Introduction

Nitinol, a nickel-titanium alloy, is a remarkable material with unique properties that make it highly versatile and valuable across various industries. Known for its shape memory effect and superelasticity, Nitinol has revolutionized the way we approach engineering challenges. This introduction will delve into the properties and diverse uses of Nitinol, shedding light on its widespread applications and impact on different sectors.

Understanding Nitinol Alloy

Nitinol is a type of shape memory alloy (SMA) composed of almost equal parts of nickel and titanium. This combination results in a material that can remember its original shape even after being deformed, making it incredibly resilient and adaptable for different purposes.

Properties of Nitinol

The unique properties of Nitinol include its ability to return to a predetermined shape when subjected to heat or stress, known as the shape memory effect. Additionally, it exhibits superelastic behavior, allowing it to undergo substantial deformation without permanent damage. These properties make Nitinol an exceptional choice for various applications.

Exploring the Diverse Uses of Nitinol

Nitinol's versatility has led to its wide-ranging applications in fields such as medicine, aerospace, automotive industries, consumer products, and more. Its biocompatibility and corrosion resistance have made it particularly valuable in medical devices and implants. Moreover, its flexibility and resilience have found uses in consumer products like eyeglass frames and bra wires.

The Fascinating Properties of Nitinol

Nitinol: Properties, Applications, and Uses

Nitinol, a nickel-titanium alloy, possesses remarkable properties that make it a valuable material in various industries. One of its most intriguing properties is the shape memory effect, allowing it to return to its original shape when heated after being deformed. This unique characteristic makes it ideal for applications requiring precise and controlled movements, such as in medical devices and aerospace technology.

Shape Memory Effect

The shape memory effect of Nitinol has led to its widespread use in dentistry, where it is utilized in orthodontic wires that apply gentle pressure to shift teeth into proper alignment. Additionally, this property enables the creation of minimally invasive medical instruments like catheters and stents that can be inserted into the body in a compact form and then expand to their original shape when heated.

Superelasticity

Another remarkable property of Nitinol is its superelasticity, allowing it to undergo substantial deformation and recover without permanent damage. This quality makes it ideal for use in orthopedic implants like bone plates and screws, providing flexibility and support without the risk of fracture or breakage.

Biocompatibility and Corrosion Resistance

Nitinol's biocompatibility and corrosion resistance further enhance its value in medical applications, as it can safely interact with biological tissues without causing adverse reactions or deteriorating over time. These properties make Nitinol an excellent choice for guidewires used during minimally invasive surgeries and stents implanted within blood vessels.

Applications of Nitinol in Medicine

Nitinol, a nickel-titanium alloy, has found numerous applications in the field of medicine due to its remarkable properties. From dentistry to orthopedics, this versatile material has revolutionized medical devices and treatments.

Uses of Nitinol in Dentistry

Nitinol is widely used in orthodontic wires and brackets due to its superelasticity, which allows for gentle yet effective tooth movement. Additionally, it is utilized in endodontic files for root canal procedures, providing flexibility and resistance to fracture.

Nitinol is also finding its way into dental implants, where its biocompatibility and shape memory properties make it an ideal material for creating custom-fit devices that can adapt to the unique contours of each patient's mouth. This allows for a more comfortable and secure fit, reducing the risk of complications and improving overall patient satisfaction. Furthermore, Nitinol's corrosion resistance makes it a durable option for long-term use in the oral environment, ensuring the longevity of dental implants for years to come.

Nitinol in Orthopedic Implants

In orthopedics, nitinol is employed in bone fixation devices such as screws and plates. Its shape memory effect enables these implants to adapt to the body's natural movements while maintaining stability and strength.

Nitinol in Guidewires and Stents

Guidewires made from nitinol are extensively used during minimally invasive surgeries as they offer excellent flexibility and kink resistance. Moreover, nitinol stents are deployed in blood vessels to treat conditions like arterial blockages with minimal invasiveness.

Nitinol's exceptional properties have also found applications in the aerospace and automotive industries. In aerospace, nitinol is used in actuators, valves, and other components due to its ability to withstand extreme temperatures and harsh conditions. Its shape memory and superelasticity make it an ideal material for various aircraft components, contributing to improved performance and safety. Similarly, in the automotive industry, nitinol is used in engine components, exhaust systems, and safety features, where its durability and resilience are highly valued.

Nitinol in Aerospace and Automotive Industries

Nitinol, with its remarkable properties, has found diverse applications in the aerospace and automotive industries. The unique characteristics of this alloy make it an ideal choice for various components and technologies.

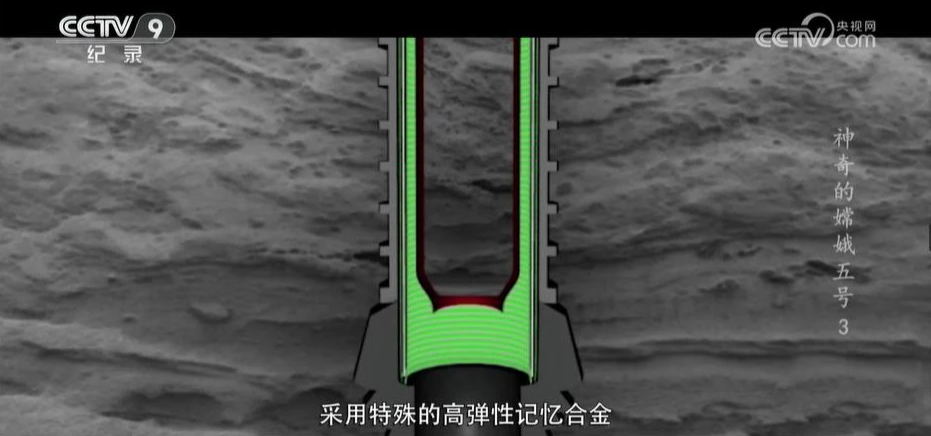

Nitinol Actuators in Space Technology

The superelasticity and shape memory effect of Nitinol make it an excellent material for actuators used in space technology. These actuators are crucial for deploying solar panels, antennas, and other moving parts on spacecraft due to their ability to withstand extreme temperatures and conditions.

Nitinol in Engine Components

In the automotive industry, Nitinol is utilized in engine components such as valves, springs, and fuel injection systems. Its high fatigue resistance and durability make it a valuable material for enhancing the performance and efficiency of internal combustion engines.

Nitinol in Smart Materials for Automotive

Nitinol's unique properties also make it suitable for smart materials used in automotive applications. These smart materials can respond to external stimuli by changing shape or stiffness, leading to innovations like self-healing car parts and adaptive aerodynamics systems.

Nitinol in Consumer Products

Nitinol, with its remarkable shape memory effect and superelasticity, has found its way into various consumer products, revolutionizing the way we use everyday items. From eyeglass frames to bra wires and antenna technology, the versatility of Nitinol has opened up a world of possibilities for innovative designs and enhanced performance.

Eyeglass Frames

Nitinol's flexibility and durability make it an ideal material for eyeglass frames. Its ability to return to its original shape after being bent or twisted ensures a longer lifespan for eyewear, providing users with comfortable and reliable glasses that can withstand daily wear and tear.

Nitinol's unique properties also make it an excellent choice for eyeglass frames because it is lightweight, making it comfortable to wear for extended periods. Additionally, its corrosion resistance ensures that the frames will not deteriorate over time, maintaining their sleek appearance. This makes Nitinol frames a practical and stylish option for those in need of reliable eyewear.

Bra Wires

The use of Nitinol in bra wires has transformed the undergarment industry by offering women a more comfortable and supportive alternative to traditional metal wires. The unique properties of Nitinol allow bra wires to adapt to the body's movements while maintaining their shape, providing a seamless fit and superior comfort.

In addition to providing superior comfort, the use of Nitinol in bra wires also offers a longer lifespan for undergarments. Traditional metal wires are prone to bending and warping over time, leading to discomfort and an uneven fit. With Nitinol, bra wires can maintain their shape and support for a much longer period, reducing the need for frequent replacements and saving women both time and money.

Antenna Technology

In the realm of technology, Nitinol has made significant contributions to antenna design. Its high strength-to-weight ratio and resistance to corrosion make it an excellent choice for creating efficient and durable antennas for various communication devices, ensuring reliable connectivity in diverse environments.

Nitinol's unique properties have also paved the way for the development of smaller and more compact antennas, allowing for greater flexibility in design and placement. This has been particularly beneficial in the advancement of wearable technology, where space is at a premium and efficient connectivity is essential. As a result, Nitinol has played a crucial role in enabling the seamless integration of antennas into smartwatches, fitness trackers, and other wearable devices, enhancing their overall performance and user experience.

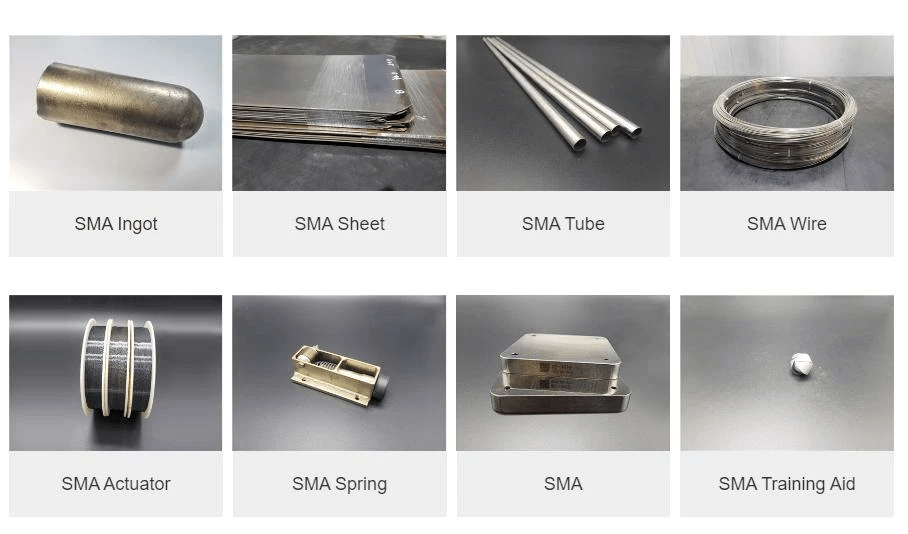

GEE SMA: Leaders in Nitinol Alloys

At GEE SMA, we take pride in crafting high-quality nitinol components that meet the highest industry standards. Our team of experts utilizes state-of-the-art technology and precision engineering to ensure the reliability and durability of our nitinol products.

Crafting High-Quality Nitinol Components

Our advanced manufacturing processes allow us to create intricate nitinol components with exceptional shape memory and superelasticity. Whether it's for medical devices, aerospace applications, or consumer products, our commitment to quality shines through in every piece we produce.

Our team of experienced engineers and technicians are dedicated to understanding the unique needs of our customers, ensuring that every nitinol component we produce is tailored to their specific requirements. By working closely with our clients, we are able to create customized solutions that meet the highest standards of quality and performance. This collaborative approach allows us to consistently deliver nitinol components that exceed expectations and provide exceptional value to our customers.

Tailoring Nitinol to Meet Customer Needs

We pride ourselves on our swift customer response and product enhancement capabilities. Our team is dedicated to providing timely and efficient service, ensuring that our clients' needs are met in a timely manner. Additionally, we continuously seek opportunities to enhance our products, whether it's through improved manufacturing processes or the development of new nitinol alloys with enhanced properties.

Swift Customer Response and Product Enhancement

At GEE SMA, customer satisfaction is at the core of everything we do. We prioritize swift response times and effective communication to ensure that our clients' expectations are not only met but exceeded. Additionally, we continually enhance our products based on customer feedback and technological advancements.

In addition to our commitment to swift customer response and product enhancement, we also place a strong emphasis on building long-term relationships with our clients. We believe that open and transparent communication is key to fostering trust and loyalty, and we strive to ensure that our clients feel valued at every touchpoint. By prioritizing customer satisfaction and relationship-building, we aim to not only meet but exceed expectations, solidifying our position as a trusted partner in our clients' success.

Conclusion

Exploring the Endless Possibilities of Nitinol

The versatility of nitinol allows for its use in a wide array of industries, from medicine to aerospace. Its unique shape memory effect and superelasticity make it an ideal material for various applications, paving the way for endless possibilities in innovation and technology.

The unique properties of nitinol also make it a game-changer in the field of robotics and automation. Its ability to remember its original shape after being deformed allows for the creation of self-repairing and self-assembling robotic components, reducing maintenance costs and increasing efficiency. This opens up new possibilities for the development of advanced robotic systems that can adapt to changing environments and perform complex tasks with precision.

Nitinol: Revolutionizing Industries Worldwide

With its remarkable properties and diverse uses, nitinol has revolutionized industries worldwide. From medical devices to consumer products and beyond, the impact of nitinol can be seen across different sectors, driving advancements and improvements in various fields. Nitinol's unique shape memory and superelasticity make it an ideal material for minimally invasive medical devices, such as stents and guidewires, allowing for more effective treatments with reduced patient discomfort. Additionally, the biocompatibility of nitinol alloys has contributed to their widespread adoption in surgical tools and implants, further enhancing patient outcomes and recovery processes. The versatility of nitinol also extends to consumer products, where its flexibility and durability have led to innovative applications in eyeglass frames, mobile phone antennas, and even orthodontic wires, providing consumers with high-performance products that enhance their daily lives.

Embracing the Versatility of Nitinol Alloys

As industries continue to embrace the versatility of nitinol alloys, the demand for high-quality components crafted from this remarkable material is on the rise. With its biocompatibility, corrosion resistance, and unique mechanical properties, nitinol has become an indispensable resource for innovation and progress.

Remember that embracing the potential of nitinol alloys is not just about utilizing a material; it's about embracing a new era of possibilities and pushing boundaries to achieve greater feats in technology and engineering. The future holds endless opportunities for leveraging the incredible properties of nitinol to create groundbreaking solutions that will shape our world for years to come.