Introduction

Nitinol medical sheets have revolutionized the field of medical devices, offering a unique combination of properties that make them ideal for various healthcare applications. From their shape memory and superelasticity to their biocompatibility and corrosion resistance, nitinol sheets have sparked a new wave of innovation in the medical industry. As we delve into the potential of nitinol sheets for medical devices, it's crucial to understand their profound impact on healthcare innovation, paving the way for improved treatment outcomes and patient care.

Advantages of Nitinol Medical Sheets

Nitinol's shape memory and other properties make it a valuable material for medical devices.

Here's why nitinol medical sheets are advantageous:

- Shape Memory: Nitinol can be deformed and then return to its original shape when exposed to heat or stress. This allows for minimally invasive procedures where the device is compressed for insertion and then expands to its intended form inside the body.

- Flexibility and Durability: Nitinol is incredibly flexible and resistant to fatigue, ensuring the devices can withstand the body's movements without breaking or losing shape over time. This is crucial for long-term implants like stents.

Nitinol medical sheets offer unique properties that contribute to developing advanced, adaptable, and long-lasting medical devices.

Exploring the Potential of Nitinol Sheets for Medical Devices

The potential of nitinol sheets extends beyond traditional medical devices, with researchers and innovators exploring new ways to harness their properties for cutting-edge healthcare solutions. From orthopedic implants to surgical instruments, nitinol's unmatched characteristics offer promising avenues for improving patient care and advancing medical technology.

The unique properties of nitinol sheets also make them ideal for use in minimally invasive medical procedures. Their flexibility and shape memory allow the creation of innovative tools and devices to navigate through small incisions with precision, reducing trauma to surrounding tissues and improving patient recovery times. As researchers continue to explore the potential applications of nitinol in this area, we can expect to see a new generation of surgical instruments that offer enhanced performance and improved patient outcomes.

The Impact of Nitinol Medical Sheets in Healthcare Innovation

Integrating nitinol medical devices has significantly transformed healthcare practices by enhancing treatment outcomes and patient comfort. With its widespread adoption in various clinical settings, nitinol technology has set a new standard for medical device performance and safety.

The widespread adoption of nitinol technology in various clinical settings has improved treatment outcomes and patient comfort. Still, it has also led to a new medical device performance and safety standard. Using nitinol medical sheets has allowed for more precise and minimally invasive procedures, reducing the risk of complications and shortening recovery times. This has ultimately resulted in a positive impact on healthcare innovation, as it continues to push the boundaries of what is possible regarding patient care and treatment options.

Now, let's explore how ethical considerations are crucial in utilizing this groundbreaking technology in healthcare practices.

The Unique Properties of Nitinol Sheets

Nitinol medical sheets are renowned for their unique properties, which make them ideal for various medical applications. One of the most remarkable features is their shape memory and superelasticity, which allow them to return to their original shape after deformation, making them perfect for minimally invasive procedures. Additionally, nitinol sheets exhibit excellent biocompatibility and corrosion resistance, ensuring they can be safely used within the human body without adverse reactions. Furthermore, their flexibility and fatigue resistance make them durable and reliable for long-term use in medical devices.

1. Shape Memory and Superelasticity

Nitinol sheets can remember their original shape and return to it when subjected to heat or stress. This unique property enables the creation of innovative medical devices, such as self-expanding stents that can be deployed with precision in blood vessels or other anatomical structures. The superelasticity of nitinol allows these devices to withstand significant deformation without permanent damage, providing flexibility not achievable with traditional materials.

In addition to their remarkable shape memory and superelasticity, nitinol sheets also exhibit excellent biocompatibility and corrosion resistance, making them ideal for use in medical devices. Nitinol's ability to interact favorably with the human body reduces the risk of adverse reactions or rejections when implanted, ensuring the safety and effectiveness of medical treatments. Furthermore, its corrosion resistance ensures that nitinol devices can maintain their structural integrity over time, providing long-lasting support within the body.

2. Biocompatibility and Corrosion Resistance

In medical technology, biocompatibility is crucial to ensure that materials implanted in the body do not trigger adverse reactions from the immune system or surrounding tissues. Nitinol's excellent biocompatibility makes it an ideal choice for implants and devices that come into direct contact with bodily fluids or tissues. Moreover, its corrosion resistance ensures longevity and reliability in medical applications where exposure to bodily fluids is inevitable.

Nitinol's flexibility is another key factor that makes it a top choice for medical implants and devices. Its unique ability to return to its original shape after deforming allows for greater design flexibility and customization in medical applications. This means that Nitinol implants can be tailored to fit each patient's unique anatomy, leading to better outcomes and improved patient comfort.

3. Flexibility and Fatigue Resistance

The flexibility of nitinol sheets allows for creating intricate designs that can conform to complex anatomical structures within the body. This property is particularly valuable in developing catheters and guidewires used in minimally invasive procedures where precise navigation through narrow passages is essential. Additionally, nitinol's fatigue resistance ensures that devices made from this material can withstand repeated use without experiencing structural failure or degradation over time.

Applications of Nitinol Medical Sheets

Nitinol medical sheets have revolutionized the field of medical devices. Their unique properties make them ideal for various applications.

1. Stents and Stent Delivery Systems

Nitinol sheets are widely used in the production of stents and stent delivery systems due to their shape memory and superelasticity, allowing for easy insertion and expansion within the body. The flexibility and fatigue resistance of nitinol sheets also make them a preferred material for these critical cardiovascular devices.

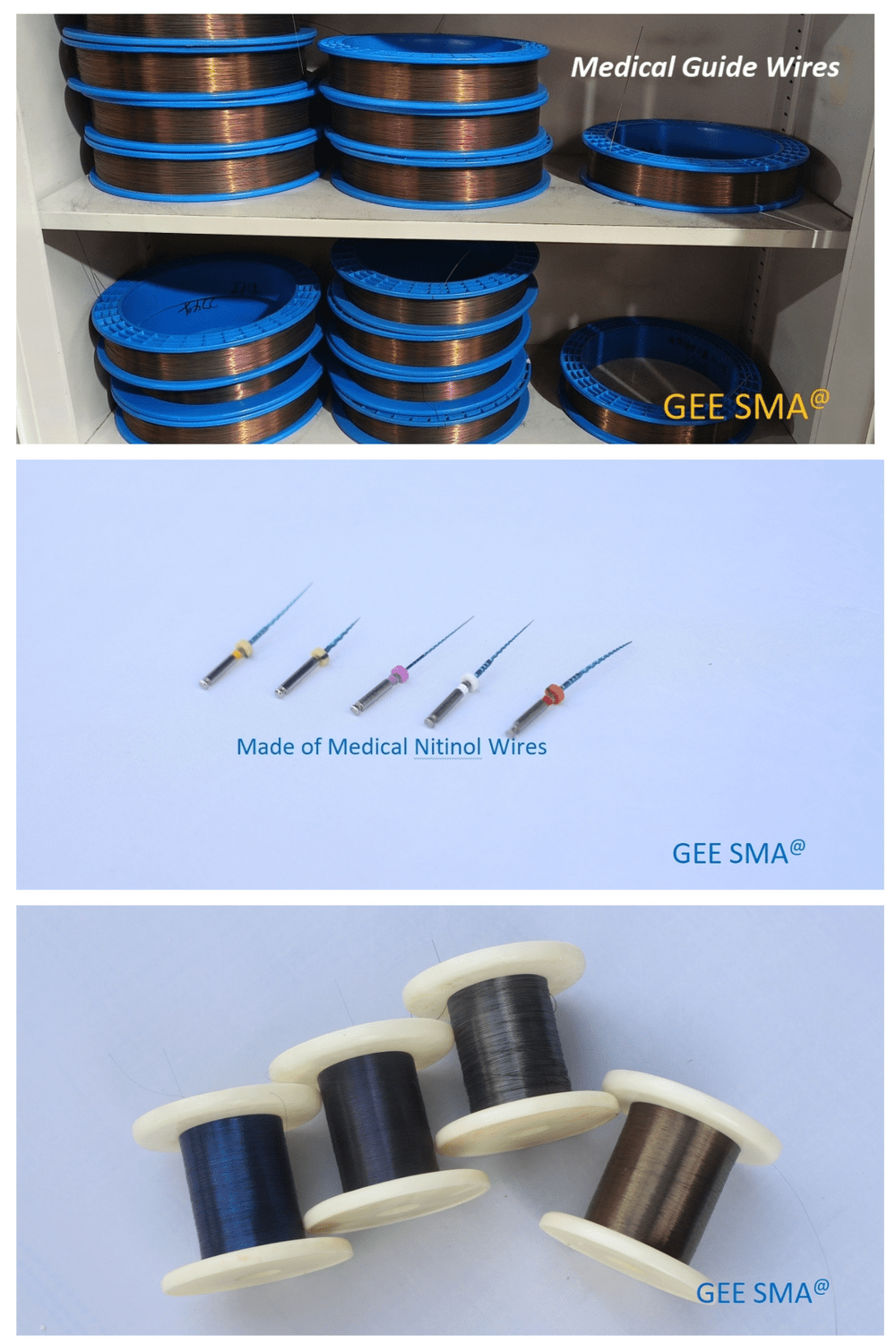

Nitinol sheets are essential for stents and stent delivery systems and play a crucial role in the production of guide wires and catheters. The shape memory and superelasticity of nitinol allow these medical devices to navigate through the body's intricate pathways with ease, providing physicians with the precision and control necessary for successful procedures. Additionally, the fatigue resistance of nitinol ensures that guide wires and catheters can withstand the rigors of repeated use, making them a reliable choice for medical professionals.

2. Guide Wires and Catheters

Nitinol sheets' biocompatibility and corrosion resistance make them perfect for guide wires and catheters, ensuring patient safety during minimally invasive procedures. Their ability to maintain shape while navigating blood vessels or organs is crucial for successful medical interventions.

In addition to their biocompatibility and corrosion resistance, nitinol sheets offer excellent flexibility and kink resistance, making them ideal for guide wires and catheters. This allows for smooth navigation through the body's intricate pathways, reducing the risk of injury to delicate tissues. Furthermore, the durability of nitinol ensures that guide wires and catheters can withstand the rigors of medical procedures, providing reliable support for healthcare professionals.

3. Orthopedic Implants and Surgical Instruments

The unique properties of nitinol sheets benefit orthopedic implants and surgical instruments, providing long-term durability, reliability, and enhanced patient comfort during procedures. Nitinol's flexibility allows for the creation of innovative orthopedic implants that adapt to the body's movements.

Orthopedic implants and surgical instruments benefit from the unique properties of nitinol sheets, providing long-term durability, reliability, and enhanced patient comfort during procedures. The flexibility of nitinol allows for the creation of innovative orthopedic implants that adapt to the body's movements. This adaptability is particularly beneficial in joint replacement surgeries, where patients can experience an improved range of motion and reduced risk of implant failure. Additionally, nitinol's biocompatibility makes it an ideal material for orthopedic implants, as it minimizes the risk of adverse reactions or rejections by the body.

FDA Guidance on Nitinol Medical Devices

Compliance with Regulatory Standards

Adhering to the strict regulatory standards set by the FDA is crucial for the production and use of nitinol medical devices. These standards ensure that the devices are manufactured and utilized in a manner that prioritizes patient safety and well-being. By complying with these regulations, manufacturers and healthcare providers can instill confidence in the reliability and efficacy of nitinol medical sheets.

Ensuring Safety and Efficacy

The FDA guidance for nitinol medical devices emphasizes the need to prioritize safety and efficacy throughout all stages of development, from design to clinical use. This involves thorough testing and evaluation to guarantee that these devices perform as intended without harming patients. By upholding these standards, healthcare professionals can confidently rely on nitinol sheets for various medical applications.

Navigating the Approval Process

Navigating the FDA approval process for nitinol medical devices requires meticulous attention to detail and adherence to regulatory requirements. This involves submitting comprehensive data on device performance, biocompatibility, and material properties, among other factors. By carefully navigating this process, manufacturers can ensure that their nitinol medical sheets meet all necessary criteria for approval and subsequent use in clinical settings.

Incorporating Nitinol technology into medical devices requires a deep understanding of ethical considerations and compliance with regulatory standards set by organizations like the FDA. Uni Health Medical PC is committed to upholding these principles while embracing innovation in healthcare delivery.

Advantages for Healthcare Providers and Patients

Improved Treatment Outcomes

Nitinol medical sheets offer healthcare providers the advantage of improved treatment outcomes due to their unique properties, such as shape memory and flexibility. These qualities allow for precise placement of medical devices, leading to better procedural success rates and patient recovery. Using nitinol sheets in stents and orthopedic implants has shown promising results in enhancing patient health outcomes.

Enhanced Patient Comfort and Recovery

Healthcare providers also benefit from nitinol medical devices as they enhance patient comfort and quicker recovery times. The biocompatibility and fatigue resistance of nitinol sheets reduce the risk of adverse reactions, ensuring a smoother post-procedural patient experience. This ultimately leads to higher patient satisfaction and improved overall healthcare delivery.

Long-Term Durability and Reliability

Furthermore, nitinol medical devices' long-term durability and reliability provide healthcare providers with a cost-effective solution for patient care. Nitinol sheets exhibit corrosion resistance, ensuring the longevity of implanted devices while maintaining their structural integrity over time. This translates to reduced need for device replacements, lowering healthcare costs and improving resource allocation.

Ethical Considerations in Using Nitinol Medical Sheets

Nitinol medical sheets have revolutionized the healthcare industry, but ethical considerations must be carefully examined. Beneficence and non-maleficence are crucial in ensuring that nitinol sheets benefit patients without causing harm. When incorporating this innovative technology into medical devices, healthcare providers must prioritize patient well-being and safety.

1. Beneficence and Non-maleficence

Integrating nitinol sheets into medical devices should prioritize beneficence by promoting patient welfare and improving treatment outcomes. At the same time, non-maleficence requires healthcare professionals to avoid causing harm or potential risks to patients when utilizing nitinol technology in medical interventions. Striking a balance between these ethical principles is essential for the responsible adoption of nitinol medical sheets.

2. Autonomy and Justice

Respecting patient autonomy is fundamental when considering the use of nitinol medical devices. This allows individuals to make informed decisions about their treatment options involving this innovative material. Furthermore, justice must be upheld to ensure fair access to advanced healthcare technologies like nitinol sheets for all patients, regardless of socioeconomic status or geographical location.

3. Ethical Decision-Making in Healthcare

Ethical decision-making processes should be followed rigorously when incorporating nitinol medical sheets into developing new medical devices. This involves considering the potential benefits and risks associated with using nitinol technology and consulting with patients and relevant stakeholders to ensure that ethical standards are upheld throughout the innovation process.

By carefully considering beneficence, non-maleficence, autonomy, and justice in conjunction with adopting nitinol medical sheets for healthcare applications, ethical integrity can be maintained while embracing technological advancements for improved patient care.

Conclusion

Nitinol medical sheets offer unprecedented potential for revolutionizing medical device innovation, providing enhanced performance and patient outcomes. With their unique properties and versatile applications, nitinol sheets are poised to drive significant advancements in healthcare technology.

Manufacturers and healthcare providers must adhere to FDA regulations and guidance when developing and utilizing nitinol medical devices. By following these standards, the safety and efficacy of these innovative technologies can be upheld, ensuring optimal patient care.

Incorporating nitinol technology into medical practice requires careful consideration of ethical principles such as beneficence, non-maleficence, autonomy, and justice. By prioritizing patient well-being and equitable access to advanced treatments, healthcare professionals can responsibly navigate the ethical implications of adopting nitinol medical sheets.

Remember that ethical decision-making is crucial in healthcare innovation, ensuring that advancements in technology are aligned with the values of patient-centered care and ethical practice. As we continue to explore the potential of nitinol sheets in medical devices, it is imperative to prioritize regulatory compliance and ethical considerations for the benefit of patients worldwide.