Introduction

When it comes to medical manufacturing, NiTi alloy wire is a game-changer. But what exactly is NiTi alloy? How does it compare to stainless steel? And what role does it play in skeletal health? These are the questions we'll explore in this comprehensive guide.

Understanding NiTi Alloy

NiTi alloy, also known as Nitinol, is a shape memory nickel titanium alloy wire that exhibits unique properties such as superelasticity and shape memory effect. This makes it an ideal material for medical applications, especially in orthodontics and fracture fixation. In comparison to stainless steel, NiTi alloy offers greater flexibility and resistance to corrosion, making it a preferred choice for medical devices. Additionally, the superelasticity of NiTi alloy allows for more comfortable and effective treatment in orthodontic applications, providing patients with a better experience overall.

Comparing NiTi Alloy to Stainless Steel

Unlike stainless steel, NiTi wire offers superior flexibility and biocompatibility, making it a preferred choice for medical devices and implants. Its ability to return to its original shape after deformation sets it apart from traditional materials like stainless steel.

NiTi alloy's unique properties make it an ideal material for skeletal health applications. Its superior flexibility allows for more natural movement within the body, reducing the risk of discomfort or injury. Additionally, its biocompatibility ensures that it is well-tolerated by the body, minimizing the potential for adverse reactions or complications. These qualities make NiTi wire a top choice for orthopedic implants and devices designed to support skeletal health.

NiTi Alloy in Skeletal Health

In the field of skeletal health, medical grade nitinol wire has revolutionized treatment options by providing enhanced tensile strength and shape memory properties for orthodontic applications and fracture fixation. This innovative alloy, composed of nickel and titanium, allows for greater flexibility and durability in orthopedic devices, leading to improved patient outcomes. Additionally, the biocompatibility of NiTi alloy makes it an ideal choice for implants, as it reduces the risk of adverse reactions or rejections in the body. Its unique properties also enable minimally invasive procedures, reducing recovery time and improving overall patient comfort.

What is NiTi Alloy?

Definition and Properties

NiTi alloy, also known as Nitinol, is a type of shape memory alloy made from nearly equal parts of nickel and titanium. This unique material exhibits the ability to return to a predetermined shape when heated, making it ideal for medical applications such as orthodontic wires and cardiovascular stents.

Nitinol's unique properties also make it an excellent choice for minimally invasive medical procedures. Its ability to return to its original shape allows for the creation of self-expanding stents that can be inserted into blood vessels with minimal trauma to the patient. This has revolutionized the treatment of cardiovascular disease, providing a more effective and less invasive alternative to traditional surgical methods. Additionally, Nitinol's biocompatibility and resistance to corrosion make it a safe and durable option for long-term implantation in the body.

Advantages in Medical Applications

The exceptional properties of NiTi alloy make it highly desirable for medical manufacturing. Its superelasticity and shape memory capabilities allow for minimally invasive procedures and reduced recovery times for patients. Additionally, its biocompatibility and corrosion resistance make it suitable for long-term implantation in the human body.

Furthermore, the NiTi alloy's ability to withstand harsh bodily environments makes it an ideal material for medical devices such as stents, orthopedic implants, and dental braces. This durability ensures that the devices remain intact and functional over extended periods, reducing the need for frequent replacements and minimizing patient discomfort. The reliability of NiTi alloy in medical applications contributes to improved patient outcomes and overall satisfaction with medical treatments.

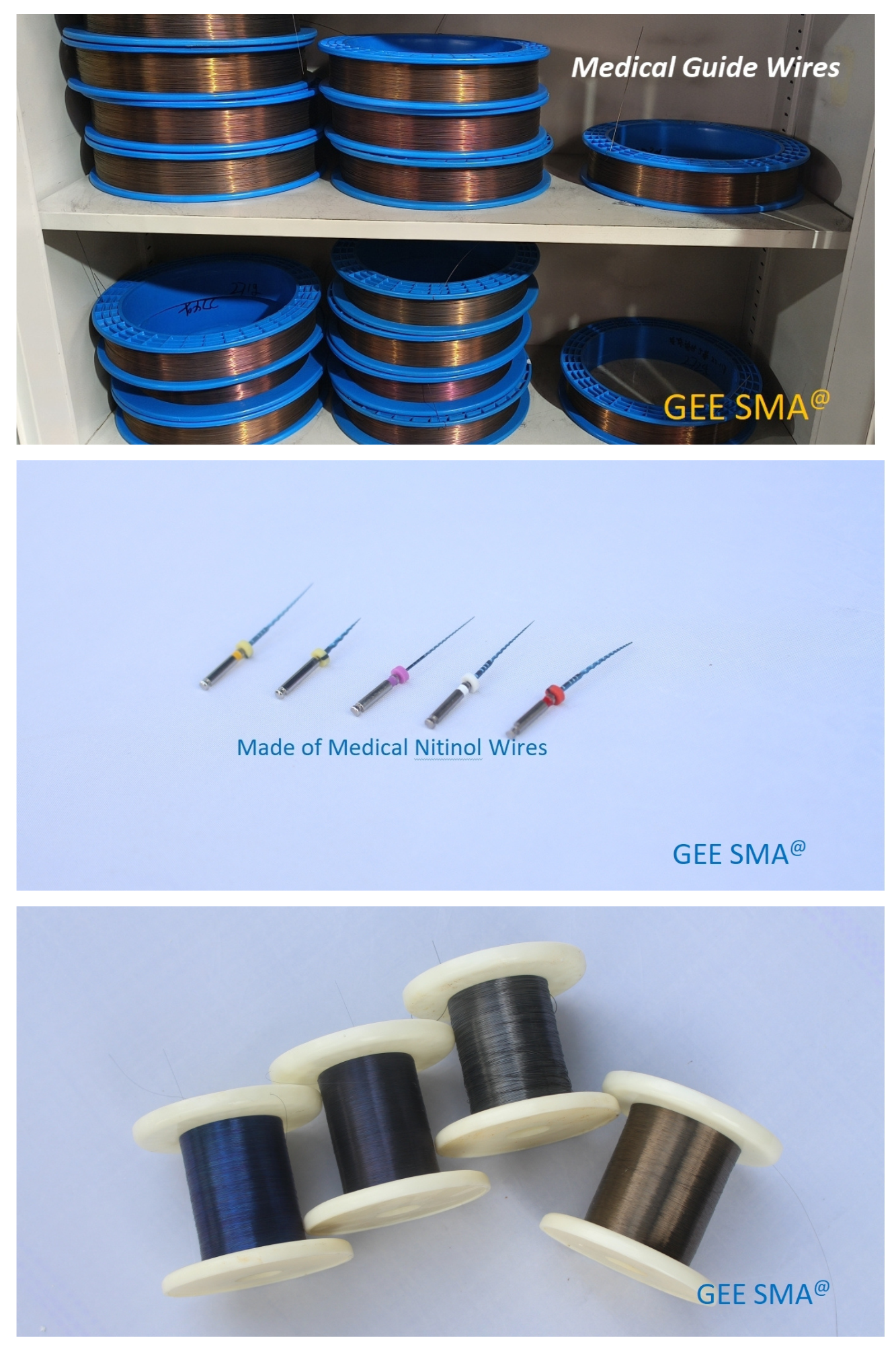

GEE SMA's Expertise in NiTi Alloy Production

GEE SMA specializes in the production of high-quality medical grade nitinol wire for a wide range of applications. With cutting-edge technology and a deep understanding of the unique properties of NiTi alloy, GEE SMA is a trusted source for reliable and precise nitinol materials used in medical devices.

GEE SMA's expertise in NiTi alloy production extends beyond just the manufacturing process. The company also offers comprehensive testing and quality control measures to ensure that every nitinol wire meets the highest standards for medical use. This dedication to excellence sets GEE SMA apart as a leader in the industry, providing peace of mind to medical device manufacturers and end-users alike.

NiTi Alloy Wire vs. Stainless Steel Wire

Strength and Flexibility Comparison

When comparing medical NiTi alloy wire to stainless steel wire, the most notable difference lies in their strength and flexibility. NiTi alloy wire, also known as shape memory nickel titanium alloy wire, is highly flexible and exhibits superelasticity, allowing it to return to its original shape after deformation. On the other hand, stainless steel wire is more rigid and lacks the same level of flexibility as NiTi alloy wire. This makes medical grade nitinol wire ideal for various medical applications where flexibility is crucial.

In addition to its superior strength and flexibility, NiTi alloy wire also boasts impressive biocompatibility and corrosion resistance. This means that it is well-suited for use within the human body without causing adverse reactions or deteriorating over time. In contrast, stainless steel wire may not offer the same level of biocompatibility and is more prone to corrosion, making it less suitable for long-term medical applications where durability and compatibility are essential.

Biocompatibility and Corrosion Resistance

Another key difference between stainless steel and NiTi alloy wire lies in their biocompatibility and corrosion resistance. Medical grade nitinol wire offers superior biocompatibility, making it suitable for use within the human body without causing adverse reactions. Additionally, NiTi alloy exhibits excellent corrosion resistance, ensuring its durability even in harsh physiological environments. In contrast, stainless steel may not possess the same level of biocompatibility or corrosion resistance as Nitinol Wire for Medical Manufacturing.

Furthermore, the unique shape memory and superelasticity properties of NiTi alloy wire make it an ideal material for various medical products, such as stents, orthodontic wires, and guidewires. Its ability to return to its original shape after deformation allows for better patient comfort and reduced risk of complications during medical procedures. In contrast, stainless steel may not offer the same level of flexibility and adaptability in medical device applications, making Nitinol wire a preferred choice for many medical manufacturers.

Medical Grade Nitinol Wire for Multiple Products

The unique properties of NiTi alloy, such as its superelasticity and biocompatibility, make it an ideal material for manufacturing medical devices used in skeletal health. Whether it's for orthopedic implants or spinal instrumentation, medical grade nitinol wire offers the flexibility and strength needed to support bone healing and reconstruction. Its ability to withstand repeated bending and twisting without permanent deformation makes it a reliable choice for implants that require long-term durability in the body.

NiTi Alloy Wire in Skeletal Health

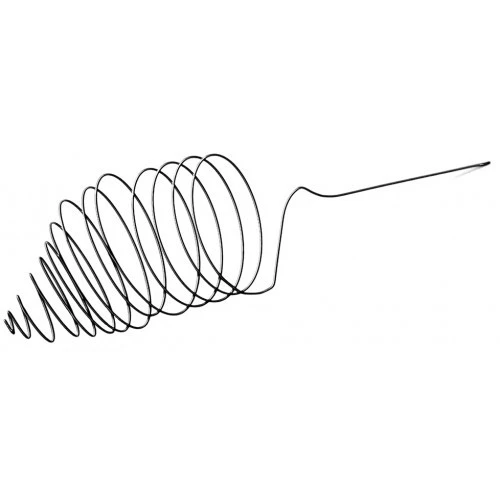

Shape Memory Properties for Orthodontic Applications

NiTi alloy wire is widely used in orthodontic applications due to its unique shape memory properties. This allows the wire to return to its original shape even after being bent, making it ideal for braces and other dental appliances. The flexibility and resilience of NiTi wire make it a preferred choice for orthodontic treatment, providing patients with effective and comfortable dental care.

NiTi wire's ability to maintain its shape and provide consistent force over time is crucial for successful orthodontic treatment. This unique property allows for gradual and controlled movement of the teeth, resulting in more predictable and efficient outcomes. Additionally, the biocompatibility of NiTi wire reduces the risk of allergic reactions or tissue irritation, ensuring a safe and comfortable experience for patients undergoing orthodontic treatment. With its remarkable shape memory properties, NiTi wire continues to revolutionize the field of orthodontics, offering innovative solutions for dental practitioners and their patients.

Tensile Medical Grade Nitinol Wire for Fracture Fixation

In the field of fracture fixation, medical grade nitinol wire offers exceptional tensile strength and flexibility, providing reliable support for bone healing. Unlike stainless steel wire, NiTi alloy wire's biocompatibility and corrosion resistance make it an excellent choice for internal fixation devices. Its superior performance and compatibility with the human body make it a top choice for orthopedic surgeons.

In addition to its biocompatibility and corrosion resistance, medical grade nitinol wire also offers enhanced super-elasticity, allowing for greater flexibility and adaptability within the body. This makes it an ideal choice for skeletal health applications, as it can accommodate natural movement and stress on the bones without compromising its structural integrity. Orthopedic surgeons can rely on NiTi alloy wire to provide long-lasting support for bone healing while minimizing the risk of complications or discomfort for the patient.

Enhanced Super-Elastic NiTi Alloy Wire for Skeletal Health

For various skeletal health applications, enhanced super-elastic NiTi alloy wire provides unparalleled performance and durability. Its ability to withstand repeated bending without permanent deformation makes it an ideal material for a wide range of medical devices, including stents, guidewires, and catheters. With its exceptional properties, medical grade nitinol wire continues to revolutionize skeletal health treatments.

Remember that using high-quality NiTi alloy materials is crucial in achieving successful skeletal health treatments. As a leading expert in producing superior NiTi alloy products, GEE SMA is committed to delivering innovative solutions that advance the field of medical manufacturing and improve patient outcomes.

Conclusion

NiTi alloy wire offers unique benefits in medical manufacturing, providing shape memory properties and high tensile strength for multiple products. With its superior flexibility and biocompatibility, NiTi alloy wire is advancing skeletal health in orthodontic applications and fracture fixation. GEE SMA is your trusted source for high-quality NiTi alloy materials.

Unique Benefits of NiTi Alloy

NiTi alloy, also known as shape memory nickel titanium alloy wire, is a versatile material with exceptional properties for medical applications. Its ability to return to a predetermined shape after deformation makes it ideal for use in various medical devices, offering unmatched performance and reliability.

NiTi alloy's unique ability to withstand repeated deformation without losing its shape makes it an ideal material for medical devices used in orthopedic and dental procedures. Its exceptional flexibility and durability allow for the creation of innovative implants and instruments that can adapt to the body's natural movements, providing patients with greater comfort and improved outcomes. This remarkable property of NiTi alloy has revolutionized the field of skeletal health, offering new possibilities for minimally invasive treatments and enhanced patient care.

Advancing Skeletal Health with NiTi Alloy

The use of NiTi alloy wire has revolutionized skeletal health by providing innovative solutions for orthodontic treatments and fracture fixation. Its unique properties allow for precise control of tooth movement and optimal bone healing, leading to improved patient outcomes and faster recovery times. Additionally, NiTi alloy materials offer superior biocompatibility, reducing the risk of allergic reactions and inflammation commonly associated with traditional metal implants. This makes them an ideal choice for patients with sensitivities or allergies, ensuring a smoother and more comfortable recovery process.

GEE SMA: Your Trusted Source for NiTi Alloy Materials

GEE SMA specializes in the production of high-quality medical grade nitinol wire for a wide range of applications. With our expertise in NiTi alloy manufacturing, we are committed to delivering reliable and cost-effective solutions to meet the diverse needs of the medical industry.

At GEE SMA, we understand the critical importance of consistent quality and performance in medical devices. That's why we take great care in every step of the manufacturing process, from material selection to production and testing. Our nitinol wire is meticulously crafted to ensure superior shape memory and superelasticity, making it an ideal choice for a wide range of medical applications, including stents, guidewires, and orthodontic devices.