Introduction

Welcome to the fascinating world of Nitinol Spring Actuators, where innovation meets precision engineering. Nitinol, a shape memory alloy, has revolutionized the field of actuators with its unique properties and versatility. From medical devices to aerospace technology, Nitinol Actuators have shown immense potential in various applications, making it a highly sought-after material in precision engineering.

Understanding Nitinol Spring Actuators

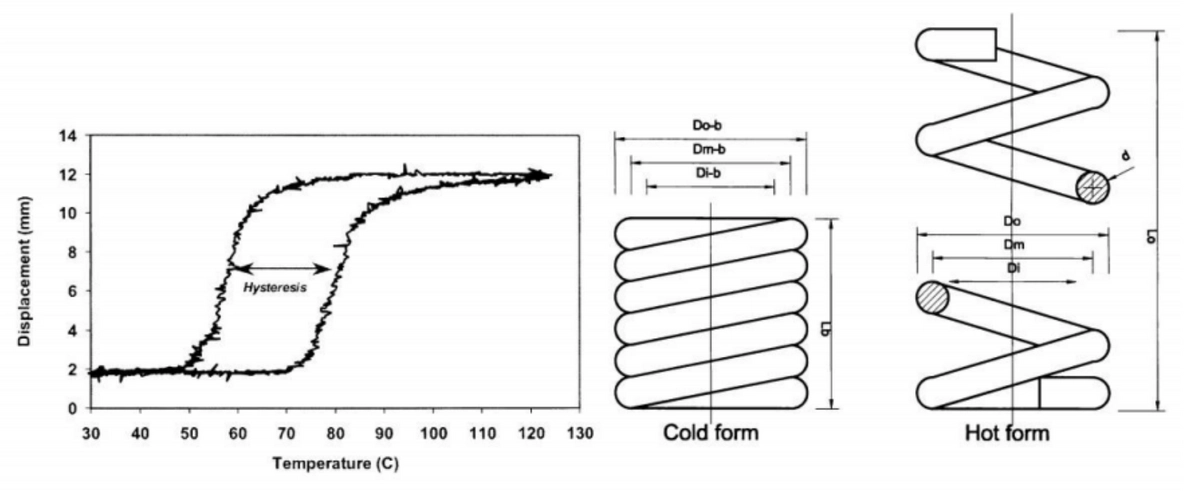

Nitinol Spring Actuators are a type of actuator made from Nitinol Shape Memory Alloys (SMA), which have the ability to remember their original shape and return to it when heated. This remarkable property allows for precise and controlled movement in various applications such as robotics, automotive engineering, and consumer electronics.

Exploring the Potential of Nitinol Actuators

The potential of Nitinol Actuators lies in their ability to provide efficient and reliable performance in demanding environments. With its unique shape memory properties, Nitinol offers a wide range of possibilities for designing innovative solutions that require compact and precise actuation.

The Versatility of Nitinol in Precision Applications

Nitinol's versatility in precision applications is unmatched, as it can be tailored to meet specific design requirements for various industries. From medical implants to microsurgical tools, the adaptability of Nitinol Spring Actuators makes them an ideal choice for achieving high levels of accuracy and control.

What is a Nitinol Actuator?

Nitinol spring actuators are devices that utilize the unique properties of Nitinol shape memory alloys to produce mechanical movement. When heated, Nitinol memory spring coils return to their original shape, allowing for precise and repeatable actuation in various applications.

The Science Behind Nitinol Shape Memory Alloys

Nitinol actuators work by utilizing the unique properties of the alloy to create mechanical motion. When the Nitinol is deformed at a lower temperature, it takes on a martensitic structure, which allows it to be easily manipulated into a new shape. Then, when heat is applied, the Nitinol undergoes a phase transformation back to its original austenitic structure, causing it to revert to its original shape. This process of deformation and recovery can be harnessed to create movement in various devices and systems.

How Nitinol Actuators Work

Nitinol actuators are widely used in precision engineering due to their ability to produce highly controlled and repeatable mechanical movement. This makes them ideal for applications such as micro-positioning, valve control, and other tasks that require precise and reliable actuation. Additionally, Nitinol actuators can be designed to operate silently and with minimal power consumption, making them suitable for use in sensitive environments or in battery-powered devices. Overall, the shape memory effect of Nitinol actuators offers a unique combination of performance characteristics that make them a valuable tool in precision engineering applications.

Applications of Nitinol Actuators in Precision Engineering

Nitinol actuators find wide-ranging applications in precision engineering, including medical devices, aerospace components, robotics, and automotive systems. Their ability to provide precise and reliable actuation makes them invaluable in industries where accuracy is paramount.

Nitinol actuators are also utilized in the field of adaptive optics, where they play a crucial role in adjusting and controlling the shape of mirrors and lenses with extreme precision. This application is particularly important in astronomical telescopes and high-powered microscopes, where maintaining optimal optical performance is essential for capturing clear and detailed images. By leveraging the unique properties of Nitinol, these actuators enable real-time adjustments to compensate for atmospheric disturbances or other environmental factors that can affect the quality of optical systems.

Advantages and Disadvantages of Nitinol

The Benefits of Using Nitinol Actuators

Nitinol spring actuators offer numerous advantages in precision engineering applications. These shape memory alloys provide exceptional flexibility, allowing for intricate movements and precise control. Additionally, their unique ability to return to a predetermined shape after deformation makes them ideal for various mechanical and biomedical applications.

Potential Drawbacks and Limitations of Nitinol

Despite their many benefits, nitinol actuators also have some limitations. One of the main disadvantages of nitinol is its relatively high cost compared to traditional materials. Additionally, working with nitinol requires specialized knowledge and equipment, which can pose challenges for manufacturers and engineers.

Overcoming Challenges in Working with Nitinol Spring Actuators

To overcome the challenges associated with working with nitinol spring actuators, it's essential to partner with a reputable supplier like GEE SMA that specializes in crafting high-quality materials and components. By leveraging the expertise of a trusted provider, engineers can ensure the successful integration of nitinol components into their precision applications.

Cost and Purpose of Spring Actuators

Exploring the Cost-effectiveness of Nitinol Actuators

Nitinol spring actuators are cost-effective solutions for precision engineering applications, offering long-term durability and reliability. While the initial investment may be higher than traditional actuators, the extended lifespan and low maintenance requirements make nitinol actuators a cost-efficient choice in the long run. GEE SMA specializes in producing high-quality nitinol memory spring coils at competitive prices, ensuring that customers receive exceptional value for their investment.

Nitinol spring actuators are also known for their high energy efficiency, making them an environmentally friendly choice for precision engineering applications. By utilizing the unique properties of nitinol, these actuators require minimal power input to operate, reducing overall energy consumption and lowering operational costs. This makes them a sustainable and cost-effective solution for businesses looking to minimize their environmental impact while maximizing efficiency.

Understanding the Purpose and Functionality of Spring Actuators

The purpose of a spring actuator is to convert energy into mechanical motion through the use of a spring-like component. Nitinol spring actuators utilize shape memory alloys to achieve precise and controlled movements, making them ideal for applications that require accurate positioning and fine adjustments. With their unique functionality, nitinol spring actuators offer unparalleled versatility in various industries, from medical devices to aerospace engineering.

Nitinol spring actuators are widely used in the medical field for applications such as minimally invasive surgery, where precise and controlled movements are essential. These actuators can be utilized in surgical tools and devices to provide accurate positioning and fine adjustments, allowing for more efficient and effective procedures. Additionally, nitinol spring actuators have also found applications in aerospace engineering, where their versatility and reliability make them valuable components in various systems and mechanisms used in aircraft and spacecraft.

Real-world Applications of Nitinol Spring Actuators

Nitinol spring actuators find extensive use in real-world applications such as minimally invasive surgical instruments, where their small size and precise motion control capabilities are essential for delicate procedures. Additionally, they are employed in robotics for intricate movements and in automotive systems for efficient energy conversion. GEE SMA's nitinol actuators products have been integral in powering cutting-edge technologies across diverse industries, showcasing the practicality and effectiveness of these innovative components.

Nitinol Actuators Products

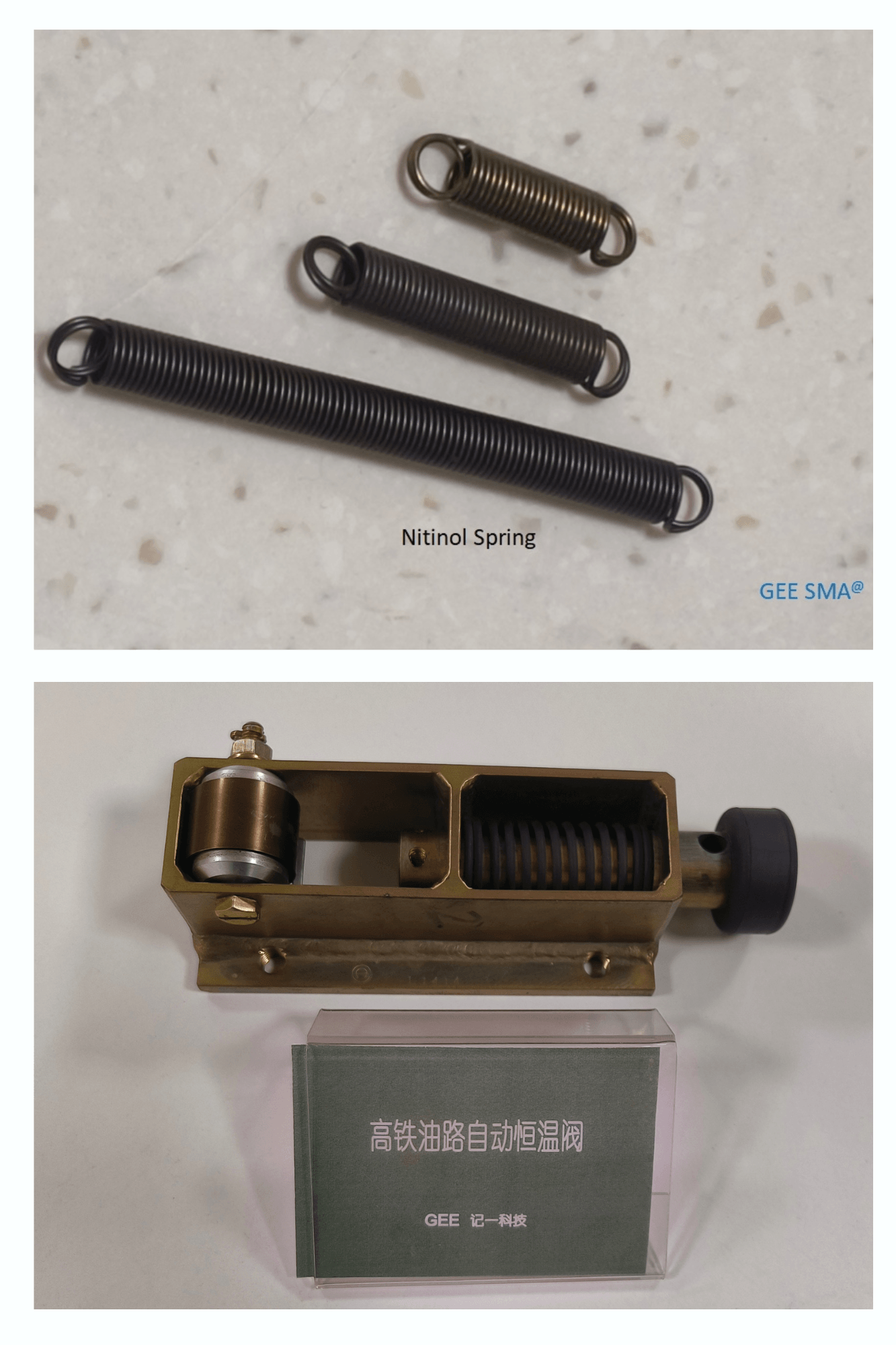

GEE SMA offers a diverse range of nitinol spring actuators, including nitinol memory spring coils, designed for precision applications in various industries. Our products are meticulously crafted to meet the unique needs of our customers, ensuring high performance and reliability.

Diverse Range of Nitinol Actuators Available

Our catalog includes a wide selection of nitinol actuators, ranging from standard sizes to custom designs. Whether you need a specific shape or size for your application, GEE SMA can provide the perfect nitinol spring actuator to meet your requirements.

With our extensive range of nitinol actuators, you can choose from various shapes and sizes to suit your specific application needs. Whether you require a standard size or a completely custom design, GEE SMA has the expertise to deliver the perfect nitinol spring actuator for your project. Our team is dedicated to providing tailored solutions that meet your exact requirements, ensuring optimal performance and reliability.

Customization Options for Nitinol Spring Actuators

As a leader in nitinol spring actuator technology, we pride ourselves on our ability to provide customization options that meet the unique specifications of each project. Whether you require specific dimensions, material composition, or performance characteristics, our team of experts is dedicated to working with you to tailor the components to fit your exact needs. This level of customization ensures that your nitinol spring actuators will deliver optimal performance and reliability in your specific application, giving you peace of mind and confidence in the quality of our products.

Quality Assurance and Reliability of Nitinol Actuators

Quality is our top priority at GEE SMA. Our nitinol actuators undergo rigorous testing and inspection to ensure they meet the highest standards of reliability and performance. You can trust that our products will deliver consistent results in your precision applications.

Our commitment to quality extends beyond just meeting industry standards. We continuously invest in research and development to push the boundaries of nitinol technology, ensuring that our actuators are at the forefront of innovation. By staying ahead of the curve, we can offer you cutting-edge solutions that outperform traditional actuators in precision applications.

Tailoring Nitinol for Precision Applications

GEE SMA specializes in the production of Nitinol Shape Memory Alloys, crafting high-quality materials and components that are ideal for precision applications. Our expertise lies in tailoring Nitinol spring actuators and memory spring coils to meet the unique requirements of our customers, ensuring that they are perfectly suited for their intended purpose.

Crafting High-Quality Materials with GEE SMA

At GEE SMA, we take pride in our ability to produce top-notch Nitinol spring actuators and memory spring coils that are durable, reliable, and high-performing. Our advanced manufacturing processes and stringent quality control measures guarantee that our materials meet the highest standards, making them ideal for precision engineering applications. In addition to our standard product offerings, we also excel in addressing unique requirements by providing tailored Nitinol components that are customized to meet specific design and performance needs. Whether it's a custom shape or size, or a unique functionality requirement, our team of experts can work with you to create the perfect solution for your application.

Addressing Unique Requirements with Tailored Nitinol Components

We understand that every customer has unique needs and specifications when it comes to Nitinol components. That's why we work closely with our clients to address their specific requirements, offering customized solutions that perfectly align with their project goals. Whether it's a specialized shape or a specific performance characteristic, we have the expertise to tailor Nitinol components accordingly.

In addition to offering customized solutions for unique Nitinol component needs, we also prioritize product quality and customer satisfaction. Our team is committed to delivering high-quality components that meet the exact specifications and performance characteristics required by our clients. By working closely with our customers, we ensure that the tailored Nitinol components not only align with their project goals but also exceed their expectations in terms of quality and functionality.

Enhancing Product Quality and Customer Satisfaction

By customizing Nitinol components to meet the specific requirements of our clients, we not only improve the overall quality of our products but also guarantee customer satisfaction. Our dedication to providing personalized solutions ensures that our materials perform exceptionally well in their designated applications, leading to delighted customers who have confidence in the dependability of our products. This tailored approach also allows us to build strong and lasting relationships with our clients, as they recognize the value and attention to detail we put into meeting their unique needs.

Conclusion

Nitinol spring actuators have proven to be a game-changer in precision engineering, offering unparalleled versatility and reliability. GEE SMA's expertise in crafting high-quality Nitinol components ensures that the potential of Nitinol actuators is fully explored, overcoming limitations and challenges with innovative solutions. By tailoring Nitinol components to meet unique customer needs, GEE SMA continues to lead the way in precision applications.

Exploring the Potential of Nitinol Actuators

The potential of Nitinol spring actuators is vast, with applications ranging from medical devices to aerospace technology. With GEE SMA's dedication to enhancing product quality and addressing customer requirements, the possibilities for Nitinol actuators are endless.

Overcoming Limitations and Challenges with Nitinol

While there are disadvantages to using Nitinol, such as potential drawbacks and limitations, GEE SMA's expertise allows for innovative solutions to overcome these challenges. By continuously improving manufacturing processes and materials, GEE SMA ensures that the full potential of Nitinol is realized.

Tailoring Nitinol Components to Meet Unique Customer Needs

GEE SMA's commitment to tailoring Nitinol components to meet unique customer needs sets them apart in the industry. By understanding the specific requirements of each customer and providing customized solutions, GEE SMA ensures that every application of Nitinol spring actuators is optimized for success.