Introduction

Are you ready to dive into the fascinating world of Nitinol? This incredible shape memory alloy has captured the imagination of scientists, engineers, and innovators around the globe. From its unique properties to its wide-ranging applications, Nitinol continues to amaze and inspire with its endless possibilities.

Understanding the Basics of Nitinol

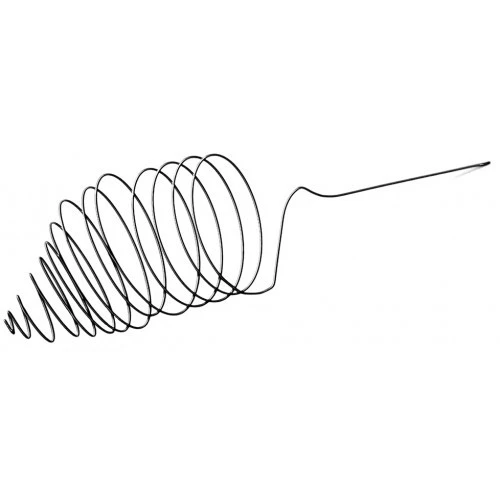

To truly appreciate the wonders of Nitinol, it's essential to understand its composition and properties. This remarkable metal alloy, comprised primarily of nickel and titanium, exhibits extraordinary characteristics such as shape memory effect and superelasticity.

Unraveling the Mysteries of Nitinol

Nitinol's mysteries lie in its ability to remember its original shape and return to it when subjected to specific stimuli. This phenomenon, known as the shape memory effect, has revolutionized the healthcare and aerospace industries.

Exploring the Wonders of Nitinol

Nitinol, a shape-memory alloy with extraordinary properties, has found its way into many applications. Let’s explore some of the most exciting uses for this remarkable material.

- Medical Devices: Nitinol's biocompatibility and shape-memory effects make it ideal for stents, orthodontic wires, and surgical instruments.

- Automotive Components: This shape-memory alloy is used in actuators, sensors, and other components due to its strength, corrosion resistance, and ability to recover its original shape.

- Consumer Products: From eyeglass frames to self-adjusting clothing, Nitinol’s unique properties enhance the functionality and durability of everyday items.

Nitinol's possibilities are endless, and its impact on various industries is only set to grow. As we continue innovating and discovering new applications, we expect to see even more remarkable advancements driven by this extraordinary material.

What is Nitinol?

Nitinol, a nickel-titanium alloy, is renowned for its unique properties and applications across various industries. Nitinol is composed of approximately 50% nickel and 50% titanium, which exhibits remarkable shape memory and superelasticity, making it a highly sought-after material in engineering and manufacturing.

Composition and Properties of Nitinol

Nitinol's composition, with equal parts of nickel and titanium, allows it to remember its original shape and return to it when subjected to heat or pressure. This shape memory effect makes Nitinol invaluable in medical devices such as stents and orthodontic wires, where precise shaping is crucial for successful treatment.

Unique Characteristics of Nitinol

Nitinol's superelasticity allows it to undergo significant deformation without permanent damage, making it ideal for automotive engineering and aerospace technology applications. Its ability to recover its original form after being bent or twisted makes it a reliable choice for critical components in these fields.

Nitinol's superelasticity also makes it a valuable material for medical devices, such as stents and orthodontic wires. Its ability to withstand deformation without permanent damage allows these devices to be inserted into the body with minimal risk of breakage or failure. This unique characteristic has revolutionized the field of medical technology, providing patients with safer and more reliable treatment options.

Applications of Nitinol in Various Industries

From intricate medical devices to durable fishing wire and muscle-like actuators, Nitinol's versatility extends across multiple sectors. Its unique combination of properties has been used in consumer products like eyeglass frames and mobile phone antennas, showcasing the adaptability of this remarkable material.

Remember that when searching for nitinol wire prices where to buy, quality should be prioritized over cost. The price for nitinol may vary depending on the specific requirements, such as size, shape, and quantity needed. For those seeking nitinol wire prices in the USA or other regions, consulting with reputable suppliers is key to obtaining competitive pricing.

In conclusion, the composition and properties of Nitinol make it an exceptional material with a wide range of applications across different industries. Its unique characteristics allow for innovative solutions that continue to push the boundaries of what's possible in engineering and manufacturing. Whether used in medical devices or consumer products, the potential of Nitinol remains an exciting frontier worth exploring further.

How Does Nitinol Work?

Shape Memory Effect in Nitinol

Nitinol's shape memory effect is one of its most fascinating properties. This unique characteristic allows the material to remember its original shape and return to it when heated, even after being deformed. This makes it ideal for applications such as stents in medical devices, where it can be compressed for insertion and then return to its original shape once inside the body.

Nitinol's superelasticity is another remarkable property that differentiates it from other materials. This allows the alloy to undergo large deformations and return to its original shape when the stress is removed. As a result, Nitinol is widely used in orthodontic wires, where it can apply continuous forces to move teeth into their correct positions without breaking. Its ability to withstand repeated bending and twisting makes it an ideal choice for applications requiring durable and resilient materials.

Superelasticity of Nitinol

Another remarkable feature of nitinol is its superelasticity, also known as pseudoelasticity. This means the material can undergo large deformations and return to its undeformed shape when the external force is removed. This property makes nitinol perfect for orthodontic wires, where it can continuously apply a gentle force to move teeth into position without breaking.

Furthermore, nitinol's superelasticity also makes it an ideal material for use in medical stents. When inserted into a blood vessel, a nitinol stent can expand and contract with the vessel, providing support and preventing blockages without causing damage. This unique property has revolutionized the treatment of cardiovascular diseases, offering patients a less invasive and more effective solution for maintaining healthy blood flow.

Deformation and Recovery of Nitinol

Nitinol exhibits a reversible phase transformation under stress, allowing it to recover its original shape after deforming. This ability to repeatedly deform and recover without experiencing permanent damage makes nitinol an excellent choice for applications such as actuators in robotics, where precise and reliable movement is crucial.

Nitinol's unique ability to recover its original shape after deforming has also made it an ideal material for medical devices such as stents and guidewires. Its superelasticity allows these devices to be easily inserted into the body and then expand or contract as needed, providing essential support to blood vessels and ensuring the success of minimally invasive procedures. This remarkable property has revolutionized the field of interventional cardiology and significantly improved patient outcomes.

Crafting Nitinol Materials

When crafting Nitinol materials, GEE SMA stands out for its expertise in Nitinol production. With years of experience and cutting-edge technology, GEE SMA ensures the highest quality in every component it creates. Its skilled team is dedicated to customizing Nitinol materials to meet specific requirements, making it a top choice for industries seeking reliable and tailored solutions.

GEE SMA's Expertise in Nitinol Production

GEE SMA's expertise in Nitinol production is unmatched. They utilize advanced techniques and state-of-the-art equipment to ensure precision and consistency in every material they craft. Their commitment to innovation and quality makes them a trusted partner for businesses looking to incorporate Nitinol into their products.

Quality and Customization of Nitinol Components

GEE SMA offers the highest quality and customization of Nitinol components. From shape memory alloy nitinol wire to nitinol muscles, its diverse range of products caters to a wide array of applications across various industries. Whether it's medical devices or consumer products, GEE SMA delivers top-notch components tailored to specific needs.

Nitinol Wire Price and Availability

For those wondering about the price of nitinol or where to buy nitinol wire, GEE SMA provides competitive pricing and availability options that suit different budgets and timelines. Their commitment to customer satisfaction extends beyond the quality of their materials, ensuring that businesses can access premium Nitinol components without breaking the bank.

In addition to offering competitive pricing, GEE SMA provides flexible availability options to accommodate different project timelines. Whether you need nitinol wire for a quick turnaround project or a longer-term production schedule, GEE SMA has the resources and expertise to meet your needs. This flexibility level ensures businesses can rely on GEE SMA as a dependable source for their nitinol wire requirements.

Practical Uses of Nitinol

With its unique properties and versatility, Nitinol has found widespread applications in various industries. One of the most significant areas where nitinol has profoundly impacted is the development of medical devices. From stents and guidewires to orthodontic wires and surgical tools, nitinol's shape memory effect and superelasticity have revolutionized medicine, offering innovative solutions for minimally invasive procedures and patient care.

Medical Devices and Nitinol

The automotive and aerospace industries have also embraced nitinol's remarkable properties. Its ability to withstand extreme conditions, such as high temperatures and repetitive stress, makes it an ideal material for components like actuators, sensors, and springs in these sectors. The use of nitinol in these industries has led to advancements in fuel efficiency, safety systems, and overall vehicle and aircraft performance.

Nitinol in Automotive and Aerospace Industries

In addition to its critical roles in healthcare and transportation, nitinol has also made its way into consumer products. From eyeglass frames that can return to their original shape after being bent to lightweight fishing wire that maintains tension while resisting corrosion, nitinol's unique properties have enhanced the durability and functionality of various everyday items.

Nitinol in Consumer Products

Nitinol, a remarkable alloy, is revolutionizing the consumer product industry with its exceptional properties. This shape-memory material has found innovative applications across various products, including:

- Eyewear: Nitinol frames are flexible and durable, resisting bending and twisting without losing their original shape.

- Consumer Electronics: Bendable smartphone cases leverage Nitinol's flexibility and resilience to protect devices while offering a unique design.

- Underwear and Orthodontics: Nitinol's ability to remember its shape makes it ideal for comfortable and effective bra underwires and orthodontic wires.

As consumer preferences shift towards innovative and long-lasting products, Nitinol's potential to shape the future of consumer goods is undeniable.

The Future of Nitinol

Innovations and Developments in Nitinol Technology

Innovations and developments in Nitinol technology drive the creation of advanced medical devices, automotive components, and consumer products. Researchers are constantly exploring new ways to enhance the properties of nitinol, such as by improving its superelasticity and shape memory effect. These advancements are revolutionizing how we use Nitinol in various industries, paving the way for cutting-edge applications and solutions.

Advancements in Nitinol Manufacturing Processes

With the increasing demand for Nitinol materials, manufacturers invest in state-of-the-art production processes to meet the market's needs. This has improved manufacturing efficiency, resulting in a more cost-effective production of Nitinol components. As a result, the price for Nitinol wire and sheet has become more competitive, making it more accessible for a wide range of applications.

With the increasing demand for Nitinol materials, manufacturers invest in state-of-the-art production processes to meet the market's needs. This has improved manufacturing efficiency, resulting in a more cost-effective production of Nitinol components. As a result, the price for Nitinol wire and sheet has become more competitive, making it more accessible for a wide range of applications.

Nitinol's Role in Sustainable Solutions

Nitinol is a standout material in the growing pursuit of sustainability. Its unique properties make it a valuable asset in creating a greener future.

Nitinol offers several advantages for sustainable solutions:

- Durability and recyclability: Reducing waste and conserving resources.

- Energy efficiency: Lowering energy consumption in various applications.

- Shape memory properties: Enabling reusability and minimizing waste.

From extending the lifespan of medical implants to enhancing the efficiency of automotive components, Nitinol's versatility drives innovation in sustainable industries. By harnessing the potential of this remarkable material, we can make significant strides towards a more environmentally responsible world.

Unlock the Potential of Nitinol

With its unique properties and applications, Nitinol has truly unlocked a world of potential for various industries. Its shape memory effect and superelasticity have revolutionized the way we approach material science and engineering, embracing its versatility in countless applications.

Nitinol has proven to be a game-changer in medical devices, the automotive, and aerospace industries. Its ability to return to a predetermined shape after deformation has paved the way for innovations in minimally invasive medical procedures and cutting-edge engineering solutions.

Embracing the Versatility of Nitinol

The price for Nitinol wire may vary depending on size, quality, and customization. However, GEE SMA offers competitive prices for Nitinol wire in the USA, ensuring accessibility for those looking to harness the power of this remarkable metal fishing wire.

Exploring New Frontiers with Nitinol Technology

As we look towards the future, advancements in Nitinol manufacturing processes will continue to push boundaries and open up new possibilities. With an eye toward sustainable solutions, Nitinol's role in shaping a greener future is becoming increasingly apparent.