Introduction

Nitinol SE508 wire is a fascinating material that combines unique properties with a wide range of applications. This alloy, primarily composed of nickel and titanium, boasts remarkable features such as shape memory and superelasticity. As we explore the world of Nitinol SE508 wire, we'll uncover what makes it so special and why it has become an essential component in various industries.

Understanding Nitinol SE508 Wire

What does the O in Nitinol stand for? While many may wonder about the nomenclature, it's actually derived from Nickel Titanium Naval Ordnance Laboratory, where this remarkable alloy was first developed. Nitinol SE508 wire is specifically engineered to enhance performance in critical applications due to its superior mechanical characteristics and responsiveness to temperature changes.

Applications of Nitinol Wire

So, what is nitinol wire used for? The answer spans several sectors including medical devices, aerospace innovations, and robotics. Its unique properties make it invaluable in creating stents that expand at body temperature or actuators that respond dynamically to environmental changes.

Key Features of Nitinol SE508

When discussing Nitinol SE508 wire properties, it's crucial to highlight its exceptional shape memory effect and superelastic capabilities. These features allow the wire to revert to a predetermined shape when heated or return to its original state when stress is applied. Additionally, its resistance to corrosion ensures longevity and durability in various applications—making it a go-to choice for engineers and designers alike.

Nitinol Wire Composition

Understanding the composition of Nitinol wire is essential to grasp its unique properties and applications. Nitinol SE508 wire, a specific type of Nitinol, is composed primarily of nickel and titanium in varying proportions that contribute to its remarkable characteristics. This section delves into what makes up this fascinating material.

What Does Nitinol Stand For?

Nitinol is an acronym that stands for Nickel Titanium Naval Ordnance Laboratory, which reflects its origins in military applications. The Ni represents nickel, while the Ti symbolizes titanium—two elements that combine to create this extraordinary alloy. The O in Nitinol refers to Ordnance, highlighting its initial development for use in naval weaponry and other advanced technologies.

Insights into Chemical Properties

The chemical properties of Nitinol wire are what set it apart from conventional metals. Its unique phase transformation allows it to return to a predetermined shape when heated above a specific temperature—this phenomenon is known as the shape memory effect, making it ideal for various applications like medical devices and robotics. Additionally, the alloy's superelasticity provides exceptional flexibility under stress, which is crucial for many innovative uses.

The Role of Nickel and Titanium

Nickel and titanium play pivotal roles in defining the characteristics of Nitinol SE508 wire. Nickel contributes to the alloy’s strength and corrosion resistance, ensuring durability even in challenging environments; meanwhile, titanium enhances its biocompatibility, making it suitable for medical applications such as stents and guidewires. The precise ratio of these elements can be adjusted to tailor the properties of Nitinol wire further, allowing engineers to optimize performance based on specific needs.

What is Nitinol Wire Used For?

Nitinol wire has carved out a niche for itself across various industries, thanks to its unique properties. But what is nitinol wire used for exactly? From medical devices to aerospace innovations and even robotics, the applications are as diverse as they are fascinating.

Medical Applications and Devices

In the medical field, nitinol SE508 wire shines brightly due to its remarkable shape memory effect and superelastic properties. These characteristics make it ideal for use in stents, guidewires, and other minimally invasive devices that need to navigate complex bodily structures. When you ask, What does the O in nitinol stand for?—it’s actually an abbreviation for Nickel Titanium Naval Ordnance Laboratory, underscoring its origins in high-stakes applications.

The ability of nitinol wire to return to a predetermined shape when heated makes it particularly valuable in surgical instruments that require precision and reliability. This activation process—How do you activate nitinol wire?—involves subjecting it to specific temperature changes that trigger its unique behaviors. As a result, healthcare professionals can rely on these devices for better patient outcomes.

Aerospace Industry Innovations

The aerospace industry has also embraced nitinol SE508 wire with open arms due to its lightweight yet strong characteristics. Engineers are continually exploring how this versatile material can enhance aircraft design by reducing weight without sacrificing strength or durability. The question of What is so special about nitinol? becomes clear when considering how it can withstand extreme conditions while providing reliable performance.

Nitinol's superelasticity allows components made from this material to endure significant stress without permanent deformation, making it an attractive option for various aerospace applications such as actuators and couplings. Its resistance to corrosion further enhances its appeal in environments where exposure to moisture or chemicals is common. As the industry continues to innovate, we can expect even more exciting uses of nitinol wire in future aircraft designs.

Robotics and Actuation

When we turn our gaze toward robotics, the role of nitinol SE508 wire becomes increasingly important in actuation systems that require precise movement and flexibility. Robots equipped with actuators made from this material can perform intricate tasks with remarkable efficiency thanks to the unique properties of nitinol wire—particularly its ability to change shape under thermal conditions.

In robotic applications, understanding How do you activate nitinol wire? is crucial for achieving desired movements or responses from robotic limbs or tools. By manipulating temperature changes effectively, engineers can harness the shape memory effect of this alloy for sophisticated control mechanisms that mimic natural motion patterns. Moreover, the longevity and durability associated with Nitinol SE508 Wire Properties ensure that these robotic systems remain reliable over time.

What is So Special About Nitinol?

Nitinol SE508 wire stands out in the world of materials due to its remarkable properties that lend themselves to a variety of applications. From medical devices to robotics, the unique characteristics of this alloy make it a game-changer in multiple industries. Let’s dive into what makes nitinol so special.

Unique Shape Memory Effect

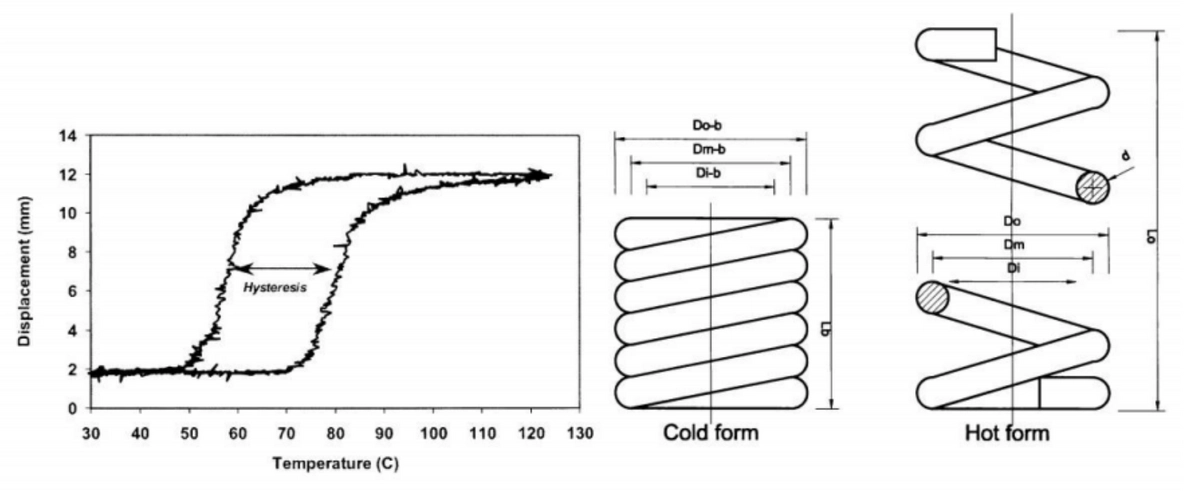

One of the most fascinating features of nitinol is its unique shape memory effect, which allows it to return to a predetermined shape when heated above a certain temperature. This means that if you bend or twist nitinol SE508 wire at room temperature, it will revert back to its original form once heated, making it incredibly versatile for various applications. This property is especially valuable in medical devices, where precise movements are critical; imagine stents that expand automatically upon reaching body temperature!

Superelastic Properties Explained

In addition to its shape memory effect, nitinol also exhibits superelastic properties that allow it to undergo significant deformation without permanent damage. When subjected to stress, the wire can stretch and bend far beyond typical materials before returning to its original shape once the stress is removed—this elasticity makes nitinol SE508 wire ideal for applications requiring flexibility and resilience. The combination of these two properties—shape memory and superelasticity—truly sets nitinol apart from other materials.

Longevity and Durability

Another compelling aspect of nitinol SE508 wire is its longevity and durability under various environmental conditions. Unlike many metals that succumb to fatigue over time, nitinol maintains its functional integrity even after repeated cycles of deformation and activation—this is crucial for long-term applications such as implants or aerospace components. Plus, with excellent resistance against corrosion and wear, you can rest assured that your investment in nitinol will last for years without compromising performance.

How Do You Activate Nitinol Wire?

Activating Nitinol SE508 wire is a fascinating process that reveals the unique properties of this remarkable material. Understanding how to activate it effectively can unlock its potential in various applications, from medical devices to robotics. This section will delve into the nuances of thermal activation, temperature changes, and practical activation tips.

Understanding Thermal Activation

Thermal activation is the key to harnessing the unique properties of Nitinol wire. When heated above a specific temperature, known as the transformation temperature, Nitinol SE508 wire undergoes a phase change that allows it to return to its pre-deformed shape. This ability to revert to its original form is what makes people often ask, What is so special about nitinol? The thermal activation process enables this shape memory effect, which can be utilized in numerous applications.

The Role of Temperature Changes

Temperature changes play a crucial role in activating Nitinol wire effectively. When discussing What does the O in nitinol stand for?, it’s important to note that it refers to 'Ordinary,' highlighting how common temperature variations can trigger extraordinary responses in this alloy. As temperatures rise or fall, the wire can shift between its martensitic (low-temperature) and austenitic (high-temperature) states, leading to significant mechanical changes that are essential for various uses.

Practical Tips for Activation

To successfully activate Nitinol SE508 wire, there are several practical tips you should consider. First and foremost, ensure that you accurately measure the transformation temperatures specific to your Nitinol variant; knowing these details will help you avoid under or overheating your wire. Additionally, experimenting with different heating methods—such as using hot water or a heat gun—can provide insights into what works best for your particular application involving What is nitinol wire used for? Lastly, always allow sufficient cooling time after activation; this ensures that the material maintains its desired shape and performance characteristics outlined by Nitinol SE508 Wire Properties.

Nitinol SE508 Wire Properties

Nitinol SE508 wire boasts a range of impressive properties that make it a standout material in various applications. From its mechanical characteristics to its resistance to corrosion and fatigue, this wire is engineered for performance. Understanding these properties is essential for anyone asking, What is nitinol wire used for?

Mechanical Characteristics

The mechanical characteristics of nitinol SE508 wire are quite remarkable, particularly due to its unique shape memory and superelastic properties. This allows the wire to return to a predefined shape when heated, making it invaluable in industries like medical devices and robotics. Additionally, the tensile strength of nitinol SE508 ensures that it can withstand significant stress without permanent deformation, further enhancing its utility.

Resistance to Corrosion and Fatigue

One of the standout features of nitinol SE508 wire is its impressive resistance to corrosion and fatigue, which contributes significantly to its longevity and durability. The alloy's composition includes nickel and titanium in specific ratios, providing an inherent ability to resist oxidation in various environments. This makes it ideal for applications ranging from medical implants—where biocompatibility is crucial—to aerospace components that face harsh conditions.

Thermal Properties and Performance

When considering how do you activate nitinol wire?, it's important to note that thermal properties play a pivotal role in its performance. Nitinol SE508 exhibits excellent thermal conductivity, allowing it to respond quickly to temperature changes during activation processes. This responsiveness not only enhances the efficiency of devices utilizing nitinol but also ensures reliability across diverse applications—from actuation systems in robotics to innovative uses in aerospace technology.

Conclusion

In wrapping up our exploration of Nitinol SE508 wire, it's clear that this remarkable material offers a plethora of applications across various industries. From medical devices to aerospace innovations, the versatility of Nitinol SE508 wire is undeniable. Its unique properties make it a go-to choice for engineers and designers looking to leverage the benefits of shape memory and superelasticity.

Recap of Nitinol SE508 Wire Uses

So, what is nitinol wire used for? The answer spans a broad range of fields, prominently featuring medical applications such as stents and guidewires that benefit from its shape memory effect. Additionally, in the aerospace sector, Nitinol SE508 wire contributes to lightweight structures and mechanisms that require reliable actuation under varying conditions.

Beyond these industries, robotics has also embraced Nitinol wire due to its ability to create responsive movements without bulky components. This makes it an ideal candidate for innovative robotic designs that prioritize efficiency and performance. As we’ve seen throughout this discussion, the uses for Nitinol SE508 are vast and continue to grow as technology advances.

Importance of Quality from GEE SMA

When discussing Nitinol SE508 wire properties, quality cannot be overlooked—especially when sourced from reputable manufacturers like GEE SMA. Their commitment to producing high-quality materials ensures that users can trust in the performance and reliability of their products in critical applications. After all, when dealing with specialized materials like nitinol wire, subpar quality can lead to failures in crucial systems.

Moreover, GEE SMA's rigorous testing processes guarantee that each batch meets strict industry standards—ensuring optimal performance whether you're activating nitinol wire or relying on its unique properties in medical or aerospace settings. The importance of sourcing quality materials cannot be understated; it’s essential for fostering innovation while maintaining safety standards across all applications.

Future Trends in Nitinol Applications

Looking ahead at future trends in nitinol applications reveals exciting possibilities driven by ongoing research and technological advancements. As industries continue exploring what makes nitinol so special—its shape memory effect and superelasticity—we can expect new uses to emerge regularly. For instance, developments in smart materials could lead to even more sophisticated solutions integrating Nitinol SE508 wire into everyday products.

Furthermore, advancements in activation methods may enhance how we utilize nitinol wire's capabilities—making it even easier for engineers to incorporate into their designs without complications related to temperature changes or activation techniques. With its durability and resistance properties continuing to evolve alongside modern engineering practices, there's no telling just how far we can push the boundaries with this extraordinary material.