Introduction

SMA springs are making a significant impact in the world of smart devices. These innovative shape memory alloy (SMA) components offer unique benefits that enhance the resilience and performance of various devices. At the forefront of this engineering revolution is GEE SMA, a leading provider of SMA technology solutions that play a crucial role in ensuring the durability and reliability of smart devices.

Understanding SMA Springs

SMA springs, also known as shape memory alloy springs, are a type of memory shape metal that can return to their original shape after deforming. This unique property makes them ideal for smart devices, where flexibility and resilience are essential for optimal performance.

SMA springs are revolutionizing the world of smart devices by providing a level of flexibility and resilience previously unattainable. These memory-shaped metal springs can withstand repeated deformation and return to their original shape, ensuring that smart devices maintain their performance over time. Whether in wearable technology, medical devices, or robotics, SMA springs are enhancing the functionality and durability of smart devices in various industries.

The Impact of SMA Springs on Smart Devices

Shape memory alloy (SMA) springs are transforming the functionality of smart devices. Here's how:

- Durability and Longevity: Unlike traditional springs, SMA springs can withstand repeated deformations and return to their original shape. This significantly improves the lifespan of various smart devices, from delicate medical implants to everyday consumer electronics.

- Smaller, Lighter, and More Flexible Designs: The resilience of SMA springs allows for the creation of smaller, lighter, and more flexible smart devices. This enables seamless integration into our daily lives, with wearable tech and unobtrusive medical devices becoming a reality.

- Expanding Capabilities and Applications: SMA springs have opened doors for new functionalities and applications by making smart devices more durable and adaptable. This paves the way for further innovation in the ever-evolving field of smart technology.

SMA springs are a game-changer for smart devices, enhancing durability, enabling innovative designs, and pushing the boundaries of what's possible in this exciting field.

Exploring the Role of GEE SMA in Engineering Resilience

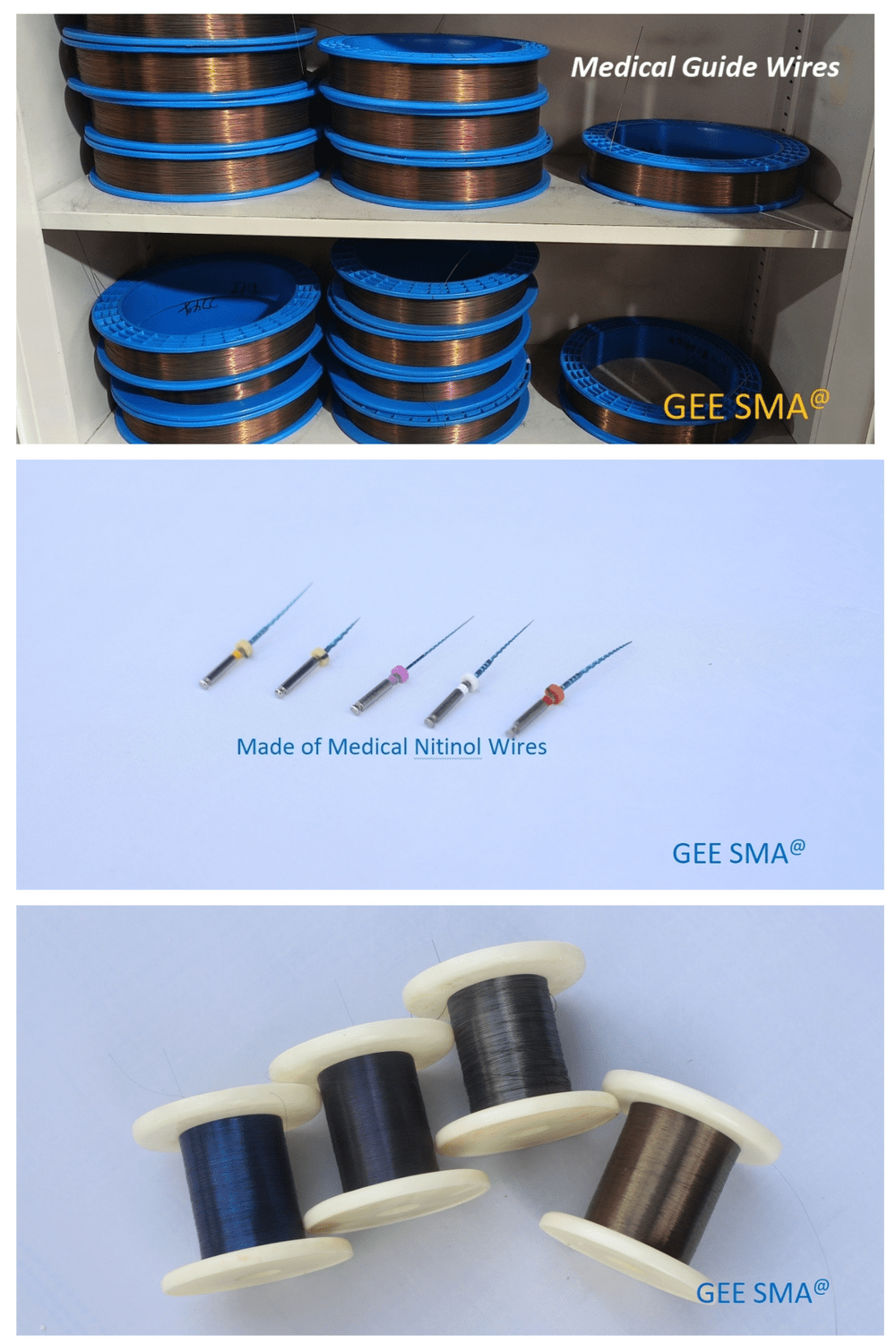

GEE SMA has been at the forefront of developing cutting-edge shape memory alloy wire and sheet technology that has redefined engineering resilience in smart devices. Their innovative solutions have paved the way for enhanced performance and reliability in diverse applications, setting new standards for excellence in the industry.

GEE SMA's commitment to pushing the boundaries of shape memory alloy technology has resulted in the development of materials that exhibit exceptional durability and resilience. By incorporating its SMA wire and sheet technology into smart devices, GEE SMA has revolutionized how engineers approach design and functionality. Their contributions have elevated performance standards and opened up new possibilities for creating more robust and reliable products across various industries.

Now, let's dive into the science behind SMA springs and how they enhance device resilience.

The Science Behind SMA Springs

Shape Memory Alloys in Smart Devices

Shape memory alloy (SMA) springs are a game-changer in smart devices, thanks to their unique ability to return to their original shape after being deformed. This remarkable property is due to the shape-memory effect, which allows the material to remember its original shape and revert to it when heated. As a result, SMA springs are widely used in various smart devices such as medical implants, automotive components, and consumer electronics.

How SMA Springs Enhance Device Resilience

The use of SMA springs significantly enhances the resilience of smart devices by allowing them to withstand repeated deformations without permanent damage. This is particularly valuable in applications where reliability and durability are critical, such as medical implants and aerospace components. The unique mechanical properties of SMA springs make them ideal for ensuring that smart devices can continue functioning optimally even under challenging conditions.

Key Properties of Nitinol in Engineering Applications

Nitinol, a nickel-titanium alloy, is revolutionizing smart devices with its unique properties. Here's how:

- Superelasticity: Nitinol can undergo significant deformation without breaking and spring back to its original shape once the pressure is off. This makes it ideal for durable smart devices that withstand everyday wear and tear.

- Shape Memory: Nitinol can be "trained" to remember a specific shape and return to it when exposed to a particular temperature. This opens doors for innovative features in smart devices.

- Corrosion Resistance: Nitinol is highly resistant to rust and corrosion, ensuring long-lasting performance in smart devices, even in harsh environments.

- Biocompatibility: Nitinol is safe for human contact, making it suitable for wearable smart devices and medical applications.

Nitinol's exceptional properties make it possible to create smarter, more resilient, and versatile devices that can enhance our everyday lives.

Advantages of Using SMA Springs

SMA springs offer many benefits for smart devices, making them essential to modern engineering. The flexibility and durability of shape memory alloy springs allow for seamless integration into various device designs, ensuring optimal performance and longevity. Additionally, the unique properties of SMA wire contribute to improved resilience and reliability in smart devices, setting them apart from traditional materials.

Flexibility and Durability in Smart Devices

Shape-memory alloy springs provide smart devices with unparalleled flexibility, allowing for intricate movements and adjustments without compromising structural integrity. This flexibility is crucial in medical and wearable technology applications, where user comfort is paramount. Furthermore, the inherent durability of SMA springs ensures that these devices can withstand constant use and environmental stressors, making them a reliable choice for long-term performance.

Improved Performance and Reliability

Shape memory alloy springs significantly enhance the performance and reliability of smart devices by providing consistent mechanical properties over time. This allows for precise control and predictable responses in various operating conditions, ultimately improving the overall functionality of these devices. Whether in the aerospace or automotive industries, using SMA springs leads to smoother operations and reduced maintenance needs, resulting in cost-effective solutions for manufacturers.

GEE SMA's Contribution to Smart Device Innovation

GEE SMA has been driving innovation in smart device technology through its advancements in shape memory alloys. GEE SMA has created cutting-edge smart devices with unprecedented capabilities by continually refining the manufacturing processes and material compositions. Their commitment to pushing the boundaries of engineering resilience has paved the way for new possibilities in fields such as consumer electronics and medical implants.

Applications of SMA Springs in Smart Devices

Medical Devices and Implants

Shape memory alloy springs are revolutionizing the medical industry, offering unparalleled benefits in devices and implants. From orthodontic braces to stents and surgical tools, SMA springs provide flexibility, durability, and biocompatibility for enhanced patient outcomes.

Shape memory alloy (SMA) springs have also been instrumental in developing minimally invasive surgical tools, allowing for greater precision and control during procedures. The flexibility of SMA springs enables them to be incorporated into intricate designs, making them ideal for use in endoscopic and laparoscopic instruments. This has improved surgical outcomes, reduced recovery times, and minimized scarring for patients undergoing minimally invasive procedures.

Aerospace and Automotive Industries

In aerospace and automotive engineering, shape memory alloy wire has transformed the design of safety mechanisms and structural components. SMA springs offer lightweight resilience, high fatigue resistance, and the ability to withstand extreme conditions, making them ideal for airbags, actuators, and engine components.

In addition to safety mechanisms and structural components, shape memory alloy wire has also revolutionized the automotive industry's design of fuel injection systems and exhaust components. The unique properties of SMA wire allow for precise control and efficient operation, leading to improved fuel efficiency and reduced emissions. This innovative use of shape memory alloy technology is helping to drive advancements in automotive engineering, making vehicles more environmentally friendly and economical to operate.

Consumer Electronics and Wearable Technology

The integration of shape-memory alloy technology has revolutionized how we interact with consumer electronics and wearable devices. With SMA springs, manufacturers can create products that mold to the user's body, providing a customized and comfortable experience. This innovation has opened up new possibilities for design and functionality, allowing for more ergonomic and user-friendly gadgets.

Now let's move on to the next section: V. Future Trends and Innovations in SMA Technology

Future Trends and Innovations in SMA Technology

Smart Materials in the Internet of Things

As smart devices evolve, integrating shape memory alloy (SMA) springs into the Internet of Things (IoT) is becoming increasingly prevalent. SMA springs offer unique benefits such as shape memory, superelasticity, and high damping capacity, making them ideal for IoT applications where compactness and reliability are essential. With the ability to return to their original shape after deformation, SMA springs can enhance the durability and longevity of IoT devices, reducing maintenance costs and improving overall performance. Their high damping capacity also allows for better shock absorption, ensuring that IoT devices remain operational even in harsh environments or during sudden impacts.

Sustainable Design and Engineering

Shape Memory Alloy (SMA) springs are becoming a game-changer in sustainable design and engineering. Here's how they contribute to a greener future:

- Reduced energy consumption: SMA springs can be designed to be more energy-efficient than traditional springs.

- Enhanced product longevity: Products with SMA springs can last longer, requiring fewer replacements.

- Potential for cost savings: Over time, the durability and energy efficiency of SMA springs can lead to significant cost savings.

By incorporating SMA springs into smart devices, manufacturers can create more durable products. This reduces the need for frequent replacements, ultimately lowering the environmental impact of electronic waste. In conclusion, the shift towards sustainable engineering solutions with SMA springs benefits both the planet and businesses. Companies can align with consumer demand for eco-friendly products while reducing waste.

GEE SMA's Ongoing Research and Development Efforts

GEE SMA remains at the forefront of ongoing research and development efforts aimed at further enhancing the capabilities of shape memory alloy technology. The company's commitment to innovation is evident in its exploration of new applications for SMA springs and continuous improvement of shape memory alloy sheet materials. These efforts are poised to drive significant advancements in smart device resilience and performance.

Furthermore, GEE SMA's research and development efforts also focus on integrating shape memory alloy technology into biomedical devices, such as stents and orthodontic wires. By leveraging SMA's unique properties, the company aims to revolutionize the field of medical implants, providing enhanced flexibility and biocompatibility for improved patient outcomes. This strategic expansion into the healthcare sector demonstrates GEE SMA's forward-thinking approach to innovation and its dedication to addressing diverse industry needs.

GEE SMA's Commitment to Quality and Innovation

SMA springs are poised to revolutionize the world of smart devices, offering unparalleled flexibility, durability, and resilience. As the demand for cutting-edge technology continues to grow, the future of SMA springs in smart devices looks promising, with endless possibilities for innovation and advancement.

The Future of SMA Springs in Smart Devices

The future of SMA springs in smart devices is bright, with their unique properties making them an indispensable component in various applications. From medical devices to consumer electronics, shape memory alloy springs are expected to soar as technology continues to evolve and demand for high-performance devices grows.

The unique properties of SMA springs, such as their ability to return to their original shape after being deformed, make them an ideal choice for smart devices. As technology continues to evolve, the demand for high-performance devices is expected to grow, further driving the use of SMA springs in various applications. Their durability and reliability also make them indispensable in medical devices, where precision and consistency are crucial.

GEE SMA remains at the forefront of quality and innovation in developing and producing shape memory alloy springs. With a commitment to excellence, GEE SMA continues to advance smart device technology through cutting-edge research and development efforts.

GEE SMA's dedication to quality and innovation extends beyond developing shape memory alloy springs. The company also focuses on engineering resilience by harnessing the potential of Nitinol, a nickel-titanium alloy with unique shape memory and superelastic properties. By leveraging Nitinol's capabilities, GEE SMA can create resilient components that can withstand extreme conditions, making them ideal for various applications in aerospace, medical devices, and automotive engineering.

Harnessing the Potential of Nitinol for Engineering Resilience

As a leader in engineering resilience, GEE SMA is dedicated to harnessing the full potential of Nitinol and shape memory alloy technology. With a focus on sustainable design and engineering, GEE SMA is paving the way for a future where smart devices are high-performing, environmentally friendly, and resilient. By leveraging the unique properties of Nitinol, such as its shape memory effect and superelasticity, GEE SMA can create innovative solutions for various industries, including medical devices, aerospace, and consumer electronics. This allows for developing products that adapt to changing conditions, withstand extreme environments, and contribute to a more sustainable and resilient world.

This concludes our exploration into the impact and potential of SMA springs in smart devices. As we look ahead, it's clear that these innovative components will continue to play a pivotal role in shaping the future of technology across various industries.