Introduction

When it comes to medical procedures, precision and reliability are crucial. This is where medical Niti guide wires come into play. These small but mighty tools play a significant role in various medical procedures, providing support and guidance for other instruments. Whether it's navigating through blood vessels in the cath lab or assisting in orthopedic surgeries, understanding the importance of medical guide wires is essential.

Understanding Medical Niti Guide Wires

Medical Niti guide wires are thin, flexible wires used to guide and support the placement of various medical devices during surgical and diagnostic procedures. They are commonly made from nitinol, a nickel-titanium alloy known for its superelasticity and shape memory properties. This unique material allows the guide wire to bend without breaking and return to its original shape once released.

What is a Medical Guide Wire?

A medical guide wire is a crucial tool used in catheterization procedures to navigate through blood vessels with precision and ease. It provides a pathway for other instruments such as catheters or stents to be inserted into the body, allowing healthcare professionals to perform minimally invasive interventions with accuracy.

Exploring Niti Guide Wires

In orthopedic surgeries, Ortho guide wires are utilized to aid in the placement of implants such as screws or plates within bones. These specialized guide wires provide stability and guidance during the surgical procedure, ensuring proper alignment and positioning of orthopedic devices.

The Basics of Medical Guide Wires

What is a nitinol guidewire?

A nitinol guidewire is commonly used in catheterization procedures in the cath lab. Its unique properties make it an essential tool for navigating through blood vessels and other anatomical structures with precision and ease. The superelasticity of the nitinol alloy allows the wire to withstand the forces exerted during insertion and manipulation, reducing the risk of damage to delicate tissues. Additionally, its shape memory ensures that the wire maintains its original form once inside the body, providing reliable support for the placement of catheters and other medical devices.

What is the guide wire used in cath lab?

In the cath lab, a specialized type of medical guide wire called a coronary guidewire is used for various cardiac procedures such as angioplasty and stent placement. These wires are designed to be highly flexible and have a hydrophilic coating to reduce friction as they navigate through blood vessels.

In addition to coronary guidewires, orthopedic guide wires are also used in the cath lab for procedures such as orthopedic surgeries and fracture repair. These guide wires are designed to provide stability and precision during bone drilling and implant placement. They are typically made of stainless steel or titanium, offering strength and durability to support the surgical process. Ortho guide wires come in various lengths and diameters to accommodate different patient anatomies and surgical requirements.

What is the Ortho guide wire used for?

Orthopedic guide wires are specifically designed for orthopedic surgeries such as fracture fixation or joint replacement procedures. These wires are typically stronger and stiffer than other types of medical guide wires, allowing them to withstand the forces required for bone drilling and fixation.

Orthopedic guide wires are essential tools in orthopedic surgeries, providing stability and precision during procedures. Their strength and stiffness allow surgeons to navigate through bone tissue with ease, reducing the risk of complications and ensuring accurate placement of implants. Additionally, these guide wires are designed to minimize trauma to surrounding tissues, promoting faster healing and recovery for patients.

Choosing the Right Niti Guide Wire

When selecting a medical guide wire, there are several factors to consider. The type of procedure being performed, the patient's anatomy, and the physician's experience all play a role in determining the best guide wire for the job. Additionally, the flexibility, torqueability, and pushability of the wire are crucial aspects to take into account when making a selection.

Factors to consider when selecting a guide wire

The NiTi Guide Wire company options available in the market should be carefully evaluated. It's important to choose a reputable company with a track record of producing high-quality medical guide wires. Consider factors such as material composition, manufacturing processes, and any certifications or accreditations held by the company.

NiTi Guide Wire company options

Key features to look for in a medical guide wire include tip design, hydrophilic coating, and radiopacity. The tip design should facilitate smooth navigation through vessels or other anatomical structures. A hydrophilic coating can reduce friction during insertion and improve trackability. Radiopacity is essential for visualization under fluoroscopy during procedures.

Now that we've covered what to consider when choosing a Niti guide wire and explored some company options, let's dive into the key features to look for in this essential medical tool.

Key features to look for in a medical guide wire

In conclusion, selecting the right Niti guide wire is crucial for successful medical procedures. By carefully considering various factors such as procedure requirements, company reputation, and key features of the wire itself, healthcare professionals can ensure optimal outcomes for their patients.

Applications of Medical Guide Wires

Using guide wires in different medical procedures

Medical guide wires are essential tools used in a variety of medical procedures, including cardiac catheterization, angioplasty, and endovascular surgeries. They are also used in orthopedic surgeries to guide the placement of implants and repair fractured bones.

Advantages of using Niti guide wires

Niti guide wires offer several advantages over traditional guide wires, including increased flexibility, shape memory, and resistance to kinking or deformation during procedures. Their biocompatibility and radiopacity make them ideal for use in minimally invasive surgeries and diagnostic imaging.

Common challenges and solutions with medical guide wires

One common challenge with medical guide wires is the risk of vessel injury during navigation. This can be mitigated by using hydrophilic coatings to reduce friction and improve trackability. Another challenge is the potential for wire breakage, which can be addressed by using high-quality Niti materials with superior tensile strength.

The Future of Niti Guide Wire Technology

With advancements in medical technology, the future of Niti guide wire technology looks promising. Innovations in medical guide wire design are focused on enhancing flexibility, trackability, and pushability to improve maneuverability during procedures. Potential advancements in Niti guide wire materials involve developing stronger and more durable alloys to increase longevity and performance. The impact of Niti guide wires on the medical industry is expected to revolutionize minimally invasive procedures, leading to improved patient outcomes and reduced recovery times.

Innovations in medical guide wire design

Innovations in medical guide wire design are centered around improving the overall functionality and performance of these essential tools. New designs aim to enhance flexibility, allowing for easier navigation through complex anatomical structures. Additionally, advancements seek to improve trackability, enabling smoother advancement through tortuous vessels while maintaining stability. These innovations are set to revolutionize interventional procedures by providing physicians with greater precision and control.

Furthermore, potential advancements in Niti guide wire materials are also being explored to enhance the performance of medical guide wires. The utilization of shape memory alloys such as Nitinol can provide improved flexibility and kink resistance, allowing for smoother navigation through intricate vascular pathways. These materials also offer the advantage of increased durability, reducing the risk of breakage during procedures and ensuring reliable performance. By incorporating these advanced materials into guide wire design, medical professionals can expect greater ease of use and enhanced patient outcomes.

Potential advancements in Niti guide wire materials

The potential advancements in Niti guide wire materials focus on developing alloys with superior mechanical properties. By incorporating new materials or refining existing ones, manufacturers aim to create guide wires that are stronger, more kink-resistant, and have better torque response. These advancements will contribute to increased durability and reliability during procedures, ultimately improving patient safety and procedural success rates.

The development of Niti guide wire materials with superior mechanical properties will also lead to more precise and efficient medical procedures. With better torque response and kink resistance, physicians will be able to navigate through the vasculature with greater ease and accuracy, reducing the risk of complications and improving overall patient outcomes. These advancements will not only benefit patients but also streamline the workflow for healthcare providers, ultimately leading to cost savings and improved resource allocation within the medical industry.

Impact of Niti guide wires on the medical industry

The impact of Niti guide wires on the medical industry is far-reaching. As these devices continue to evolve, they play a crucial role in advancing minimally invasive techniques across various medical specialties. From cardiology to orthopedics, the use of Niti guide wires enables less invasive procedures with reduced risks and faster recovery times for patients. This shift towards minimally invasive interventions is reshaping the landscape of modern medicine by offering innovative solutions for complex conditions.

The use of Niti guide wires has also led to a significant reduction in the need for open surgeries, as these wires allow for precise navigation through the body's intricate network of blood vessels and tissues. This has not only minimized the risks associated with traditional surgical procedures but has also resulted in shorter hospital stays and lower healthcare costs for patients. Additionally, the increased adoption of Niti guide wires has paved the way for more outpatient procedures, giving patients the convenience of receiving treatment without prolonged hospitalization.

Ensuring Quality and Safety in Medical Guide Wires

When it comes to the production of medical Niti guide wires, adherence to strict standards and regulations is crucial. These guidelines ensure that the materials and components used in guide wire manufacturing meet the highest safety and quality standards, ultimately benefiting patients and healthcare providers.

Standards and regulations for Niti guide wire production

The FDA and ISO have established comprehensive standards for the production of medical guide wires, covering everything from material composition to manufacturing processes. These regulations are designed to guarantee the reliability, biocompatibility, and performance of Niti guide wires, providing assurance to medical professionals and patients alike.

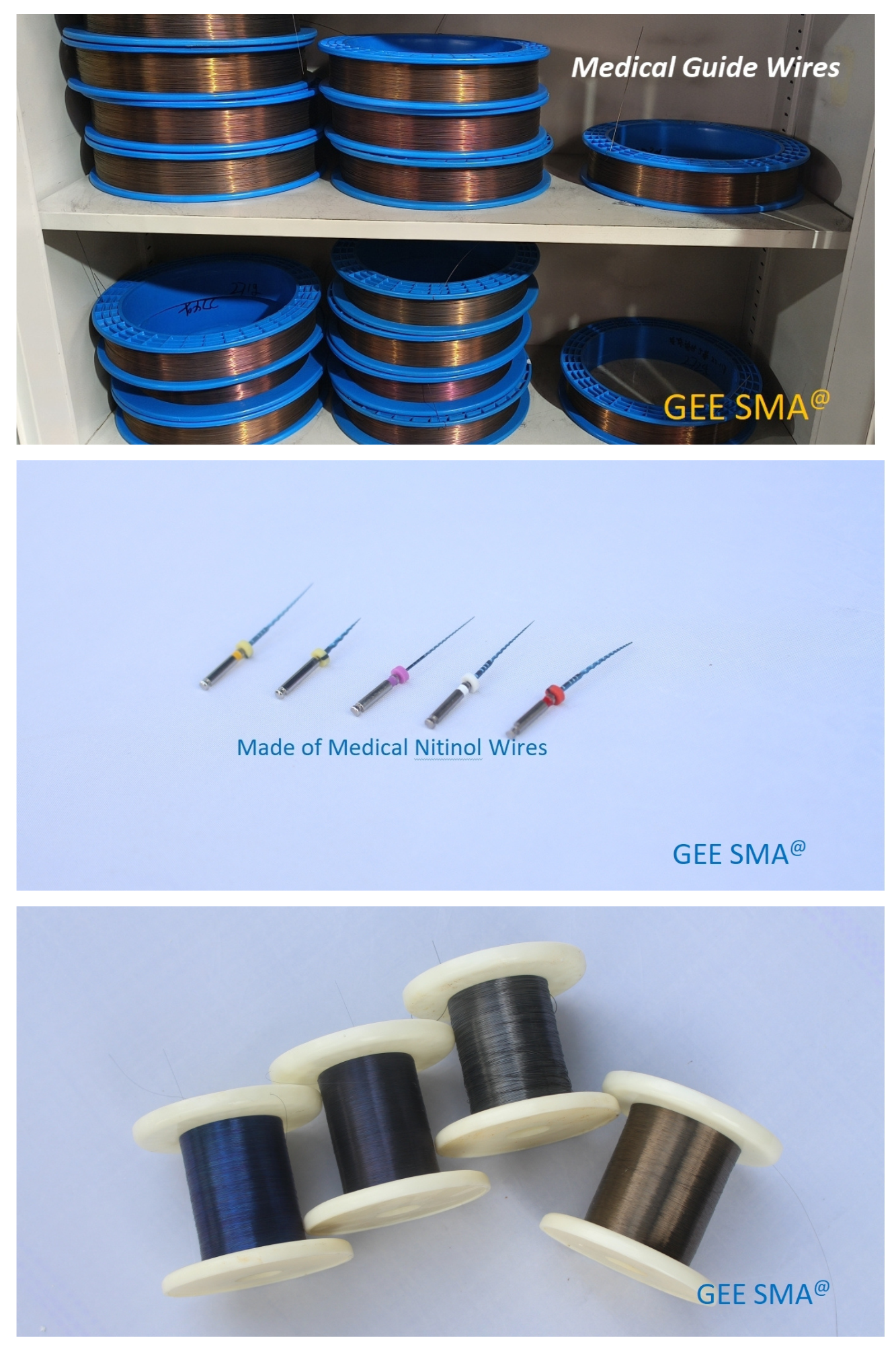

GEE SMA's commitment to high-quality Niti materials

As a leading NiTi Guide Wire company, GEE SMA is dedicated to upholding the highest standards when it comes to producing Niti materials for medical applications. With a focus on precision engineering and rigorous quality control measures, GEE SMA ensures that their Niti guide wires consistently meet or exceed industry requirements.

GEE SMA's commitment to high-quality Niti materials is evident in their dedication to using the latest manufacturing techniques and cutting-edge technology. By staying at the forefront of advancements in Niti material production, GEE SMA ensures that their guide wires are not only reliable but also at the forefront of innovation in the medical industry. This commitment to staying ahead of the curve ultimately benefits healthcare professionals and patients alike, as they can trust in the quality and performance of GEE SMA's Niti guide wires for even the most delicate procedures.

Importance of reliability in medical guide wire selection

When selecting a medical guide wire for use in procedures such as catheterization or orthopedic surgery, reliability is paramount. The integrity of the guide wire directly impacts patient outcomes, making it essential for healthcare providers to choose products from reputable manufacturers like GEE SMA that prioritize safety and performance.

Remember that when it comes to ensuring quality and safety in medical guide wires, adherence to strict standards is key. GEE SMA's commitment to high-quality Niti materials reflects their dedication to providing reliable solutions for healthcare professionals across various specialties.

Conclusion

The role of Niti guide wires in modern medicine

Niti guide wires play a crucial role in modern medicine, offering precision and flexibility in various medical procedures. From navigating through blood vessels in the cath lab to guiding orthopedic implants, these medical guide wires are essential tools for healthcare professionals.

Considerations for choosing the right medical guide wire

When selecting a medical guide wire, it's important to consider factors such as flexibility, tip design, and material quality. It's also crucial to choose a reputable NiTi Guide Wire company that offers a wide range of options and key features like radiopacity and hydrophilic coatings to ensure successful procedures.

GEE SMA's dedication to crafting high-quality Niti materials and components

GEE SMA is dedicated to crafting high-quality Niti materials and components for medical guide wires, ensuring reliability and safety in every use. With a commitment to meeting standards and regulations for production, GEE SMA provides innovative solutions that contribute to advancements in medical technology.