Introduction

Nitinol wire, also known as niti wire, is a unique alloy with extraordinary properties that have revolutionized the medical field. Its shape memory and superelasticity make it an invaluable material for various medical applications. From stents to guidewires, the versatility of Nitinol Tubing and Wire has transformed the way we approach minimally invasive procedures.

Understanding the Basics of Nitinol Wire

Understanding the composition and structure of Nitinol: Properties, Applications, and Uses is crucial in grasping its potential in the medical field. Comprised of nearly equal parts nickel and titanium, this alloy exhibits remarkable elasticity and flexibility, making it ideal for medical grade nitinol wire applications.

Nitinol wire is also known for its shape memory and superelasticity, allowing it to return to its original shape after being deformed. This unique property makes it an excellent choice for medical devices such as stents, orthodontic wires, and guidewires. Additionally, the biocompatibility of Nitinol further enhances its suitability for use in the human body, reducing the risk of adverse reactions or rejections.

Exploring the Versatility of Nitinol Alloys

The versatility of nitinol alloys is truly astounding. With its ability to remember its original shape after being deformed, it has opened up a world of possibilities in medical device manufacturing. From orthodontic wires to catheter guide wires, nitinol's adaptability has expanded the scope of what can be achieved in modern medicine.

The adaptability of nitinol alloys has revolutionized the medical field, allowing for the creation of innovative devices such as stents and guidewires that can be easily inserted and manipulated within the body. This shape memory alloy's unique properties have also made it possible to develop minimally invasive surgical tools, enhancing patient comfort and recovery times. Furthermore, nitinol's biocompatibility and corrosion resistance make it an ideal material for long-term implantation in the human body, paving the way for advanced treatments and therapies.

Applications of Nitinol Wire in the Medical Field

The applications of nitinol wire in the medical field are vast and varied. Its use in minimally invasive procedures such as angioplasty and endovascular surgery has significantly improved patient outcomes while reducing recovery times. The exceptional biocompatibility and durability of medical grade nitinol wire make it an indispensable material for creating life-saving devices.

Nitinol wire is also used in orthodontic braces and dental archwires, providing patients with a more comfortable and efficient teeth-straightening experience. The flexibility and shape memory of nitinol wire allow for gradual tooth movement without the need for frequent adjustments, ultimately reducing the overall treatment time. Additionally, its biocompatibility ensures that patients do not experience adverse reactions or discomfort during their orthodontic treatment.

What is Nitinol Wire?

Nitinol wire, also known as Niti wire, is a type of shape memory alloy made from nearly equal parts of nickel and titanium. This unique combination gives it the ability to return to a predetermined shape when subjected to heat, making it ideal for various medical applications. Nitinol wire is composed of a crystalline structure that allows it to exhibit superelasticity and shape memory properties.

Composition and Structure of Nitinol Alloys

Nitinol alloys are typically made up of 55% nickel and 45% titanium, although slight variations in composition can result in different properties. The crystalline structure of nitinol wire consists of two intermetallic phases - austenite and martensite - which allow it to undergo reversible phase transformations under certain conditions. This unique composition and structure give nitinol wire its remarkable shape memory and superelastic properties.

Nitinol alloys are known for their unique ability to remember their original shape after being deformed, a property known as shape memory. This means that nitinol wire can be bent or twisted and then return to its original form when subjected to the appropriate conditions. Additionally, nitinol wire exhibits superelasticity, allowing it to undergo large deformations and still return to its undeformed state. These remarkable properties make nitinol alloys invaluable in a wide range of applications, from medical devices to aerospace engineering.

Unique Properties of Nitinol Wire

One of the most remarkable properties of nitinol wire is its ability to return to its original shape after being deformed, simply by being heated above its transformation temperature. This makes it an incredibly versatile material for medical devices such as stents, guidewires, and orthodontic wires. Additionally, nitinol wire exhibits superelasticity, allowing it to undergo significant deformation without permanent damage.

In contrast to traditional metal alloys, nitinol wire also has the unique ability to maintain its shape memory even after multiple deformations, making it an ideal choice for applications where repeated use and reshaping are necessary. This makes nitinol wire a cost-effective and durable option for medical devices, as it can withstand the rigors of everyday use without compromising its structural integrity. Furthermore, the biocompatibility of nitinol wire makes it a safe choice for implantable medical devices, reducing the risk of adverse reactions in patients.

Comparison with Other Metal Alloys

When compared to other metal alloys such as stainless steel or cobalt-chromium alloys, nitinol wire stands out due to its unique combination of superelasticity and shape memory properties. While stainless steel may be more rigid and less flexible, nitinol's ability to revert back to its original shape sets it apart in various medical applications.

In addition to its unique properties, nitinol wire also offers excellent biocompatibility, making it suitable for use in medical implants and devices. This means that nitinol is less likely to cause adverse reactions or be rejected by the body, further enhancing its appeal in the medical field. Its ability to withstand corrosion and fatigue also makes it a reliable choice for long-term applications, setting it apart from other metal alloys.

Nitinol: Properties, Applications, and Uses

Nitinol wire, also known as Niti wire, is a unique alloy composed of nickel and titanium. Its exceptional properties, such as shape memory and superelasticity, make it a valuable material in various industries, especially in the medical field.

Medical Grade Nitinol Wire

Medical grade nitinol wire is specifically designed for use in medical devices and implants due to its biocompatibility and corrosion resistance. It is commonly used in stents, guidewires, orthodontic archwires, and other minimally invasive surgical instruments.

Medical grade nitinol wire is also valued for its superelasticity and shape memory properties, allowing it to return to its original shape after being bent or deformed. This makes it an ideal material for devices that need to withstand repeated bending and flexing within the body. Additionally, the high tensile strength of nitinol wire ensures that medical devices made from this material are durable and long-lasting, providing reliable support and treatment for patients.

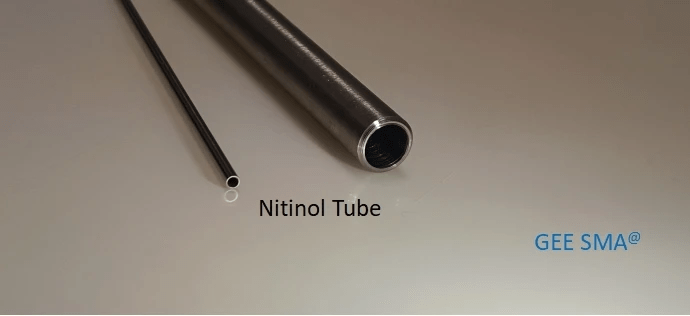

Nitinol Tubing and Wire Applications

Nitinol tubing and wire are widely utilized in medical applications such as endovascular stents for treating cardiovascular diseases, orthopedic implants for bone fixation, and neurovascular devices for treating aneurysms. Its flexibility and durability make it suitable for various intricate medical procedures. Additionally, Nitinol's superelasticity allows it to withstand the dynamic forces within the body, providing long-term support and stability to the implanted devices. This unique property minimizes the risk of device failure and reduces the need for frequent replacements, improving patient outcomes and reducing healthcare costs.

Advantages of Nitinol Wire in Medical Devices

The use of nitinol wire in medical devices offers several advantages such as improved patient outcomes, reduced recovery time, and enhanced treatment efficacy. Its ability to withstand deformation without permanent damage allows for safer and more effective procedures.

In addition, nitinol wire's biocompatibility and corrosion resistance make it an ideal material for medical devices that come into direct contact with bodily fluids and tissues. This reduces the risk of adverse reactions or complications, providing a higher level of safety for patients undergoing procedures involving nitinol-based devices. Furthermore, the flexibility and shape memory properties of nitinol wire allow for minimally invasive techniques, leading to smaller incisions, less tissue damage, and faster recovery times for patients.

The Role of Nitinol Wire in Medical Devices

Nitinol Wire in Minimally Invasive Procedures

Nitinol wire is revolutionizing minimally invasive procedures in the medical field. Its unique superelasticity and shape memory properties allow for the creation of small, flexible medical devices that can navigate through intricate pathways within the body, reducing the need for invasive surgeries.

Nitinol Shape Memory Alloys (GEE SMA)

Nitinol shape memory alloys (SMAs) are a game-changer in medical device technology. These alloys have the remarkable ability to revert to their original shape after being deformed, making them ideal for applications such as stents, orthodontic wires, and guidewires used in various medical procedures.

Advancements in Nitinol Wire Technology

The advancements in nitinol wire technology have opened up new possibilities for medical device design and manufacturing. With ongoing research and development, engineers are continuously improving the properties and performance of nitinol alloys to meet the evolving needs of the healthcare industry.

By leveraging the exceptional properties of nitinol wire, medical professionals can provide patients with more effective treatment options while minimizing discomfort and recovery time. As this versatile material continues to evolve, its role in shaping the future of medicine is undeniable.

Conclusion

The Future of Nitinol Wire in Medicine

As medical technology continues to advance, the future of medical nitinol wire looks promising. With its unique properties and versatility, niti wire is poised to play a crucial role in the development of innovative medical devices and procedures. From minimally invasive surgeries to cutting-edge medical implants, the use of nitinol tubing and wire is expected to revolutionize the field of medicine.

Innovations in Nitinol Wire Manufacturing

Innovations in nitinol wire manufacturing are driving the development of more advanced and intricate medical devices. As manufacturers continue to refine their processes, we can expect to see even more precise and reliable medical grade nitinol wire being used in a wide range of applications. These advancements will ultimately lead to better patient outcomes and improved quality of care.

Harnessing the Potential of Nitinol Alloys

The potential of nitinol alloys is vast, with ongoing research exploring new ways to harness its unique properties for medical applications. As we uncover more about the capabilities of nitinol: properties, applications, and uses will continue to expand, opening doors for groundbreaking innovations in healthcare. By capitalizing on the remarkable characteristics of nitinol alloys, we can look forward to a future where medical treatments are safer, more effective, and less invasive.