Introduction

Regarding cutting-edge medical technology, super-elastic nitinol wires are at the forefront of innovation. This shape memory alloy, known as nitinol, is a nickel-titanium wire with remarkable flexibility and durability. With its unique properties, nitinol has found a wide range of medical applications, making it an indispensable material for various medical devices and instruments. When sourcing high-quality nitinol alloys, GEE SMA stands out as the leader in providing top-notch nitinol wires for medical use.

Understanding Super-Elastic Nitinol Wires

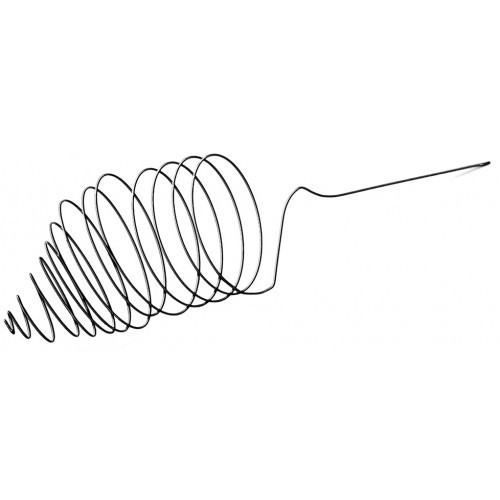

Super-elastic nitinol, also referred to as a metal nitinol or titanium wire, is a type of shape memory alloy that can return to its original shape after deformation. This remarkable property makes it ideal for creating springs and other components that require flexibility and resilience in medical devices.

Applications of Nitinol in Medicine

Nitinol alloys have revolutionized medicine with their diverse applications in various medical devices. These remarkable materials offer a unique combination of properties ideal for minimally invasive procedures and long-term implants. Here are some of the ways nitinol is changing medicine:

- Stents: Nitinol stents can be compressed for delivery through a catheter and then expand to hold open narrowed arteries.

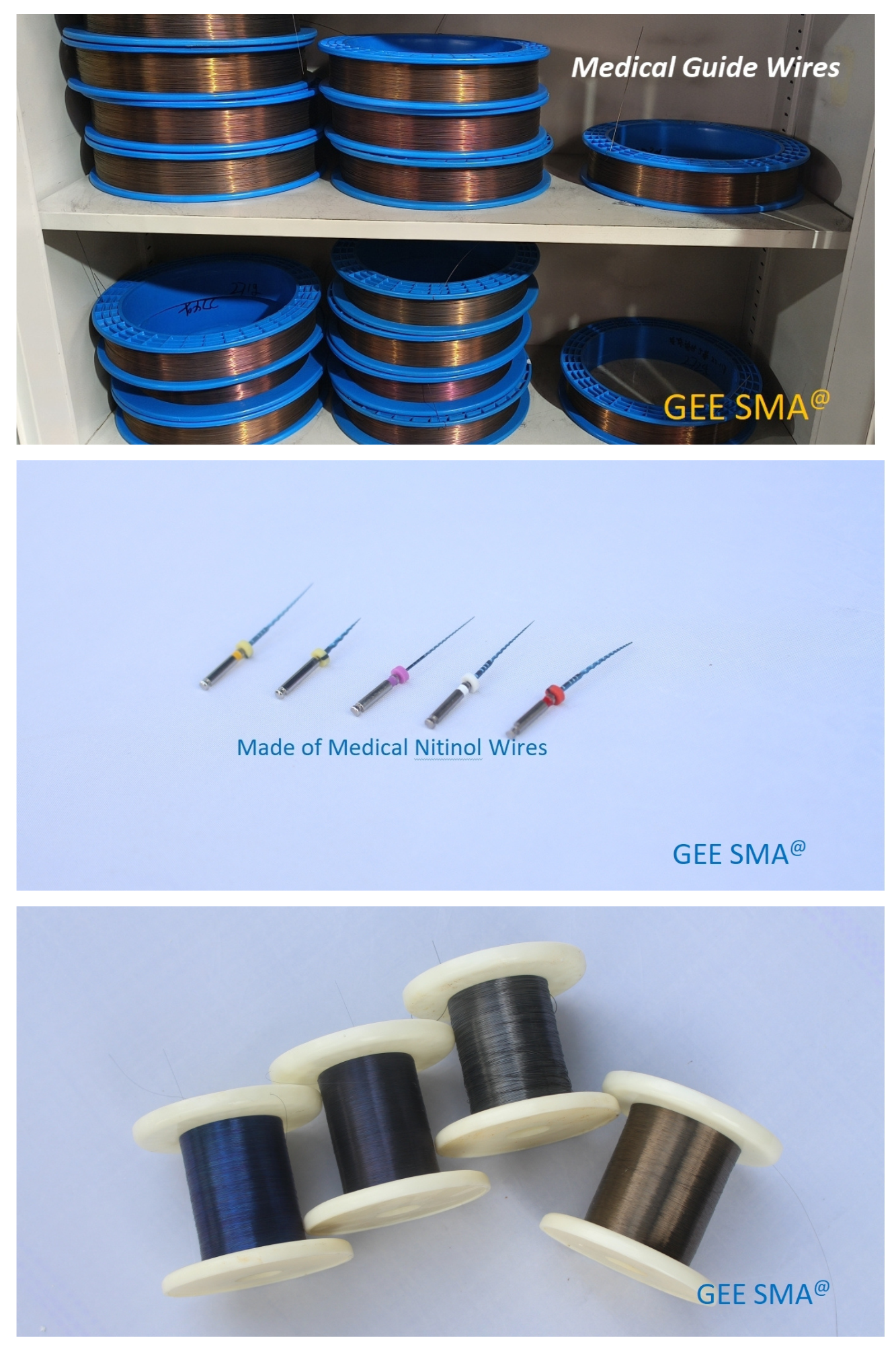

- Guidewires: Thin, flexible guidewires made from nitinol can navigate complex anatomy to deliver catheters and other instruments.

- Catheters: Nitinol catheters can be shaped to reach specific areas within the body and maintain their form during procedures.

- Orthodontic instruments: Nitinol archwires apply gentle, continuous pressure to move teeth into their proper positions.

- Dental tools: Nitinol root canal files can effectively clean curved canals without breaking.

Nitinol's biocompatibility ensures safe use within the human body, improving patient outcomes and revolutionizing medical care.

Why GEE SMA is the Leader in Nitinol Wires

As a trusted supplier of nitinol materials, GEE SMA sets itself apart with its commitment to producing high-quality nitinol wires tailored to unique specifications. With a swift response to customer needs and a dedication to product quality, GEE SMA has earned its reputation as the go-to source for superior nitinol alloys.

The Unique Properties of Super-Elastic Nitinol

Super-elastic nitinol, also known as shape memory alloy, is a remarkable material with extraordinary properties that make it ideal for various medical applications. Its flexibility and durability allow for intricate designs in medical devices without sacrificing strength or resilience. Whether used as a nitinol wire or spring, its ability to withstand repeated deformation without permanent damage makes it invaluable in medicine.

Flexibility and Durability

Nitinol alloys, composed of nickel and titanium, exhibit remarkable flexibility and durability that set them apart from traditional metals. This unique combination creates intricate shapes and structures that can be manipulated without fear of breakage or deformation. Whether as a thin nitinol wire or a more robust nitinol spring, its inherent resilience ensures longevity and reliability in medical devices.

Nitinol alloys are also known for their shape memory effect, allowing them to return to their original shape after deforming. This unique property makes nitinol particularly well-suited for applications in medical devices, such as stents and guidewires, where the material must withstand bending and twisting without losing its structural integrity. The ability of nitinol to "remember" and recover its shape adds an extra layer of functionality and reliability to these critical components, ensuring that they can adapt to the dynamic conditions within the human body.

Shape Memory Effect

One of the most intriguing properties of super-elastic nitinol is its shape memory effect, where it can remember its original shape and return to it when subjected to certain stimuli such as heat or stress. This characteristic is particularly useful in medical devices like stents, where the nitinol alloy can be compressed for delivery through a catheter before expanding back to its original shape once deployed within the body.

Nitinol's shape memory effect also makes it ideal for orthodontic wires, where continuous, gentle pressure can be applied to shift teeth into the desired position. This property reduces the need for frequent adjustments and discomfort often associated with traditional braces, making the orthodontic treatment process more convenient and less painful for patients. Additionally, nitinol's ability to maintain its shape over time ensures that the orthodontic wires remain effective throughout treatment, resulting in better patient outcomes.

Biocompatibility in Medical Devices

Superelastic nitinol's unique properties have made it a game-changer in medical device manufacturing. Here's why:

- Excellent Biocompatibility: Nitinol plays well with the body. It exhibits minimal corrosion and low ion release, reducing the risk of adverse patient reactions.

- Superelasticity: Nitinol can bend and flex significantly without breaking, allowing for intricate device designs and easier insertion through narrow openings.

- Shape Memory: Nitinol can be "trained" to remember a specific shape and return to it upon exposure to a certain temperature, enabling features like self-expanding stents.

- Durability: Nitinol can withstand repeated use without losing shape or strength, making it ideal for long-term implants.

Superelastic nitinol's biocompatibility, shape manipulation capabilities, and durability offer unparalleled versatility for innovative medical devices, ultimately improving patient care.

Medical Applications of Nitinol Wires

Super-elastic nitinol wires, also known as shape memory alloys, have revolutionized the medical industry with their remarkable properties. Due to their flexibility, durability, and biocompatibility, these nickel-titanium wires are widely used in various medical applications.

Stents and Stent Delivery Systems

Nitinol alloys are extensively utilized in fabricating stents and delivery systems for cardiovascular interventions. The super-elasticity of nitinol allows these devices to be compressed for insertion into blood vessels and then expand to their original shape once deployed, providing crucial support to keep arteries open.

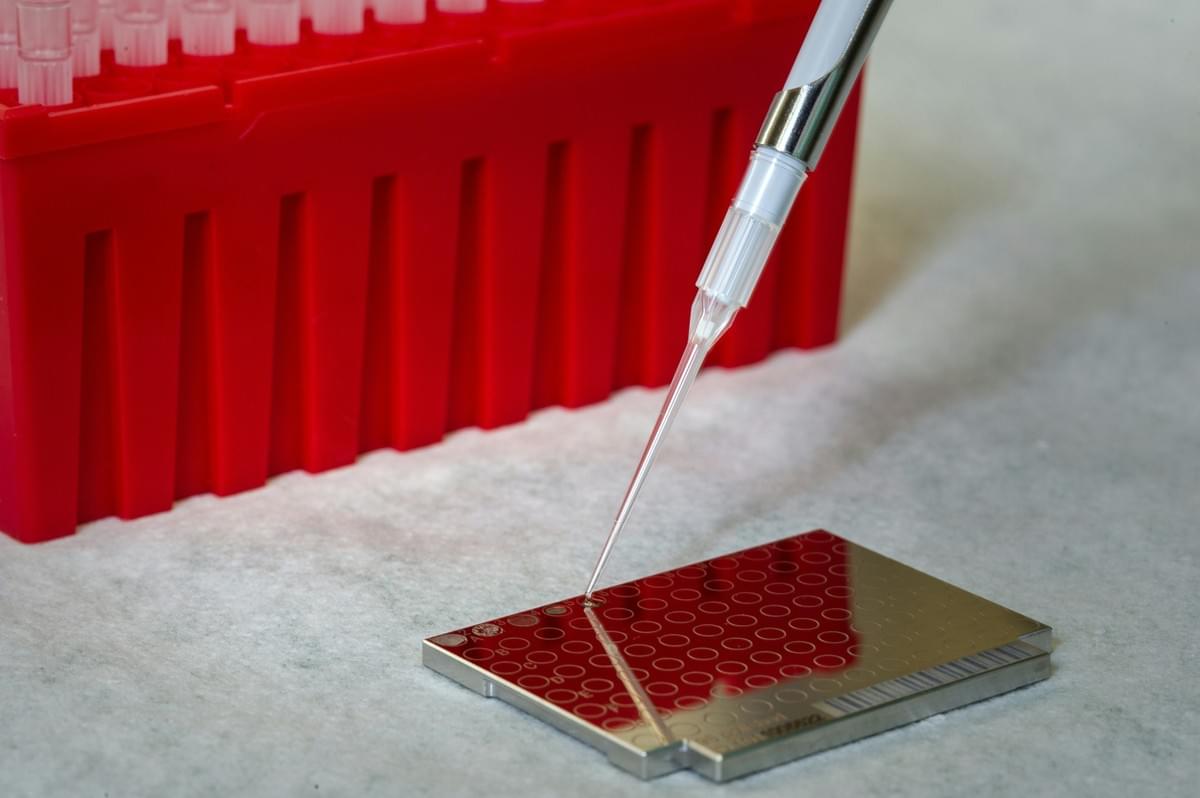

Guidewires and Catheters

Guidewires and catheters from nitinol wire have become indispensable tools in minimally invasive procedures such as angioplasty and endovascular surgeries. The unique properties of super-elastic nitinol enable these instruments to navigate through tortuous pathways within the body with exceptional flexibility while maintaining sufficient stiffness for precise positioning.

Orthodontic and Dental Instruments

In orthodontics and dentistry, nitinol springs and wires are widely used for braces, archwires, and other dental instruments due to their shape memory effect. These devices can apply controlled forces to move teeth into proper alignment over time, offering patients a more comfortable treatment experience than traditional metal braces.

With its unparalleled versatility and reliability, super-elastic nitinol has opened up new possibilities in medical technology, allowing for safer and more effective treatments across various healthcare disciplines. As the demand for innovative solutions continues to grow, the future of nitinol in medical advancements looks incredibly promising.

Advantages of Using Nitinol in Medical Devices

Super-elastic nitinol offers numerous advantages in medical devices, making it a popular choice for healthcare professionals and patients. One key benefit is the improved patient comfort that nitinol wires provide. Due to their unique flexibility and shape memory effect, nitinol alloys can conform to the body's natural contours, reducing discomfort and enhancing the overall patient experience during medical procedures.

Improved Patient Comfort

In addition to improved patient comfort, super-elastic nitinol enhances device performance. The remarkable flexibility and durability of nitinol wires allow for smoother navigation through the body's intricate pathways, resulting in more precise and effective medical interventions. This superior performance ultimately leads to better patient outcomes, making nitinol an invaluable material in medical technology.

Enhanced Device Performance

Furthermore, the longevity and reliability of nitinol alloys make them an ideal choice for medical devices. Nitinol springs and wires are known for their exceptional resistance to fatigue and corrosion, ensuring that devices made from this shape memory alloy can withstand prolonged use without compromising their structural integrity or functionality. This reliability translates to cost savings for healthcare providers and increased patient safety.

Longevity and Reliability

One of the key advantages of using Nitinol in medical devices is its exceptional longevity and reliability. Nitinol wires are known for their ability to withstand repeated bending and flexing without losing their shape or structural integrity. This makes them ideal for applications such as stents and guidewires, where durability is essential for long-term patient care. Additionally, Nitinol alloys have a proven track record of reliability, giving both healthcare providers and patients confidence in the performance of these innovative medical devices. With Nitinol's unmatched longevity and reliability, it's no wonder that GEE SMA is the leader in supplying high-quality Nitinol materials for cutting-edge medical innovations.

GEE SMA: Crafting High-Quality Nitinol Alloys

GEE SMA takes great pride in its commitment to product quality. We ensure that every super-elastic nitinol wire and shape memory alloy meets the highest industry standards. Our team of experts meticulously inspects and tests each nickel-titanium wire to guarantee exceptional performance and reliability in medical applications.

Commitment to Product Quality

At GEE SMA, we understand the importance of producing top-notch nitinol alloys for medical devices. Our state-of-the-art manufacturing processes and stringent quality control measures ensure that every nitinol spring and titanium wire that leaves our facility is of superior quality, providing peace of mind to medical professionals and patients alike.

Furthermore, our commitment to product quality extends beyond the manufacturing process. We also prioritize ongoing research and development to ensure that our nitinol alloys are at the forefront of medical technology. This dedication to innovation allows us to improve our products continually, stay ahead of industry standards, and meet the evolving needs of medical professionals and patients.

Swift Response to Customer Needs

We pride ourselves on our ability to respond swiftly to the unique needs of our customers. Whether it's a specific size requirement for a nitinol wire or a custom shape memory alloy design, our team is dedicated to delivering personalized solutions with efficiency and expertise, setting us apart as a trusted partner in the industry.

Our commitment to meeting customer needs extends beyond just providing personalized solutions. We also offer exceptional support and communication throughout the entire process, ensuring that our clients feel heard and valued every step of the way. Our team is always available to answer questions, provide updates, and address any concerns, fostering a strong sense of trust and reliability in our partnerships.

Tailoring Nitinol Materials to Unique Specifications

GEE SMA specializes in tailoring nitinol materials to meet the unique specifications of each medical device application. From custom shapes and sizes to specific performance characteristics, our agile approach allows us to collaborate closely with customers to develop bespoke solutions that perfectly align with their requirements.

The Future of Nitinol in Medical Technology

As the demand for minimally invasive medical procedures grows, innovative developments in nitinol alloys are poised to revolutionize healthcare. These shape memory alloys, such as super-elastic nitinol, offer remarkable flexibility and durability, making them ideal for various medical applications. With ongoing research and advancements in manufacturing techniques, we can expect to see even more versatile and high-performance nitinol materials shortly.

Innovative Developments in Nitinol Alloys

Cutting-edge research and development efforts are focused on enhancing the properties of nitinol alloys, such as improving their superelasticity and shape memory effect. These advancements aim to create nitinol wires that can withstand even greater stresses while maintaining their unique properties. With ongoing innovations in material science and engineering, we anticipate the emergence of next-generation nitinol materials to further expand medical device design and performance possibilities.

As research and development efforts continue to push the boundaries of nitinol alloy properties, there is a growing emphasis on improving biocompatibility for expanded applications in healthcare. By refining the surface characteristics of nitinol materials, such as reducing nickel ion release and enhancing corrosion resistance, medical device designers can explore new possibilities for implantable devices and minimally invasive surgical tools. These advancements in biocompatibility will pave the way for safer and more reliable nitinol-based medical solutions, ultimately benefiting patients and healthcare providers.

Expanding Applications in Healthcare

The versatility of nitinol wires has already led to their widespread use in various medical devices, from stents and guidewires to orthodontic instruments. We can anticipate a broader range of applications for these remarkable nickel-titanium alloys. As researchers continue to explore new ways to harness the unique properties of super-elastic nitinol, we may see its integration into novel medical technologies that could transform patient care across numerous specialties.

As researchers delve deeper into the potential applications of nitinol wires, we may see advancements in minimally invasive surgery techniques. The unique properties of super-elastic nitinol could enable the development of more flexible and maneuverable surgical instruments, allowing for greater precision and control during procedures. This could ultimately lead to shorter recovery times and improved patient outcomes.

Potential Impact on Patient Care

The ongoing evolution of nitinol alloys holds significant promise for improving patient outcomes and quality of life. By enabling the development of more advanced medical devices with enhanced performance characteristics, these materials have the potential to revolutionize treatment options for a wide range of conditions. From cardiovascular interventions to orthopedic procedures, the continued advancement of super-elastic nitinol is poised to profoundly impact patient care by offering safer, more effective solutions.

Here's how nitinol alloys can improve patient care:

- Development of advanced medical devices: Nitinol's unique properties allow for the creation of stents, guidewires, and other flexible and strong implants.

- Reduced need for invasive procedures: Because nitinol devices can be inserted through smaller incisions, they can minimize patient trauma and recovery times.

- More precise and targeted treatments: Nitinol's shape-memory and superelastic properties enable more controlled and accurate procedures, leading to better outcomes.

Patients may experience reduced pain, faster recovery, and a better long-term prognosis. With continued research and development, nitinol alloys hold the potential to reshape the landscape of modern medicine.

The Versatility of Super-Elastic Nitinol Wires

Super-elastic nitinol wires are revolutionizing the medical industry with their unique shape, memory alloy properties, and flexibility. From stents to orthodontic instruments, nitinol wires' versatility is unmatched, offering innovative solutions for various medical applications.

GEE SMA: Your Trusted Nitinol Supplier

GEE SMA stands out as a trusted supplier when sourcing high-quality nitinol alloys. With a commitment to product quality and a swift response to customer needs, they ensure that medical device manufacturers can access top-notch nitinol wires for their cutting-edge innovations.

Embracing the Benefits of Nitinol in Medical Innovations

As medical technology advances, embracing the benefits of super-elastic nitinol is crucial for driving innovation in patient care. With its potential impact on improving device performance and patient comfort, the future of nitinol in medical innovations is bright.