Introduction

Are you curious about nitinol wire cost and price? Want to learn more about the basics of nitinol wire forming and its advantages? Look no further! GEE SMA is your go-to source for all things nitinol wire. As experts in the field, we're here to provide valuable insights and guidance on purchasing nitinol wire.

Understanding Nitinol Wire Cost

When it comes to understanding nitinol wire cost, various factors contribute to pricing. Material quality, manufacturing processes, and market demand all play a significant role in determining the cost of nitinol wire.

Exploring Nitinol Wire Price

Exploring nitinol wire prices can be an overwhelming task, especially with the wide range of options available in the market. At GEE SMA, we aim to simplify this process by offering transparent pricing and detailed product information.

The Basics of Nitinol Wire Forming

Nitinol wire forming involves intricate processes that result in its unique properties such as shape memory and superelasticity. Understanding these basics is crucial for making informed decisions when purchasing nitinol wire.

The Advantages of Nitinol Wire

Nitinol wire stands out as a truly remarkable material due to its unique properties. Let's delve into the key advantages that make nitinol wire so sought-after across various industries:

- Shape Memory Magic: One of nitinol's most fascinating properties is its shape memory. When deformed at a low temperature, it can "remember" its original shape upon exposure to a higher temperature. This characteristic allows for the creation of medical devices like stents that can be compressed for insertion and then expand to their original form within the body.

- Superelasticity Superstar: Nitinol also exhibits superelasticity. This means it can be deformed to a great extent without permanent damage and spring back to its original shape once the stress is released. This property makes nitinol ideal for applications like orthodontic wires and eyeglass frames that require flexibility and resilience.

- Biocompatible Champion: Biocompatibility is crucial for medical applications. Nitinol is exceptionally biocompatible, meaning it doesn't cause adverse tissue reactions within the body. This makes it a safe and reliable material for implants, stents, and other medical devices that come into contact with human tissue.

- Corrosion Resistant Contender: Nitinol demonstrates excellent corrosion resistance. This property is especially valuable in medical implants and devices that must function reliably within the body for extended periods.

- High Strength and Durability: Nitinol boasts remarkable strength and durability despite its shape-changing abilities. This combination allows nitinol components to withstand repeated stresses and strains without failure.

- Heat Actuation Versatility: Nitinol's actuation temperature can be tailored during the manufacturing process. This allows engineers to design components that respond to specific temperature triggers, offering greater control and functionality in various applications.

- Fatigue Resistant: Nitinol exhibits exceptional fatigue resistance. It can withstand repeated bending and deformation without experiencing metal fatigue or failure. This is crucial for applications like heart valves that undergo millions of movement cycles throughout their lifespan.

Nitinol wire's advantages are vast and far-reaching. Its unique combination of shape memory, superelasticity, biocompatibility, corrosion resistance, and durability makes it a game-changer in various fields. From enabling minimally invasive medical procedures to creating durable aerospace components, nitinol wire is a material that continues to push the boundaries of innovation and design.

GEE SMA: Your Nitinol Wire Experts

As your trusted nitinol wire experts, GEE SMA is committed to providing top-quality products, exceptional customer support, and tailored solutions for your specific requirements. With our expertise and dedication to excellence, we strive to be your preferred supplier for all things nitinol.

Factors Affecting Nitinol Wire Cost

When considering nitinol wire cost, it's essential to understand the factors that contribute to its pricing. Material quality and purity play a significant role in determining the cost of nitinol wire, as higher quality materials often come at a premium. Additionally, the manufacturing processes used to produce nitinol wire can impact its price, with more complex processes leading to higher costs. Market demand also influences nitinol wire price, as fluctuations in demand can lead to price variations. Furthermore, size and shape variations of nitinol wire can affect its cost, with custom sizes and shapes typically commanding higher prices.

1. Material Quality and Purity

The quality and purity of the materials used in nitinol wire production directly impact its cost. Higher quality, meticulously refined and purified materials tend to result in a more reliable and durable product. Still, they also come at a higher price point due to the increased manufacturing costs.

2. Manufacturing Processes

The manufacturing processes involved in producing nitinol wire can significantly affect its cost. More intricate processes, such as shape setting or heat treatment, may require specialized equipment and expertise, leading to higher production costs reflected in the nitinol wire's final price.

3. Market Demand

Market demand plays a crucial role in determining the cost of nitinol wire. Fluctuations in demand can lead to price variations, with high demand driving prices up while lower demand may result in more competitive pricing.

4. Size and Shape Variations

The size and shape of nitinol wire can impact its cost, with custom sizes or unique shapes often carrying a premium due to the additional manufacturing steps required for customization.

Remember that understanding these factors is essential when evaluating the pricing of nitinol wire for your specific needs. By considering these elements, you can make informed decisions when purchasing nitinol wire for your applications without overspending on unnecessary features or compromising on quality.

Where to Buy Nitinol Wire

Finding Reliable Manufacturers

When buying nitinol wire, it's crucial to find reliable manufacturers with a proven track record of producing high-quality products. Conduct thorough research and seek recommendations from industry experts to ensure that you are dealing with reputable suppliers who can meet your specific requirements.

Assessing Product Quality

Before making a purchase, carefully assess the product quality offered by different manufacturers. Look for certifications and quality control measures to guarantee that the nitinol wire meets industry standards and specifications. Insist on samples or product testing to validate the quality before committing to a purchase.

Comparing Prices

While cost is important, it should not be the sole consideration when buying nitinol wire. Compare prices from different manufacturers, considering factors such as material purity, manufacturing processes, and product specifications. Opt for competitive pricing without compromising on quality or reliability.

Customer Reviews and Testimonials

One effective way to gauge the reputation of nitinol wire manufacturers is by checking customer reviews and testimonials. Look for feedback on product performance, customer service, and overall satisfaction with the purchasing experience. Positive reviews can provide valuable insights into the credibility and trustworthiness of potential suppliers.

Remember that finding the right supplier for your nitinol wire needs is essential in ensuring product quality, reliability, and value for money. By carefully evaluating manufacturers based on these key factors, you can make informed decisions that benefit your business in the long run.

How Nitinol Wire Works

Nitinol wire is a unique alloy known for its shape memory properties, allowing it to return to a predetermined shape when heated. This remarkable characteristic makes it ideal for various applications in industries such as medical devices, aerospace, and robotics. The ability to remember and recover its original form sets nitinol wire apart from traditional materials, making it a popular choice for innovative engineering solutions.

Shape Memory Properties

Nitinol wire exhibits shape memory properties due to its ability to undergo reversible martensitic phase transformation. When deformed at low temperatures, the material retains this new shape until heated above its transformation temperature, at which point it reverts to its original form. This unique behavior allows nitinol wire to be used in minimally invasive medical procedures, where it can be compressed for insertion and then expanded once inside the body.

Superelasticity and Pseudoelasticity

In addition to shape memory properties, nitinol wire demonstrates superelasticity or pseudoelasticity. This means that even when bent or deformed significantly beyond its yield point, the material can recover its initial shape upon unloading. This remarkable flexibility and resilience make nitinol wire an excellent choice for applications requiring durable and reliable components that can withstand repeated deformation without permanent damage.

Heat Treatment and Phase Transformation

The unique properties of nitinol wire are achieved through careful heat treatment processes that establish the desired phase transformations within the alloy. By controlling the material's composition and thermal processing parameters, manufacturers can tailor nitinol wire to exhibit specific characteristics suited for different applications. This level of customization ensures that the material meets the exact requirements of each project, providing optimal performance and reliability.

Applications in Various Industries

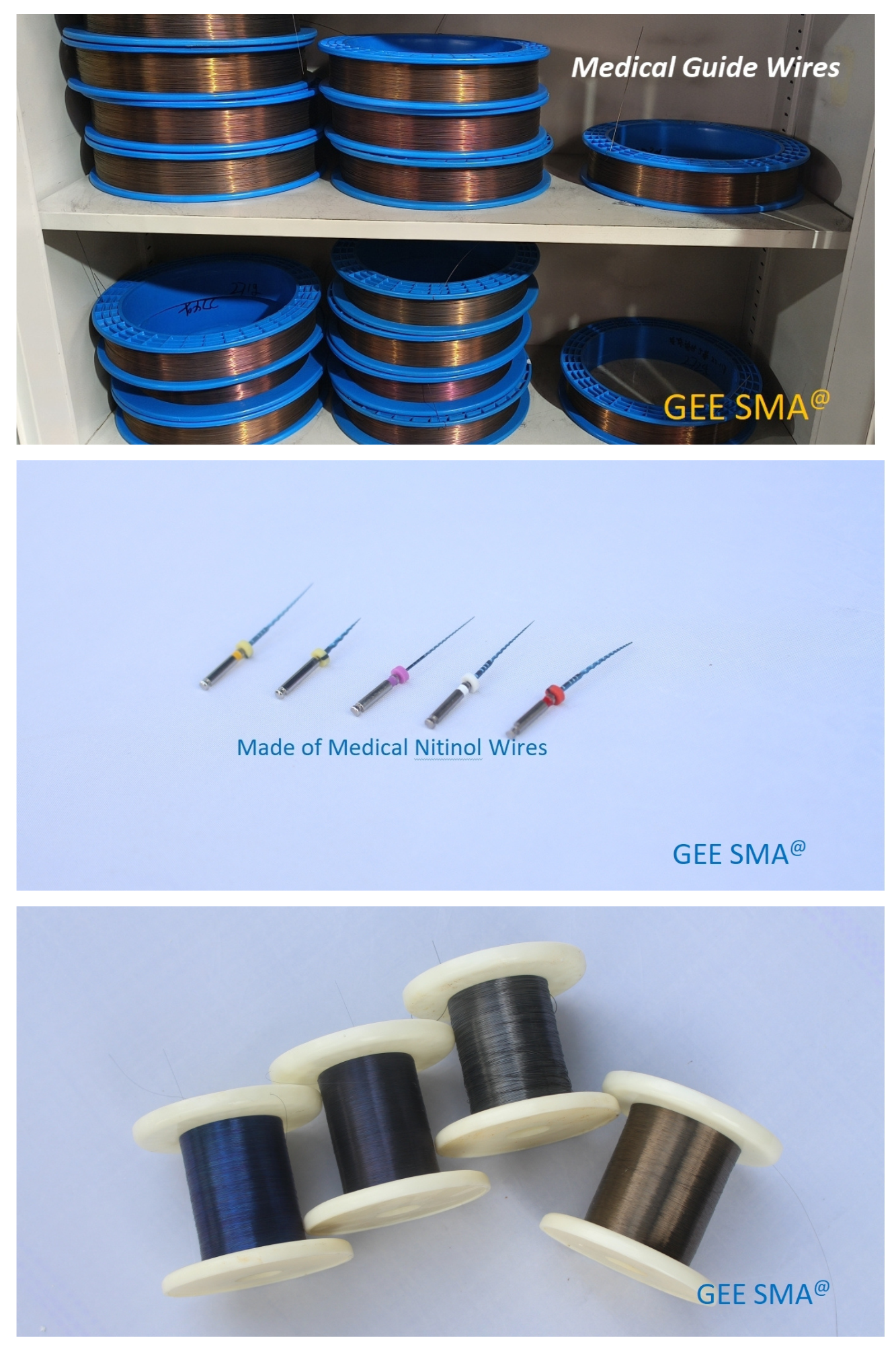

Due to its exceptional properties, nitinol wire finds extensive use in diverse industries, such as medical devices (stents, guidewires), orthodontics (braces), automotive (actuators), aerospace (deployable structures), and consumer goods (eyeglass frames). Its versatility makes it a valuable resource for engineers seeking innovative solutions that demand precise control over material behavior.

Understanding the Nitinol Wire Market

Trends and Developments

The nitinol wire market is experiencing a surge in demand due to its versatile applications in various industries such as medical, aerospace, and automotive. The latest trend shows an increase in the use of nitinol wire in minimally invasive medical devices and robotics, driving up the global market value.

Global Availability

Nitinol wire is readily available worldwide, with major manufacturers and suppliers offering their products in key markets such as the USA, Europe, and Asia. This widespread availability ensures businesses can easily source high-quality nitinol wire to meet their specific needs.

Industry Regulations

Stringent industry regulations govern the production and distribution of nitinol wire to ensure compliance with quality standards and safety requirements. Businesses must partner with reputable manufacturers who adhere to these regulations to guarantee the reliability and performance of their nitinol wire products.

Future Outlook

The future outlook for the nitinol wire market is promising, with continued advancements in manufacturing processes leading to improved quality and cost-effectiveness. As industries continue to innovate and expand their use of nitinol wire, the market is expected to grow steadily, offering new opportunities for businesses seeking innovative solutions.

Maximizing Value with GEE SMA

At GEE SMA, we understand that every project has unique requirements, so we offer customized nitinol solutions to meet your specific needs. Whether you need a particular size, shape, or composition, our team of experts will work closely with you to deliver the perfect nitinol wire for your application.

1. Customized Nitinol Solutions

Our team of experienced engineers and metallurgists can develop tailored nitinol solutions that fit your precise specifications. From custom alloys to unique shapes and sizes, we have the expertise to create the perfect nitinol wire for your project. With our personalized approach, you can be confident that you are getting the best value for your investment.

2. Exceptional Customer Support

When you choose GEE SMA as your nitinol wire supplier, you can expect exceptional customer support every step of the way. Our dedicated team is committed to providing timely and helpful assistance, ensuring that all your questions are answered and needs are met. We pride ourselves on delivering a seamless and stress-free experience for our clients. In addition to our responsive customer support, we also offer personalized solutions tailored to your specific requirements. Whether you need a custom nitinol wire size or a specialized coating, our team will work closely with you to ensure that the final product meets your exact specifications.

3. Quality Assurance and Testing

We prioritize quality assurance and testing to guarantee that our nitinol wire meets the highest standards in the industry. Our state-of-the-art facilities and rigorous testing procedures ensure that every product we deliver is of superior quality and performance. With GEE SMA, you can trust that you are receiving top-notch nitinol wire at competitive prices.

In addition to our rigorous testing procedures, we also offer customized testing solutions to meet unique customer requirements. Our team of experts can work with you to develop specialized testing protocols that align with your specific needs and industry standards. This tailored approach ensures that our nitinol wire meets the highest industry standards and exceeds your individual expectations.

4. Tailored Products for Unique Requirements

No matter how unique or complex your requirements may be, GEE SMA can produce tailored products that align with your specific needs. Whether it's a specialized shape memory alloy or a custom superelasticity solution, we have the resources and expertise to deliver precisely what you need.

Choose the Right Nitinol Wire Supplier

When it comes to nitinol wire cost, it's essential to make informed decisions on purchases. Understanding the factors that affect nitinol wire price, such as material quality and manufacturing processes, can help you leverage the benefits of this versatile material while staying within budget. Choosing the right nitinol wire supplier ensures high-quality products at competitive prices.

Making Informed Decisions on Nitinol Wire Purchases

Making informed decisions on nitinol wire purchases involves thorough research on material quality, manufacturing processes, and market trends. By understanding these factors, you can effectively assess the true value of nitinol wire and make cost-effective choices for your specific needs.

Understanding the material quality of nitinol wire is crucial in making informed purchasing decisions. High-quality nitinol wire will exhibit superior shape memory and superelasticity, ensuring reliable application performance. By researching the material quality, you can confidently select a nitinol wire that meets your specific requirements and delivers long-term value for your investment.

Leveraging the Benefits of Nitinol Wire

Despite its initial cost, nitinol wire offers numerous advantages such as shape memory properties and superelasticity that justify its price in various industries. Understanding how nitinol wire works and its applications can maximize its benefits and achieve long-term value for your investments.

Finding reliable nitinol wire manufacturers is crucial in ensuring product quality and competitive pricing. By comparing prices, assessing product quality, and considering customer reviews, you can confidently choose a supplier that meets your requirements while offering reasonable nitinol wire prices in the USA.

When choosing the right nitinol wire supplier, it's important to consider the supplier's production capacity and lead times. A manufacturer with a larger production capacity may be able to offer more competitive pricing due to economies of scale. Additionally, shorter lead times can help you meet tight production schedules and respond quickly to market demands. By evaluating these factors, you can ensure that your supplier can meet your business needs efficiently.