Introduction

Nitinol shape memory alloys have revolutionized various industries with their unique properties. GEE SMA has been at the forefront of innovating with nitinol, unlocking its full potential. The science behind nitinol's memory is a fascinating field of study that continues to intrigue researchers and engineers alike.

Understanding Nitinol Shape Memory Alloys

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is composed of nearly equal parts nickel and titanium. This unique composition gives it the ability to remember its original shape, making it a material that stands out in the industry.

GEE SMA: Innovating with Nitinol

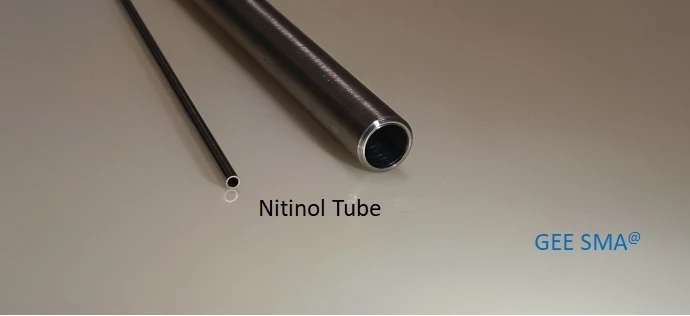

GEE SMA has been pushing boundaries in the field of nitinol, developing customized solutions for various applications. Their cutting-edge research and advancements have contributed significantly to the understanding and utilization of nitinol shape memory alloys.

The Science Behind Nitinol's Memory

The reason why nitinol remembers its shape lies in its crystallographic structure and phase transformation mechanism. These intricate processes enable nitinol to exhibit remarkable superelasticity and shape memory properties.

What is Nitinol?

Nitinol’s Unique Composition

Nitinol is a unique alloy composed of nickel and titanium, hence the name NiTi. This composition gives it the ability to remember its original shape after being deformed, making it a shape memory alloy (SMA). The combination of these two metals creates a material with remarkable properties that set it apart from other alloys.

Nitinol’s unique composition of nickel and titanium not only gives it the ability to remember its original shape but also makes it highly resistant to corrosion and wear. This means that Nitinol is ideal for use in medical devices such as stents and orthodontic wires, where durability and biocompatibility are essential. Additionally, its superelasticity allows Nitinol to undergo large deformations without permanent damage, making it an invaluable material in a wide range of applications.

The Origin of Nitinol

The discovery of Nitinol can be traced back to the 1960s when researchers at the Naval Ordnance Laboratory in the United States stumbled upon its unique properties while experimenting with different metal alloys. The name Nitinol itself is derived from its composition - Nickel (Ni), Titanium (Ti), and the Naval Ordnance Laboratory (NOL) where it was first developed.

After the initial discovery, further research and development of Nitinol were carried out by GEE SMA, a company specializing in shape memory alloys. GEE SMA played a crucial role in advancing the understanding and application of Nitinol in various industries. Their expertise and innovation led to the commercialization of Nitinol-based products, ranging from medical devices to consumer goods.

GEE SMA's Contribution to Nitinol Advancements

GEE SMA has been at the forefront of advancing Nitinol technology through cutting-edge research and innovation. Their expertise in shaping and manipulating Nitinol for various applications has led to significant advancements in its use across different industries, making them a key player in unlocking the potential of this remarkable shape memory alloy.

GEE SMA's expertise in shaping and manipulating Nitinol has not only led to significant advancements in its use across different industries but has also opened up new possibilities for medical devices, aerospace engineering, and consumer products. By understanding the unique properties of Nitinol, GEE SMA has been able to develop innovative solutions that harness its shape memory and superelasticity, paving the way for groundbreaking applications in fields such as minimally invasive surgery and orthodontics.

How Nitinol Remembers Its Shape

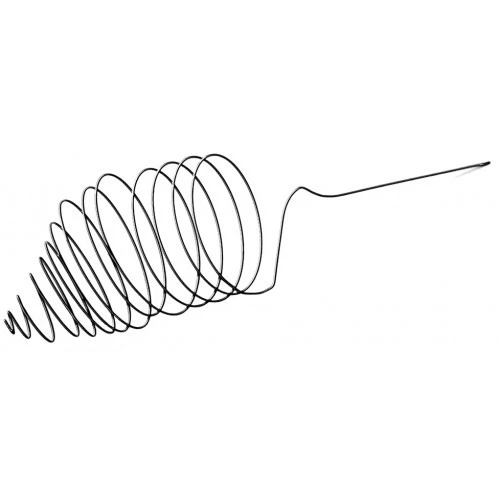

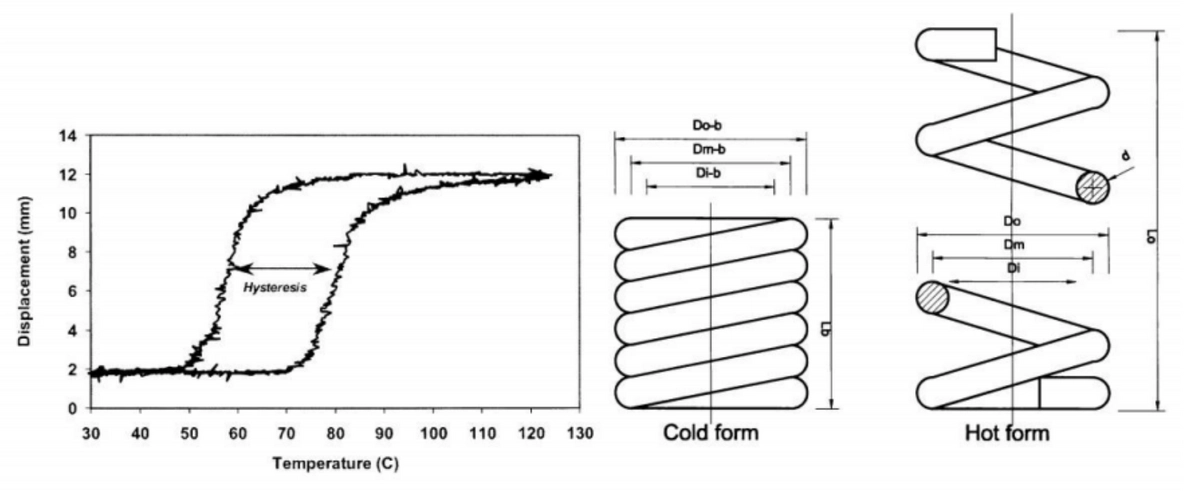

Nitinol's unique ability to remember its original shape is due to the shape memory effect, a fascinating characteristic that sets it apart from other materials. When deformed at a low temperature, nitinol retains this new shape until it is heated above its transformation temperature, at which point it returns to its original form. This remarkable behavior makes nitinol an incredibly versatile and valuable material in various industries.

The Shape Memory Effect

Nitinol's shape memory effect is a result of its crystallographic structure, which allows it to undergo reversible phase transformations. This means that nitinol can remember and recover its original shape even after being subjected to significant deformation. This unique property has made nitinol a sought-after material in fields such as medicine, aerospace engineering, and consumer electronics.

Nitinol's Thermal Properties

The thermal properties of nitinol play a crucial role in its shape memory effect. As the alloy undergoes a phase transformation from austenite to martensite or vice versa, heat is either absorbed or released. This thermal response allows nitinol to exhibit superelasticity and recoverability, making it ideal for applications where precise and reliable shape recovery is essential.

GEE SMA's Cutting-Edge Research on Nitinol Behavior

GEE SMA has been at the forefront of cutting-edge research on nitinol behavior, delving into the intricate mechanisms behind its shape memory effect. Through advanced testing and analysis, GEE SMA has uncovered new insights into how nitinol responds to different stimuli, paving the way for innovative advancements in the field of shape memory alloys.

The Applications of Nitinol

Nitinol is a remarkable material that finds extensive use in various industries due to its unique properties. One of the most significant applications of nitinol is in the field of medical devices, where its shape memory and superelasticity make it ideal for minimally invasive procedures. From stents and guidewires to orthodontic braces and surgical tools, nitinol's ability to remember its shape ensures precise positioning and reliable performance in critical medical interventions.

Nitinol in Medical Devices

Nitinol's exceptional biocompatibility, corrosion resistance, and ability to return to its original shape after deformation make it an indispensable material for a wide range of medical devices. Whether it's a self-expanding stent that can be delivered through small incisions or a catheter guide wire that can navigate tortuous blood vessels with ease, nitinol's unique properties have revolutionized the field of interventional medicine.

Nitinol's versatility extends beyond medical devices, as it is also widely used in aerospace engineering. Its unique combination of strength and flexibility makes it an ideal material for components such as actuators and sensors in aircraft and spacecraft. The ability of nitinol to withstand extreme temperatures and return to its original shape after deformation makes it invaluable for applications in the demanding environment of space travel. In addition, its resistance to corrosion ensures the reliability and longevity of aerospace components, further solidifying its importance in this field.

Nitinol in Aerospace Engineering

In aerospace engineering, the demand for lightweight yet durable materials has led to the widespread use of nitinol in various applications. From actuators and sensors to deployable structures and adaptive airfoil systems, nitinol's shape memory effect allows for compact and efficient designs that can withstand extreme conditions. Its ability to change shape based on temperature variations makes it an invaluable component in advanced aerospace technologies.

As aerospace technology continues to advance, the demand for innovative materials like nitinol is only expected to grow. Its unique properties make it a versatile material for a wide range of applications, from structural components to mechanisms that require precise and reliable performance. The ability of nitinol to withstand extreme temperatures and conditions makes it an ideal choice for aerospace engineering, where reliability and durability are paramount. With ongoing research and development, the potential uses of nitinol in aerospace engineering are likely to expand even further in the future.

GEE SMA's Customized Nitinol Solutions

GEE SMA has been at the forefront of developing customized nitinol solutions for a wide range of industries, including medical, aerospace, automotive, and consumer electronics. With expertise in alloy composition, fabrication techniques, and thermal processing methods, GEE SMA offers tailored solutions that leverage the unique properties of nitinol to meet specific application requirements. Whether it's designing intricate medical implants or precision actuators for space exploration missions, GEE SMA's innovative approach ensures optimal performance and reliability.

GEE SMA's expertise in nitinol solutions extends to the automotive industry, where the unique properties of nitinol are harnessed for a variety of applications. From shape memory alloys used in engine components to actuators and sensors that improve vehicle performance and safety, GEE SMA's customized solutions play a critical role in advancing automotive technology. By understanding the specific requirements of the automotive sector, GEE SMA ensures that their nitinol solutions meet the highest standards of quality and reliability.

Why Does Nitinol Remember Its Shape?

Nitinol's unique ability to remember its shape can be attributed to its crystallographic structure, which allows it to undergo reversible phase transformations. This means that when nitinol is deformed, it can return to its original shape when subjected to the appropriate stimulus, such as heat or stress. This crystallographic structure is what sets nitinol apart from other materials and enables it to exhibit shape memory properties.

Nitinol's Crystallographic Structure

Nitinol is composed of a nickel-titanium alloy with a specific crystalline structure known as martensite and austenite phases. When nitinol is deformed at low temperatures, it retains the martensitic phase, allowing it to remember the new shape. However, when heated above a certain temperature called the transformation temperature, nitinol transitions back to the austenitic phase and returns to its original shape.

Nitinol's Phase Transformation Mechanism

The phase transformation mechanism in nitinol is responsible for its remarkable ability to change shape in response to external stimuli. This occurs through a process called thermoelastic martensitic transformation, where the material undergoes reversible changes in crystal structure based on temperature variations or mechanical stress. This unique behavior makes nitinol an ideal choice for applications requiring precise control over shape memory properties.

GEE SMA's Role in Unraveling Nitinol Mysteries

As a leader in nitinol innovation, GEE SMA has played a pivotal role in uncovering the mysteries behind why nitinol remembers its shape. Through cutting-edge research and development, GEE SMA has contributed significantly to advancing our understanding of nitinol's crystallographic structure and phase transformation mechanisms. By delving into these complexities, GEE SMA continues to push the boundaries of what is possible with this extraordinary material.

Conclusion

Nitinol's remarkable ability to remember its shape has revolutionized various industries, from medical devices to aerospace engineering. GEE SMA has been at the forefront of pioneering Nitinol innovations, unlocking its potential for cutting-edge applications. As the future of Nitinol in industry continues to evolve, GEE SMA remains committed to pushing the boundaries of what this incredible shape memory alloy can achieve.

Unlocking the Potential of Nitinol Technology

GEE SMA's relentless pursuit of understanding why nitinol remembers its shape has led to groundbreaking advancements in utilizing this unique material. By delving deep into nitinol's composition and behavior, GEE SMA has unlocked new possibilities for creating innovative solutions that harness the full potential of nitinol technology.

GEE SMA's pioneering research into nitinol technology has not only uncovered the reasons behind its shape memory, but has also led to the development of cutting-edge applications in various industries. By pushing the boundaries of traditional thinking, GEE SMA has been able to create innovative solutions that leverage the unique properties of nitinol, opening up new possibilities for medical devices, aerospace components, and consumer products. This forward-thinking approach has positioned GEE SMA as a leader in nitinol innovation, with a proven track record of delivering groundbreaking advancements in material science.

GEE SMA: Pioneering Nitinol Innovations

As a leader in nitinol research and development, GEE SMA has consistently pushed the boundaries of what is possible with shape memory alloys. Through cutting-edge research and development, GEE SMA continues to pave the way for new applications and uses for nitinol, solidifying its position as a pioneer in nitinol innovations.

GEE SMA's commitment to innovation has led to the development of advanced nitinol products that are revolutionizing various industries. From medical devices to aerospace components, nitinol's unique properties are being harnessed in ways previously thought impossible. With a focus on continuous improvement and exploration, GEE SMA is at the forefront of shaping the future of nitinol in industry, opening up new possibilities for engineers and designers.

The Future of Nitinol in Industry

The future of nitinol in industry looks incredibly promising, with endless possibilities for applications across various sectors. As advancements continue to be made in understanding how nitinol works and why it retains its shape memory properties, we can expect to see even more innovative uses emerge, further solidifying nitinol's place as a revolutionary material shaping the future.