Introduction

In the realm of modern engineering, few innovations have captured the imagination quite like shape memory alloys (SMAs). These remarkable materials can remember their original shape and return to it when heated, making them ideal for a variety of applications. Among these, memory alloy actuators stand out as a transformative technology that merges science with practicality.

Discovering Shape Memory Alloys

Shape memory alloys were first discovered in the 1930s but gained significant attention in the 1960s when their unique properties were understood. These alloys can undergo phase transformations, allowing them to switch between different shapes depending on temperature changes. This discovery opened doors to innovative applications, such as in robotics and medical devices, where precise movements are crucial.

The Magic Behind Memory Alloy Actuators

So how do shape memory alloy actuators work? At their core, they leverage the unique properties of SMAs to convert thermal energy into mechanical work. When an SMA wire is heated above its activation temperature, it transforms and exerts force—an elegant solution for achieving motion without bulky motors or complex mechanisms.

Why Nitinol is a Game Changer

Among various SMAs, nitinol has emerged as a game changer due to its exceptional characteristics—such as high fatigue resistance and biocompatibility. Nitinol's versatility allows it to be utilized in diverse fields ranging from aerospace engineering to minimally invasive medical devices. As we explore how nitinol is used in actuators, it's clear that this material not only enhances performance but also paves the way for future innovations in shape memory actuators.

What is a Memory Alloy Actuator?

Memory alloy actuators are fascinating devices that utilize the unique properties of shape memory alloys (SMAs) to create motion in response to temperature changes. These materials can remember their original shapes and return to them when heated, making them ideal for various applications. By understanding how these innovative actuators function, we can appreciate their role in modern technology.

Defining Shape Memory Alloys

Shape memory alloys are metallic materials that exhibit a remarkable ability to change shape when subjected to specific thermal conditions. When cooled, these alloys can be deformed into a different shape, but upon heating above a certain temperature—known as the activation temperature—they revert back to their original form. This unique property is what makes SMAs so appealing for use in memory alloy actuators and other advanced technologies.

Applications in Modern Technology

The applications of memory alloy actuators span a wide range of industries, from aerospace to medical devices and robotics. In the medical field, for instance, SMAs are utilized in stents and surgical tools due to their biocompatibility and ability to adapt under varying temperatures. Similarly, aerospace innovations leverage the lightweight yet powerful capabilities of these actuators for precise control systems where traditional solutions may fall short.

Comparing Conventional Actuators and SMA

When comparing conventional actuators with shape memory actuators (SMA), several key differences emerge that highlight the advantages of SMAs. Traditional systems often rely on electric motors or hydraulic mechanisms that can be bulky and energy-intensive; in contrast, SMA-based systems offer compact designs with significant energy efficiency. Furthermore, while conventional actuators may require complex control systems, memory alloy actuators simplify operation by responding directly to temperature changes—making them not only smarter but also more reliable over time.

How Do Shape Memory Alloy Actuators Work?

Shape Memory Alloy (SMA) actuators are fascinating devices that leverage the unique properties of materials like Nitinol to create motion in response to temperature changes. The magic lies in their ability to undergo a phase transformation, allowing them to return to a predetermined shape when heated. This section will dive into the science behind this transformation, the critical role of activation temperature, and some real-world examples showcasing how these memory alloy actuators function.

The Science of Phase Transformation

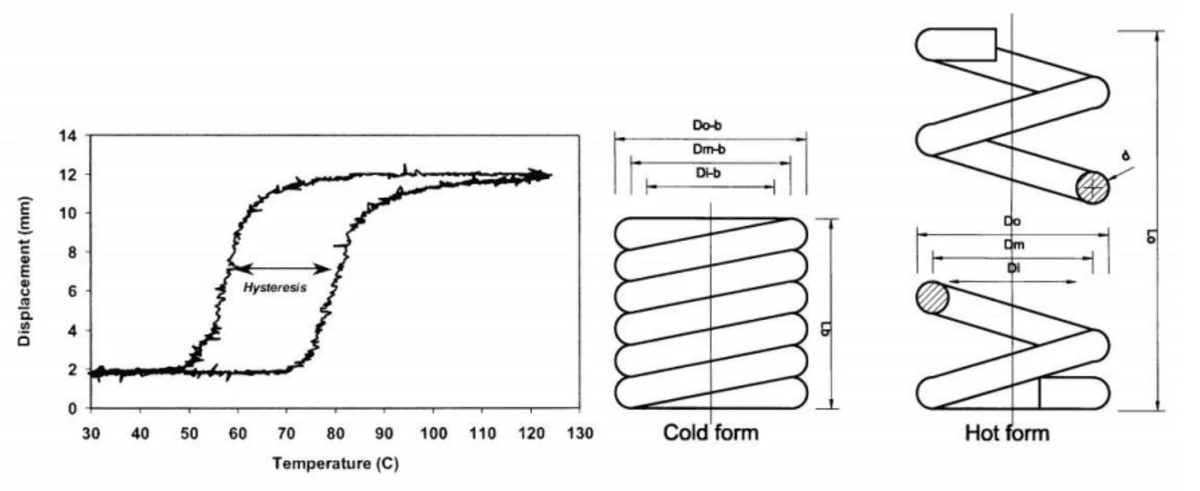

At the heart of every memory alloy actuator is the remarkable phenomenon known as phase transformation. When an SMA is heated above its activation temperature, it transitions from a martensitic phase—where it can be easily deformed—to an austenitic phase, where it regains its original shape. This reversible process is what enables SMA actuators to perform tasks ranging from simple movements to complex mechanical actions.

The beauty of this phase transformation lies in its efficiency and reliability. Unlike traditional actuators that rely on motors or hydraulic systems, shape memory alloy actuators utilize thermal energy for actuation, making them lighter and more compact. This efficiency not only reduces power consumption but also enhances the overall design flexibility for various applications.

Activation Temperature and Its Role

Activation temperature is a critical factor that determines how do shape memory alloy actuators work effectively in different environments. Each type of SMA has a specific activation temperature range that dictates when it will transition between phases. For instance, Nitinol typically has an activation range between 60°C and 100°C, allowing engineers to tailor applications based on desired performance characteristics.

Understanding this temperature range allows for precise control over the actuator's movement and response times. In practical terms, this means that by simply applying heat—be it through electrical resistance or other heating methods—a memory alloy actuator can be activated or deactivated as needed. This feature makes SMAs incredibly versatile across various industries such as robotics and biomedical devices.

Real-World Examples of Operation

Real-world applications vividly illustrate how SMA wire works within different systems, showcasing their innovative capabilities as memory alloy actuators. For example, in medical devices like stents or guidewires used during surgeries, Nitinol expands when heated inside the body at body temperature—allowing doctors to navigate complex vascular structures with ease while ensuring patient safety.

In aerospace engineering, SMAs are employed in deployable structures such as wings or flaps that adjust automatically based on flight conditions; they respond quickly without requiring bulky mechanical components or excessive energy consumption. These examples highlight not just how is nitinol used in actuators but also underscore their transformative potential across multiple sectors.

How Does SMA Wire Work?

Shape Memory Alloy (SMA) wire is a fascinating component at the heart of many innovative memory alloy actuators. But how does SMA wire work? To answer this, we need to delve into its unique mechanical properties, construction considerations, and the numerous benefits it offers when integrated into actuators.

Mechanical Properties of SMA Wire

The mechanical properties of SMA wire are what set it apart from traditional materials. This wire can undergo significant deformation while maintaining its ability to return to its original shape upon heating—a phenomenon known as the shape memory effect. In addition to this, SMA wire exhibits superelasticity, allowing it to stretch and bend without permanent deformation when activated within specific temperature ranges.

This unique combination of properties enables memory alloy actuators to perform tasks that conventional materials simply cannot manage effectively. By leveraging these characteristics, engineers can design systems that are not only efficient but also capable of precise movements across a variety of applications. Understanding how these mechanical properties interact with temperature changes is crucial in answering the question: How do shape memory alloy actuators work?

Construction and Design Considerations

When considering how SMA wire works within actuators, it's essential to look at construction and design elements that maximize performance. The diameter and length of the SMA wire play critical roles in determining the actuator's response time and force output; thus, careful selection is necessary for optimal functionality. Additionally, since Nitinol—a popular type of SMA—is sensitive to heat, effective thermal management becomes vital in ensuring reliable operation.

Moreover, actuator designs often incorporate various configurations such as springs or coils to enhance performance further. These configurations allow for greater displacement and force generation while minimizing energy consumption—an important factor in modern technology's push for efficiency. So when pondering how is Nitinol used in actuators? The answer lies in these thoughtful design choices that capitalize on its unique properties.

Benefits of Using SMA Wire in Actuators

The benefits of using SMA wire in memory alloy actuators are numerous and compelling for various industries looking for innovative solutions. First off, they offer significant energy efficiency compared to traditional systems because they require minimal power input for operation—ideal for battery-powered devices or compact applications where space is limited.

Additionally, the compact design features inherent in SMAs allow engineers to create smaller devices without sacrificing performance or reliability; this is particularly useful in fields like robotics or medical devices where space constraints are a constant challenge. Enhanced reliability and durability also make shape memory actuators an attractive choice since they have fewer moving parts than conventional systems—leading to reduced wear and tear over time.

In summary, understanding how does SMA wire work reveals a world brimming with potential applications through its unique properties and advantages as part of a broader memory alloy actuator system.

How is Nitinol Used in Actuators?

Nitinol, a fascinating alloy of nickel and titanium, has emerged as a game changer in the realm of memory alloy actuators. Its unique properties allow it to return to a predetermined shape when heated, making it an ideal candidate for various applications. Understanding how nitinol is employed in actuators provides insight into its transformative capabilities in modern technology.

Introduction to Nitinol and Its Properties

Nitinol stands out due to its remarkable shape memory effect and superelasticity, which are key attributes for any effective memory alloy actuator. This alloy can undergo phase transformations between martensite and austenite at specific temperatures, enabling it to perform mechanical work efficiently. Moreover, its biocompatibility makes nitinol particularly appealing for applications that require safe interaction with biological systems.

Applications in Medical Devices

One of the most innovative uses of nitinol is found in medical devices such as stents and guidewires, where its properties are harnessed for precision and reliability. In these applications, the memory alloy actuator can expand or contract based on temperature changes within the body, ensuring optimal functionality without invasive procedures. The ability of nitinol to adapt makes it invaluable in minimally invasive surgeries, providing both safety and effectiveness.

Aerospace Innovations Utilizing Nitinol

In the aerospace sector, nitinol's lightweight nature and strength have made it an essential component in various systems requiring actuation mechanisms. For instance, memory alloy actuators powered by nitinol can be used for adaptive wing structures that change shape during flight for improved aerodynamics. This innovative approach not only enhances performance but also contributes to fuel efficiency—an ever-important factor in modern aviation.

Advantages of Shape Memory Actuators

The rise of shape memory actuators in modern technology is not just a trend; it’s a revolution that brings numerous advantages over traditional systems. These remarkable devices are engineered to respond to specific stimuli, making them incredibly efficient and versatile. With their unique properties, memory alloy actuators are reshaping industries from aerospace to medical applications.

Energy Efficiency Compared to Traditional Systems

One of the standout features of shape memory actuators is their impressive energy efficiency compared to conventional systems. When exploring how do shape memory alloy actuators work?, it's clear that they require significantly less power for operation, especially during the activation phase. This efficiency translates into reduced energy consumption, which is a game changer for battery-operated devices and applications where power supply is limited.

Additionally, because SMA actuators only consume energy when changing shape or position, they can remain in a low-energy state while maintaining their form. This characteristic not only prolongs battery life but also minimizes heat generation during use—an essential factor in sensitive environments like medical devices. As we continue to innovate with these materials, the potential for even greater energy savings becomes increasingly apparent.

Compact Design Features

Shape memory actuators are renowned for their compact design features that allow them to fit into tight spaces where traditional actuators simply cannot go. The question What is SMA actuator? often leads to discussions about their sleek size and lightweight nature—ideal for applications ranging from robotics to miniaturized medical instruments. Their ability to deliver high force output relative to size makes them indispensable in fields requiring precision engineering.

Furthermore, this compactness does not come at the expense of performance; rather, it enhances versatility in design and application possibilities. By integrating these small yet powerful devices into larger systems, engineers can create more efficient and space-saving solutions without sacrificing functionality or reliability. Thus, the design advantages provided by SMA wire make it a preferred choice across various industries.

Enhanced Reliability and Durability

Reliability and durability are critical factors when choosing an actuator for any application, and shape memory actuators excel in both areas. The materials used in SMA wire exhibit remarkable fatigue resistance under repeated thermal cycling—a key component of how does SMA wire work? This means that even after countless cycles of expansion and contraction, these wires maintain their structural integrity over time.

Moreover, Nitinol's unique properties contribute significantly to its longevity as an actuator material; it can withstand extreme conditions without losing its effectiveness or performance capabilities. In sectors such as aerospace or healthcare where failure is not an option, the enhanced reliability offered by shape memory actuators provides peace of mind that traditional systems may lack. As we embrace this technology's potential further down the road, we can expect even more advancements in durability standards across various applications.

Conclusion

As we wrap up our exploration of shape memory alloys and their remarkable capabilities, it's clear that memory alloy actuators are not just a fleeting trend but a transformative technology poised to redefine various industries. The innovative properties of these materials, particularly Nitinol, highlight the potential for advancements in design and functionality across numerous applications. With ongoing research and development, the future of memory alloy technology looks promising, paving the way for smarter solutions that enhance efficiency and performance.

The Future of Memory Alloy Technology

The future of memory alloy technology is bright, with continuous advancements in understanding how do shape memory alloy actuators work? Researchers are delving deeper into optimizing activation temperatures and improving phase transformation processes to increase efficiency and responsiveness. As industries seek more compact and reliable systems, the demand for SMA actuators will likely expand into new territories such as robotics, automotive applications, and even consumer electronics.

GEE SMA's Role in Advancing SMA Solutions

GEE SMA has emerged as a key player in advancing SMA solutions by focusing on innovative designs that leverage how does SMA wire work? Their commitment to research enables them to develop cutting-edge products tailored for specific applications like medical devices and aerospace technologies. By continually pushing the boundaries of what is possible with Nitinol-based systems, GEE SMA is setting the stage for widespread adoption of shape memory actuators across various sectors.

Embracing the Potential of Shape Memory Actuators

Embracing the potential of shape memory actuators means recognizing their ability to revolutionize how we approach design challenges in engineering and technology. With advantages such as energy efficiency and enhanced reliability compared to traditional systems, it’s time for industries to consider what is an SMA actuator can offer them. As we look ahead, integrating these remarkable materials into everyday applications could lead us toward a more innovative future where flexibility meets functionality seamlessly.