Introduction

Regarding innovative engineering solutions, SMA spring actuators are at the forefront of cutting-edge technology. These shape memory alloy (SMA) devices offer a unique combination of flexibility and resilience, making them ideal for various applications. Whether in the medical field, aerospace industry, or robotics sector, SMA spring actuators are indispensable tools for achieving precision and efficiency.

Understanding SMA Spring Actuators

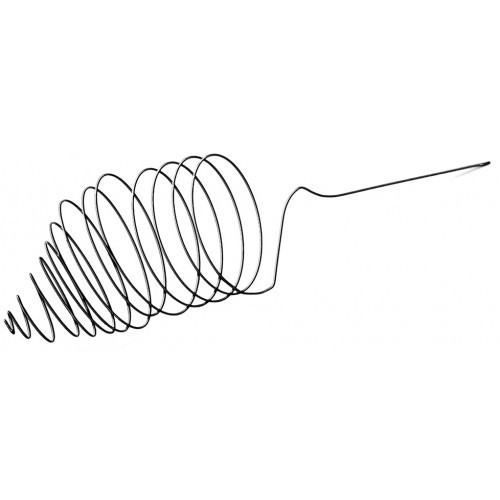

SMA spring actuators leverage the unique properties of superelastic nitinol wire (SMA wire) to deliver controlled movement and shape memory. These capabilities are critical for various engineering applications. Here are some of the key benefits of SMA spring actuators:

- Durability: They can withstand repeated stress and strain without deformation.

- Reliability: Their shape memory ensures consistent performance.

- Efficiency: They offer a compact and efficient actuation solution.

SMA spring actuators provide a compelling solution for applications demanding reliable, efficient, and durable actuation. They are a versatile technology with many potential aerospace, robotics, and medicine applications.

Importance of SMA Spring Actuator Design

The design of SMA spring actuators plays a crucial role in determining their performance and longevity. Engineers can ensure these actuators deliver precise and consistent results over extended periods by carefully selecting the appropriate superelastic alloy and optimizing coil design techniques. This makes them indispensable in industries where reliability and durability are paramount.

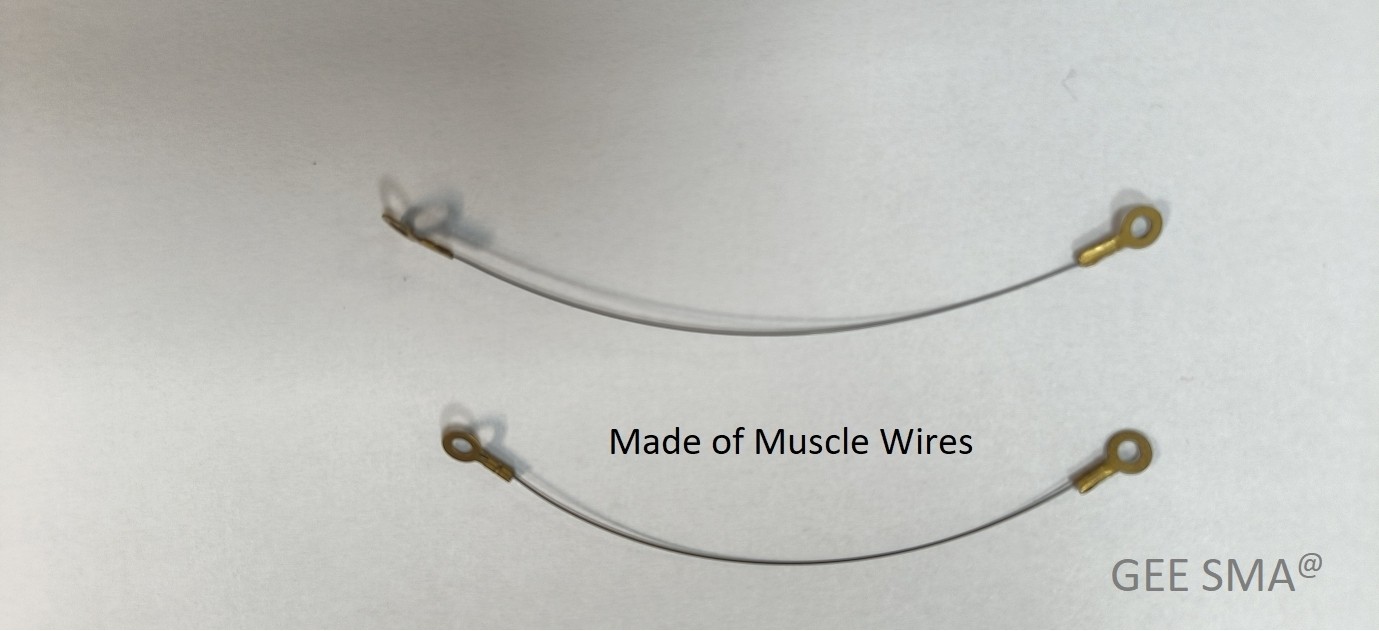

GEE SMA's Expertise in SMA Alloy

GEE SMA has established itself as a leader in developing and applying SMA alloy technology. With a deep understanding of super-elastic nitinol wire and its properties, GEE SMA is at the forefront of advancing the capabilities of shape memory alloys for various industries. Their expertise in designing high-performance SMA spring actuators sets them apart as an industry leader.

Key Factors in SMA Spring Actuator Design

Material selection plays a crucial role in determining performance and reliability when designing SMA spring actuators. GEE SMA's expertise in SMA alloy allows for a deep understanding of the benefits and limitations of using SMA wire versus superelastic nitinol. Both materials offer unique properties that can be optimized for specific applications, making the selection process a critical step in the design phase.

Material Selection: SMA Wire vs. Super Elastic Nitinol

SMA wire, also known as shape memory alloy wire, is widely used in spring actuators due to its ability to return to a predetermined shape when heated. On the other hand, super elastic nitinol wire exhibits exceptional flexibility and high recoverable strain, making it an attractive option for applications that require significant deformation without permanent damage.

Coil Design Techniques for Improved Performance

In addition to material selection, coil design techniques play a key role in enhancing the performance of SMA spring actuators. By carefully engineering the coil geometry and layout, GEE SMA can optimize factors such as force output, stroke length, and response time to meet specific application requirements.

Stress-Strain Behavior in Super Elastic Wire

Understanding the stress-strain behavior of superelastic wire is essential for designing reliable and efficient spring actuators. GEE SMA's expertise in analyzing the unique mechanical properties of super-elastic nitinol allows for precise control over factors such as transformation temperatures, hysteresis behavior, and fatigue resistance.

Optimizing Performance with SMA Spring Actuators

Temperature Control in SMA Actuators

One crucial aspect of optimizing performance in SMA spring actuators is temperature control. By carefully monitoring and adjusting the temperature of the SMA alloy, precise and reliable actuation can be achieved. This ensures the actuator responds consistently to external stimuli, making it ideal for various applications.

Dynamic Response and Hysteresis

Understanding the dynamic response and hysteresis of super-elastic nitinol wire is essential for optimizing the performance of SMA spring actuators. By carefully analyzing these characteristics, designers can fine-tune the actuator's behavior to meet specific application requirements, allowing for improved precision and efficiency in various industries.

Designing for Longevity and Durability

To optimize performance, it's crucial to design SMA spring actuators for longevity and durability. This involves selecting high-quality materials, implementing robust coil designs, and ensuring that the actuator can withstand repeated cycles of activation without degradation. By prioritizing longevity and durability, GEE SMA ensures that its actuators deliver reliable performance over an extended lifespan.

Innovative Approaches to SMA Spring Actuator Design

As the demand for advanced shape memory technologies grows, SMA spring actuators are at the forefront of innovation. GEE SMA has been leading the way in developing cutting-edge solutions that leverage the unique properties of superelastic nitinol wire and other SMA alloys. These advanced materials enable precise control and high performance in various applications, from medical devices to aerospace systems.

Advanced Shape Memory Technologies

GEE SMA's expertise in advanced shape memory technologies has led to groundbreaking developments in SMA spring actuator design. By harnessing the unique properties of superelastic nitinol wire, our engineers have created actuators with unparalleled precision and reliability. These advancements have paved the way for new possibilities in robotics, where intricate movements and rapid response times are crucial.

Adaptive Control Systems for SMA Actuators

Incorporating adaptive control systems into SMA actuators has been a game-changer in optimizing performance and efficiency. By dynamically adjusting parameters based on real-time feedback, these systems ensure that the actuators operate at peak levels under varying conditions. This level of adaptability is precious in industries such as automotive manufacturing, where precise control is essential for safety and productivity.

Integration with Smart Materials and IoT

Integrating SMA spring actuators with smart materials and IoT technology has opened up a world of possibilities for automation and connectivity. By incorporating sensors and data-driven algorithms, these actuators can seamlessly interact with their environment, making them ideal for applications ranging from smart home devices to industrial automation systems. This integration enhances functionality and enables predictive maintenance and real-time monitoring.

With innovative approaches like advanced shape memory technologies, adaptive control systems, and integration with smart materials and IoT, GEE SMA continues to push the boundaries of what's possible with SMA spring actuators. These developments drive progress within existing industries and pave the way for entirely new markets where precise motion control is paramount. As we look towards the future, these innovations will undoubtedly play a pivotal role in shaping the next generation of smart devices and automated systems.

Industry Applications and Success Stories

Medical Devices Utilizing SMA Actuators

One of the most exciting applications of SMA spring actuators is in the field of medical devices. The unique properties of SMA alloy, such as its shape memory and super elastic behavior, make it an ideal choice for minimally invasive surgical instruments and implantable devices. From catheter-based tools to stents and orthodontic braces, SMA actuators enable precise and reliable performance in critical healthcare applications.

Furthermore, SMA actuators are increasingly being used in aerospace and automotive applications. The ability of SMA springs to generate high force and displacement with minimal power input makes them ideal for use in control surfaces, landing gear, and other critical components of aircraft and spacecraft. In the automotive industry, SMA actuators are being integrated into various systems, such as engine valves, fuel injectors, and active suspension systems, where their ability to respond quickly and reliably to changing conditions is highly valued.

Aerospace and Automotive Applications

SMA spring actuators are revolutionizing design possibilities in the aerospace and automotive industries. By leveraging the exceptional properties of superelastic nitinol wire, engineers can create adaptive components that respond to changing conditions. Here's how they are making a difference:

- Enhanced Aircraft Performance: SMA actuators are used in aircraft wing flaps and engine components for active vibration damping and shape control, improving overall flight efficiency.

- Lighter, More Reliable Cars: In the automotive industry, SMA actuators contribute to active vibration damping and shape control, making cars lighter and more reliable due to the lightweight nature and reliability of SMA alloys.

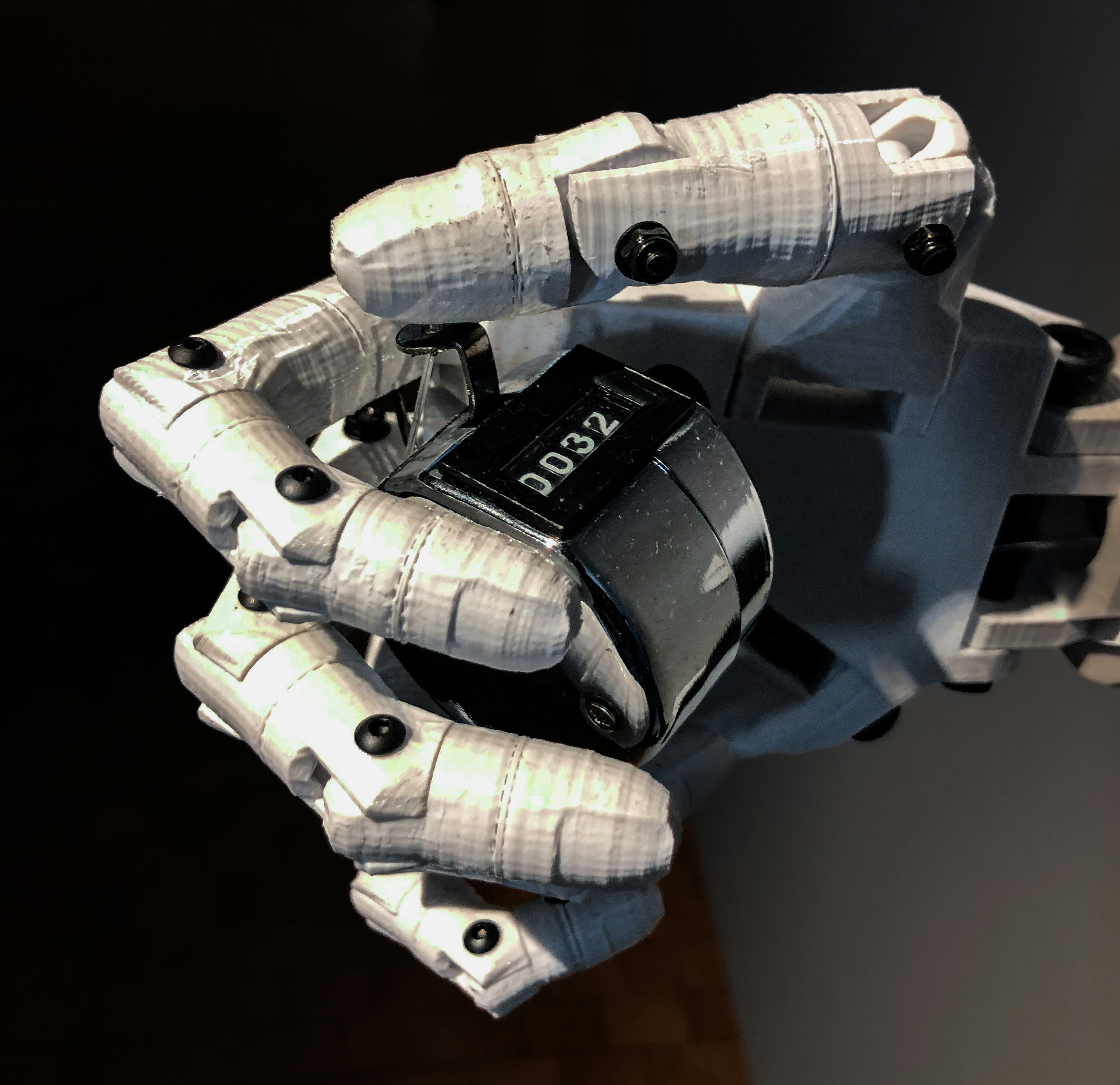

- The Future of Robotics and Automation: SMA spring actuators are being integrated into robotics and automation systems to improve efficiency and flexibility. Nitinol wire's ability to undergo large deformations without permanent damage makes it ideal for precise control and movement in robotic arms, grippers, and other automated machinery.

With automation playing a crucial role across industries, SMA spring actuators offer a competitive advantage due to their adaptability and responsiveness. With SMA spring actuators at the forefront, the future of design looks bright.

Robotics and Automation Systems

Robots equipped with SMA spring actuators are unlocking new levels of skill and efficiency in automation systems. The superelastic wire's ability to undergo large deformations while returning to its original shape makes it an ideal candidate for robotic end-effectors, grippers, and prosthetic limbs. The precise control offered by SMA actuators enables robots to handle delicate objects with finesse while maintaining robustness for industrial tasks.

By showcasing real-world examples across various industries, we can see how the versatility of SMA alloy is driving innovation in medical devices, aerospace engineering, automotive design, robotics, and automation systems.

Future Trends in SMA Spring Actuator Design

Miniaturization and Microactuators

As the demand for smaller, more precise devices grows, the trend toward miniaturization in SMA spring actuators is becoming increasingly important. Engineers are exploring innovative ways to scale down SMA coil designs and create microactuators that can be used in various applications, from medical implants to tiny robotic systems.

With the increasing focus on sustainability, engineers are also exploring using sustainable materials in the manufacturing processes of SMA spring actuators. This includes using recycled materials or bio-based polymers to create microactuators that are smaller, more precise, and environmentally friendly. By incorporating sustainable materials and manufacturing processes, engineers can meet the demand for miniaturization while reducing these devices' environmental impact.

Sustainable Materials and Manufacturing Processes

With a focus on sustainability, there is a shift towards using eco-friendly materials and manufacturing processes to produce SMA spring actuators. This includes exploring new ways to recycle and reuse SMA alloy components and adopting energy-efficient manufacturing techniques to reduce environmental impact.

Furthermore, using sustainable materials and manufacturing processes for SMA spring actuators benefits the environment and aligns with increasing consumer demand for eco-friendly products. Manufacturers can reduce their carbon footprint and appeal to environmentally conscious consumers by incorporating recycled and reusable SMA alloy components. This shift towards sustainability also allows companies to differentiate themselves in the market and gain a competitive edge.

Emerging Markets for SMA Actuators

Shape memory alloy (SMA) spring actuators are finding new applications as technology advances. This opens exciting opportunities for innovation. Here are just a few of the emerging markets:

- Wearable medical devices: SMA actuators can be used in devices that conform to the body and provide gentle, controlled force.

- Smart home automation systems: Imagine windows that automatically open and close for ventilation based on temperature or furniture that adjusts to your needs.

- Emerging fields: The possibilities extend further into robotics and aerospace.

With their unique properties, SMA spring actuators are poised to revolutionize various industries.

Maximize Performance and Reliability with SMA Spring Actuators

In conclusion, the design and optimization of SMA spring actuators are crucial in various industries, and GEE SMA's expertise in SMA alloy is unmatched. By leveraging advanced design techniques and materials such as super-elastic nitinol wire, we can maximize the performance and reliability of SMA actuators. Implementing innovative approaches and staying ahead of trends will ensure that SMA spring actuators continue revolutionizing medical devices, aerospace applications, robotics, and more.

Leveraging GEE SMA's Expertise in SMA Alloy

GEE SMA's extensive knowledge of shape memory alloys (SMA) ensures that our spring actuators are designed with the highest quality materials for optimal performance. Our expertise in utilizing super-elastic nitinol wire sets us apart in delivering cutting-edge solutions for various applications.

Our team at GEE SMA is committed to staying at the forefront of design techniques for SMA actuators. By incorporating advanced design methods, we can enhance the performance and reliability of our spring actuators, ensuring that they meet the highest industry standards. This dedication to innovation allows us to continuously push the boundaries of what is possible with SMA alloy technology, providing our clients with state-of-the-art solutions for their needs.

Implementing Advanced Design Techniques for SMA Actuators

By implementing advanced coil design techniques and understanding stress-strain behavior in super elastic wire, we can enhance the functionality and efficiency of SMA spring actuators. This enables us to meet the complex demands of various industries while pushing the boundaries of what is possible with shape memory technology.

By optimizing the coil design and understanding the stress-strain behavior of superelastic wire, we can improve the performance and reliability of SMA spring actuators and ensure consistent functionality over a longer lifespan. This is crucial for industries with demanding applications, where precision and durability are essential for smooth operations. Furthermore, this advanced approach allows us to explore new possibilities in shape memory technology, opening doors to innovative solutions that were previously unattainable.

The key to maximizing performance and reliability with SMA spring actuators lies in temperature control, dynamic response, hysteresis management, longevity, durability, adaptive control systems, integration with smart materials, and IoT. By focusing on these factors, we can ensure that our actuators deliver exceptional results across diverse industry applications.

Furthermore, advancements in material science and engineering are continuously improving the capabilities of SMA spring actuators. By leveraging these innovations, we can enhance the performance and reliability of our actuators even further, opening up new possibilities for their use in various industries. This ongoing evolution ensures that SMA spring actuators remain at the forefront of technological development, providing cutting-edge solutions for various applications.