstand continuous use without wearing out, providing a reliable and long-lasting solution for robotic applications.

Nitinol muscles also offer the advantage of efficient energy conversion, making them an ideal choice for robotic applications. Their ability to convert energy into mechanical motion with minimal waste ensures that robots can operate efficiently, reducing the need for frequent recharging or maintenance. This energy-saving feature not only enhances robots' overall performance but also contributes to cost savings and environmental sustainability.

Efficient Energy Conversion

One of the most impressive features of nitinol muscles is their efficient energy conversion capabilities. When heated, these muscles contract with significant force, converting thermal energy into mechanical energy with exceptional efficiency. This makes them ideal for creating lightweight and energy-efficient robots that can operate for extended periods without frequent recharging or battery replacements.

Nitinol muscles also offer precise control and responsiveness, allowing for more natural and fluid movements in robotic applications. This level of control is essential in tasks that require delicate manipulation or interaction with the environment, such as in surgical robots or prosthetic limbs. The ability to convert energy efficiently while maintaining precise control makes nitinol muscles a game-changer in robotics, opening up new possibilities for advanced and lifelike robotic systems.

Applications in Robotics

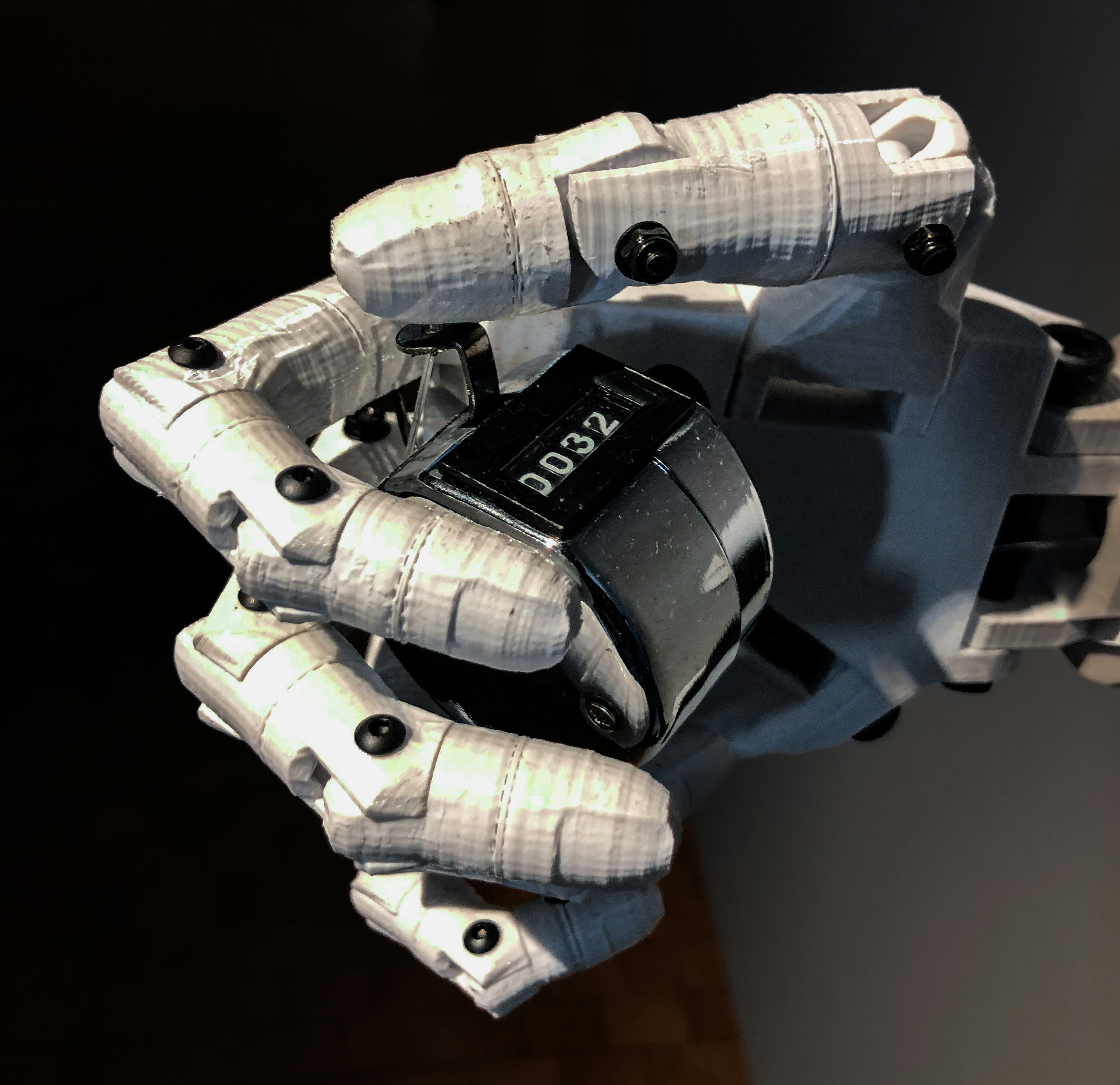

Nitinol muscles, with their unique properties, are transforming the field of robotics. Here's how:

- Enhanced Dexterity and Control: Nitinol muscles enable robots to perform complex tasks with precision and reliability, thanks to their responsiveness and ability to mimic natural muscle movement.

- Lightweight and Flexible Designs: Robots built with nitinol muscles can be lighter and more flexible, making them ideal for applications in prosthetics, exoskeletons, and soft robotics.

- Diverse Applications: From medical devices to industrial automation, nitinol muscles drive innovation across various industries.

Nitinol muscles hold immense potential to revolutionize robotics for industrial applications and improve the quality of life for people with disabilities.

Crafting with Nitinol Springs

Nitinol springs are game-changers in robotics due to their versatility in design. These springs can be crafted into various shapes and sizes, allowing for customized solutions in robotic applications. Whether a compact, intricate design or a larger, more robust spring, nitinol springs offer the flexibility to meet specific project requirements.

Versatility in Design

Crafting with nitinol springs opens up a world of possibilities for engineers and designers. The material's unique properties allow for intricate and complex spring designs that adapt to different robotic applications. From coil springs to torsion springs, nitinol's malleability makes it an ideal choice for crafting components that require precise engineering and tailored solutions.

Crafting with nitinol springs allows for intricate and complex designs and provides a level of reliability and consistency that is essential for robotic applications. The material's ability to maintain its shape and elasticity over time ensures that the springs will continue to perform at a high level, even in demanding environments. This makes nitinol attractive for engineers and designers who prioritize durability and longevity.

Reliability and Consistency

Nitinol springs offer unmatched reliability and consistency, making them essential to robotics projects. Their ability to maintain shape and performance over countless cycles ensures that robotic systems operate smoothly without the risk of spring fatigue or failure. This reliability is crucial for keeping robotic applications efficient and lasting.

Nitinol springs are also highly adaptable, making them suitable for various robotic applications. Their flexibility allows for easy integration into multiple designs and mechanisms, providing engineers with the freedom to innovate and create more advanced robotic systems. This versatility is a key advantage for robotics projects, enabling engineers to customize their designs without compromising reliability or performance.

Integration in Robotics Projects

Nitinol springs are becoming increasingly popular in robotics due to their unique properties and versatility. Here are some of the key benefits they offer:

- Enhanced Functionality: Nitinol springs seamlessly integrate into robotic systems, acting as actuators, sensors, or other mechanical components. Their consistent performance improves overall functionality.

- Durability and Precision: These springs can withstand repetitive movements without sacrificing precision, making them invaluable assets in various robotic applications.

- Shape Memory: Nitinol's ability to return to its original shape after deformation allows for precise and repeatable movements, which is ideal for many robotics projects.

- Space Efficiency: Remarkably, nitinol can generate high forces in a compact space, making it an efficient choice for robots with limited space.

Nitinol springs are revolutionizing the field of robotics by enhancing performance, opening doors for innovative designs, and expanding the functional capabilities of robotic systems.

Unleashing Nitinol Memory Wires

Shape Memory Properties

Nitinol memory wires are renowned for their unique shape memory properties, allowing them to return to a predetermined shape when subjected to heat. This remarkable feature makes them ideal for intricate robotic applications, where precision and reliability are essential.

Here's why nitinol memory wires are so well-suited for robotics:

- Shape Memory: Nitinol wires can be deformed and hold that shape but then return to their original form when heated. This allows for pre-programming complex movements into the wire itself.

- Precision Control: The ability to precisely control the wire's shape through temperature changes enables highly accurate movements within robotic systems.

- Seamless Integration: Nitinol's compact size and versatility allow it to integrate easily into complex robotic designs.

Nitinol memory wires offer unique properties that make them invaluable for developing precise and reliable robotic systems.

Precision and Control

Robotic engineers can achieve unparalleled precision and control in their designs with nitinol memory wires. The wires respond predictably to changes in temperature, allowing for smooth and accurate movements in robotic actuators. This level of control is crucial in creating lifelike movements in robotic limbs and enhancing the overall agility of robotic systems. Additionally, using nitinol memory wires reduces the need for complex and bulky mechanical systems, resulting in sleeker and more efficient robotic designs. This not only improves the aesthetics of the robots but also makes them more practical for various applications.

Robotic Actuation and Movement

The application of nitinol memory wires in robotics extends to actuation and movement, where their shape memory properties play a pivotal role. These wires can create lifelike movements in robotic joints, mimicking human limbs' natural range of motion. As a result, robots equipped with nitinol memory wires can perform delicate tasks with finesse and agility, making them invaluable assets across various industries.

Moreover, using nitinol memory wires in robotics also enhances precision and control. The shape memory properties of these wires enable robots to make intricate movements with accuracy, making them ideal for tasks requiring a high skill level. This level of precision is especially beneficial in industries such as healthcare and manufacturing, where the ability to perform delicate procedures or assemble intricate components is crucial.

GEE SMA: The Expert in Nitinol Alloys

GEE SMA is renowned for its exceptional quality assurance and certification processes. These processes ensure that all nitinol products, including nitinol muscles, springs, and memory wire, meet the highest industry standards. Our team of experts meticulously inspects and tests each alloy to guarantee reliability and performance in robotics applications.

Quality Assurance and Certification

Our rigorous quality assurance protocols and industry certifications reflect our commitment to excellence. We adhere to strict guidelines to maintain the integrity of our nitinol alloys, providing peace of mind to robotics engineers and designers seeking dependable solutions for their projects. At GEE SMA, we prioritize product reliability and consistency to deliver superior performance in every application.

Tailored Solutions for Robotics

With a deep understanding of the unique requirements of robotics projects, GEE SMA offers tailored solutions that leverage the power of nitinol technology. Whether designing custom nitinol springs or providing specialized nitinol muscle actuators, our team collaborates closely with clients to develop innovative solutions that enhance the functionality and efficiency of robotic systems.

Customer-Centric Approach

At GEE SMA, we emphasize fostering strong partnerships with our clients by adopting a customer-centric approach. We prioritize open communication, flexibility, and responsiveness to ensure that every client receives personalized attention and support throughout their collaboration with us. We aim to empower robotics professionals with cutting-edge nitinol technology while delivering an exceptional customer experience.

In addition to our customer-centric approach, we understand the importance of staying ahead of industry trends and technological advancements. Our team is committed to continuous learning and innovation, ensuring we can provide our clients with the most up-to-date nitinol technology solutions. By staying proactive and adaptable, we can offer tailored recommendations and support to meet the evolving needs of robotics professionals.

GEE SMA's Commitment to Innovation

Nitinol technology has revolutionized the robotics industry, with its incredible potential in nitinol muscles, springs, and memory wire. The flexibility and durability of nitinol muscles make them a game-changer in inefficient energy conversion for robotic applications. GEE SMA's commitment to innovation ensures that tailored solutions for robotics projects are always at the forefront of technological advancement.

Leveraging Nitinol Technology in Robotics

By leveraging the power of nitinol technology, robotics engineers can create more agile and responsive machines that can perform complex tasks with precision. Nitinol muscles offer a unique combination of strength and flexibility, allowing robots to mimic human movements with remarkable accuracy. This opens up new possibilities for healthcare, manufacturing, and space exploration industries.

By leveraging nitinol technology, robotics engineers can design robots with enhanced durability and longevity. Nitinol's unique properties make it resistant to fatigue and deformation, ensuring that robots can operate continuously without frequent maintenance or repairs. This reliability is crucial for industries such as healthcare and manufacturing, where precision and consistency are paramount.

GEE SMA is dedicated to pushing the boundaries of what is possible with nitinol alloys. Their expertise in crafting nitinol springs and wires ensures that robotics projects have access to reliable and consistent components that can withstand the demands of real-world applications. With a focus on quality assurance and certification, GEE SMA is a trusted partner for those seeking cutting-edge solutions.

GEE SMA's commitment to innovation extends beyond providing reliable components for robotics projects. They constantly explore new applications for nitinol alloys, pushing the boundaries of what is possible in robotics. By staying at the forefront of technological advancements, GEE SMA ensures its clients can access the latest and most cutting-edge solutions for their projects. This dedication to innovation sets GEE SMA apart as a leader in the industry, always striving to offer the best and most advanced products.

Advancing Robotic Projects with Nitinol Muscles

Integrating nitinol muscles in robotic systems represents a significant leap forward in automation. These advanced materials provide precise control over movement, allowing robots to perform delicate tasks with unparalleled accuracy. As GEE SMA continues to innovate and refine its offerings, the potential for advancements in robotic projects powered by nitinol muscles is limitless.

Furthermore, using nitinol muscles in robotic systems also offers significant energy efficiency benefits. These advanced materials require minimal power, making them ideal for long-duration tasks and reducing energy consumption. With the ability to perform intricate movements with minimal energy input, robots powered by nitinol muscles can operate for extended periods without frequent recharging or refueling, making them highly cost-effective and environmentally friendly.