Introduction

When it comes to shape memory alloys, nitinol foil is a game-changer. This unique material, such as the NT0402 Nitinol Foil, offers remarkable properties that make it ideal for a wide range of applications. From medical devices to industrial uses, the versatility of nitinol foil is unmatched.

Understanding Nitinol Foil

Nitinol foil is a type of shape memory alloy (SMA) that exhibits the extraordinary ability to return to its original shape after deformation. This remarkable characteristic makes it highly sought after in various industries where flexibility and resilience are crucial.

Nitinol SMA Overview

Nitinol SMA stands for Nickel Titanium Shape Memory Alloy, and it is renowned for its exceptional superelasticity and shape memory properties. This allows it to be bent or deformed and then return to its original form when exposed to heat or stress.

Benefits of Nitinol Foil

The benefits of nitinol foil are numerous. Its high strength-to-weight ratio, biocompatibility, corrosion resistance, and unique mechanical properties make it an ideal choice for critical applications in fields such as aerospace, automotive, medical devices, and more.

Different Thickness Options

When it comes to nitinol foil, there are various thickness options available to suit different applications. The NT0402 Nitinol Foil, for example, is a popular choice for medical devices due to its thin and flexible nature. This allows it to be easily manipulated and shaped for intricate medical components.

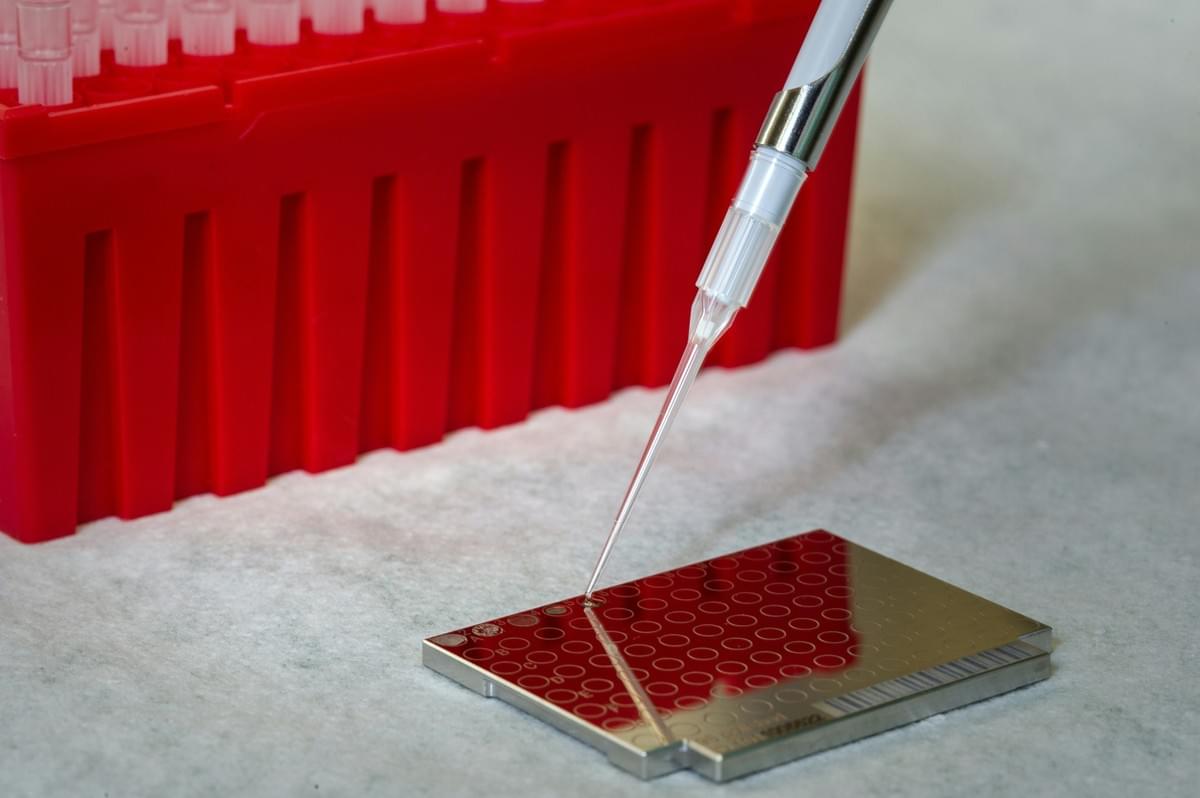

Thin Nitinol Foil for Medical Devices

Thin nitinol foil is ideal for medical devices such as stents and guidewires, where flexibility and biocompatibility are crucial. The NT0402 Nitinol Foil, in particular, offers exceptional shape memory properties and superelasticity, making it a top choice for minimally invasive medical procedures. Its high fatigue resistance also ensures long-term durability in the human body.

Thin nitinol foil is also highly resistant to corrosion, making it an excellent choice for long-term implantation in the human body. This durability ensures that medical devices made from NT0402 Nitinol Foil will maintain their structural integrity over time, providing patients with reliable and effective treatment options. Additionally, the flexibility of nitinol foil allows for easier insertion and manipulation during medical procedures, reducing the risk of tissue damage and improving patient outcomes.

Thick Nitinol Foil for Industrial Applications

On the other hand, thick nitinol foil is well-suited for industrial applications that require robustness and strength. Industries such as aerospace and automotive rely on thick nitinol foils for components that can withstand extreme conditions and heavy loads. The versatility of nitinol allows it to be tailored to specific thickness requirements based on the application's needs.

Custom Thickness Options Available

For those with unique project requirements, custom thickness options are readily available from reputable nitinol foil suppliers like GEE SMA. Whether you need ultra-thin foils or extra-thick ones, these suppliers can work with you to create bespoke solutions that meet your exact specifications.

GEE SMA understands that every project is unique, and that's why they offer custom thickness options for their nitinol foils. Whether you require ultra-thin foils for a delicate application or extra-thick ones for a heavy-duty project, GEE SMA can cater to your specific needs. This level of flexibility ensures that you get the perfect solution for your project, without having to compromise on quality or performance.

High Quality Nitinol Foils

When it comes to high quality nitinol foils, GEE SMA Nitinol Foil stands out as a top choice for various applications. The NT0402 Nitinol Foil offered by GEE SMA is known for its exceptional material properties, making it a reliable option for demanding projects. With superior durability and flexibility, this nitinol foil is designed to meet the highest standards of performance.

GEE SMA Nitinol Foil

GEE SMA Nitinol Foil is a trusted name in the industry, known for providing top-notch nitinol products to meet the needs of diverse sectors. The NT0402 Nitinol Foil offered by GEE SMA is manufactured with precision and expertise, ensuring consistent quality and reliability. As one of the leading nitinol foil suppliers, GEE SMA takes pride in delivering high performance materials to its customers.

GEE SMA Nitinol Foil is committed to staying at the forefront of nitinol technology, constantly innovating and improving its products to meet the evolving needs of various industries. The NT0402 Nitinol Foil is designed to offer exceptional shape memory and superelasticity, making it an ideal choice for applications in medical devices, aerospace, automotive, and more. With a focus on research and development, GEE SMA continues to push the boundaries of nitinol material properties, ensuring that its customers have access to the most advanced and reliable products on the market.

Superior Material Properties

The NT0402 Nitinol Foil from GEE SMA boasts superior material properties that set it apart from other options in the market. With excellent shape memory and superelasticity, this nitinol foil offers unmatched performance in various applications. Its ability to recover its original shape after deformation makes it an ideal choice for critical projects where reliability is paramount.

The NT0402 Nitinol Foil's durability and flexibility make it an exceptional choice for a wide range of applications. Its high resistance to corrosion and fatigue ensures long-term performance in challenging environments, making it a reliable option for critical projects. Additionally, its exceptional flexibility allows for easy shaping and forming, providing versatility in design and manufacturing processes.

Durability and Flexibility

In addition to its superior material properties, the NT0402 Nitinol Foil from GEE SMA is known for its exceptional durability and flexibility. This makes it suitable for a wide range of applications that require resilience and adaptability. Whether used in medical devices or industrial machinery, this nitinol foil can withstand challenging conditions while maintaining its structural integrity.

By choosing high quality nitinol foils like the NT0402 Nitinol Foil from GEE SMA, businesses can ensure reliable performance and longevity in their projects. Whether it's for medical devices or industrial applications, the superior material properties, durability, and flexibility make this nitinol foil an excellent choice for demanding requirements.

Nitinol Foil Suppliers

When it comes to finding reliable partners for your nitinol foil needs, it's crucial to look for suppliers with a proven track record of excellence. GEE SMA stands out as a trusted supplier with extensive experience in providing high-quality NT0402 Nitinol Foil to various industries. Their commitment to customer satisfaction and product quality makes them an ideal choice for all your nitinol foil requirements.

Finding Reliable Partners

Finding a reliable supplier for nitinol foil can be a daunting task, but it's essential for the success of your projects. Look for a supplier that offers comprehensive support and expertise in the field, ensuring that you receive the right materials tailored to your specific needs. GEE SMA understands the importance of reliability and consistency, making them an excellent partner for all your nitinol foil requirements.

GEE SMA as a Trusted Supplier

GEE SMA has earned its reputation as a trusted supplier of high-quality nitinol foils, including the innovative NT0402 Nitinol Foil. Their dedication to delivering top-notch products and exceptional customer service sets them apart in the industry. With GEE SMA as your supplier, you can rest assured that you are receiving superior nitinol foil backed by extensive knowledge and expertise.

Quality Assurance and Certification

When choosing a nitinol foil supplier, it's crucial to prioritize quality assurance and certification. GEE SMA adheres to stringent quality control measures and holds relevant certifications to guarantee the excellence of their products. By partnering with GEE SMA, you gain access to certified nitinol foils that meet industry standards, ensuring optimal performance and peace of mind.

Nitinol Superelastic Foil

Nitinol Superelastic Foil is a remarkable material with unique mechanical properties that set it apart from traditional metals. Its ability to return to its original shape after deformation makes it ideal for applications in aerospace and automotive industries.

Unique Mechanical Properties

Nitinol Superelastic Foil exhibits extraordinary flexibility and resilience, allowing it to withstand repeated bending and stretching without permanent deformation. This remarkable property makes it an excellent choice for intricate components in advanced engineering projects.

Nitinol Superelastic Foil's unique mechanical properties also make it an ideal material for applications in the aerospace and automotive industries. Its ability to withstand repeated bending and stretching without permanent deformation means that it can be used to create intricate components that are essential for high-performance aircraft and vehicles. Whether it's used in engine components, landing gear, or structural elements, Nitinol Superelastic Foil offers the durability and reliability required for these demanding applications.

Applications in Aerospace and Automotive

The exceptional properties of Nitinol Superelastic Foil make it a preferred material for critical components in aerospace and automotive applications. From intricate springs to complex actuator systems, this versatile material offers unmatched performance and reliability.

Furthermore, Nitinol Superelastic Foil is able to maintain its shape and performance even in extreme conditions, such as high temperatures and intense pressure. This makes it an ideal choice for critical components that need to withstand harsh environments in aerospace and automotive applications. Whether it's for use in engine components or landing gear systems, this versatile material provides the durability and reliability necessary for safe and efficient operation.

Performance in Extreme Conditions

Whether subjected to extreme temperatures or high levels of stress, Nitinol Superelastic Foil maintains its integrity and functionality. Its ability to perform consistently under harsh conditions makes it an indispensable material for demanding aerospace and automotive environments.

With its exceptional mechanical properties, diverse applications, and resilience under extreme conditions, Nitinol Superelastic Foil is revolutionizing the aerospace and automotive industries. As the demand for high-performance materials continues to grow, Nitinol Superelastic Foil stands out as a reliable solution for complex engineering challenges.

Conclusion

When it comes to choosing the right Nitinol foil supplier, it's essential to prioritize reliability, quality, and expertise. GEE SMA stands out as a trusted partner for high-quality Nitinol foils, offering the NT0402 Nitinol Foil with superior material properties and custom thickness options. Exploring these custom thickness options is crucial for meeting specific project requirements and ensuring optimal performance. Additionally, the benefits of Nitinol Superelastic Foil in applications such as aerospace and automotive industries highlight its unique mechanical properties and resilience in extreme conditions.

Choosing the Right Nitinol Foil Supplier

Choosing a reliable Nitinol foil supplier is crucial for ensuring the success of your project. With GEE SMA, you can trust in their expertise and commitment to delivering high-quality Nitinol foils that meet stringent industry standards. Their NT0402 Nitinol Foil offers exceptional material properties and reliability, making them a top choice for various applications.

When exploring custom thickness options for Nitinol foil, GEE SMA stands out as a supplier that can meet your specific requirements. Whether you need a thinner or thicker foil, their expertise and advanced manufacturing capabilities allow them to produce Nitinol foils in custom thicknesses with precision and consistency. This flexibility ensures that you can obtain the exact material properties you need for your project, without compromising on quality or reliability.

Exploring Custom Thickness Options

Custom thickness options for Nitinol foils provide flexibility and versatility for different project requirements. Whether you need thin Nitinol foil for medical devices or thick foil for industrial applications, having access to custom thickness options allows you to tailor the material to your specific needs. GEE SMA offers this level of customization, ensuring that you have the right Nitinol foil for your project. In addition to the flexibility in thickness, custom Nitinol foils also offer enhanced durability and shape memory properties, making them ideal for a wide range of applications. This means that no matter the specific demands of your project, custom Nitinol foils can be engineered to meet those requirements with precision and reliability. With GEE SMA's expertise in customizing Nitinol foils, you can be confident that your material will perform exactly as needed.

Benefits of Nitinol Superelastic Foil

Nitinol Superelastic Foil offers unique mechanical properties that make it ideal for demanding applications in aerospace and automotive industries. Its ability to withstand extreme conditions while maintaining flexibility and durability sets it apart from other materials. The benefits of using Nitinol Superelastic Foil extend beyond its exceptional performance, making it a valuable investment for various projects.

In addition to its exceptional mechanical properties, Nitinol Superelastic Foil also offers excellent corrosion resistance, making it a reliable choice for applications in harsh environments. This resistance to corrosion ensures that the material will maintain its integrity and performance over time, reducing the need for frequent maintenance and replacement. As a result, projects utilizing Nitinol Superelastic Foil can benefit from lower long-term costs and increased reliability, making it a cost-effective solution for demanding industries.