Introduction

Nitinol wire for guide wire is a revolutionary material that has transformed the medical device industry. This unique alloy, composed of nickel and titanium, offers exceptional flexibility and shape memory, making it ideal for crafting guide wires used in various medical procedures. The versatility of nitinol wire extends to its use in creating hydrophilic nitinol guidewires, which further enhances its performance in medical applications. The advantages of using nitinol wire for guide wires are numerous, including improved maneuverability and reduced risk of vessel damage during procedures.

Understanding Nitinol Wire for Guide Wire

Nitinol wire for guide wire is a superelastic material with the ability to return to its original shape after deformation. This property allows guide wires made from nitinol to navigate through tortuous vessels without kinking or breaking, providing physicians with greater control during procedures.

Exploring the Versatility of Nitinol Wire

Nitinol wire can be used for a wide range of medical devices beyond guide wires, including stents, orthodontic archwires, and bone anchors. Its unique properties make it an invaluable material in the field of interventional medicine and minimally invasive surgery.

The Advantages of Using Nitinol Wire for Guide Wires

The use of nitinol wire for guide wires offers several advantages over traditional materials such as stainless steel or polymer-based wires. These include enhanced flexibility, improved trackability, and reduced trauma to blood vessels and tissues during insertion and manipulation.

What is Nitinol Wire?

The Composition and Properties of Nitinol

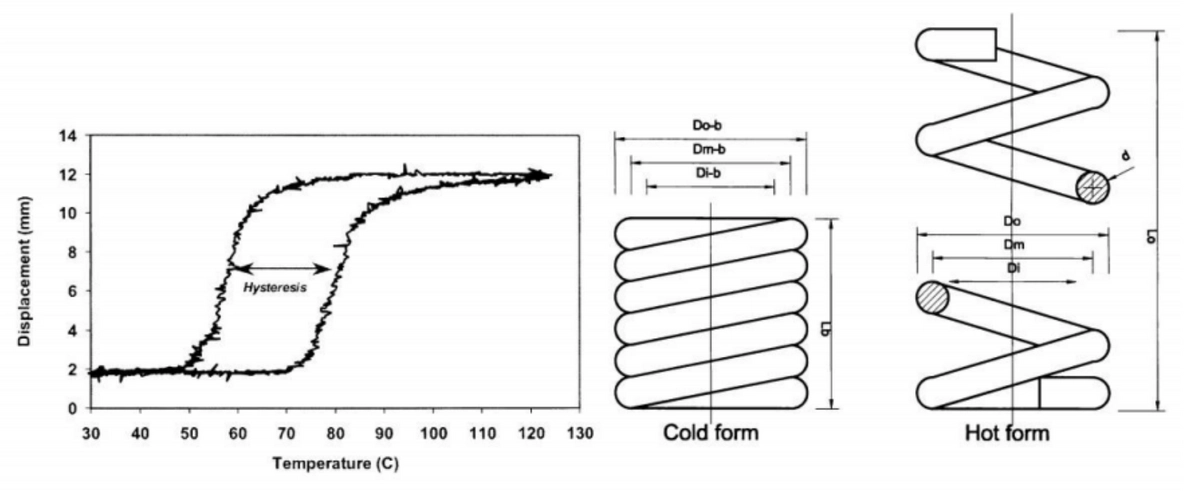

Nitinol wire is a nickel-titanium alloy known for its unique properties, including shape memory and superelasticity. It is composed of approximately 50% nickel and 50% titanium, which gives it the ability to return to a predetermined shape when heated. This makes it ideal for medical devices such as guide wires, where flexibility and resilience are crucial.

Applications of Nitinol in Medical Devices

Nitinol has a wide range of applications in medical devices, including stents, orthodontic wires, and guide wires. Its superelasticity allows it to withstand bending and kinking without permanent deformation, making it an excellent choice for devices that need to navigate through the body's intricate pathways.

Benefits of Nitinol Wire for Guide Wire

When used as a guide wire, nitinol offers several advantages such as enhanced flexibility, kink resistance, and excellent torque response. These properties make nitinol guide wires easier to maneuver through tortuous anatomies, ultimately improving the efficiency and safety of medical procedures.

Now that we have explored the composition and properties of nitinol wire and its applications in medical devices let's dive deeper into specific products like the HiWire nitinol core wire guide and hydrophilic nitinol guidewires to understand their unique features and benefits.

The HiWire Nitinol Core Wire Guide

The HiWire Nitinol Core Wire Guide is a revolutionary medical device that utilizes nitinol wire for guide wire applications. It is designed to provide exceptional flexibility and kink resistance, making it an ideal choice for navigating tortuous anatomy during medical procedures. The core wire guide is engineered to deliver superior performance and reliability, ensuring optimal outcomes for patients and healthcare professionals.

Overview of HiWire Nitinol Core Wire Guide

The HiWire Nitinol Core Wire Guide features a unique construction that incorporates advanced nitinol technology, offering exceptional shape memory and superelasticity. This allows the guide wire to effortlessly conform to the anatomy of the patient, enabling precise navigation through complex vasculature. With its hydrophilic coating, the HiWire Nitinol Core Wire Guide further enhances lubricity for smooth advancement and reduced friction during use.

The HiWire Nitinol Core Wire Guide's advanced nitinol technology also provides exceptional kink resistance, ensuring reliable performance and durability during procedures. This feature reduces the risk of wire breakage or deformation, allowing for smoother navigation and manipulation within the vasculature. Additionally, the innovative design of the guide wire minimizes the potential for vessel trauma, contributing to improved patient safety and overall procedural success.

Advantages of Using HiWire Nitinol Core Wire Guide

The utilization of nitinol wire for guide wire in the HiWire Core Wire Guide provides numerous advantages, including enhanced durability, flexibility, and trackability. Its ability to maintain shape memory ensures consistent performance throughout procedures, while its superelasticity minimizes the risk of deformation or breakage. These attributes contribute to improved procedural success rates and patient safety.

Customer Testimonials on HiWire Nitinol Core Wire Guide

Healthcare professionals have lauded the HiWire Nitinol Core Wire Guide for its exceptional performance and reliability in various clinical settings. Physicians have reported seamless navigation through challenging anatomies with minimal resistance, resulting in reduced procedure times and improved patient outcomes. Nurses have also commended the ease of use and maneuverability of the guide wire, highlighting its contribution to efficient workflow in healthcare facilities.

Furthermore, healthcare professionals have praised the durability of the HiWire Nitinol Core Wire Guide, noting its ability to withstand repeated use without compromising performance. This has resulted in cost savings for healthcare facilities, as the need for frequent replacements has been minimized. Additionally, the guide wire's enhanced visibility under fluoroscopy has been a standout feature, allowing for precise placement and reducing the risk of complications during procedures.

Understanding Hydrophilic Nitinol Guidewire

Nitinol wire for guide wire is often coated with a hydrophilic material to improve its lubricity and reduce friction during medical procedures. This coating allows for smoother navigation through the body's intricate pathways, making it an essential feature for delicate surgeries and interventions.

The Role of Hydrophilic Coating in Nitinol Guidewire

The hydrophilic coating on nitinol guidewire serves as a lubricious surface that attracts and retains water molecules, creating a slippery layer that enhances the device's maneuverability within the body. This reduces the risk of tissue damage or vessel trauma, ensuring a safer and more efficient procedure for both patients and healthcare professionals.

Advantages of Using Hydrophilic Nitinol Guidewire

The use of hydrophilic nitinol guidewire offers numerous benefits, including improved trackability, reduced friction, enhanced steerability, and minimized kinking or buckling during navigation through tortuous anatomies. These advantages ultimately contribute to better patient outcomes and increased procedural success rates.

In addition to the aforementioned benefits, the use of hydrophilic nitinol guidewire also reduces the risk of vessel trauma and perforation during navigation, leading to a safer and more efficient procedure. This can result in shorter procedure times and decreased patient discomfort, ultimately improving the overall patient experience. Furthermore, the hydrophilic coating on the guidewire allows for smoother advancement through tortuous vessels, reducing the likelihood of complications and ensuring a more successful outcome.

Case Studies Demonstrating the Effectiveness of Hydrophilic Nitinol Guidewire

Several clinical case studies have illustrated the effectiveness of hydrophilic nitinol guidewires in various medical scenarios, showcasing their ability to facilitate smooth access to target sites while minimizing potential complications. These real-world examples highlight the invaluable role of this technology in modern healthcare practices.

In addition to facilitating smooth access and minimizing complications, hydrophilic nitinol guidewires have also been shown to reduce procedure times, allowing for quicker interventions and improved patient outcomes. By providing excellent trackability and pushability, these guidewires enable physicians to navigate through challenging anatomical structures with precision and ease. This not only enhances the overall efficiency of medical procedures but also contributes to a more positive experience for both patients and healthcare providers.

Crafting Guide Wires with GEE SMA Nitinol Shape Memory Alloys

GEE SMA's Specialization in Nitinol Shape Memory Alloys

GEE SMA is a leading expert in the field of Nitinol shape memory alloys, with a focus on producing high-quality guide wires for medical applications. Their specialized knowledge and advanced technology make them a trusted name in the industry.

GEE SMA's expertise in Nitinol shape memory alloys extends beyond just production, as they also offer comprehensive consulting services to help clients optimize their manufacturing processes. By leveraging their in-depth knowledge and cutting-edge technology, GEE SMA can provide valuable insights and recommendations to enhance the quality and efficiency of guide wire production. This holistic approach sets them apart as a trusted partner for medical device manufacturers looking to stay at the forefront of innovation in the industry.

The Process of Crafting High-Quality Guide Wires with GEE SMA Nitinol

GEE SMA utilizes state-of-the-art manufacturing processes to create guide wires that meet the highest standards of quality and performance. Their attention to detail and commitment to excellence ensures that each wire is crafted with precision and care, resulting in reliable and effective products.

GEE SMA's dedication to using cutting-edge manufacturing processes ensures that their guide wires are not only of the highest quality, but also consistently meet the performance standards required in the medical industry. By staying at the forefront of technological advancements, GEE SMA is able to produce guide wires that are reliable and effective, providing healthcare professionals with the tools they need to deliver exceptional patient care. This commitment to innovation sets GEE SMA apart as a leader in the field of medical device manufacturing.

Customer Success Stories with GEE SMA Nitinol Guide Wires

Customers have consistently praised GEE SMA's Nitinol guide wires for their durability, flexibility, and overall performance. Medical professionals rely on these guide wires for their ability to navigate complex anatomies with ease, making them an essential tool in various medical procedures. In addition to their technical capabilities, customers have also highlighted the exceptional customer service provided by GEE SMA. The company's dedication to ensuring customer satisfaction has further solidified the trust and confidence of medical professionals in the reliability of GEE SMA's products.

Conclusion

When it comes to choosing the best nitinol wire for guide wire, it's important to consider the specific needs of the medical procedure and the unique properties of nitinol. Whether it's the HiWire nitinol core wire guide or a hydrophilic nitinol guidewire, understanding the diverse applications of nitinol wire is crucial for medical device innovation in the future.

Choosing the Best Nitinol Wire for Guide Wire

With its superelasticity and shape memory properties, nitinol wire is an ideal material for crafting guide wires that need to navigate through complex anatomical pathways with precision and control. The HiWire nitinol core wire guide, known for its exceptional torque response and kink resistance, is a popular choice among medical professionals for various interventional procedures.

Exploring the Diverse Applications of Nitinol Wire

Nitinol wire can be used in a wide range of medical devices beyond guide wires, including stents, catheters, and orthodontic tools. Its versatility and biocompatibility make it an invaluable material in modern healthcare technology, constantly pushing boundaries in minimally invasive treatments and surgical interventions.

The Future of Nitinol in Medical Device Innovation

As medical device innovation continues to advance, so does the role of nitinol in shaping the future of healthcare. From developing more advanced hydrophilic nitinol guidewires to exploring new applications in robotics and neurovascular interventions, there's no doubt that nitinol will play a pivotal role in driving progress within the medical industry.