Introduction

Regarding advanced materials, nitinol alloy stands out for its remarkable properties and versatility. From its unique shape memory abilities to its high fatigue resistance, nitinol has found diverse applications across various industries. One of the most notable uses of nitinol is tubing, where its superelasticity and biocompatibility make it an ideal choice for critical applications.

Understanding Nitinol Alloy

Nitinol alloy, a combination of nickel and titanium, exhibits extraordinary properties that set it apart from conventional materials. Its ability to return to a predetermined shape after deformation makes it invaluable in numerous industries, particularly in medical and engineering fields.

Nitinol alloy's unique properties include its superelasticity, allowing it to withstand large amounts of strain without permanent deformation. This makes it ideal for applications such as medical procedure stents or robotics actuators. Additionally, Nitinol exhibits shape memory, meaning it can "remember" its original shape and return to it when heated after being deformed, adding a new dimension of versatility to its use in various industries.

Exploring Nitinol Properties

The properties of nitinol are truly fascinating, with superelasticity being one of its most remarkable traits. This unique characteristic allows the material to undergo substantial deformation without permanent damage, making it an excellent choice for applications that require flexibility and resilience.

The Versatility of Nitinol Tubing

Nitinol tubing is a versatile material prized for its unique properties, making it a valuable asset in various industries. Here's a breakdown of its key advantages:

- Shape Memory: Nitinol can be deformed and then "remember" its original shape when exposed to a specific temperature. This allows for intricate designs that return to their intended form upon heat application, making it ideal for minimally invasive medical devices.

- Corrosion Resistance: Nitinol tubing exhibits exceptional resistance to corrosion, ensuring long-lasting performance even in demanding environments like the human body or marine settings.

- Superelasticity: Nitinol possesses superior elasticity, allowing it to undergo significant deformation without permanent damage. This superelasticity makes it highly durable and flexible, perfect for applications that require repeated stress cycles like stents or orthodontic wires.

Nitinol tubing's remarkable combination of shape memory, corrosion resistance, and superelasticity sets it apart from other materials. This unique property profile makes it a highly sought-after material in medical devices, aerospace engineering, and consumer products for its versatility and reliable performance.

The Advantages of Superelastic Nitinol Tube

When it comes to design flexibility, the superelastic nitinol tube is unmatched. Its unique ability to be bent, twisted, and shaped without losing its original form makes it a top choice for intricate and customized designs. Whether for medical devices or industrial equipment, the superelastic tube allows for complex and innovative product designs that meet specific requirements.

Flexibility in Design

The superelastic nitinol tube offers unparalleled flexibility in design, allowing engineers and designers to create intricate and customized products easily. Its remarkable ability to withstand deformation and return to its original shape makes it an ideal choice for applications that require complex shapes and precise dimensions. The superelastic tube provides endless possibilities for innovative design solutions, from medical stents to industrial components.

Shape Memory Abilities

One of the key advantages of the superelastic nitinol tube is its shape memory abilities. This unique property allows the tube to remember its original shape and return to it after being deformed, providing consistent performance over time. This makes it an excellent choice for applications that require reliable and repeatable functionality, such as in medical devices where precise positioning is critical.

In addition to its shape memory abilities, the superelastic nitinol tube offers enhanced biocompatibility. This means it is well-tolerated by the human body and can be used in medical devices without causing adverse reactions. The material's ability to integrate seamlessly with biological tissues makes it a top choice for applications such as stents, orthodontic wires, and other implantable devices. Its biocompatibility ensures that patients experience minimal discomfort and reduces the risk of complications.

Enhanced Biocompatibility

Superelastic nitinol tubing offers a unique combination of properties ideal for various medical applications. Here's why:

- Superior Biocompatibility: Nitinol exhibits excellent compatibility with the human body, minimizing the risk of rejection or adverse reactions. This makes it suitable for long-term implants, surgical tools, and other medical devices that come into contact with bodily fluids.

- Exceptional Mechanical Properties: Superelastic nitinol tubes can undergo significant deformation without permanent damage. This flexibility allows for intricate designs and enables the tubes to withstand harsh conditions within the body.

- Shape Memory Capability: Nitinol can be "trained" to remember a specific shape and return to it upon exposure to a certain temperature. This property is valuable for minimally invasive procedures where the tube can be compressed for insertion and regain its original shape at body temperature.

Biocompatibility, exceptional mechanical properties, and shape memory ability make superelastic nitinol tubing a versatile and reliable material for various medical applications.

The Properties of Nitinol

Nitinol, a unique nickel-titanium alloy, possesses exceptional properties that make it an ideal material for various applications. One of its key properties is its high fatigue resistance, allowing it to withstand repeated stress without experiencing permanent deformation. This makes superelastic nitinol tubes a reliable choice for demanding applications where durability is essential.

Nitinol's high fatigue resistance makes it an excellent choice for medical devices such as stents and guidewires. These applications require materials that can withstand the repeated stress of bodily movement without compromising their structural integrity. Nitinol's ability to maintain its shape and function under these conditions has made it a valuable resource in medical technology, where reliability is paramount.

High Fatigue Resistance

Nitinol's remarkable ability to withstand cyclic loading without succumbing to fatigue failure makes it a sought-after material in industries such as medical devices and aerospace engineering. Whether used in stents for cardiovascular interventions or actuators for space exploration equipment, nitinol's high fatigue resistance ensures the components' longevity and reliability.

Superelasticity

Another defining property of nitinol is its superelasticity, which enables it to recover its original shape after undergoing substantial deformation. This unique characteristic makes superelastic nitinol tubes an excellent choice for applications requiring flexibility and resilience, such as in minimally invasive surgical instruments and orthodontic archwires.

Corrosion Resistance

In addition to its mechanical properties, nitinol exhibits excellent corrosion resistance, making it suitable for use in harsh environments where exposure to moisture or chemicals is a concern. This property enhances the longevity and reliability of nitinol components, ensuring their performance remains uncompromised over time.

Furthermore, nitinol's corrosion resistance allows for its use in medical implants and devices, where exposure to bodily fluids is common. This property ensures that nitinol components remain unaffected by the body's natural environment, contributing to the longevity and reliability of these life-saving devices. As a result, patients can have confidence in the performance of their medical implants over extended periods.

Applications of Nitinol Material

Due to its unique properties and versatility, nitinol has found a wide range of applications across various industries. From medical devices to consumer goods, the applications of nitinol continue to expand, making it a highly sought-after material in the manufacturing world.

Medical Devices

In medicine, superelastic nitinol tube is widely used for manufacturing stents, guidewires, and other minimally invasive surgical instruments. Its superelasticity and shape memory abilities make it ideal for intricate medical procedures, providing flexibility and durability in critical applications.

In addition to its use in stents and guidewires, superelastic nitinol tube is also employed in creating orthodontic wires and dental implants. The material's ability to return to its original shape after being deformed allows for comfortable and effective dental treatments, while its flexibility ensures a secure fit within the patient's mouth. This versatility has made nitinol a valuable asset in orthodontics and dental surgery.

Industrial Equipment

In industrial settings, nitinol alloy is used for actuators, sensors, and other components requiring high fatigue resistance and precise control. Its unique properties make it suitable for industrial equipment that demands reliability and performance under extreme conditions.

Nitinol's ability to maintain precise control and high fatigue resistance makes it an ideal material for industrial equipment used in manufacturing processes. Its shape memory properties allow for the creation of actuators that can perform repetitive tasks accurately, while its superelasticity ensures durability even in harsh working environments. As a result, nitinol alloy is increasingly being integrated into industrial machinery to enhance productivity and reliability.

Consumer Goods

Nitinol tubing is also being used in consumer goods such as eyeglass frames, mobile phone antennas, and orthodontic wires due to its corrosion resistance and shape memory capabilities. Nitinol in consumer products demonstrates its potential to enhance functionality and longevity in everyday items.

With its remarkable properties and diverse applications, nitinol material continues to revolutionize various industries by offering innovative solutions that meet complex engineering requirements while improving overall product performance.

Now, let's dive into the intricate process of manufacturing superelastic nitinol tubes with precision and quality control measures.

The Manufacturing Process of Superelastic Nitinol Tube

Nitinol Melting Point

The first step in creating a superelastic nitinol tube is understanding the nitinol melting point, which typically ranges from 1310 to 1315 degrees Celsius. This high melting point allows the alloy to be manipulated and shaped without risk of deformation, making it an ideal material for medical devices and industrial applications.

Fabrication Techniques

Fabrication techniques for superelastic nitinol tubes involve combining cold working and heat treatment processes. Cold working, such as drawing or rolling, helps to shape the tube while maintaining its superelastic properties. Heat treatment is then applied to set the desired shape memory and superelasticity characteristics, ensuring that the final product meets specific performance requirements.

Quality Control Measures

Quality control measures ensure that superelastic nitinol tubes meet strict industry standards. Non-destructive testing methods, such as ultrasonic inspection and eddy current testing, are employed to detect any defects or inconsistencies in the material. Additionally, dimensional inspections are carried out to verify precise tolerances and dimensions of the finished tubes.

Remember that GEE SMA specializes in crafting high-quality nitinol components with advanced manufacturing techniques!

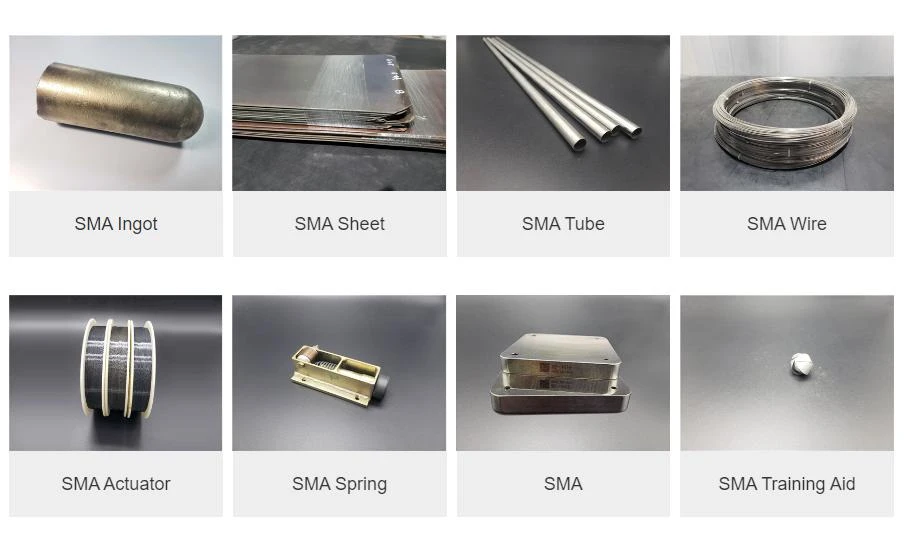

GEE SMA: Crafting High-Quality Nitinol Components

GEE SMA prides itself on tailoring nitinol materials to meet its clients' specific needs. Whether it's a superelastic nitinol tube for medical devices or industrial equipment, GEE SMA has the expertise to customize the alloy's properties to ensure optimal performance.

Tailoring Nitinol Materials

At GEE SMA, we understand that each project requires unique material specifications. Our team of experts works closely with clients to customize the superelastic nitinol tube based on shape memory, fatigue resistance, and corrosion resistance. This tailored approach ensures that the nitinol material meets the application's exact requirements.

Addressing Customer Requirements

Customer satisfaction is at the core of our operations at GEE SMA. We prioritize open communication and collaboration with our clients to understand their needs and challenges. By addressing customer requirements with precision, we can deliver superelastic nitinol tubes that exceed expectations in quality and performance.

Enhancing Product Quality

Quality is non-negotiable at GEE SMA. We employ rigorous quality control measures throughout manufacturing to ensure that every superelastic nitinol tube meets industry standards and client expectations. Our commitment to enhancing product quality makes us a trusted partner for high-quality nitinol components.

Choose the Right Nitinol Component

When choosing the right nitinol component, the superelastic nitinol tube stands out for its flexibility, shape memory abilities, and enhanced biocompatibility. With its high fatigue resistance, superelasticity, and corrosion resistance, this material offers numerous benefits across various industries. Partnering with GEE SMA ensures access to high-quality nitinol components tailored to specific requirements.

Selecting the perfect nitinol component is crucial for achieving optimal performance and efficiency. The superelastic nitinol tube provides unparalleled flexibility in design and shape memory abilities, making it an ideal choice for various applications. Understanding the properties of nitinol material is essential in making informed decisions when choosing the right component for your specific needs.

Benefits of Superelastic Nitinol

Superelastic nitinol, a nickel-titanium alloy, is a remarkable material prized for its unique properties in various applications. Here are some of its key benefits:

- High Fatigue Resistance: Nitinol can withstand repeated deformations without experiencing permanent damage. This exceptional durability makes it ideal for applications requiring continuous movement or stress, such as stents implanted in arteries or orthodontic wires.

- Superelasticity: Nitinol exhibits remarkable shape memory, allowing it to recover significant strain after deformation. This property proves advantageous in applications requiring flexibility and resilience, such as guidewires that navigate catheters through narrow blood vessels.

- Corrosion Resistance: Nitinol demonstrates exceptional corrosion resistance, ensuring its longevity and functionality in diverse environments, including the harsh biological environment inside the human body.

Nitinol's superior fatigue resistance, superelasticity, and corrosion resistance make it a valuable material for various demanding applications in medicine, aerospace, and other industries.

Partnering with GEE SMA

Partnering with GEE SMA guarantees access to top-notch manufacturing processes and high-quality nitinol components tailored to meet customer requirements. By addressing specific needs and enhancing product quality through rigorous quality control measures, GEE SMA ensures that customers receive reliable and efficient superelastic nitinol tubes for their applications.

With a comprehensive understanding of the properties of nitinol alloy and the advantages of superelastic tubes, partnering with GEE SMA is a strategic decision for obtaining superior quality components tailored to specific requirements across various industries.