Introduction

In the realm of modern engineering, few innovations have captured the imagination quite like nitinol actuators. These remarkable devices, built from a unique alloy of nickel and titanium, offer a fascinating glimpse into the future of automation and robotics. With their ability to change shape in response to temperature variations, nitinol wire actuators are not just a novelty; they are game-changers that redefine how we think about movement and control.

Discover the Wonders of Nitinol Actuators

Imagine a material that can remember its shape and return to it when heated—this is precisely what nitinol actuators do! The versatility of actuators built from nitinol lies in their capacity to convert thermal energy into mechanical motion with incredible efficiency. From medical devices to aerospace applications, these innovative components are revolutionizing industries by providing solutions that were previously unimaginable.

Why Nitinol Wires Are Game-Changers

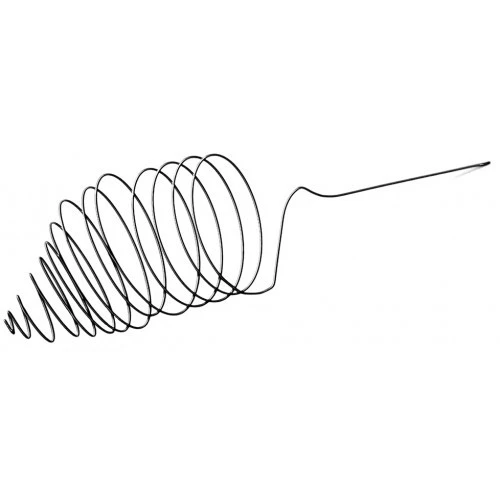

Nitinol wires stand out for their unique properties that combine both superelasticity and shape memory effects. This dual capability allows engineers to design compact systems that deliver powerful performance without bulky mechanisms or complex controls. As we explore how nitinol is used in actuators, it becomes evident that these wires not only enhance functionality but also open up new avenues for creativity in product design.

The Science Behind Shape Memory Alloys

At the heart of every nitinol wire actuator lies the fascinating science of shape memory alloys (SMAs). These materials undergo phase transformations at specific temperatures, allowing them to remember their original shape after being deformed. Understanding how you activate nitinol wire through temperature changes or electrical signals provides insight into why these actuators are so fast and efficient—an essential factor as we consider how fast is the actuation of nitinol compared to traditional methods.

What is a Nitinol Wire Actuator?

Nitinol wire actuators are fascinating devices that harness the unique properties of shape memory alloys to create motion in a controlled manner. These actuators built from Nitinol can contract or expand when subjected to specific stimuli, making them incredibly versatile for various applications. By understanding how these components function, we can appreciate their potential across multiple industries.

Understanding Shape Memory Alloys

Shape memory alloys (SMAs) like Nitinol have an extraordinary ability to return to their original shape after being deformed, thanks to their unique crystalline structure. This means that when a Nitinol wire actuator is heated beyond a certain temperature, it remembers its original configuration and returns to it with impressive force. This property not only allows for precise movement but also enables the creation of compact and lightweight designs that traditional actuators struggle to achieve.

How Nitinol Powers Actuators

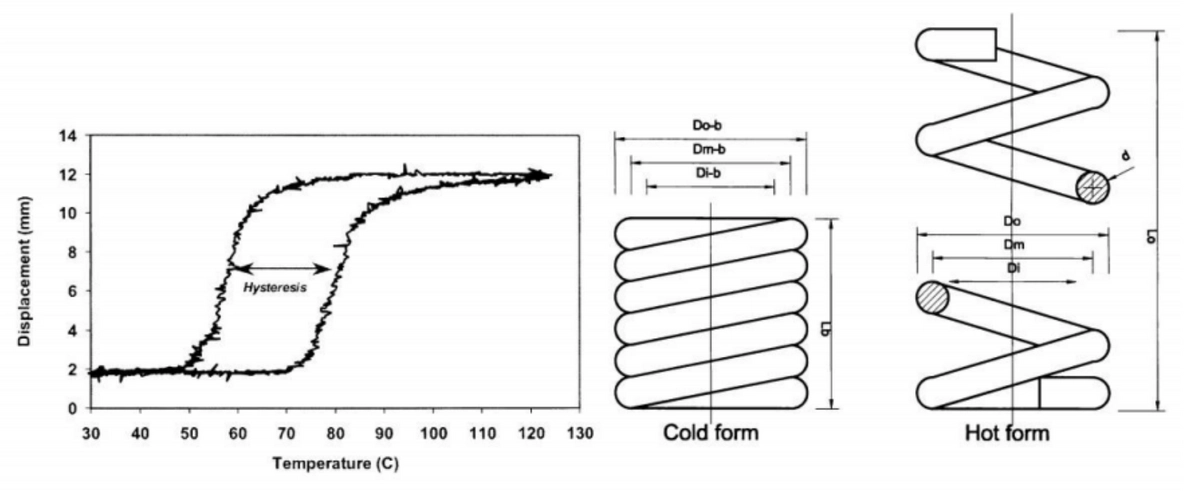

The magic behind how Nitinol powers actuators lies in its phase transformation between two distinct states: martensite and austenite. When cooled, the material exists in the martensitic state, which is easily deformable; upon heating, it transforms into austenite and contracts significantly. This transformation generates movement that drives various mechanisms—an elegant solution for those wondering how nitinol is used in actuators—creating motion without complex gears or motors.

Applications in Various Industries

Nitinol wire actuators find applications across diverse fields such as robotics, medical devices, and aerospace engineering due to their reliability and efficiency. In medical technology, for instance, they are used in stents and guidewires where precise control is crucial for patient safety. Similarly, in robotics, these actuators enable smooth movements while maintaining energy efficiency—a key consideration for developers looking at how fast the actuation of nitinol can be achieved while minimizing power consumption.

How is Nitinol Used in Actuators?

Nitinol wire actuators are revolutionizing the way we think about motion and control in various applications. These innovative devices leverage the unique properties of Nitinol, a shape memory alloy, to provide efficient and reliable actuation. By understanding how Nitinol is used in actuators, we can appreciate their significant advantages over traditional technologies.

Mechanisms of Nitinol in Motion

Nitinol wire actuators operate on the principle of shape memory effect and superelasticity, which are inherent characteristics of this remarkable material. When heated above a specific temperature, the Nitinol wire returns to its pre-defined shape, generating motion that can be harnessed for various tasks. This transformation is not just a simple contraction; it enables precise movements that make actuators built from Nitinol ideal for applications requiring accuracy and responsiveness.

The activation process involves either thermal or electrical stimulation, which prompts the Nitinol actuator wire to change its state. For instance, when an electric current passes through the wire, it heats up quickly due to its electrical resistance, causing it to contract and perform work. This seamless mechanism allows for quick responses in devices ranging from robotics to medical instruments.

Key Benefits of Nitinol Actuators

One of the standout advantages of using a nitinol wire actuator is its ability to deliver significant force while occupying minimal space—perfect for compact designs where every millimeter counts. Additionally, these actuators boast high energy efficiency because they require less power compared to conventional systems while still maintaining impressive performance levels. This efficiency translates into longer operational lifetimes and reduced energy costs for users.

Another benefit lies in their durability; nitinol actuators are resistant to fatigue and wear over time due to their unique material properties. They can withstand numerous cycles without losing effectiveness or performance quality—a crucial factor in demanding environments like aerospace or medical devices where reliability is paramount. These key benefits make nitinol actuators an attractive option across multiple sectors.

Real-World Applications and Innovations

Nitinol wire actuators have found their niche across various industries thanks to their versatility and reliability. In the medical field, they are frequently employed in minimally invasive surgical tools that require precise movements without damaging surrounding tissues—a game-changer for patient outcomes! Similarly, robotics has embraced these innovative devices as they allow for more fluid motion patterns that enhance functionality.

The aerospace industry also benefits from nitinol technology by utilizing these actuators for adaptive wing mechanisms that improve aerodynamic performance during flight—who knew shape-shifting wings could be so effective? Furthermore, cutting-edge research continues exploring new applications such as soft robotics and wearable technology where nimble yet powerful actuation is essential. With ongoing innovations around how nitinol is used in actuators, there’s no doubt this technology will continue shaping our future.

How Do You Activate Nitinol Wire?

Activating a nitinol wire actuator is a fascinating process that transforms the way we think about motion in various applications. The unique properties of nitinol, a shape memory alloy, enable it to change shape and exert force when exposed to specific activation methods. By understanding these activation techniques, we can harness the full potential of actuators built from nitinol for innovative solutions across multiple industries.

Activation Techniques Explained

The activation of nitinol wire involves several techniques that leverage its inherent properties. Primarily, thermal activation is utilized, where the wire is heated above its transformation temperature, causing it to revert to its memorized shape and create movement. Additionally, electrical activation can also be employed—passing an electric current through the wire generates heat due to resistance, triggering the actuation process without needing external heating sources.

Nitinol actuators can be finely tuned for performance based on these techniques, allowing engineers to choose the most suitable method for their specific application needs. This versatility makes them ideal for various uses, such as robotics and medical devices. Understanding how to activate nitinol wire effectively opens up new possibilities for innovation in actuator design.

Temperature and Electrical Activation

Temperature plays a crucial role in how we activate nitinol wire actuators effectively. When heated beyond their designated transformation temperature—typically ranging from 60°C (140°F) to 100°C (212°F)—the wires undergo a phase change that enables them to contract or expand dramatically based on their pre-set configurations. This property allows designers to create highly responsive systems capable of precise movements.

On the other hand, electrical activation provides an alternative means of control by manipulating current flow within the nitinol actuator wire. This method offers rapid response times and precise control over actuation speed—crucial factors when considering how fast is the actuation of nitinol? By integrating both temperature and electrical methods into designs, engineers can maximize efficiency while minimizing energy consumption.

Role of GEE SMA in Activation

GEE SMA has been at the forefront of innovations surrounding nitinol technology and its applications in actuators built from nitinol. Their expertise helps refine activation processes by developing advanced materials that enhance thermal conductivity and responsiveness during actuation cycles. With their cutting-edge solutions, GEE SMA aims not only to improve efficiency but also ensure reliability across diverse applications.

Moreover, GEE SMA’s commitment extends into research focused on optimizing both temperature-based and electrical activation techniques for better performance metrics in real-world scenarios. As they explore new avenues for activating nitinol wire actuators more effectively, they are paving the way toward smarter designs with increased functionality and adaptability in various industries—from aerospace engineering to biomedical devices.

How Fast is the Actuation of Nitinol?

Speed Comparison with Other Actuators

In the world of automation and robotics, speed is often a critical factor. Nitinol wire actuators can achieve actuation speeds that rival those of piezoelectric actuators, which are known for their quick response times. However, while piezoelectric devices may excel in speed, they often lack the versatility and ease of use found in actuators built from Nitinol—making Nitinol an appealing option for many engineers.

Factors Influencing Actuation Speed

Several factors influence how fast the actuation of Nitinol occurs. Temperature plays a significant role; as the temperature increases, so does the speed at which the actuator responds to stimuli. Additionally, the design and thickness of the nitinol actuator wire can affect its responsiveness—thinner wires tend to heat up faster and thus react more quickly than thicker ones.

Performance in Real-Life Applications

The performance of nitinol wire actuators shines brightly when put into real-life applications across various industries. For instance, in medical devices such as stents or surgical tools, these actuators provide rapid movement necessary for precision procedures without compromising safety or reliability. As industries continue to adopt this technology, we see an increasing number of innovations that leverage the unique capabilities offered by Nitinol actuation—demonstrating that not only is it fast but also incredibly effective.

The Future of Nitinol Wire Actuators

As we look ahead, the future of nitinol wire actuators is bursting with potential and innovation. These remarkable devices, built from nitinol, are not just a trend; they are paving the way for advancements across various industries. With their unique properties and capabilities, it's no wonder that researchers and engineers are eager to explore how nitinol can revolutionize actuator technology.

Emerging Trends in Nitinol Technology

One of the most exciting emerging trends in nitinol technology is the integration of smart materials that respond to environmental stimuli. This means that actuators built from nitinol can adapt their behavior based on temperature changes or even electrical signals, enhancing their versatility in applications such as robotics and medical devices. Moreover, advancements in miniaturization are allowing for smaller yet more powerful nitinol wire actuators, opening doors to previously unimaginable applications.

Another trend gaining traction is the development of hybrid systems that combine nitinol with other materials to improve performance. This approach not only amplifies the benefits of using a nitinol actuator wire but also addresses some limitations associated with traditional actuator technologies. As these trends continue to evolve, we can expect a surge in innovative products that leverage the unique characteristics of shape memory alloys.

Advancements in Design and Functionality

The design landscape for nitinol wire actuators is undergoing significant transformation as engineers experiment with new configurations and functionalities. For instance, there’s a growing focus on optimizing actuation speed—an essential factor when considering how fast is the actuation of nitinol? Enhanced designs now allow for quicker response times while maintaining energy efficiency, making them suitable for high-performance applications.

Moreover, advancements in manufacturing processes are leading to more precise control over the properties of nitinol itself. This means that actuators built from nitinol can be tailored specifically for their intended use—whether it’s a delicate motion required in surgical instruments or robust movements needed in industrial machinery. With these improvements in design and functionality, we’re witnessing an era where custom solutions become commonplace.

GEE SMA's Vision for Nitinol Innovations

At GEE SMA, our vision for the future revolves around pushing boundaries through continuous innovation within the realm of nitinol technology. We believe that understanding how is nitinol used in actuators will lead to breakthroughs that redefine industry standards across multiple sectors—from aerospace engineering to healthcare solutions. Our commitment includes investing heavily in research and development aimed at expanding application possibilities while enhancing activation methods.

In addition to exploring new activation techniques—such as advanced temperature control systems—we're focused on improving user accessibility by simplifying how do you activate nitinol wire? By streamlining these processes, we aim to empower engineers and designers everywhere with tools that maximize performance without sacrificing ease-of-use or reliability.

As we move forward into this exciting future filled with potential breakthroughs driven by innovations like our Nitinol Actuator Wire technology, GEE SMA remains dedicated to leading this charge—ensuring our clients have access to cutting-edge solutions tailored specifically for their needs.

Conclusion

Nitinol actuators stand out as efficient and versatile components in the world of engineering and robotics. With their unique ability to change shape in response to temperature variations, these actuators built from Nitinol are revolutionizing how we think about motion and control. The flexibility and reliability of Nitinol actuator wire make it a top choice for a variety of applications, from medical devices to aerospace technologies.

Nitinol Actuators: Efficient and Versatile

The efficiency of nitinol actuators lies in their remarkable energy conversion capabilities, turning thermal energy into mechanical movement seamlessly. These actuators can respond quickly to changes in temperature, making them ideal for applications where precision is key. Their versatility allows them to be integrated into countless systems, proving that when it comes to actuation, nothing beats the nimble nature of nitinol wire actuator technology.

The Role of GEE SMA in Advancements

GEE SMA has been at the forefront of advancements in nitinol technology, pushing boundaries with innovative designs and applications for nitinol wire actuators. Their commitment to research and development ensures that the latest breakthroughs are incorporated into their products, enhancing performance across various industries. As they continue to explore new possibilities for how nitinol is used in actuators, GEE SMA is setting the stage for even more exciting developments in this field.

Why You Should Consider Nitinol for Your Projects

If you're looking to enhance your projects with cutting-edge technology, consider incorporating a nitinol wire actuator into your designs. The benefits are clear: fast actuation speeds combined with lightweight materials make these actuators an excellent choice for both small-scale gadgets and large machinery alike. With ongoing advancements ensuring improved functionality and efficiency, there’s never been a better time to embrace the power of Nitinol.