Introduction

Medical micro machining is a specialized process that involves the fabrication of tiny, intricate components for use in medical devices. These precision components play a crucial role in ensuring the effectiveness and safety of medical equipment. Nitinol, a shape memory alloy, has emerged as a key material for such components due to its unique properties and versatility in medical micro machining.

Understanding Medical Micro Machining

Medical micro machining refers to the manufacturing of minuscule parts and components used in medical devices. This highly specialized process requires advanced techniques and equipment to achieve the necessary level of precision and accuracy.

Medical micro machining plays a crucial role in the development and production of medical devices, as these precision components are essential for ensuring the safety and effectiveness of these devices. Without the ability to manufacture minuscule parts with such high accuracy, many medical advancements and procedures would not be possible. From pacemakers to surgical tools, the need for precision components in medical devices cannot be overstated.

Importance of Precision Components in Medical Devices

The demand for precision components in medical devices cannot be overstated. These components are essential for ensuring the reliability and functionality of various medical equipment, ranging from stents to surgical instruments.

The precision components used in medical devices play a crucial role in ensuring patient safety and the effectiveness of medical treatments. From pacemakers to catheters, these components are designed to meet strict tolerances and specifications to guarantee accurate performance. Without precision components, the reliability of medical equipment could be compromised, potentially leading to adverse outcomes for patients.

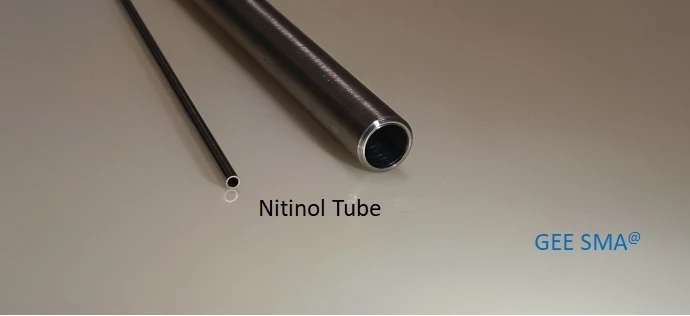

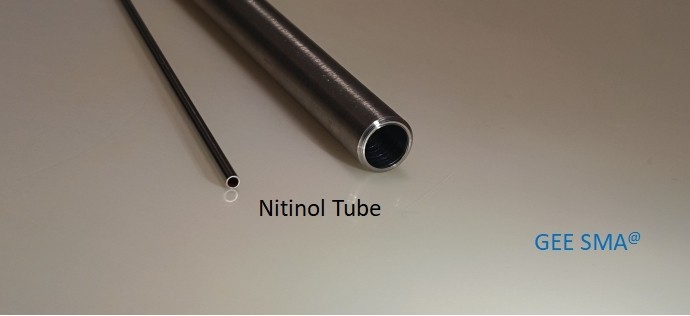

The Role of Nitinol Components in Medical Micro Machining

Nitinol, a nickel-titanium alloy with unique shape memory properties, has become indispensable in the field of medical micro machining. Its ability to return to a predetermined shape after being deformed makes it ideal for applications such as stents and other implantable devices.

Nitinol's unique properties also make it an ideal material for micro machining processes, as it can be easily shaped and manipulated to create intricate medical components with precision and accuracy. The alloy's biocompatibility further enhances its suitability for medical applications, ensuring that it can be safely used within the human body without causing adverse reactions. This combination of shape memory, machinability, and biocompatibility has positioned Nitinol as a critical component in the production of advanced medical devices, driving innovation and improving patient outcomes.

Nitinol Machining and Finishing Techniques

Laser Micromachining of Nitinol Stents

Laser micromachining is a crucial technique in the fabrication of Nitinol stents for medical devices. This process allows for precise shaping and cutting of Nitinol components, ensuring the highest level of quality and performance. With our advanced laser micromachining capabilities, GEE SMA delivers exceptional Nitinol stents that meet the stringent requirements of medical micro machining.

Laser micromachining also allows for the customization of Nitinol stents to meet the specific needs of patients, ensuring a perfect fit and optimal performance. This level of precision is essential in the medical field, where even the smallest deviation can have significant consequences. Our team at GEE SMA takes great pride in our ability to utilize laser micromachining to create Nitinol stents that not only meet industry standards but also exceed expectations in terms of quality and reliability.

Nitinol Stent & Nitinol Medical Devices Shape Setting

The shape setting of Nitinol stents and other medical devices is a critical step in the manufacturing process. Our expertise in this area ensures that the shape memory properties of Nitinol are harnessed to create reliable and durable components for medical applications. GEE SMA's dedication to precision and quality is evident in every Nitinol stent and medical device we produce.

Our team at GEE SMA understands the intricate process of Nitinol machining and the importance of precision in shaping medical devices. By leveraging our expertise, we are able to ensure that every Nitinol stent and medical device meets the highest standards for quality and performance. From intricate designs to complex shapes, we are committed to delivering exceptional products that uphold the reliability and durability expected in medical applications.

GEE SMA's Expertise in Nitinol Machining

At GEE SMA, we have honed our expertise in Nitinol machining to deliver exceptional results for medical device manufacturers. Our team's deep understanding of the unique properties of Nitinol allows us to develop innovative machining techniques that optimize the performance of medical components. From laser cutting to shape setting, our comprehensive approach to Nitinol machining sets us apart as a leader in the field.

Furthermore, our state-of-the-art facilities and advanced equipment enable us to achieve unparalleled precision in Nitinol machining. This allows us to produce intricate and complex medical components with the highest level of accuracy, meeting the stringent requirements of medical device manufacturers. Our commitment to staying at the forefront of technological advancements in Nitinol machining ensures that we consistently deliver cutting-edge solutions to our clients.

Micro Metals Processing for Medical Applications

Benefits of Microdrilling of Nitinol

When it comes to medical micro machining, microdrilling of Nitinol offers numerous benefits. This process allows for the creation of precise, small holes in Nitinol components, which is crucial for medical devices such as stents and implants. Microdrilling ensures that the components have the necessary features to function effectively within the human body, providing patients with optimal outcomes.

Microdrilling of Nitinol also allows for the production of intricate and complex designs, giving medical device manufacturers the flexibility to create innovative products. This process enables the fabrication of customized features that are tailored to specific patient needs, ultimately improving the overall performance and comfort of medical implants. Additionally, microdrilling helps to minimize material waste, making it a cost-effective and sustainable solution for producing high-quality Nitinol components.

Precision Machining of Nitinol and Specialty Allo

Precision machining of Nitinol and specialty alloys is essential for producing high-quality medical devices. This process involves using advanced techniques to shape and refine these materials into intricate components that meet strict medical standards. The precision achieved through this machining ensures that the final products are reliable, durable, and safe for patient use. Additionally, the use of innovative micro metals processing techniques by GEE SMA sets a new standard in the industry, allowing for even greater precision and customization in the manufacturing of medical devices. These cutting-edge techniques enable the production of complex designs with unparalleled accuracy, meeting the evolving demands of the healthcare sector.

GEE SMA's Innovative Micro Metals Processing Techniques

GEE SMA is at the forefront of innovative micro metals processing techniques for medical applications. With a focus on Nitinol and specialty alloys, GEE SMA utilizes cutting-edge methods to manipulate these materials into complex shapes and structures required for medical devices. Their commitment to innovation ensures that they can tailor their processes to meet unique customer needs in the ever-evolving field of medical micro machining.

Quality Control and Testing for Precision Medical Components

Ensuring Precision and Quality in Medical Micro Machining

At GEE SMA, we understand the critical importance of precision and quality in medical micro machining. Our state-of-the-art facilities and expert team ensure that every component meets the highest standards of accuracy and performance. From initial design to final production, we prioritize precision at every step of the process.

Our commitment to precision extends to our use of advanced materials such as Nitinol and specialty alloys for medical devices. These materials are known for their unique properties, including superelasticity and shape memory, making them ideal for a wide range of medical applications. Our expertise in working with these materials ensures that the final products meet the exact specifications required for optimal performance and reliability in the field of medical micro machining.

Nitinol and Specialty Alloy Solutions for Medical Devices

When it comes to medical devices, the choice of materials is crucial. That's why we specialize in Nitinol and other specialty alloy solutions for medical applications. These materials offer exceptional biocompatibility, corrosion resistance, and superelasticity, making them ideal for a wide range of medical devices, from stents to surgical tools. In addition to their physical properties, Nitinol and specialty alloys also allow for intricate designs and precise manufacturing processes, ensuring that medical devices meet the highest standards of quality and performance. Our commitment to staying at the forefront of material innovation means that we are constantly researching and developing new alloy solutions to address the evolving needs of the medical industry.

GEE SMA's Commitment to Product Quality and Customer Satisfaction

At GEE SMA, our commitment to product quality goes hand in hand with our dedication to customer satisfaction. We work closely with our clients to understand their unique needs and tailor our Nitinol components accordingly. Our rigorous quality control processes ensure that every component meets the highest standards before it reaches our customers.

By providing cutting-edge solutions in Nitinol machining and finishing for medical devices, GEE SMA is revolutionizing the field of medical micro machining. Our expertise in laser micromachining of Nitinol stents, shape setting for Nitinol medical devices, microdrilling of Nitinol, and innovative micro metals processing techniques sets us apart as leaders in the industry.

Keep up with advancements in medical micro machining techniques by partnering with GEE SMA - your trusted source for precision components that meet the highest standards of quality in the medical device industry. With our dedication to tailoring Nitinol components for unique customer needs, you can be confident that your products will stand out in terms of both performance and reliability.

Conclusion

Advancements in Medical Micro Machining Techniques have revolutionized the precision and quality of medical devices, especially with the use of Nitinol Components. The development of Laser Micromachining of Nitinol stents and shape setting for Nitinol medical devices has opened up new possibilities for innovative medical solutions.

Ensuring Precision and Quality in Medical Devices is crucial for patient safety and successful treatment outcomes. With the use of advanced Nitinol machining and finishing techniques, such as microdrilling of nitinol, medical device manufacturers can guarantee the reliability and effectiveness of their products.

GEE SMA's Dedication to Tailoring Nitinol Components for Unique Customer Needs sets them apart as a leader in micro metals processing for medical applications. Their expertise in providing Nitinol and Specialty Alloy Solutions for medical devices ensures that each component is customized to meet specific requirements, ultimately improving patient care.