Introduction

Are you curious about the world of nitinol companies? Whether you're a medical professional, engineer, or just someone interested in cutting-edge materials, nitinol is a fascinating topic. From understanding how it's manufactured to exploring the leading suppliers and manufacturers, there's much to uncover in this innovative industry.

Exploring Nitinol Companies

When it comes to nitinol companies, one of the first questions that may come to mind is What company makes nitinol? The answer lies in a handful of reputable manufacturers who have perfected the art of crafting this unique material. From medical device companies to industrial component producers, there are numerous players in the market vying for top position.

Understanding Nitinol Manufacturing

How is nitinol manufactured? This question delves into the intricate process of creating shape memory alloys and nitinol wire. The manufacturing process involves precise engineering and expertise to ensure that the final product meets rigorous quality standards. Understanding this process sheds light on why nitinol has gained such widespread use across various industries.

Nitinol Suppliers and Manufacturers

In your quest for knowledge about nitinol, you'll inevitably encounter a wide range of suppliers and manufacturers offering this remarkable material. But what sets them apart? It's essential to consider factors such as cost, quality, and reliability when choosing a supplier for your specific needs.

The Leading Nitinol Suppliers

When it comes to finding top-notch nitinol suppliers, GEE SMA is a name that stands out. With a strong reputation for quality and reliability, GEE SMA has established itself as a leading player in the industry. Their commitment to innovation and customer satisfaction makes them a go-to choice for businesses looking for high-grade nitinol materials.

GEE SMA

GEE SMA is renowned for its extensive range of nitinol products, including wires, tubes, and components that cater to various industries such as medical devices, aerospace, and automotive. The company's dedication to research and development ensures that they stay at the forefront of nitinol technology, providing cutting-edge solutions for their clients' needs.

GEE SMA's commitment to innovation and quality has positioned them as a leader in the nitinol industry. Their state-of-the-art manufacturing facilities and rigorous quality control processes ensure that their products meet the highest standards. This dedication to excellence has earned GEE SMA a reputation for reliability and performance, making them the preferred choice for clients seeking top-notch nitinol solutions.

Johnson Matthey

Johnson Matthey is another key player in the nitinol industry, offering a wide array of high-quality nitinol alloys and components. With their global presence and commitment to sustainable manufacturing practices, Johnson Matthey has earned a reputation as a trusted supplier for businesses seeking reliable nitinol materials.

Johnson Matthey's extensive experience in the nitinol industry allows them to offer innovative solutions for a wide range of applications, from medical devices to aerospace components. Their advanced research and development capabilities ensure that they stay at the forefront of nitinol technology, providing customers with cutting-edge materials and products. With a strong focus on customer satisfaction, Johnson Matthey is known for delivering personalized service and technical support to meet the unique needs of each client.

SAES Group

SAES Group is known for its expertise in shape memory alloys and its innovative approach to nitinol manufacturing. The company's focus on precision engineering and advanced material science has positioned them as a leading provider of specialized nitinol solutions for diverse applications.

SAES Group has established itself as a leader in the nitinol industry by consistently pushing the boundaries of innovation and technology. Their commitment to precision engineering and advanced material science has allowed them to develop cutting-edge nitinol solutions that cater to a wide range of applications, from medical devices to aerospace components. This dedication to excellence has earned SAES Group a stellar reputation for delivering top-notch materials that not only meet, but exceed, the specific requirements of their clients.

By choosing any of these leading nitinol suppliers, businesses can be confident in obtaining top-notch materials that meet their specific requirements while ensuring exceptional quality and performance.

Nitinol Manufacturing Process

When it comes to the manufacturing process of nitinol, it all starts with the creation of nitinol alloys. These unique alloys are typically made from nearly equal parts of nickel and titanium, resulting in a material that exhibits superelasticity and shape memory properties. The combination of these two elements is what gives nitinol its remarkable characteristics, making it a highly sought-after material for various applications.

Nitinol Alloys

Nitinol alloys are created through a process called shape setting, where the metal is heated and then cooled in a specific shape to set its memory. This allows the material to return to its original form after being deformed, making it ideal for applications where precise movements are required. Companies such as GEE SMA and Johnson Matthey are known for their expertise in producing high-quality nitinol alloys that meet stringent industry standards.

Shape Memory Alloys

The unique properties of shape memory alloys, such as nitinol, allow them to remember their original shape and return to it when subjected to heat or pressure. This makes them incredibly valuable in industries like aerospace and medical devices, where intricate components need to maintain their shape under varying conditions.

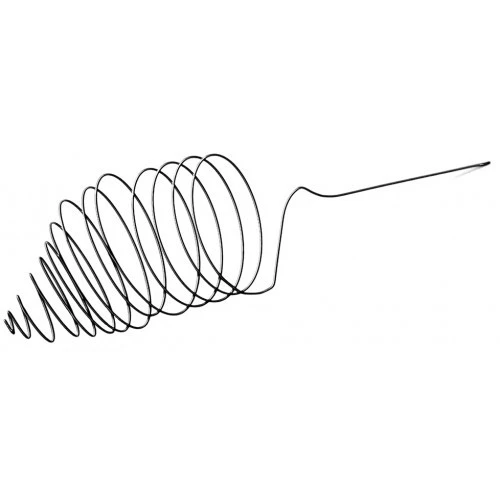

Nitinol Wire Manufacturers

Nitinol wire manufacturers play a crucial role in shaping this versatile material into various forms that can be used in different applications. Whether it's for medical stents or industrial actuators, these manufacturers use specialized techniques to produce nitinol wires with precise dimensions and mechanical properties.

Nitinol Applications and Uses

Nitinol, a shape memory alloy, has a wide range of applications across various industries. Medical devices are one of the primary uses of nitinol due to its unique properties such as superelasticity and biocompatibility. From stents to orthodontic wires, nitinol is a crucial material in the medical field.

Medical Devices

In the medical industry, nitinol is used in a variety of applications such as cardiovascular implants, surgical tools, and dental braces. Its ability to return to its original shape after deformation makes it ideal for minimally invasive medical procedures. Companies like Johnson Matthey have been at the forefront of supplying high-quality nitinol materials for medical devices.

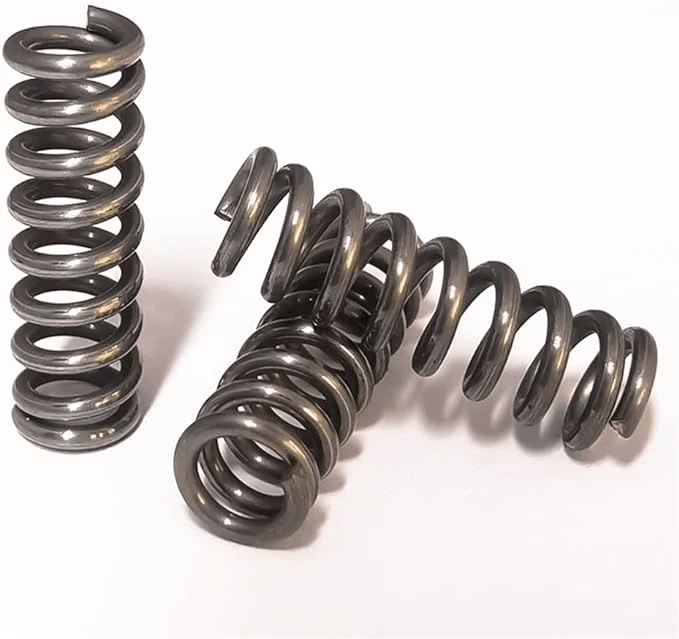

Industrial Components

Nitinol's unique properties also make it valuable in industrial components such as actuators, sensors, and valves. Its shape memory effect allows for precise control and movement in industrial machinery, while its superelasticity ensures durability and resilience under extreme conditions.

Consumer Products

From eyeglass frames to mobile phone antennas, nitinol is increasingly finding its way into consumer products due to its flexibility and resilience. GEE SMA is among the leading suppliers that cater to consumer product manufacturers looking to leverage the benefits of nitinol in their designs.

Cost and Pricing of Nitinol

Nitinol, a shape memory alloy, is known for its unique properties, but many wonder, is nitinol expensive? The cost of nitinol can vary depending on the supplier and the quality of the material. While it may have a higher price tag compared to other metals, its value and performance often justify the investment.

Is Nitinol Expensive?

When compared to traditional metals like steel or aluminum, nitinol can be considered relatively expensive. This is due to its specialized manufacturing process and the unique properties it possesses. However, the benefits it offers in terms of shape memory and superelasticity make it a worthwhile investment for many industries.

Price Factors

The price of nitinol is influenced by various factors such as the purity of the alloy, the manufacturing process used, and market demand. Additionally, the complexity of shaping nitinol into specific forms can also impact its cost. Understanding these price factors can help companies make informed decisions when sourcing nitinol materials.

Value and Quality

While nitinol may come with a higher price tag, its value lies in its exceptional properties such as shape memory effect and biocompatibility. These qualities make it an invaluable material for medical devices and other high-performance applications. When considering cost and pricing, it's essential to prioritize quality to ensure optimal performance.

Advantages of Nitinol Materials

Nitinol, a shape memory alloy, offers several advantages that make it a popular choice in various industries. One of the key advantages is its remarkable shape memory effect, which allows the material to return to its original shape after deformation. This unique property makes it ideal for applications such as medical stents and orthodontic wires, where precise shape retention is crucial.

Shape Memory Effect

Nitinol's shape memory effect is a result of its ability to undergo a reversible phase transformation under certain conditions. This means that the material can be deformed at low temperatures and then revert to its original shape when exposed to higher temperatures. This property has revolutionized the medical device industry, allowing for the development of minimally invasive treatments and innovative surgical procedures.

Nitinol's shape memory effect has also found applications beyond the medical device industry. It has been used in industries such as aerospace and automotive, where its ability to revert to its original shape after deformation has proven valuable in creating resilient and durable components. This unique property of Nitinol has opened up new possibilities for engineering and design, allowing for the development of advanced technologies that can withstand extreme conditions and demanding environments.

Superelasticity

Another advantage of nitinol is its superelasticity, also known as pseudoelasticity. This unique characteristic enables the material to undergo large deformations and still return to its undeformed state without permanent damage. As a result, nitinol components can withstand significant stress and strain without experiencing fatigue failure, making them highly durable and reliable in demanding applications.

Biocompatibility

Nitinol's biocompatibility is another key advantage that has contributed to its widespread use in medical devices and implants. The material exhibits excellent corrosion resistance and compatibility with bodily fluids and tissues, making it suitable for long-term implantation without adverse reactions or tissue rejection. This makes nitinol an ideal choice for cardiovascular stents, orthopedic implants, and other biomedical applications.

Furthermore, nitinol's biocompatibility extends beyond its resistance to corrosion and compatibility with bodily fluids. The material also has the ability to adapt to the body's temperature, allowing for self-expansion and contraction within the body. This unique property is particularly advantageous in the design of cardiovascular stents, as it enables a more precise and customized fit within blood vessels. Additionally, this adaptability reduces the risk of complications and improves patient outcomes, further solidifying nitinol's position as a top choice for medical implants.

Conclusion

In conclusion, choosing the right nitinol supplier is crucial for ensuring quality and reliability in your products. When selecting a nitinol company, it's important to consider factors such as experience, reputation, and customer service. Look for companies like GEE SMA, Johnson Matthey, and SAES Group that have a proven track record in providing high-quality nitinol materials.

Choosing the Right Nitinol Supplier

When looking for a nitinol company, it's essential to do thorough research to find the best fit for your specific needs. Consider factors such as manufacturing capabilities, product range, and customer reviews to make an informed decision. Remember that quality and reliability should be prioritized over cost when selecting a nitinol supplier.

Innovations in Nitinol Technology

As technology continues to advance, so does the innovation in nitinol materials. Manufacturers are constantly developing new techniques and alloys to improve the performance and versatility of nitinol products. Keep an eye out for companies that are at the forefront of these innovations to ensure that you are using the most advanced materials available.

The Future of Nitinol Materials

The future of nitinol materials looks promising as researchers and manufacturers continue to explore new applications and advancements in this field. With ongoing developments in medical devices, industrial components, and consumer products, the demand for high-quality nitinol will only continue to grow. As technology evolves, so will the potential uses for this remarkable material.

Remember that choosing a reliable nitinol company is key to ensuring success in your projects. Stay informed about industry trends and advancements to make sure you are always using the best materials available for your needs.