Introduction

Nitinol alloys, a combination of nickel and titanium, are known for their unique properties such as shape memory effect and superelasticity. Actuators built from Nitinol offer precise control and reliability in various applications. Understanding Nitinol Linear Actuators involves delving into the technical information behind this innovative technology, which has revolutionized industries like medical devices, robotics, and aerospace.

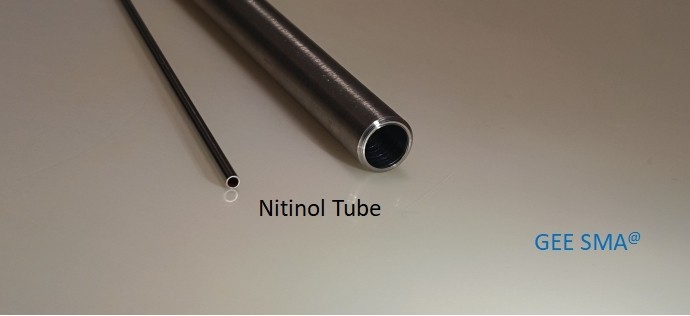

Understanding Nitinol Alloys

Nitinol alloys are a type of smart material that can remember its original shape when heated after being deformed. This shape memory effect makes them ideal for creating Nitinol Linear Actuators that can perform two-way movements with high precision and accuracy.

Nitinol Linear Actuators are widely used in various industries such as aerospace, medical devices, robotics, and automotive engineering. Their ability to undergo reversible deformation and return to their original shape with high precision makes them highly sought after for applications that require accurate and reliable movement. Whether it's controlling the movement of surgical instruments in minimally invasive procedures or adjusting the position of components in a satellite, Nitinol Linear Actuators offer a level of control and performance that is unmatched by traditional actuators.

Exploring Nitinol Linear Actuators

A Nitinol Linear Actuator is a device that converts energy into linear motion using Nitinol wires or strips. These actuators are capable of generating large forces while maintaining small form factors, making them suitable for intricate applications in various industries.

Nitinol Linear Actuators are highly versatile and can be used in a wide range of applications, from medical devices to aerospace technology. Their ability to generate significant forces in a compact form factor makes them ideal for intricate tasks such as surgical instruments or miniature robotics. Additionally, the shape memory properties of Nitinol allow for precise control and repeatability, making these actuators suitable for applications where accuracy is paramount.

Applications of Nitinol Actuators

The versatility of Nitinol-based Medical Devices has made them indispensable in the healthcare sector, where they are used in stents, guidewires, and surgical tools. Additionally, the use of Nitinol actuators in robotics has led to advancements in prosthetics and exoskeletons, while aerospace applications benefit from their lightweight yet powerful nature.

The unique properties of Nitinol actuators have also found applications in the field of automotive engineering, where they are used in various components such as fuel injectors, throttle control systems, and active aerodynamics. The ability of Nitinol to withstand high temperatures and provide precise control makes it an ideal material for enhancing the performance and efficiency of modern vehicles. As automotive technology continues to evolve, Nitinol actuators are poised to play a crucial role in driving innovation and pushing the boundaries of what is possible in the industry.

The Science Behind Nitinol Alloys

Nitinol alloys are a fascinating class of materials with unique properties that make them ideal for various applications, including actuators. One of the most remarkable characteristics of Nitinol is its shape memory effect, which allows it to return to its original shape after being deformed. This makes it perfect for creating Nitinol actuators that can perform precise movements in medical devices, robotics, and aerospace technology.

Shape Memory Effect

The shape memory effect in Nitinol alloys is a result of their ability to undergo a reversible phase transformation under certain conditions. When the material is deformed at low temperatures, it retains this new shape until it is heated above a critical temperature, at which point it reverts back to its original form. This unique property enables the creation of Nitinol actuators that can be used in a wide range of applications, from medical devices to industrial machinery.

The superelasticity of Nitinol alloys is another remarkable property that sets them apart from other materials. This unique feature allows Nitinol to undergo large deformations and still return to its original shape when the stress is removed, making it an ideal choice for applications that require high flexibility and resilience. From minimally invasive medical devices to aerospace components, the superelasticity of Nitinol has opened up new possibilities in various industries, revolutionizing the way we design and manufacture products.

Superelasticity

Another key attribute of Nitinol alloys is their superelasticity, which allows them to undergo large deformations and still return to their original shape when the external force is removed. This makes Nitinol an excellent choice for actuators built from Nitinol, as they can withstand repetitive and high-stress movements without experiencing permanent deformation. As a result, Nitinol linear actuators are widely used in applications where reliability and durability are essential.

In addition to its superelasticity, Nitinol alloys also exhibit biocompatibility, making them suitable for use in medical devices and implants. This unique property allows Nitinol to be used in applications where it will come into direct contact with the human body without causing adverse reactions. As a result, Nitinol has become a popular choice for stents, guidewires, and other medical devices due to its ability to withstand the harsh conditions within the body while maintaining its structural integrity.

Biocompatibility

In addition to their remarkable mechanical properties, Nitinol alloys also exhibit excellent biocompatibility, making them suitable for use in medical devices such as stents and guidewires. This biocompatibility ensures that Nitinol-based medical devices can be safely implanted into the human body without causing adverse reactions or tissue damage. As a result, the demand for Nitinol-based medical devices continues to grow as researchers explore new ways to leverage the unique properties of these alloys for improved healthcare solutions.

With an understanding of these fundamental properties of Nitinol alloys, we can appreciate why they are so well-suited for use in actuators across various industries. Whether it's a two-way nitinol linear actuator or a nitinol finger actuator, the technical information about nitinol actuators highlights their versatility and reliability in performing precise movements required for different applications.

Nitinol Actuator Applications

Medical Devices

Actuators built from Nitinol are revolutionizing the medical industry with their precise and reliable performance. These innovative devices, such as the Nitinol Finger Actuator, are used in minimally invasive surgeries, prosthetics, and drug delivery systems. The unique properties of Nitinol allow for intricate movements and accurate control, making it an ideal material for medical applications.

In addition to medical applications, Nitinol actuators are also making significant strides in the field of robotics. These actuators are being used to create advanced robotic systems that can perform delicate and precise movements, making them ideal for tasks such as surgical procedures and assembly line operations. The unique shape memory and superelastic properties of Nitinol allow these robotic systems to adapt to changing conditions, providing unparalleled flexibility and reliability in various industrial settings.

Robotics

What is a Nitinol actuator? It's a game-changer in the field of robotics. Nitinol Linear Actuators provide seamless motion control in robotic exoskeletons, grippers, and other automated systems. The superelasticity of Nitinol allows these actuators to withstand repetitive use without losing efficiency or accuracy, making them essential components in advanced robotics.

Nitinol actuators are also revolutionizing the aerospace industry, providing precise and reliable motion control in aircraft components and satellite systems. The high durability and resilience of Nitinol make it ideal for withstanding the extreme conditions of space travel, ensuring that critical aerospace equipment operates smoothly and efficiently. With Nitinol actuators, aerospace engineers can design advanced systems that are capable of withstanding the rigors of space exploration, making them indispensable in the development of next-generation aerospace technology.

Aerospace

Nitinol actuator technical information reveals its crucial role in aerospace technology. These actuators are used in aircraft wings, flaps, and landing gear to ensure precise movement and stability during flight. The lightweight yet durable nature of Nitinol makes it an ideal material for aerospace applications where reliability is paramount.

Additionally, Nitinol actuators are also used in the deployment of satellite solar panels and antenna systems. The ability of Nitinol to withstand extreme temperatures and maintain its shape under stress makes it an indispensable component in the harsh environment of outer space. This reliability is crucial for ensuring that critical satellite systems function as intended, without the need for frequent maintenance or repair.

Next section:

GEE SMA's Role in Nitinol Actuator Production

At GEE SMA, we take pride in crafting high-quality materials for nitinol actuators. Our team of experts ensures that every nitinol-based product meets the highest standards of performance and durability. By using advanced manufacturing techniques and rigorous quality control measures, we guarantee that our nitinol actuators are reliable and efficient in various applications.

Crafting High-Quality Materials

Our commitment to quality extends beyond the manufacturing process. We conduct rigorous testing and quality control measures to ensure that our nitinol materials meet the highest standards for performance and reliability. This dedication to excellence means that our actuators built from nitinol not only exhibit exceptional shape memory effect and superelasticity, but also have a proven track record of durability in demanding applications. Customers can trust that our nitinol functional materials are tailor-made for their specific needs, delivering consistent and exceptional performance.

Tailoring Nitinol Functional Materials

One of our key strengths lies in our ability to tailor nitinol functional materials according to specific technical requirements. Whether it's a two-way nitinol linear actuator or a finger actuator, we have the expertise to customize the material properties to meet the exact specifications of our clients. Our flexible approach enables us to provide innovative solutions for diverse industries, from medical devices to aerospace technology.

Addressing Customer Requirements Swiftly

At GEE SMA, customer satisfaction is paramount, which is why we prioritize addressing their requirements swiftly and effectively. Our responsive team works closely with clients to understand their unique needs and deliver tailored solutions within tight timelines. By maintaining open communication channels and a proactive approach, we ensure that every customer receives personalized service and top-notch nitinol-based products.

In addition to our swift and effective response to customer requirements, we also place a strong emphasis on continuous improvement. Our team is dedicated to staying updated with the latest advancements in nitinol technology and manufacturing processes, allowing us to offer cutting-edge solutions that meet and exceed our customers' expectations. By constantly evolving and adapting to the changing needs of the industry, we ensure that our customers receive the most innovative and high-quality products available.

Conclusion

Nitinol actuators offer a wide range of advantages, including their shape memory effect and superelasticity, making them ideal for various applications. Actuators built from Nitinol are widely used in medical devices, robotics, and aerospace due to their unique properties. As the demand for Nitinol-based medical devices continues to grow, the future looks promising for this innovative technology.

Advantages of Nitinol Actuators

Nitinol actuators are known for their high precision and reliability, making them an excellent choice for applications that require accurate and repeatable motion control. The unique properties of Nitinol allow for compact designs and efficient energy usage, making it a top choice for engineers and designers looking to optimize performance.

Additionally, Nitinol actuators are highly durable, with the ability to withstand long-term use without degradation in performance. This makes them ideal for applications in harsh environments or high-stress conditions, where reliability is crucial. Furthermore, Nitinol's biocompatibility makes it a promising material for medical devices, as it can be safely implanted in the human body without causing adverse reactions.

Future of Nitinol-based Medical Devices

The future of Nitinol-based medical devices is bright, with ongoing research and development leading to new innovations in minimally invasive surgical tools, stents, and other life-saving devices. As technology continues to advance, the use of Nitinol in medical applications is expected to expand further, improving patient outcomes and quality of care.

As technology continues to advance, the use of Nitinol in medical applications is expected to expand further, improving patient outcomes and quality of care. With its unique properties of shape memory and superelasticity, Nitinol has already revolutionized the field of interventional cardiology with the development of self-expanding stents that can adapt to the patient's anatomy. In addition, ongoing research is exploring new ways to leverage Nitinol's capabilities in areas such as orthopedics and neurology, promising even more breakthroughs in medical device innovation.

GEE SMA's Commitment to Excellence

At GEE SMA, our commitment to excellence drives us to continually push the boundaries of what's possible with Nitinol materials. Our expertise in crafting high-quality materials and tailoring functional properties allows us to address customer requirements swiftly and effectively. We are dedicated to advancing the field of Nitinol actuators and contributing to the development of cutting-edge technologies.

This concludes our exploration into the world of Nitinol actuators - from their unique properties to their diverse applications across industries. As we look ahead, it's clear that Nitinol will continue to play a pivotal role in shaping the future of advanced engineering solutions.