Introduction

When it comes to SMA coil design, understanding the intricacies of superelastic nitinol wire and its application in SMA spring actuators is crucial. SMA coils' performance directly impacts various devices' functionality, making it essential to prioritize excellence in design. At GEE SMA, our expertise in SMA coil design ensures that you receive top-notch solutions tailored to your needs.

Understanding SMA Coil Design

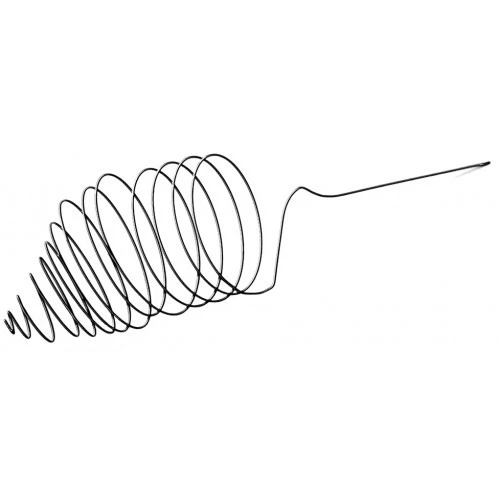

SMA coils are intricately designed components that utilize super elastic nitinol wire to achieve precise movements and functions within various devices. The careful selection of the right SMA alloy is critical in ensuring optimal performance and reliability in applications such as SMA actuators and nitinol muscles. Here are some key design considerations for SMA coils:

- SMA Alloy Selection: It is crucial to choose the appropriate nitinol alloy with specific transformation temperatures and mechanical properties for the desired function.

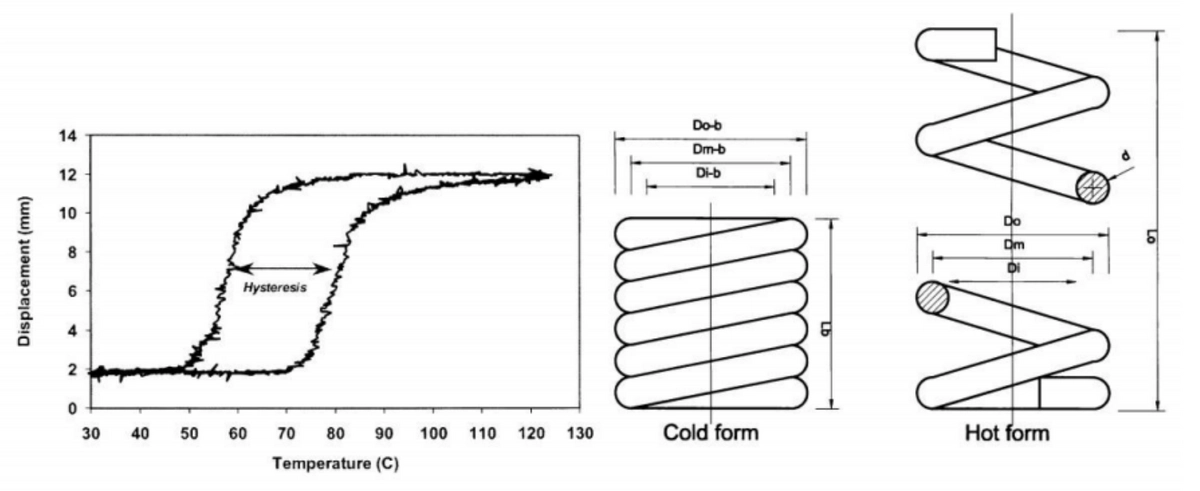

- Coil Geometry: The number of turns, coil diameter, and pitch significantly impact the force output, displacement, and stiffness of the coil.

- Heat Treatment: Precise heat treatment processes are essential for achieving the desired superelasticity and shape memory properties of the SMA coil.

By carefully considering these factors, engineers can design SMA coils that deliver optimal performance and reliability in various applications.

Importance of SMA Coil Performance

The performance of SMA coils directly influences the functionality and efficiency of integrated devices. Whether it's maximizing performance with high-quality super elastic nitinol wire or optimizing the functionality of SMA springs, achieving peak performance is essential for overall success.

High-quality super elastic nitinol wire in SMA coil design is crucial for achieving optimal performance. Nitinol wire's flexibility and durability ensure that the SMA coils can withstand repetitive use without compromising their functionality. This reliability is essential for devices that rely on SMA coils to deliver consistent and precise results, making it a top priority for manufacturers and designers.

GEE SMA's Expertise in SMA Coil Design

At GEE SMA, our extensive experience and knowledge in designing high-quality SMAs enable us to deliver exceptional solutions that meet our clients' diverse needs. From selecting the right alloy to addressing thermal management challenges, our expertise ensures that your project benefits from superior coil design.

Our team's expertise in selecting the right SMA alloy is unmatched. We carefully consider factors such as temperature requirements, stress levels, and transformation behavior to ensure optimal performance. By leveraging our deep understanding of SMA materials, we can recommend the most suitable alloy for your specific application, whether for medical devices, automotive components, or aerospace systems. This attention to detail sets our coil designs apart and ensures that your project benefits from the best possible performance and longevity.

Selecting the Right SMA Alloy

When selecting the right SMA alloy for your coil design, super elastic nitinol wire is a top choice. This versatile material offers exceptional shape memory properties and high elasticity, making it ideal for various applications in SMA coils. Its ability to recover its original shape after deformation ensures reliable performance in demanding conditions.

Choosing the Best Super Elastic Nitinol Wire

Selecting the best super elastic nitinol wire is essential for achieving optimal performance in SMA coils. GEE SMA offers a wide range of high-quality nitinol materials carefully engineered to meet specific requirements, ensuring superior functionality and durability in SMA coil designs. By choosing the right nitinol alloy, you can enhance your SMA coil's overall performance and longevity.

Choosing the right nitinol alloy is crucial for maximizing the performance of SMA spring actuators. GEE SMA's expertise in engineering high-quality nitinol materials ensures its products meet specific requirements, allowing for superior functionality and durability in SMA coil designs. With the proper nitinol wire, you can enhance your SMA spring actuators' overall performance and longevity, providing reliable and efficient operation for various applications.

Maximizing Performance with SMA Spring Actuators

SMA spring actuators play a crucial role in maximizing the performance of SMA coils. These innovative components utilize the unique properties of superelastic alloys to deliver precise and efficient actuation, making them an essential part of many advanced engineering systems. By integrating high-quality SMA spring actuators into your design, you can achieve superior functionality and responsiveness in your SMA coil applications.

SMA spring actuators are designed to provide consistent and reliable performance, ensuring your engineering systems operate at their peak efficiency. Using superelastic alloys in these actuators allows for greater flexibility and durability, making them ideal for various applications. Whether you are working on aerospace, automotive, or medical devices, integrating SMA spring actuators can significantly enhance the functionality and responsiveness of your designs.

Optimizing SMA Wire for Improved Functionality

Optimizing the properties of SMA wire is key to improving functionality in coil designs. Through advanced engineering techniques and material processing methods, GEE SMA can tailor the characteristics of super elastic nitinol wire to meet specific performance requirements, such as temperature sensitivity and response time. This optimization ensures that your SMA coil operates at peak efficiency, delivering reliable results in diverse applications.

By optimizing the properties of SMA wire, GEE SMA can ensure that your coil design meets the specific performance requirements for temperature sensitivity and response time. This tailored approach to material processing and engineering techniques allows for peak efficiency in operation, resulting in reliable performance across diverse applications. Optimizing SMA wire is essential for improved functionality and overall effectiveness in medical devices, automotive components, or industrial machinery.

Design Considerations for SMA Coils

Enhancing Performance Through Coil Geometry

Attention to coil geometry is crucial to enhancing the performance of SMA coils. By carefully designing the shape and size of the coil, we can maximize its functionality and efficiency. Whether it's a helical, conical, or straight design, each geometry impacts the overall performance of the SMA coil.

Coil geometry plays a significant role in determining the thermal management capabilities of SMA coils. The shape and size of the coil can impact heat dissipation and distribution, which are critical factors in maintaining optimal performance. For example, a spiral design may provide better airflow and heat transfer than a straight design, improving thermal management. By considering these factors during the coil design process, engineers can effectively address thermal challenges and ensure the reliability of SMA coils in various applications.

Addressing Thermal Management Challenges

One key challenge in SMA coil design is addressing thermal management issues. The unique properties of superelastic nitinol wire require careful consideration of temperature fluctuations and heat dissipation. Implementing effective thermal management strategies, such as heat sinks or insulation materials, can ensure optimal performance and longevity of the SMA coil.

Furthermore, the design of SMA coils must also consider the impact of external environmental factors on temperature regulation. This includes considering the effects of ambient temperature, humidity, and airflow on the performance of nitinol wire. By conducting thorough testing and analysis, engineers can develop innovative solutions to address these challenges and ensure the reliability of SMA actuators in various operating conditions.

The Role of Nitinol Muscles in SMA Actuators

Nitinol muscles play a critical role in SMA actuators by providing the necessary force for actuation. Understanding how to harness the power of nitinol muscles within an SMA actuator is essential for maximizing performance and responsiveness. We can achieve precise control and reliable functionality in various applications by carefully integrating nitinol muscles into the design.

Nitinol muscles are known for their unique ability to contract and expand with temperature changes, making them ideal for SMA actuators. By carefully calibrating the temperature at which nitinol muscles actuate, engineers can fine-tune the performance of SMA actuators to meet specific application requirements. This level of precision allows for seamless integration of nitinol muscles into a wide range of devices, from medical instruments to aerospace components, ensuring reliable functionality across diverse industries.

Manufacturing Best Practices

Rigorous quality control measures are essential to ensuring top-notch quality in SMA coil production. GEE SMA implements strict quality checks at every stage of the manufacturing process, from material selection to final product inspection. This meticulous approach guarantees that our SMA coils meet the highest standards for performance and reliability.

Quality Control in SMA Coil Production

At GEE SMA, we understand the critical role of quality control in delivering superior SMA coils. Our state-of-the-art facilities have advanced testing equipment to assess key parameters such as dimensional accuracy, surface finish, and mechanical properties of the super elastic nitinol wire used in our coils. This stringent quality control process ensures that each SMA coil meets or exceeds industry standards for consistency and performance.

In addition to our rigorous quality control process, we leverage advanced manufacturing techniques to ensure the production of high-quality SMA coils. Our team of experienced engineers and technicians is constantly exploring innovative methods to enhance the precision and efficiency of our coil manufacturing process. By staying at the forefront of technological advancements in materials and production methods, we can deliver SMA coils that meet industry standards and push the boundaries of performance and reliability.

Leveraging Advanced Manufacturing Techniques

To stay ahead of the curve in SMA coil production, GEE SMA leverages cutting-edge manufacturing techniques to optimize the performance of our products. From precision winding processes to advanced heat treatment methods, our manufacturing capabilities enable us to produce high-quality SMA coils with exceptional mechanical properties and functional reliability.

In addition to our advanced manufacturing techniques, GEE SMA is constantly exploring new material processing methods to enhance the performance of our SMA coils further. By utilizing innovative alloy compositions and refining our material handling processes, we can achieve superior strength and durability in our products. This commitment to continuous improvement ensures that GEE SMA remains at the forefront of SMA coil production, delivering unmatched quality and reliability to our customers.

Enhancing Performance Through Material Processing

The performance of an SMA coil hinges on the material processing techniques used during production. At GEE SMA, we leverage our expertise to craft superior nitinol alloys:

- Proprietary Processing: We utilize unique methods to enhance superelasticity and fatigue resistance.

- Continuous Innovation: Our dedicated research team explores new processing techniques to elevate performance and reliability further.

- Unmatched Quality: By optimizing material properties, we ensure exceptional performance and durability in demanding applications.

This commitment to innovation positions GEE SMA as your trusted partner for cutting-edge nitinol solutions across various industries.

The Future of SMA Coil Design and Performance

GEE SMA is your go-to partner when achieving peak performance with SMA coil design. With our expertise in super elastic nitinol wire and SMA alloy selection, we ensure the highest quality materials for your SMA spring actuators and wire. As the future of SMA coil design and performance evolves, count on GEE SMA to lead innovation and excellence.

Achieving Peak Performance with SMA Coil Design

At GEE SMA, we understand the importance of achieving peak performance with SMA coil design. Our focus on selecting the right SMA alloy, optimizing wire functionality, and addressing thermal management challenges ensures that our clients benefit from top-notch application performance.

GEE SMA: Your Partner for High-Quality Nitinol Materials

Regarding high-quality nitinol materials, GEE SMA stands out as a reliable partner. Our expertise in manufacturing best practices and quality control processes guarantees that you receive only the best super elastic nitinol wire and other components for your SMA actuator needs.

As the future of SMA coil design and performance continues to evolve, GEE SMA remains at the forefront of innovation. By investing in research and development, we are constantly exploring new materials and processes to push the boundaries of what is possible with SMA coils. Our team of experts is dedicated to staying ahead of industry trends and anticipating the needs of our customers, ensuring that our products are always at the cutting edge of technology.