Introduction

When it comes to innovative materials in various industries, the nitinol sheet price is a crucial factor to consider. Whether you are exploring the cost of nitinol sheets or understanding the benefits they offer, it's essential to delve into the intricacies of this unique metal alloy.

Understanding Nitinol Sheet Price

Nitinol sheets have gained popularity due to their exceptional properties, but understanding the price of nitinol sheets is vital for making informed decisions. From their composition to manufacturing processes, several factors contribute to the overall cost of nitinol sheets in the market.

Exploring Nitinol Sheet Cost

Exploring the nitinol sheet cost involves analyzing various aspects such as material quality, production techniques, and market demand. This exploration can provide valuable insights into how these factors influence the pricing of nitinol sheets.

Benefits of Nitinol Sheets

Nitinol sheets, composed of a nickel-titanium alloy, might have a higher price tag than some materials. However, their unique properties offer a compelling value proposition, making them a preferred choice across numerous applications. Here's a closer look at the undeniable benefits of nitinol sheets:

- Shape Memory Champion: Nitinol sheets can "remember" their original shape after being deformed. This property allows for creating innovative components that adapt or deploy upon exposure to a specific temperature or trigger. Imagine stents that expand and conform to the anatomy within the body or self-deploying aerospace components upon reaching specific altitudes.

- Superelastic Superstar: Nitinol sheets exhibit exceptional superelasticity, meaning they can undergo significant deformation and return to their original shape upon release of stress. This characteristic makes them ideal for applications requiring flexibility and resilience. Nitinol sheets in vibration-dampening systems, for example, can absorb high impacts without permanent damage, ensuring long-term functionality.

- Biocompatible Excellence: Nitinol excels in biocompatibility. The human body readily accepts nitinol sheets, minimizing the risk of rejection or adverse tissue reaction. This makes them a prime choice for medical devices like orthopedic implants and surgical instruments, offering significant advantages for patient comfort and long-term success of procedures.

- Durability and Corrosion Resistance: Nitinol sheets boast exceptional durability and resistance to corrosion. These properties ensure components can withstand harsh environments and maintain their functionality over extended lifespans. This translates to minimizing replacements and maintenance costs, leading to overall project savings.

- Design Versatility: Nitinol sheets can be formed and machined into intricate shapes, empowering engineers to design complex components with unique functionalities. This design flexibility pushes the boundaries of innovation in various industries, from aerospace and automotive to medical devices and consumer products.

Factors Affecting Nitinol Sheet Price

When understanding the nitinol sheet price, it's essential to consider several factors that influence the cost. First and foremost, material quality plays a significant role in determining the price of nitinol sheets. High-quality nitinol metal commands a higher price due to its superior properties and performance. The production process also impacts the price, as intricate manufacturing techniques may increase the overall cost. Additionally, market demand for nitinol sheets can fluctuate, affecting their price based on supply and demand dynamics.

1. Material Quality

The quality of nitinol sheets directly affects their price, with premium-grade materials commanding a higher cost due to their exceptional strength, durability, and shape memory characteristics. Nitinol sheet prices often reflect the material's composition and purity, as these factors contribute to its overall performance and reliability in various applications.

2. Production Process

The production process of nitinol sheets can vary significantly based on the required specifications and customization. Advanced manufacturing techniques such as precision rolling, heat treatment, and surface finishing may increase production costs, ultimately influencing the price of nitinol sheets in the market.

Furthermore, the production process of nitinol sheets also involves careful quality control measures to ensure that the material meets industry standards and customer requirements. This may include rigorous testing for mechanical properties, dimensional accuracy, and surface integrity, adding to the complexity and cost of production. As a result, manufacturers must carefully balance these factors to optimize production efficiency while meeting market demand for high-quality nitinol sheets.

3. Market Demand

Due to supply and demand dynamics, market demand for nitinol sheets can impact their price. Fluctuations in demand from industries such as medical devices, aerospace, and robotics can influence the availability of nitinol materials, thereby affecting their market price.

Fluctuations in market demand for nitinol sheets can also be influenced by technological advancements and innovations in the industries that rely on this material. As new applications for nitinol emerge, such as in smart materials and shape memory alloys, the demand for nitinol sheets may experience significant shifts. Additionally, changes in consumer preferences and trends towards miniaturization and efficiency can impact the overall demand for nitinol materials in various sectors.

Comparing Nitinol Sheet Price to Titanium Sheet Price

When comparing nitinol sheet price to titanium sheet price, it's important to consider the strength and durability of both materials. Nitinol sheets are known for their exceptional strength and durability, making them ideal for applications that require resilience and reliability. On the other hand, titanium sheets also offer impressive strength and durability, but may not match the unique properties of nitinol when it comes to shape memory and flexibility.

Strength and Durability

Nitinol sheets are renowned for their high tensile strength and exceptional durability, making them a popular choice in medical devices, aerospace, and robotics industries. The unique combination of nickel and titanium in nitinol allows it to withstand extreme conditions without compromising its structural integrity. In comparison, while titanium sheets also offer impressive strength and durability, they may not possess the same level of resilience as nitinol when subjected to repeated stress or strain.

Flexibility and Shape Memory

One of the key advantages of nitinol sheets over titanium sheets is their remarkable flexibility and shape memory properties. Nitinol can remember its original shape and return to it after deforming, making it highly sought after in applications where precise shape retention is crucial. In contrast, while titanium is known for its flexibility, it does not possess the same shape memory capabilities as nitinol, which sets the two materials apart regarding their suitability for specific uses.

Finding the Best Nitinol Sheet Price

When finding the best nitinol sheet price, researching suppliers is crucial. Look for companies with a proven track record of providing high-quality nitinol sheets at competitive prices. Consider their production capabilities, material sourcing, and customer service to ensure you're getting the best value for your money.

Researching Suppliers

Look for suppliers that specialize in nitinol sheets and have a deep understanding of the material and its applications. Check their certifications and quality control processes to ensure they meet industry standards. Additionally, consider their lead times and ability to fulfill large orders, as this can impact the overall cost of your project.

It's also important to consider the supplier's track record in delivering high-quality nitinol sheets. Look for customer reviews and testimonials to gauge their reputation in the industry. A supplier with a proven track record of consistent quality will give you peace of mind that you are working with a reliable partner for your project. Additionally, inquire about their customer service and responsiveness to ensure that any issues or concerns can be addressed promptly.

Quality Assurance

Quality assurance is paramount when it comes to nitinol sheets. Ensure that the supplier has stringent quality control measures to guarantee their products' consistency and reliability. This includes testing for shape memory properties, mechanical strength, and corrosion resistance to ensure you get a superior product that meets your specific requirements.

Customer Reviews

Don't underestimate the power of customer reviews when evaluating potential suppliers. Look for feedback from other businesses or professionals who have purchased nitinol sheets from the supplier. Their experiences can provide valuable insights into the supplier's reliability, product quality, and overall customer satisfaction.

Applications of Nitinol Sheets

Nitinol sheets have various applications across various industries, thanks to their unique properties and shape memory capabilities. Let's explore some of the key areas where nitinol sheets are commonly used.

Medical Devices

Nitinol sheets are extensively used in medical manufacturing devices such as stents, guidewires, and orthopedic implants. The biocompatibility and superelasticity of nitinol make it an ideal material for these critical applications, ensuring patient safety and optimal performance.

Nitinol's unique properties also make it an ideal material for aerospace applications. Its superelasticity allows it to withstand extreme temperature changes and mechanical stress, making it perfect for components in aircraft and spacecraft. Additionally, its biocompatibility ensures that it does not react with other materials, making it a safe and reliable choice for critical aerospace parts. Whether used in medical devices or aerospace technology, nitinol remains a versatile and essential material for modern engineering.

Aerospace Industry

In the aerospace industry, nitinol sheets are utilized in components like actuators, valves, and sensors due to their lightweight nature and resistance to high temperatures. Nitinol's exceptional fatigue resistance makes it a preferred choice for demanding aerospace applications.

In addition to their use in actuators, valves, and sensors, nitinol sheets are also employed in constructing aircraft wings and fuselage components. The lightweight nature of nitinol makes it an ideal material for reducing overall aircraft weight, which can lead to improved fuel efficiency and performance. Furthermore, the high-temperature resistance of nitinol allows for reliable operation in extreme conditions, making it a valuable asset in the aerospace industry.

Robotics and Automation

The unique properties of nitinol sheets make them invaluable in robotics and automation systems where precise movements and shape memory are essential. Nitinol actuators are widely used in robotic grippers, prosthetics, and other automated systems to deliver efficient and reliable performance.

With its diverse range of applications spanning from healthcare to space exploration, the versatility of nitinol sheets continues to drive innovation across industries worldwide.

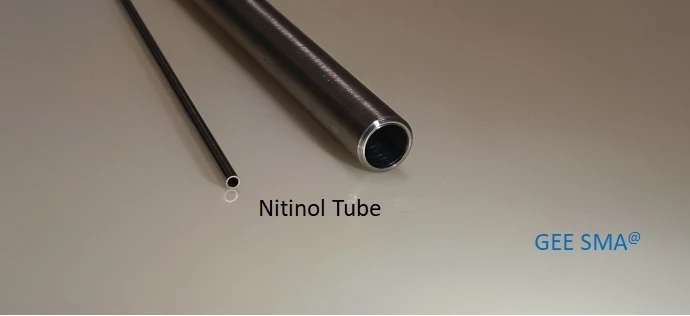

GEE SMA: Your Source for High-Quality Nitinol Sheets

When sourcing high-quality nitinol sheets, GEE SMA is your go-to supplier. Our commitment to superior craftsmanship ensures that our nitinol sheets are of the highest quality, offering exceptional durability and performance for various applications. Whether you need standard sizes or custom dimensions, our tailored solutions cater to your requirements, providing you with the perfect nitinol sheet for your project.

Superior Craftsmanship

At GEE SMA, we take pride in our superior craftsmanship in producing nitinol sheets. Our state-of-the-art manufacturing processes and stringent quality control measures guarantee that each sheet meets the highest standards of excellence. With a focus on precision and attention to detail, we ensure that our nitinol sheets deliver outstanding performance and reliability for your applications.

Tailored Solutions

Every project has unique needs, so we offer tailored solutions for your nitinol sheet requirements. Whether you require specific dimensions, surface finishes, or material properties, our team works closely with you to provide customized solutions that align with your project goals. From prototype development to large-scale production runs, we deliver nitinol sheets that meet your specifications.

Customer Satisfaction

At GEE SMA, customer satisfaction is at the core of everything. We prioritize clear communication, timely delivery, and responsive support to ensure our customers have a seamless experience when sourcing nitinol sheets from us. Our commitment to excellence extends beyond product quality – it encompasses the overall satisfaction of our customers as they partner with us for their nitinol material needs.

In conclusion, when finding high-quality nitinol sheets at competitive prices, look no further than GEE SMA. With superior craftsmanship, tailored solutions, and a focus on customer satisfaction, we are dedicated to being your trusted source for premium nitinol materials.

Partner with GEE SMA for Quality Nitinol Materials

When making informed decisions on nitinol sheet price, it's essential to consider factors such as material quality, production process, and market demand. By understanding these elements, you can better assess the true cost of nitinol sheets and ensure that you get the best value for your investment. Leveraging the benefits of nitinol sheets, including their strength, flexibility, and shape memory, can provide a competitive edge in various industries such as medical devices, aerospace, and robotics. Partnering with GEE SMA for quality nitinol materials ensures superior craftsmanship, tailored solutions, and customer satisfaction.

Making Informed Decisions on Nitinol Sheet Price

Understanding the factors that affect nitinol sheet price is crucial in making informed decisions about your purchase. Material quality plays a significant role in determining the price of nitinol sheets, as does the production process and market demand. By carefully evaluating these factors, you can ensure that you get the best value for your investment in nitinol metal.

Leveraging the Benefits of Nitinol Sheets

Nitinol sheets offer a range of benefits, including strength and durability, flexibility, and shape memory properties. These unique characteristics make them highly sought after in industries such as medical devices, where precision and reliability are paramount. Businesses can gain a competitive edge in their respective fields by leveraging these benefits.

GEE SMA is your trusted source for high-quality nitinol materials at competitive prices. With superior craftsmanship and tailored solutions to meet your needs, GEE SMA ensures customer satisfaction with every purchase. Whether you require nitinol sheets for medical devices or aerospace applications, partnering with GEE SMA guarantees access to top-notch materials that meet stringent quality standards.