Introduction

In the world of advanced materials, nitinol stands out as a remarkable alloy with unique properties that have revolutionized various industries. Its shape memory and superelastic characteristics make it a go-to choice for many applications, from medical devices to aerospace components. Understanding what nitinol does and its diverse applications is crucial for anyone looking to invest in or utilize this innovative material.

Understanding Nitinol and Its Applications

Nitinol is an alloy made primarily of nickel and titanium, known for its ability to return to a predetermined shape when heated above a certain temperature. This fascinating property has led to its widespread use in medical devices, such as stents and guidewires, where precision and reliability are paramount. Beyond healthcare, nitinol finds applications in robotics, consumer products, and even aerospace technologies—demonstrating its versatility across various sectors.

Why Choose the Right Nitinol Company?

Selecting the right nitinol company can significantly impact the quality and performance of your products. Not all manufacturers adhere to the same standards; therefore, it's essential to ask questions like What company makes nitinol? when considering options. A reputable manufacturer will not only provide high-quality nitinol but also ensure compliance with industry regulations while addressing common issues associated with nitinol production.

The Landscape of Nitinol Manufacturers

The landscape of nitinol manufacturers is diverse, featuring companies that specialize in different aspects of production and application development. Some focus on medical-grade materials while others may cater to industrial or consumer markets—making it vital for buyers to understand their specific needs before making a choice. Additionally, challenges such as pricing—often driven by factors like raw material costs—can influence which nitinol company you ultimately select for your project.

Overview of Leading Nitinol Companies

GEE SMA’s Commitment to Quality

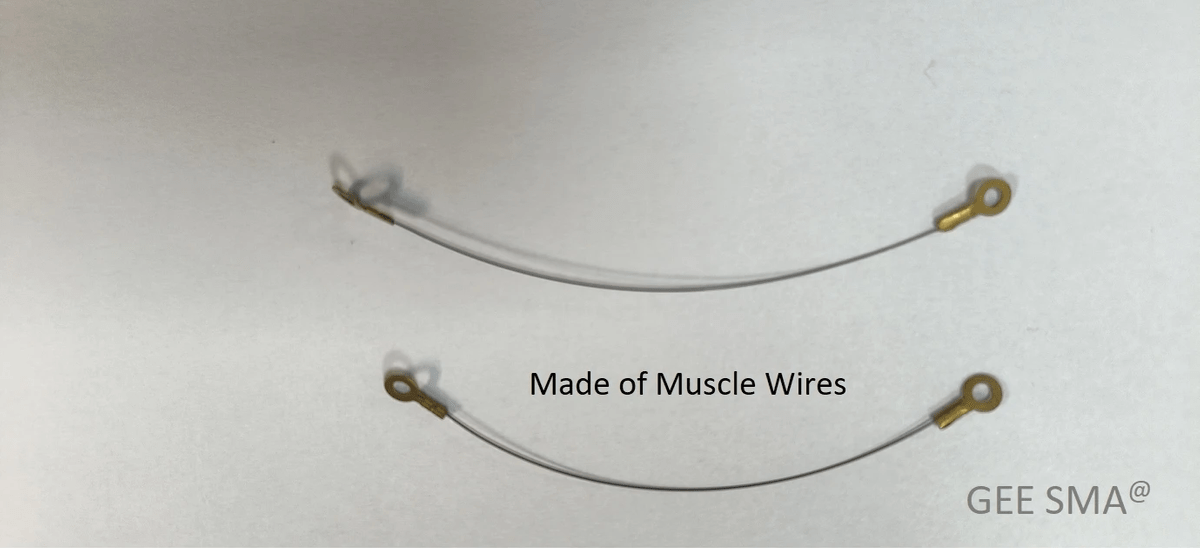

GEE SMA is a renowned nitinol company that prides itself on its unwavering commitment to quality. They emphasize stringent manufacturing processes and rigorous testing protocols, ensuring that every product meets high standards before reaching the market. With a focus on customer satisfaction, GEE SMA provides tailored solutions that cater to specific needs, making them a go-to choice for those asking, What company makes nitinol?

Quality assurance is at the heart of GEE SMA's operations, where advanced techniques are employed to manufacture nitinol with precision. This dedication not only enhances the performance of their products but also addresses common queries like Why is nitinol so expensive?—it's all about maintaining high-quality standards throughout production. By prioritizing excellence, GEE SMA continues to lead in various applications ranging from medical devices to consumer products.

Fort Wayne Metals: A Pioneering Force

Fort Wayne Metals has established itself as a pioneering force in the world of nitinol manufacturing and innovation. This company specializes in producing wire and other forms of nitinol that are essential for numerous applications, particularly in the medical field where precision is critical. When exploring options among leading nitinol companies, Fort Wayne Metals consistently stands out due to its extensive experience and expertise.

R.P.M.S Medical: Innovating with Nitinol

P.M.S Medical is another notable player committed to innovating with nitinol technology. This company focuses on creating advanced medical devices utilizing this remarkable alloy's unique properties, ensuring reliability and effectiveness for healthcare providers around the globe. As questions arise about What products are made from nitinol?, R.P.M.S Medical offers an impressive portfolio including surgical instruments and implants designed for optimal patient outcomes.

What Products Are Made from Nitinol?

Nitinol, a unique alloy of nickel and titanium, has carved out a niche in various industries due to its remarkable properties. From medical devices to consumer products and even aerospace applications, the versatility of nitinol is impressive. This section will explore the diverse range of products made from nitinol and highlight why choosing the right nitinol company can make all the difference.

Medical Devices and Implants

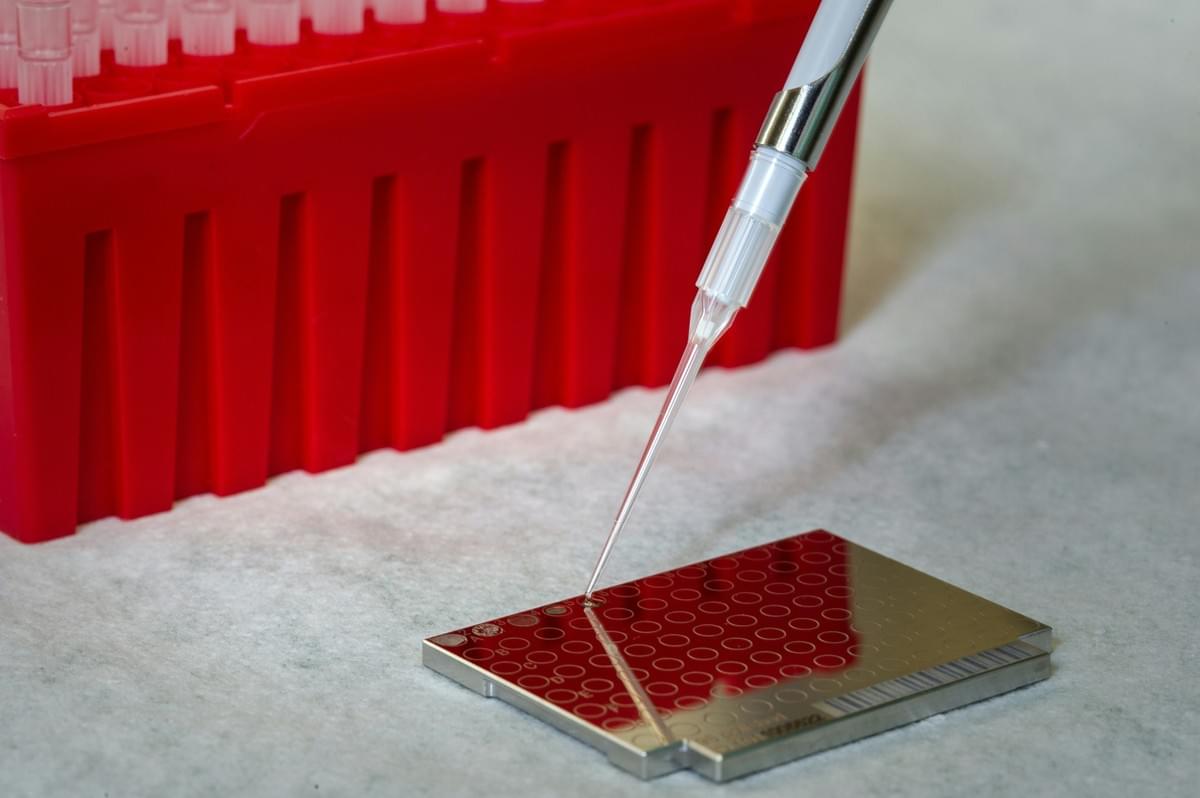

One of the most significant applications of nitinol is in the medical field, where it is used to create innovative devices and implants. Nitinol's superelasticity allows for minimally invasive surgeries, making procedures safer and more efficient for patients. Leading nitinol companies manufacture stents, guidewires, and orthopedic implants that capitalize on these unique properties, ensuring better patient outcomes.

The question often arises: What does nitinol do? In medical applications, it provides shape memory effects that allow devices to expand or contract with body temperature changes. This functionality is crucial for items like self-expanding stents that adapt perfectly to blood vessels upon insertion.

However, this innovation comes at a cost—why is nitinol so expensive? The specialized manufacturing processes required to produce high-quality nitinol components contribute significantly to their price point. Yet, when considering medical devices' life-saving potential, many healthcare providers find that investing in quality pays off.

Consumer Products Utilizing Nitinol

Beyond the realm of medicine, consumer products utilizing nitinol are gaining popularity for their durability and unique features. Items such as eyeglass frames made from nitinol are not only lightweight but also resistant to bending or breaking—perfect for active lifestyles! Many consumers are surprised by how often they encounter products made from this extraordinary alloy without realizing it.

What company makes nitinol? Several leading manufacturers focus on creating everyday items using this material; they emphasize quality while pushing innovation boundaries. With its ability to return to its original shape after deformation (thanks to its memory properties), consumers appreciate how these products enhance convenience in daily life.

Despite its numerous advantages in consumer goods, there are still challenges associated with using nitinol—what are the problems with nitinol? For instance, some consumers may find it challenging to understand care instructions specific to these materials compared with traditional alternatives. Nevertheless, as awareness grows about what products are made from nitinol and their benefits, demand continues climbing.

Aerospace Applications of Nitinol

The aerospace industry has also recognized the potential of nitinol due to its lightweight yet strong characteristics combined with excellent fatigue resistance. Components such as actuators or couplings made from this alloy can withstand extreme conditions while maintaining performance integrity—a vital requirement in aviation technology! As more aerospace companies partner with specialized nitinol manufacturers for tailored solutions, innovations continue emerging.

So why choose a reputable company when sourcing materials like these? Quality control plays an essential role in ensuring that parts meet stringent safety standards within aerospace applications; thus selecting a reliable supplier becomes paramount for engineers and designers alike.

As we look toward future advancements within aerospace technology using materials like this alloy—how do they manufacture nitinol? The process typically involves intricate techniques such as controlled cooling during solidification or heat treatment processes that enhance desired mechanical properties.

In summary, whether you're seeking top-tier medical devices or innovative consumer goods—or even exploring aerospace solutions—the versatility of what products are made from nitinol truly showcases its remarkable capabilities across various fields!

Manufacturing Processes of Nitinol

Nitinol, a unique alloy of nickel and titanium, is renowned for its remarkable shape memory and superelastic properties. The manufacturing processes involved in creating this innovative material are crucial to its functionality and applications. Understanding how nitinol is produced helps potential buyers make informed decisions when selecting a nitinol company.

How Do They Manufacture Nitinol?

The manufacturing of nitinol begins with the careful selection of raw materials—nickel and titanium—where precision is key to achieving the desired alloy composition. These metals are melted together in a vacuum or inert gas environment to prevent contamination, resulting in a homogenous mixture that can be processed further. Once cooled, the alloy undergoes various mechanical processes such as forging, rolling, or wire drawing to achieve the required shapes and sizes for different applications.

In addition to these initial steps, heat treatment plays a critical role in defining the properties of nitinol. By controlling temperature and time during this process, manufacturers can enhance specific characteristics such as shape memory or superelasticity. When considering what company makes nitinol? it's essential to choose one that employs advanced techniques to ensure high-quality production.

The Role of Alloy Composition

The alloy composition significantly influences the performance characteristics of nitinol products; small variations can lead to substantial differences in functionality. Typically composed of approximately 55% nickel and 45% titanium, slight adjustments can tailor the material's properties for specific applications like medical devices or aerospace components. This customization is vital for companies aiming to create specialized products that meet stringent industry standards.

Understanding why is nitinol so expensive? often comes down to these intricate compositions and the precision required in their manufacturing processes. Companies investing in research and development can create more efficient alloys that enhance performance while potentially reducing costs over time. Therefore, when evaluating different nitinol companies, it’s important to consider their expertise in optimizing alloy composition for your needs.

Advancements in Production Techniques

Recent advancements in production techniques have revolutionized how nitinol is manufactured, leading to improved quality and reduced costs for end-users. Innovations such as additive manufacturing (3D printing) allow for complex geometries that traditional methods struggle with—this opens new doors for product design across various industries like healthcare and aerospace where custom solutions are often necessary.

Moreover, automation has streamlined many aspects of production—from melting alloys to final inspections—ensuring consistency while minimizing human error during fabrication processes. As you explore what products are made from nitinol?, keep an eye on companies leveraging these advancements; they’re likely at the forefront of developing cutting-edge solutions that push the boundaries of what this remarkable material can achieve.

Cost Considerations in Nitinol Production

When it comes to nitinol, the price tag can often raise eyebrows. Nitinol is not your average metal; it’s an alloy of nickel and titanium that exhibits unique properties such as shape memory and superelasticity. This complexity in composition and the specialized manufacturing processes contribute significantly to why nitinol is so expensive.

Why Is Nitinol So Expensive?

The production of nitinol involves intricate processes that require high precision and advanced technology, which naturally drives up costs. What company makes nitinol? Well, leading companies invest heavily in research and development to enhance the material's properties, making it suitable for various applications—from medical devices to aerospace components. Additionally, the raw materials required for nitinol are not only costly but also subject to market fluctuations, further complicating pricing.

Factors Influencing Nitinol Pricing

Several factors come into play when determining the cost of nitinol products. The manufacturing techniques employed by a nitinol company can vary widely; some may use more efficient methods than others, impacting overall pricing strategies. Moreover, market demand plays a crucial role: as industries increasingly adopt what does nitinol do?—such as its use in stents or actuators—the demand surges, pushing prices upward.

Balancing Quality and Cost

Finding a balance between quality and cost is essential when selecting a nitinol provider. While it's tempting to go for the cheapest option available, compromises in quality can lead to significant problems with nitinol performance over time—think about durability or functionality issues that could arise from subpar materials. Ultimately, investing in high-quality products from reputable companies ensures reliability and longevity, making it a wise choice despite the initial expense.

Challenges Facing Nitinol Providers

Navigating the world of nitinol is no walk in the park, especially for those in the nitinol company sector. The unique properties of this shape-memory alloy come with their own set of challenges that can complicate production and application. From manufacturing hurdles to market dynamics, understanding these issues is crucial for anyone asking, What company makes nitinol?

What Are the Problems with Nitinol?

One of the most pressing problems with nitinol is its inherent sensitivity to temperature and composition variations. This sensitivity can lead to inconsistencies in performance, making it a challenge for manufacturers striving for quality assurance. Additionally, the complexity of its manufacturing process raises questions about durability and reliability—issues that any reputable nitinol company must address head-on.

Another significant concern lies in the cost associated with producing high-quality nitinol products. Why is nitinol so expensive? The answer lies in the meticulous processes required to create this remarkable material, from sourcing raw materials to intricate fabrication techniques. As a result, companies often grapple with balancing affordability while maintaining quality standards.

Finally, there’s also a growing concern about scalability within the industry; as demand increases for various applications—from medical devices to aerospace components—some providers struggle to keep pace without sacrificing quality or safety.

Regulatory and Compliance Issues

Regulatory hurdles pose another challenge for companies specializing in nitinol production. Given that many applications involve medical devices and implants, stringent compliance standards must be met before products hit the market. This means that any nitinol company must navigate a labyrinth of regulations that can slow down innovation and increase costs.

In addition to meeting regulatory requirements, companies face scrutiny regarding material safety and efficacy—factors that are critical when answering What does nitinol do? Manufacturers must provide extensive documentation proving their products meet health and safety guidelines while also demonstrating reliability over time.

Moreover, staying updated on changing regulations can be daunting; what was compliant yesterday may not be today due to evolving industry standards or new scientific findings related to materials like nitinol.

Market Demand and Supply Challenges

The market landscape presents its own set of challenges as well; fluctuations in demand can create supply chain issues for those who produce or utilize this versatile alloy. Companies often find themselves asking how do they manufacture nitinol efficiently while ensuring they have enough raw materials on hand? This delicate balance is crucial when considering lead times and customer satisfaction.

Additionally, competition among various manufacturers intensifies pressure on pricing structures—leading many potential customers to question why is nitinol so expensive? As more players enter the market seeking innovative applications for this unique material, established companies may need to rethink their strategies or risk losing relevance.

Lastly, global events such as trade disputes or natural disasters can disrupt supply chains further complicating how effectively companies can respond to market demands for specific products made from nitinol.

Conclusion

In wrapping up our exploration of Nitinol and its myriad applications, it's clear that the right choice of a nitinol company can significantly impact the success of your projects. With a landscape filled with various manufacturers, understanding their strengths and offerings is crucial. Selecting a company that aligns with your specific needs ensures you leverage the full potential of this unique material.

Choosing the Best Nitinol Company for You

When considering what company makes nitinol, it’s essential to evaluate their reputation, product quality, and customer service. A top-tier nitinol company will not only provide high-quality materials but also offer insights into how do they manufacture nitinol to ensure consistency and reliability in their products. Additionally, don’t hesitate to ask about their experience with specific applications; after all, finding a partner who understands what does nitinol do in your context can make all the difference.

Evaluating Nitinol Products and Their Uses

Understanding what products are made from nitinol is vital for anyone looking to utilize this remarkable alloy. From medical devices like stents and guidewires to innovative consumer products and aerospace components, the versatility of Nitinol is astounding. When evaluating these products, consider how they meet industry standards while also addressing concerns such as why is nitinol so expensive? This knowledge will empower you to make informed decisions based on your budgetary constraints.

The Future of Nitinol in Various Industries

The future of nitinol in various industries looks promising as advancements continue to emerge in manufacturing processes and applications. However, challenges persist; understanding what are the problems with nitinol—such as regulatory hurdles or market fluctuations—can help businesses navigate potential pitfalls effectively. As demand grows across sectors like healthcare and aerospace, partnering with an innovative nitinol company will be key to harnessing this material's full potential.