Introduction

Nitinol metal, a remarkable alloy of nickel and titanium, has garnered significant attention in various industries due to its unique properties and versatility. Often hailed as a smart material, nitinol exhibits two primary phenomena: the shape memory effect and superelasticity, making it an exciting subject for both researchers and manufacturers alike. However, with these advantages come challenges that prompt questions like What is the problem with nitinol? and Is nitinol stronger than titanium?

Understanding Nitinol Metal

So, what is nitinol metal? This innovative alloy is primarily composed of nickel and titanium in roughly equal proportions, which grants it its distinctive characteristics. The term nitinol itself is derived from its composition—Nickel Titanium Naval Ordnance Laboratory—where it was discovered in the 1960s.

Unique Properties of Nitinol

The unique properties of nitinol are what set it apart from other metals. Its ability to return to a predetermined shape when heated (shape memory effect) allows for fascinating applications in fields such as medicine and robotics. Additionally, nitinol's superelasticity means it can undergo significant deformation without permanent damage—perfect for scenarios where flexibility and resilience are crucial.

Applications of Nitinol Metal

When discussing nitinol metal uses, one cannot overlook its extensive applications across diverse sectors. In the medical field, it's commonly used for stents and guidewires due to its biocompatibility and flexibility. Beyond healthcare, industries like aerospace are leveraging this alloy's lightweight yet strong nature for components that require high performance under extreme conditions—showcasing just how versatile this material can be.

What is Nitinol Metal?

Nitinol metal, a remarkable alloy of nickel and titanium, is known for its unique properties that set it apart from traditional metals. This innovative material has captured the attention of various industries due to its extraordinary capabilities, such as shape memory effect and superelasticity. But what exactly is nitinol metal, and how does it function in practical applications?

Composition of Nitinol

Nitinol is primarily composed of nickel (Ni) and titanium (Ti), typically in a ratio of approximately 50:50 by atomic percentage. This specific composition grants nitinol its distinctive characteristics, making it suitable for a range of applications from medical devices to aerospace components. The precise balance between these two elements allows nitinol metal to undergo phase transformations that are pivotal for its unique properties.

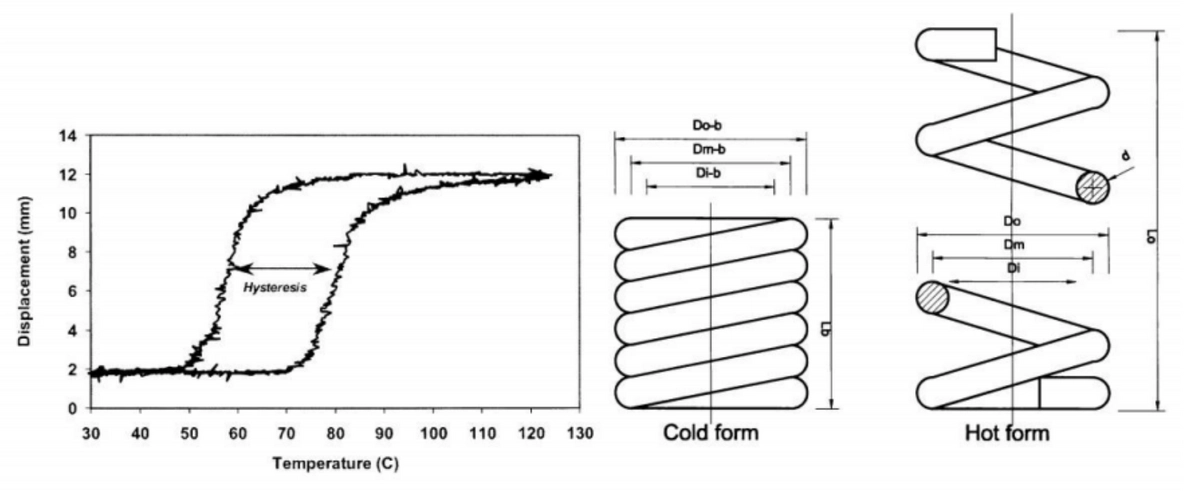

Shape Memory Effect Explained

The shape memory effect is one of the most fascinating features of nitinol metal, allowing it to remember its original shape after being deformed. When heated above a certain temperature, known as the transformation temperature, nitinol returns to its pre-deformed configuration. This property makes nitinol particularly valuable in medical applications where devices need to be inserted in a compact form but expand once they reach body temperature.

Superelasticity in Nitinol

Superelasticity is another incredible trait found in nitinol metal, enabling it to undergo significant deformation without permanent change or damage when subjected to stress within certain limits. Unlike typical metals that may break or bend under pressure, superelastic nitinol can return to its original shape upon removal of the stressor. This characteristic not only enhances the durability of products made with nitinol but also opens up new possibilities for innovation across various industries.

What is the Problem with Nitinol?

While nitinol metal has gained a reputation for its remarkable properties, it isn't without its challenges. Understanding what is the problem with nitinol? can shed light on why some industries hesitate to adopt this innovative material fully. Let's dive into three key areas of concern: biocompatibility, fatigue and durability issues, and cost factors.

Biocompatibility Concerns

One of the most pressing issues surrounding nitinol metal is its biocompatibility, especially in medical applications where it’s often used for implants and stents. Although many studies suggest that nitinol can be safely used in the human body, there are still concerns about potential allergic reactions or toxicity due to nickel content in certain formulations of NiTi. As researchers continue to explore these biocompatibility concerns, manufacturers must ensure that their products meet stringent safety standards before they hit the market.

Fatigue and Durability Issues

Another significant drawback of nitinol metal lies in its fatigue resistance and overall durability over time. While this unique alloy exhibits impressive shape memory and superelasticity under certain conditions, repeated stress can lead to premature failure or deformation in some applications. Understanding how these fatigue and durability issues impact long-term use is crucial for industries relying on nitinol's unique properties; otherwise, they risk costly failures down the line.

Cost Factors in Nitinol Metal

Lastly, let's talk about everyone's favorite topic: money! The cost factors associated with nitinol metal can be a major hurdle for widespread adoption across various sectors. Due to complex manufacturing processes and limited supply chains, prices for nitinol metal remain relatively high compared to traditional materials like stainless steel or titanium. This raises questions about whether the benefits of using NiTi outweigh the financial investment required—especially when considering what is NiTi used for?

What is NiTi Used For?

Nitinol, a fascinating alloy of nickel and titanium, boasts a variety of applications across multiple industries. From the medical field to aerospace and even consumer products, the uses of Nitinol metal are diverse and innovative. Understanding what NiTi is used for can illuminate its significance in our daily lives and future advancements.

Medical Applications of Nitinol

Nitinol metal has carved out a prominent niche in the medical industry due to its unique properties, particularly its shape memory effect and superelasticity. These characteristics make it ideal for devices such as stents, guidewires, and orthodontic archwires that require flexibility and resilience under stress. The ability to return to a predefined shape at body temperature allows for minimally invasive procedures, significantly improving patient outcomes.

However, while exploring what is the problem with nitinol?, it's essential to consider biocompatibility concerns that arise with medical applications. Despite these challenges, ongoing research continues to enhance the safety profile of nitinol metal in healthcare settings. As innovations advance, we can expect even more groundbreaking applications in medicine.

Aerospace Industry Uses

In the aerospace sector, Nitinol's lightweight yet strong composition makes it an attractive choice for various components subjected to extreme conditions. Parts made from nitinol metal can withstand high temperatures while maintaining structural integrity—a critical requirement in aircraft design and manufacturing. Additionally, its superelastic nature allows for components that can absorb shocks during turbulence or landing.

The versatility of Nitinol also extends to actuators used in aerospace systems where space is limited but functionality is crucial. By utilizing what is NiTi used for? in this industry, engineers have developed smarter solutions that enhance performance without compromising safety or efficiency. As demand grows for advanced materials in aviation technology, nitinol metal could play an increasingly vital role.

Consumer Product Innovations

Beyond specialized fields like medicine and aerospace, Nitinol has found its way into consumer products that benefit from its unique attributes—think eyeglass frames that bend without breaking or smart clothing that adapts to body movements! These innovations showcase how nitinol metal uses extend into everyday life by enhancing durability and comfort without sacrificing style or function.

As manufacturers explore creative applications of NiTi across various sectors, they are discovering new ways to incorporate this remarkable material into their product lines. However, potential buyers should keep an eye on the Nitinol metal price since it can fluctuate based on market demand and production costs associated with this advanced material. With continuous advancements on the horizon, who knows what other consumer innovations will emerge using nitinol?

Is Nitinol Stronger Than Titanium?

When it comes to the debate of whether nitinol metal is stronger than titanium, the answer isn't as straightforward as one might think. While both materials have their unique strengths and applications, they excel in different areas. To truly understand the comparison, we need to delve into aspects like strength and flexibility, performance under extreme conditions, and weight considerations.

Comparing Strength and Flexibility

Nitinol metal is renowned for its remarkable flexibility due to its unique shape memory effect and superelasticity. This means that while it may not have the same tensile strength as titanium, it can endure significant deformation without permanent damage. In practical terms, this allows nitinol to return to its original shape after being bent or twisted—an attribute that makes it ideal for applications where flexibility is paramount.

On the other hand, titanium boasts superior tensile strength compared to nitinol. It can withstand higher loads before failing, making it a go-to choice in industries where strength is critical. However, when you factor in flexibility along with strength, nitinol’s ability to absorb shock and adapt under stress gives it an edge in specific applications where resilience is key.

Performance in Extreme Conditions

When evaluating how these two metals perform under extreme conditions, it's essential to consider temperature fluctuations and environmental factors. Nitinol maintains its properties even at varying temperatures; its shape memory effect allows it to function effectively in both hot and cold settings without losing integrity. This adaptability makes nitinol metal a preferred choice in medical devices that are often exposed to diverse environments within the human body.

Conversely, titanium excels in high-stress environments such as aerospace applications due to its corrosion resistance and ability to perform well at elevated temperatures without degrading. When comparing what is NiTi used for versus traditional titanium applications, it's clear that while both materials shine under pressure, their suitability depends on the specific demands of each application.

Weight Considerations

Weight plays a crucial role when deciding between nitinol metal and titanium for various uses. Nitinol tends to be lighter than titanium while still offering impressive performance characteristics like superelasticity—making it an attractive option for lightweight designs such as stents or orthopedic devices. The reduced weight of nitinol can lead to less invasive surgical procedures or more efficient consumer products.

However, if raw strength-to-weight ratio is your primary concern—especially in aerospace or automotive contexts—titanium often takes the lead due to its incredible strength relative to its weight despite being denser than nitinol metal. Ultimately, choosing between these two materials hinges on understanding their respective advantages based on application requirements rather than simply declaring one stronger than the other.

Nitinol Metal Sheet Characteristics

Nitinol metal sheets are a fascinating product of advanced metallurgy, showcasing the unique properties of this remarkable alloy. Understanding the manufacturing processes behind these sheets is essential for appreciating their applications and advantages. From medical devices to aerospace components, nitinol metal sheets are becoming increasingly popular due to their versatility and performance.

Manufacturing Processes of Nitinol Sheets

The creation of nitinol metal sheets involves several intricate manufacturing processes that ensure the material retains its unique properties. Initially, nickel and titanium are combined in precise ratios to form the alloy known as NiTi, or nitinol metal. This mixture undergoes various treatments, including heat treatment and cold working, which help achieve the desired microstructure necessary for exhibiting both shape memory effect and superelasticity.

Once the alloy is prepared, it can be processed into sheets through methods like rolling or forging. These techniques not only enhance the mechanical properties but also allow for customization in thickness and size according to specific applications. Understanding these manufacturing processes is crucial when considering what is nitinol metal? It’s more than just an alloy; it’s a carefully engineered material designed for high-performance uses.

Advantages of Nitinol Metal Sheets

Nitinol metal sheets come with a host of advantages that make them highly desirable across various industries. One key benefit is their ability to return to a predetermined shape when heated—an aspect stemming from their shape memory effect—which can be particularly useful in applications requiring precision components that adapt under different conditions. Additionally, their superelasticity allows them to withstand significant stress without permanent deformation, making them ideal for dynamic environments.

Another advantage lies in their biocompatibility; nitinol is widely used in medical devices such as stents and guidewires due to its safe interaction with human tissue. Furthermore, these sheets are lightweight yet strong—often leading people to ask: Is nitinol stronger than titanium? While both materials have strengths suited for different applications, nitinol's unique properties provide distinct benefits where flexibility and adaptability are critical.

Market Trends and Pricing

The market trends surrounding nitinol metal sheets indicate a steady increase in demand driven by innovations across multiple sectors like healthcare and aerospace. As industries continue exploring new applications for this versatile material—ranging from consumer products to complex machinery—the pricing dynamics also evolve accordingly; currently, prices can vary based on factors such as purity levels and processing techniques involved in creating the final product.

When evaluating nitinol metal price points compared to traditional metals like titanium or stainless steel, it's essential to consider not just initial costs but long-term benefits provided by durability and performance enhancements offered by nitinol products. As manufacturers optimize production methods further while expanding into new markets, we can expect more competitive pricing alongside innovative uses that highlight what is NiTi used for? The possibilities seem limitless!

Conclusion

In summary, nitinol metal has established itself as a remarkable material with unique properties that set it apart from traditional metals. Its shape memory effect and superelasticity make it an exciting choice for various applications, from medical devices to aerospace components. However, challenges such as biocompatibility concerns and cost factors must be addressed to fully harness its potential.

Key Takeaways on Nitinol Metal

What is nitinol metal? It is a nickel-titanium alloy known for its extraordinary mechanical properties, including the ability to return to a predetermined shape when heated. Understanding what is the problem with nitinol? reveals that while it offers numerous advantages, issues like fatigue and durability can hinder its widespread adoption in more demanding environments.

Nitinol metal uses span several industries, showcasing its versatility. From stents in medical applications to innovative consumer products, the material's unique characteristics open doors for creative solutions. Nevertheless, it's essential to stay informed about the nitinol metal price and market trends as they can significantly influence its accessibility and implementation.

Future of Nitinol in Industry

The future of nitinol in industry looks promising as research continues to unveil new applications and improve existing technologies. Is nitinol stronger than titanium? While it may not always outshine titanium in raw strength, its flexibility and unique properties make it an attractive option for specific uses where those traits are essential. As industries evolve, the demand for advanced materials like nitinol will likely increase, driving innovation further.

Moreover, ongoing advancements in manufacturing processes are expected to reduce costs associated with production and enhance quality control measures. This could lead to broader adoption across various sectors including medical devices and aerospace engineering. With increasing interest from researchers and manufacturers alike, we can anticipate exciting developments on the horizon.

GEE SMA's Role in Nitinol Development

GEE SMA plays a pivotal role in advancing the development of nitinol metal by focusing on enhancing its properties through innovative manufacturing techniques. Their commitment to addressing what is the problem with nitinol? demonstrates their dedication toward improving biocompatibility and durability while managing costs effectively—key factors that will determine how widely this material can be used.

Additionally, GEE SMA actively explores new markets for what is NiTi used for?, seeking opportunities where this remarkable alloy can meet emerging needs across diverse fields. By prioritizing research into both performance enhancements and cost reductions related to nitinol metal sheet production, they position themselves at the forefront of this evolving industry landscape.

As we move forward into a future shaped by cutting-edge materials like nitinol metal, GEE SMA’s contributions will undoubtedly play a significant role in unlocking new possibilities across multiple sectors.