Introduction

In the realm of advanced engineering materials, micro torsion nitinol springs stand out as a remarkable innovation. These tiny yet powerful components harness the unique properties of nitinol, an alloy known for its shape memory and superelasticity. As industries increasingly seek precision and reliability, understanding how these micro torsion nitinol springs work becomes essential for engineers and designers alike.

Unveiling Micro Torsion Nitinol Springs

Micro torsion nitinol springs are intricate devices designed to provide exceptional torque in compact spaces, making them ideal for applications ranging from medical devices to robotics. Their unique design allows them to return to a predetermined shape when heated or deformed, showcasing the fascinating capabilities of nitinol alloys. As more industries discover their potential, these precision micro springs & wire forms are becoming indispensable tools in modern engineering.

The Magic of Nitinol Science

The science behind nitinol is nothing short of magical; it combines nickel and titanium to create an alloy that exhibits both shape memory effect and superelasticity. This means that when you manipulate a nitinol spring—say, by twisting or bending it—it can return to its original form once the stress is removed or heat is applied. Such properties make nitinol springs not only reliable but also incredibly versatile across various applications including aerospace, automotive, and medical fields.

Why Choose Micro Torsion Nitinol Springs

Choosing micro torsion nitinol springs offers numerous advantages over traditional spring materials; they are lightweight yet durable and can withstand extreme conditions without losing functionality. With the ability to customize designs through options like Nitinol flat wire or specialized configurations from trusted Nitinol springs suppliers, these components cater to specific needs with precision. Furthermore, utilizing a Nitinol wire spool allows manufacturers to create tailored solutions that enhance performance while minimizing material waste.

What Are Micro Torsion Nitinol Springs?

Micro torsion nitinol springs are remarkable components that leverage the unique properties of nitinol alloys to perform intricate tasks in various applications. These springs are designed to operate under torsional stress, enabling them to twist and return to their original shape, thanks to the shape memory effect inherent in nitinol. With their small size and exceptional performance characteristics, micro torsion nitinol springs have become indispensable in many modern engineering solutions.

The Basics of Nitinol Alloys

Nitinol is a nickel-titanium alloy known for its extraordinary mechanical properties, including superelasticity and shape memory effect. This unique combination allows micro torsion nitinol springs to exhibit remarkable resilience when subjected to varying loads and temperatures. The ability of these alloys to change shape at specific temperatures makes them highly sought after among precision micro springs & wire forms manufacturers who aim for innovative solutions.

Nitinol's composition typically consists of about 55% nickel and 45% titanium, although variations exist that can enhance specific properties tailored for different applications. As one of the most versatile materials available, it is no surprise that Nitinol has garnered attention from numerous industries looking for effective solutions—especially from reliable Nitinol springs suppliers who can provide high-quality products that meet stringent standards.

How Do Nitinol Springs Work?

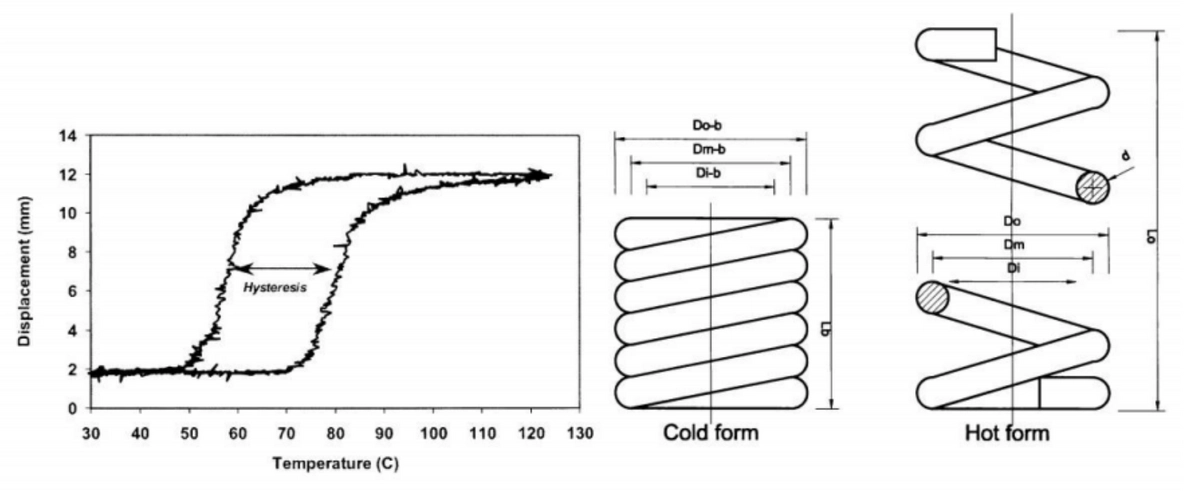

So, how do nitinol springs work? At the core of their functionality lies the shape memory effect: when deformed at a lower temperature, these springs can revert back to their designated shape upon heating above a specific threshold temperature. This allows them not only to store energy but also release it effectively when needed—making them ideal candidates for applications requiring precise control over movement.

Moreover, superelasticity plays a crucial role in how micro torsion nitinol springs operate under stress without permanent deformation. When subjected to strain within certain limits, these springs can stretch significantly while still returning to their original form once the load is removed. This dynamic behavior is what sets nitinol apart from traditional materials used in manufacturing standard spring designs like conventional steel or plastic variants.

Applications in Modern Engineering

Micro torsion nitinol springs find applications across various sectors due to their unique properties and adaptability; they are particularly valued in medical devices such as stents and guidewires where reliability is paramount. In robotics and automation systems, these innovative components enable precise movements while maintaining durability under repeated use—a testament to why engineers favor using Nitinol flat wire configurations over traditional alternatives.

Moreover, industries such as aerospace benefit substantially from integrating micro torsion nitinol springs into mechanisms where weight reduction without sacrificing performance is critical—think lightweight actuators or deployable structures! As technology continues evolving rapidly alongside growing demands for efficient solutions across sectors like automotive or consumer electronics, we can expect even broader adoption of this remarkable material moving forward.

Exceptional Properties of Nitinol Springs

Shape Memory Effect Explained

The shape memory effect is one of the most intriguing characteristics of micro torsion nitinol springs. Essentially, when these springs are deformed at a lower temperature, they can return to their original shape upon heating. This phenomenon allows designers to create complex mechanisms that can adapt and respond dynamically, which is particularly useful in applications like medical devices and robotics.

Understanding how do nitinol springs work? It all boils down to their unique crystalline structure that changes with temperature variations. This adaptability makes Nitinol flat springs ideal for precision applications where reliability and responsiveness are crucial.

Superelasticity: A Game Changer

Superelasticity is another groundbreaking feature of Nitinol torsion spring technology that sets it apart from conventional materials. Unlike typical metal components that yield under stress, superelastic Nitinol can undergo significant deformation without permanent damage when subjected to stress above a certain threshold temperature.

This property enables manufacturers to produce Precision Micro Springs & Wire Forms that can withstand extreme conditions while maintaining functionality over time. With superelasticity in play, engineers can design more compact systems without sacrificing strength or reliability—truly a game changer in the field!

Durability and Corrosion Resistance

Durability is paramount when selecting components for demanding environments; this is where micro torsion nitinol springs shine brightly! Not only do they exhibit impressive fatigue resistance due to their unique properties, but they also boast excellent corrosion resistance thanks to the formation of a protective oxide layer on their surface.

Nitinol flat wire's resilience makes it suitable for various applications—from aerospace engineering to medical devices—ensuring longevity even in harsh conditions. As industries seek reliable solutions from trusted Nitinol Springs suppliers, the durability and corrosion resistance of these innovative materials make them an undeniable choice.

Precision Micro Springs & Wire Forms

In the world of engineering, precision is key, and that's where micro torsion nitinol springs come into play. These specialized components are not just your run-of-the-mill springs; they offer tailored solutions for a variety of applications. With their unique properties and adaptability, they are essential in sectors ranging from medical devices to aerospace technology.

Customized Solutions for Every Need

Nitinol Springs Suppliers understand that each project has its unique requirements, which is why customized solutions are crucial. Whether you need a specific diameter or a particular spring constant, these suppliers can create Nitinol flat springs that meet your exact specifications.

Customization extends beyond mere dimensions; it also encompasses the specific functionality required in applications. For instance, how do nitinol springs work? Their shape memory effect and superelasticity can be harnessed for various uses—from actuators in robotics to components in complex medical equipment. The ability to tailor these properties ensures that engineers get precisely what they need without compromise.

Nitinol Flat Wire Versatility

Nitinol flat wire is another game changer in the realm of Precision Micro Springs & Wire Forms. This versatile material allows for a range of designs and configurations that traditional round wire simply cannot match. From flat wire torsion springs to custom shapes, the possibilities are endless when utilizing this innovative material.

The flexibility of Nitinol flat wire also means it can be used in applications where space constraints are an issue—think compact medical devices or intricate machinery where every millimeter counts. Its lightweight yet durable nature makes it ideal for industries demanding high performance without adding unnecessary weight or bulkiness to their products.

Role of Nitinol Wire Spool in Manufacturing

The manufacturing process of micro torsion nitinol springs heavily relies on the efficient use of a Nitinol wire spool. This essential tool helps streamline production by allowing manufacturers to easily handle and manipulate the wire during fabrication processes. With high-quality spools designed specifically for Nitinol materials, manufacturers can ensure consistent tension and feed rates, leading to superior end products.

Moreover, using a well-engineered Nitinol wire spool reduces waste and enhances overall efficiency during production runs—key factors when striving for cost-effectiveness without sacrificing quality. As demand grows across various industries for precision-engineered components like Nitinol torsion springs, optimizing manufacturing processes through effective tools becomes increasingly vital.

GEE SMA: Your Nitinol Partner

Commitment to Quality in Nitinol Production

At GEE SMA, our commitment to quality starts with the raw materials used in our production of nitinol springs. We source only the finest alloys to ensure that our micro torsion nitinol springs exhibit exceptional properties such as shape memory effect and superelasticity. This rigorous approach guarantees that our customers receive products they can trust for their engineering needs.

Our state-of-the-art manufacturing processes also play a crucial role in maintaining high quality standards. By employing advanced techniques and technologies, we ensure that every Nitinol torsion spring is crafted with precision and care. This meticulous attention to detail sets us apart from other Nitinol Springs Suppliers who may compromise on quality for cost.

Tailored Solutions for Unique Applications

One size does not fit all when it comes to micro torsion nitinol springs; that's why GEE SMA specializes in providing tailored solutions for unique applications across various industries. Whether you need custom dimensions or specific performance characteristics, we work closely with clients to develop Precision Micro Springs & Wire Forms that meet their exact requirements.

Our expertise extends beyond mere customization; we also offer a wide range of options including Nitinol Flat Springs and specialized designs utilizing Nitinol wire spool technology. This versatility allows us to cater to diverse sectors such as medical devices, aerospace, and automotive engineering seamlessly. No matter your challenge, we have the capability to deliver an optimal solution.

Why GEE SMA Stands Out Among Suppliers

In a crowded marketplace of Nitinol Springs Suppliers, what makes GEE SMA stand out? First and foremost is our unwavering focus on customer satisfaction; we prioritize understanding your needs so we can provide effective solutions tailored specifically for you. Our team is dedicated not only to producing high-quality products but also ensuring a smooth experience from order placement through delivery.

Moreover, our extensive knowledge about how do nitinol springs work? allows us to educate clients about the benefits of using these innovative materials in their projects effectively. With a reputation built on trust and reliability over years of service, customers can count on us as their preferred partner for all things related to micro torsion nitinol springs.

The Future of Micro Torsion Nitinol Springs

As we gaze into the horizon of innovation, the future of micro torsion nitinol springs appears bright and full of promise. Advancements in technology and materials are paving the way for even more sophisticated applications, making these tiny yet mighty components indispensable across various industries. With ongoing research and development, we can expect to see enhanced performance characteristics that will revolutionize how we utilize Nitinol springs in engineering designs.

Advancements in Technology and Materials

The evolution of micro torsion nitinol springs is closely tied to advancements in manufacturing techniques and material science. Innovations such as additive manufacturing are enabling the production of more complex geometries while maintaining precision, resulting in highly efficient Precision Micro Springs & Wire Forms that cater to specialized needs. Furthermore, new alloy compositions are being explored to enhance properties like fatigue resistance and temperature stability, ensuring that Nitinol flat springs can withstand demanding environments.

These technological strides not only improve performance but also open doors for novel applications where traditional materials may falter. Imagine a world where medical devices incorporate ultra-reliable Nitinol torsion springs designed with cutting-edge technology; the possibilities are endless! As suppliers continue to refine their processes, we will see a surge in customized solutions tailored specifically for unique industrial challenges.

Potential Industries Benefiting from Nitinol

Micro torsion nitinol springs are poised to make waves across multiple sectors due to their unique properties and versatility. The medical industry stands out as a primary beneficiary; devices such as stents, guidewires, and surgical instruments increasingly rely on the distinct advantages offered by Nitinol flat wire forms. In addition to healthcare, automotive manufacturers are exploring how do nitinol springs work? within systems requiring lightweight yet durable components that can endure extreme conditions.

Aerospace is another promising field where micro torsion nitinol springs can play a crucial role by reducing weight while enhancing performance reliability in critical applications like actuators and control surfaces. Furthermore, consumer electronics could leverage these advanced materials for compact devices that require precise mechanical movements without sacrificing durability or efficiency. As various industries recognize the potential of these innovative solutions, demand for high-quality Nitinol spring products will undoubtedly escalate.

Environmental Impact and Sustainability

In today's world, sustainability is at the forefront of technological advancement—and micro torsion nitinol springs are no exception! By utilizing Nitinol wire spools made from recyclable materials or developing eco-friendlier production methods, manufacturers can significantly reduce their environmental footprint while still delivering high-performance products like Nitinol flat springs. This commitment not only benefits our planet but also aligns with growing consumer preferences for sustainable practices across all sectors.

Moreover, thanks to their extraordinary durability and corrosion resistance properties, products made from micro torsion nitinol springs have longer lifespans compared to conventional alternatives—resulting in less waste over time! As industries continue embracing environmentally conscious practices alongside cutting-edge technology advancements, we anticipate a brighter future for both our planet and innovative engineering solutions alike.

Conclusion

In the ever-evolving landscape of engineering and technology, micro torsion nitinol springs stand out as a remarkable innovation. Their unique properties not only enhance performance but also offer solutions that traditional materials simply cannot match. By choosing these advanced components, industries can achieve greater efficiency, reliability, and adaptability in their applications.

Benefits of Choosing Nitinol Springs

When considering why to opt for micro torsion nitinol springs, the advantages are compelling. First and foremost is their exceptional shape memory effect; when heated or subjected to stress, these springs return to their original shape, showcasing a level of resilience that is unmatched by conventional springs. Furthermore, the superelasticity inherent in Nitinol allows for significant deformation without permanent damage—ideal for Precision Micro Springs & Wire Forms used in intricate designs.

Additionally, durability is a hallmark of Nitinol flat wire products; they resist corrosion and wear over time, making them perfect for applications in challenging environments. The versatility of Nitinol flat springs means they can be tailored to fit specific needs across various industries. With reliable suppliers like GEE SMA providing high-quality components and support on how do nitinol springs work?, you can rest assured that your investment will pay off handsomely.

Transforming Industries with Nitinol Alloys

Nitinol alloys are revolutionizing numerous sectors by offering innovative solutions that enhance functionality while reducing costs. From medical devices requiring precision-engineered components to automotive applications demanding lightweight yet durable materials, micro torsion nitinol springs are paving the way for advancements we once only dreamed about. The ability to customize Nitinol wire spool configurations allows engineers to create bespoke solutions tailored precisely to project specifications.

Moreover, industries such as aerospace benefit from the unique properties of Nitinol flat wire products due to their strength-to-weight ratio and resistance to extreme temperatures. As more sectors recognize the potential of these materials—including robotics and consumer electronics—the demand for quality Nitinol springs suppliers continues to rise dramatically. This trend signifies not just a shift in material choice but also an evolution in how products are designed and manufactured.

The Future Looks Bright for Nitinol Technology

Looking ahead, the future of micro torsion nitinol springs appears exceptionally promising as technological advancements pave new pathways for innovation. Researchers are continuously exploring ways to enhance the performance characteristics of Nitinol alloys while reducing production costs—making them even more accessible across various industries. As sustainability becomes increasingly important in manufacturing processes, eco-friendly practices associated with producing Nitinol flat springs will likely gain traction.

Moreover, with ongoing developments in smart materials technology and automation processes utilizing precision micro springs & wire forms, we may soon see even broader applications across multiple fields—from healthcare innovations like self-expanding stents to automotive safety features that adapt dynamically during operation. It’s evident that as we embrace these cutting-edge technologies today, we’re setting the stage for transformative changes tomorrow.