Introduction

Nitinol, a fascinating memory metal, has intrigued scientists and engineers alike with its shape memory properties. This alloy, known for its ability to remember its original shape, is at the forefront of innovative technologies. Let's delve into the secrets of how nitinol works and explore its wonders.

The Mystery Behind Nitinol

Nitinol's unique characteristics stem from its shape memory alloy nature, allowing it to return to a predetermined shape when subjected to heat. This remarkable feature has sparked curiosity and research into harnessing its potential for various applications.

Nitinol's shape memory alloy nature has captured the interest of researchers, engineers, and designers looking to push the boundaries of what is possible in various industries. From medical devices that can adapt to the body's natural movements to aerospace components that can withstand extreme temperatures, the potential applications for Nitinol seem limitless. As more and more experts delve into the mysteries behind this remarkable material, we can expect to see even more groundbreaking innovations emerge.

Unveiling the Secrets of Shape Memory Alloys

Shape memory alloys like nitinol are truly fascinating materials that have captured the attention of scientists and engineers alike. The ability of nitinol to remember its original shape, even after being deformed, opens up a world of possibilities in various industries. By delving deeper into the martensite and austenite phases of nitinol, researchers can uncover innovative applications that harness the full potential of these shape memory alloys.

Exploring the Wonders of Nitinol Metal

From biomedical devices to robotics, nitinol's versatility knows no bounds. Its exceptional properties have paved the way for groundbreaking innovations in diverse industries, showcasing the endless possibilities that this memory metal offers.

Understanding Nitinol Alloy

Nitinol is a unique metal alloy known for its shape memory effect. This remarkable property allows it to "remember" its original shape and return to it when heated. Here's a closer look at how nitinol works:

- Deformed at Low Temperatures: Nitinol can be bent or twisted into a new shape at relatively low temperatures.

- Transformation Upon Heating: When heated above a specific temperature, nitinol undergoes a structural change and reverts to its original shape.

- Atomic Rearrangement: This shape memory phenomenon is caused by the rearrangement of atoms within the material's crystal structure.

Nitinol's ability to return to its original shape has made it a valuable material for various applications in medicine, engineering, and aerospace.

Martensite Vs

. Austenite Transformation

The martensite phase occurs when Nitinol is deformed at low temperatures. It allows it to retain this new shape until heated above its transition temperature, at which point it reverts to austenite. This unique characteristic enables Nitinol to remember and recover its original form upon heating.

Shape Memory Phenomenon

Nitinol's shape memory effect results from its crystal structure, which allows for reversible changes in shape based on temperature variations. This exceptional property makes Nitinol ideal for applications requiring precise and controlled movements, such as in the biomedical field.

Applications in

the Biomedical Field

In the medical industry, Nitinol's ability to return to its predetermined shape has revolutionized treatments like orthodontic wires and stents in medical devices. Its biocompatibility and flexibility make it an invaluable material for crafting intricate components that adapt to the body's needs.

Furthermore, Nitinol's unique properties have paved the way for advancements in minimally invasive surgical procedures. Its shape memory effect allows for creating tools that can be inserted into the body in a compact form and then expand to their original shape once inside, reducing trauma to surrounding tissues. This has led to shorter recovery times and improved patient outcomes in various medical interventions.

The Science Behind Nitinol

Nitinol is a fascinating shape memory alloy with unique properties due to its crystal structure. The material undergoes a phase transformation between martensite and austenite, allowing it to remember its original shape. This thermal activation process enables the metal to recover its pre-deformed form when exposed to heat. The shape recovery mechanism in Nitinol is what makes it a remarkable memory metal.

Crystal Structure of Memory Alloys

The crystal structure of Nitinol alloys plays a crucial role in their shape memory capabilities. These materials have a specific arrangement of atoms that allows them to switch between martensite and austenite phases. This unique structure gives Nitinol the ability to return to its original shape after deformation, making it ideal for various applications in different industries.

Moreover, the thermal activation process is another key factor in the shape memory capabilities of Nitinol alloys. Subjecting the material to a specific temperature range effectively controls the phase transformation between martensite and austenite. This process allows for precise control over the shape recovery of Nitinol, making it a versatile material for applications such as medical devices and aerospace components.

Thermal Activation Process

Nitinol is deformed at lower temperatures, but it retains its deformed shape due to the stable martensitic phase. However, upon heating above a certain temperature called the transformation temperature, it transitions back to austenite and recovers its original form. This thermal activation process enables Nitinol to exhibit its remarkable shape memory properties.

Shape Recovery Mechanism

The shape recovery mechanism in Nitinol is based on the reversible transformation of the martensite and austenite phases. When subjected to external stimuli such as heat, stress, or magnetic fields, Nitinol can change from one phase to another and revert when conditions are reversed. This unique behavior allows for precise control over the material's shape-changing abilities.

Furthermore, Nitinol's shape recovery mechanism is limited to simple shape changes and can be harnessed for more complex applications. For example, in the medical field, Nitinol is used in minimally invasive surgical procedures where precise control over the material's shape is crucial. By exploiting the unique properties of Nitinol, medical devices can be designed to navigate through intricate pathways within the body with ease and accuracy.

GEE SMA's Expertise in Nitinol

GEE SMA prides itself on crafting high-quality materials using the innovative nitinol alloy. With a deep understanding of nitinol, their team excels in producing memory metals that exhibit remarkable shape memory properties. Through meticulous attention to detail, they ensure that each component meets the highest standards.

Crafting High-Quality Materials

GEE SMA leverages its expertise in shape memory alloys to deliver exceptional components for diverse industries. Here's what sets them apart:

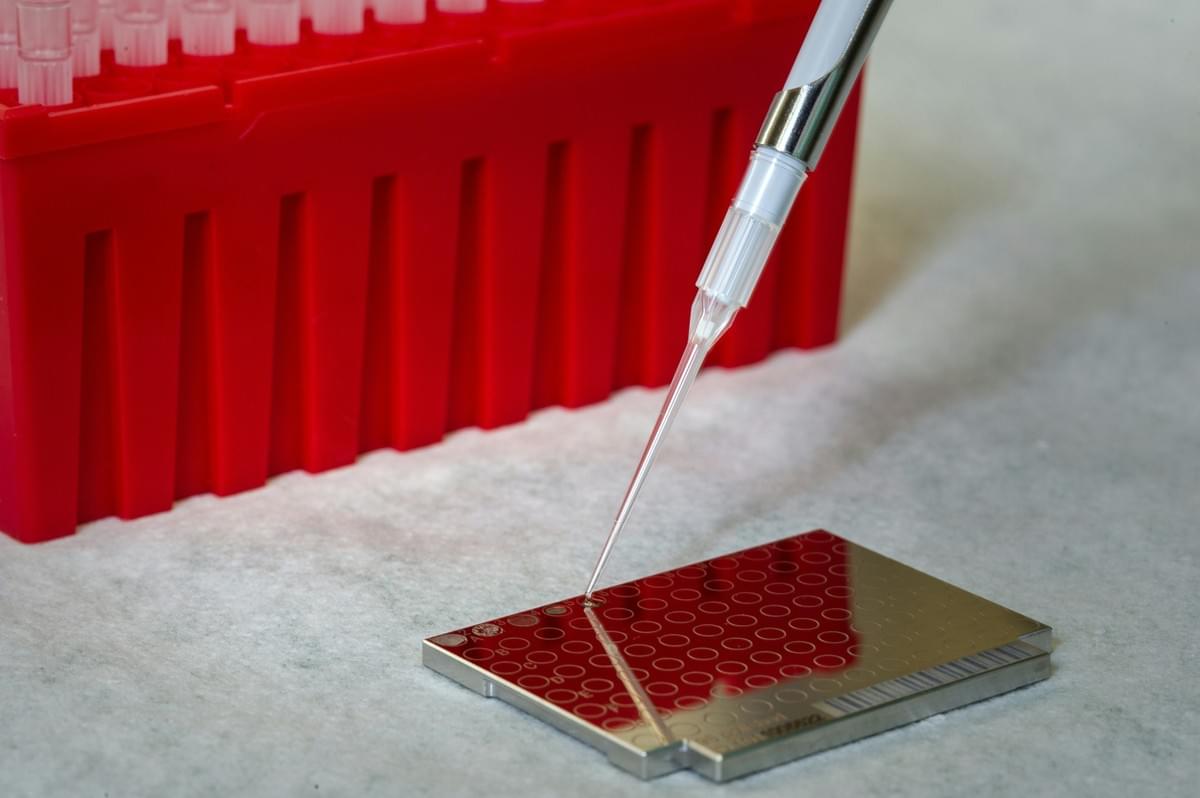

- Precision Material Selection & Processing: They meticulously select and process nitinol metal, a special alloy known for its shape memory properties.

- Martensite & Austenite Transformation: By mastering the transformation between these phases, they create memory alloys that seamlessly return to their original shape upon activation.

- Rigorous Testing & Quality Control: Their commitment to excellence goes beyond material selection. Each component undergoes rigorous testing to ensure unmatched durability and reliability, even in demanding applications.

With GEE SMA, you can be confident that you're receiving top-notch memory alloys built to perform consistently under challenging conditions.

Tailoring Components to Customer Needs

Understanding each customer's unique requirements, GEE SMA offers customized solutions tailored to specific needs. Whether designing orthodontic wires with precise shape memory capabilities or developing stents for medical devices that provide optimal performance, their team works closely with clients to deliver components that exceed expectations.

Swiftly Addressing Customer Requirements

With a commitment to customer satisfaction, GEE SMA ensures quick turnaround times for all projects. They can swiftly address customer requirements without compromising quality by leveraging their knowledge of shape memory materials and efficient manufacturing processes. This dedication to excellence sets them apart as a trusted partner in nitinol alloys.

Real-World Applications of Nitinol

Nitinol, a remarkable shape memory alloy, is extensively used in various fields due to its unique properties. One of the most common applications is in orthodontic wires, where the memory metal's ability to return to its original shape allows for gradual teeth alignment. This flexibility and resilience make nitinol an ideal choice for dental braces.

Orthodontic Wires

In orthodontics, nitinol wires apply gentle pressure on teeth, guiding them into proper alignment over time. The shape memory alloy's ability to remember and return to its predetermined form ensures a consistent force is applied for effective tooth movement. Additionally, nitinol's biocompatibility and corrosion resistance make it safe for prolonged use inside the mouth.

Furthermore, nitinol wires are known for their flexibility and durability, allowing orthodontists to make precise adjustments during treatment without the risk of breakage. This ensures that the teeth are moved gradually and accurately, reducing the chances of discomfort or complications for the patient. The reliability of nitinol wires in maintaining consistent pressure over time makes them a popular choice among orthodontic professionals.

Stents in Medical Devices

Another vital application of nitinol is in manufacturing stents for medical devices. Stents made from this memory alloy can be compressed and inserted into blood vessels or other narrow passages before expanding back to their original shape once in place. This property helps keep arteries open and ensures proper blood flow, making nitinol stents crucial in treating cardiovascular conditions.

Moreover, nitinol's unique properties make it an ideal material for robotics and aerospace industries. Its shape memory allows for intricate movements and adjustments in robotic applications, making it perfect for creating flexible joints and components. In the aerospace sector, nitinol's lightweight yet durable nature makes it a valuable material for manufacturing components that require high strength-to-weight ratios, such as actuators and sensors. The versatility of nitinol in these industries showcases its adaptability and reliability in demanding environments.

Robotics and Aerospace Industries

Nitinol, a unique metal alloy, offers remarkable properties that revolutionize aerospace and robotics. Here's how this innovative material is making a difference:

- Precision Robotics: Nitinol's shape-memory properties make it ideal for robot actuators. These actuators can mimic human muscle movements with exceptional precision and efficiency, allowing advanced robotic capabilities.

- Lightweight Durability in Aerospace: Aerospace engineers value nitinol's ability to be lightweight yet incredibly strong. This makes it perfect for crucial components like valves that need to function flawlessly under extreme conditions encountered during spaceflight.

- Reliable Performance in Space: Beyond valves, nitinol's exceptional tolerance for high temperatures and harsh environments makes it ideal for fuel line connectors and actuators in satellites and spacecraft. Engineers can depend on nitinol to deliver consistent performance, ensuring the smooth operation of critical systems in space.

Nitinol's unique combination of properties propels advancements in aerospace and robotics. Its ability to adapt, perform, and endure in demanding environments makes it a valuable asset for these high-tech fields.

Harnessing the Power of Nitinol

Nitinol, the wonder metal, continues to be captivated by its shape memory abilities and unique properties. Understanding how nitinol works opens up a world of possibilities in various industries. Embracing the future of memory alloys means pushing boundaries and innovating with this remarkable material. Unlocking the potential of shape memory materials like nitinol paves the way for groundbreaking advancements that will shape our future.

Harnessing the power of nitinol involves delving into its martensite vs. austenite transformation, unlocking its shape memory phenomenon, and exploring its vast applications in fields like medicine and robotics. By understanding how nitinol works, we can harness its potential to create cutting-edge solutions that revolutionize industries worldwide.

Delving deeper into nitinol's martensite vs austenite transformation opens up a world of possibilities for engineers and researchers alike. Understanding the intricate dance between these two phases allows us to manipulate nitinol's properties precisely, leading to once-impossible innovations. With this knowledge, we can push the boundaries of what is achievable in fields such as aerospace and automotive engineering.

Embracing the Future of Memory Alloys

Embracing the future of memory alloys means stepping into a world where traditional limitations are shattered, and new possibilities emerge. With materials like nitinol, we can push the boundaries of what was once impossible in the healthcare and aerospace industries. The resilience and adaptability of these alloys open doors to innovation and creativity that were previously unimaginable, paving the way for a future filled with groundbreaking advancements and transformative technologies. As we continue to unlock the potential of shape memory materials, we are not just embracing the future - we are shaping it with our own hands.

Unlocking the Potential of Shape Memory Materials

Unlocking the potential of shape memory materials like nitinol opens doors to revolutionary advancements in engineering and design. By tapping into the science behind these remarkable alloys, we can create smarter, more efficient solutions that push boundaries and redefine what's possible in various industries. The key lies in understanding how nitinol works and using this knowledge to unlock a world of endless possibilities.