Introduction

In the world of advanced engineering, the Nitinol Linear Actuator stands out as a high-performance marvel. This cutting-edge technology harnesses the power of Nitinol Shape Memory Alloy Wire to deliver precision and control in motion systems. With its innovative design and remarkable capabilities, the Nitinol Linear Actuator has garnered widespread attention across various industries.

Understanding High-Performance Nitinol Linear Actuator

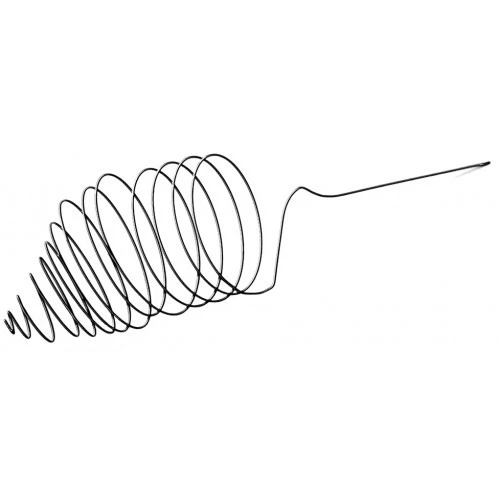

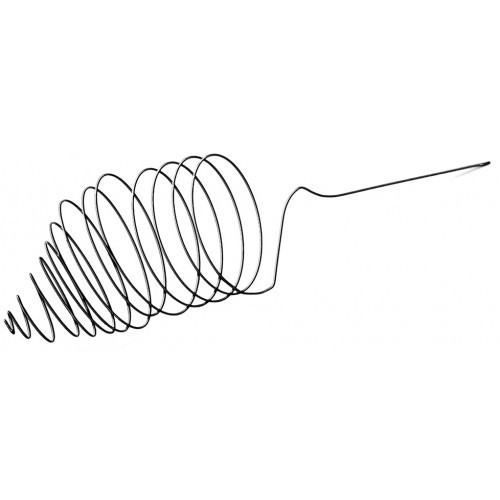

The Nitinol Linear Actuator is a two-way shape memory alloy wire that offers unparalleled speed and efficiency in its operation. This revolutionary device utilizes Nitinol, a unique material with the ability to remember its original shape and return to it when activated. This exceptional feature allows for swift and accurate movements, making it an ideal choice for intricate engineering applications.

Exploring the Applications of Nitinol Linear Actuator

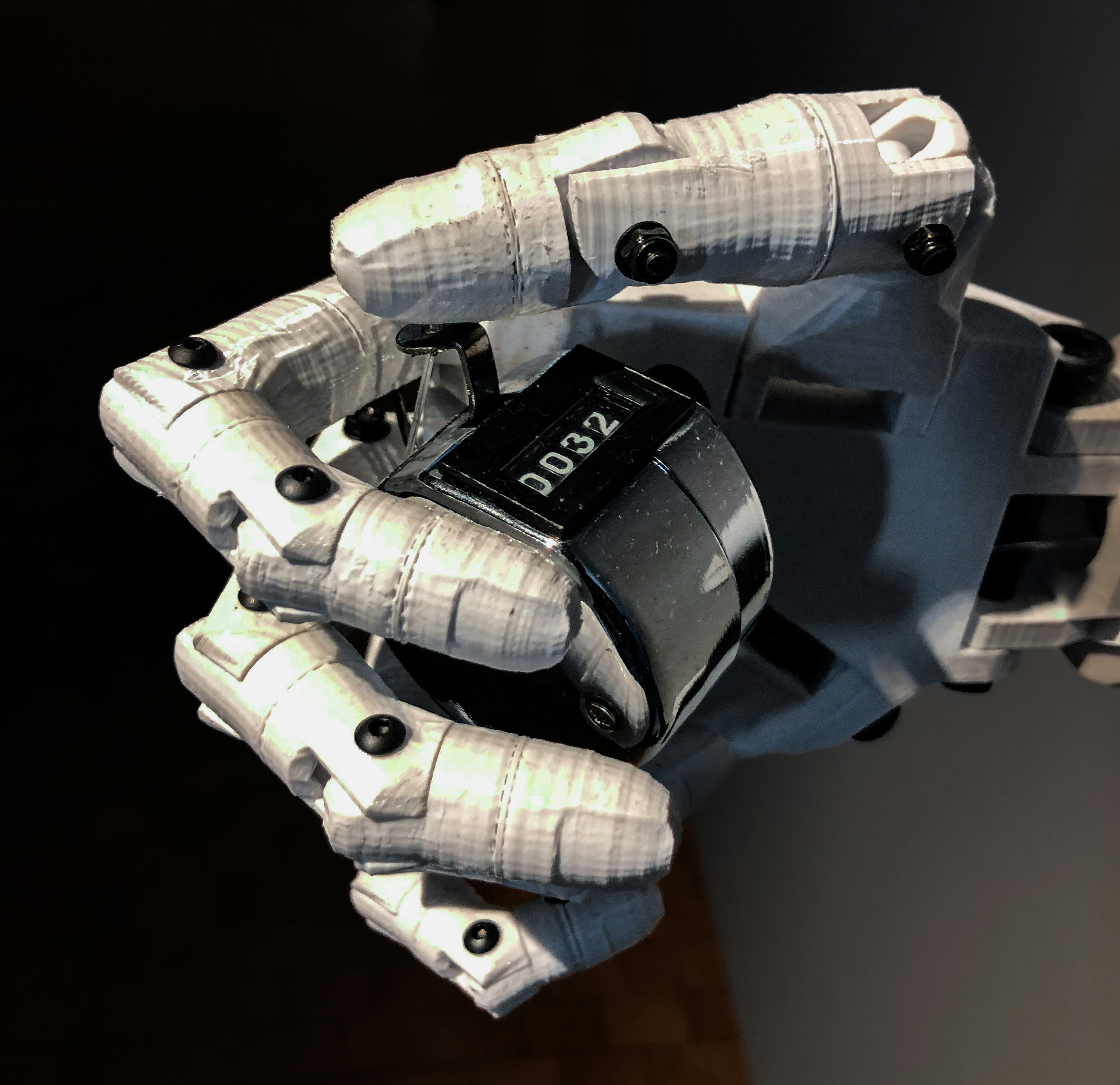

From aerospace and automotive industries to medical devices and robotics, the versatility of Nitinol Linear Actuators knows no bounds. These devices are widely used in precision instruments, automated systems, and adaptive structures where rapid responses and precise control are essential.

Nitinol Linear Actuators are also finding increasing use in the field of consumer electronics, where their compact size and high energy efficiency make them ideal for applications such as smartphone vibration motors, camera autofocus mechanisms, and wearable device actuators. The ability of Nitinol Linear Actuators to deliver precise and reliable performance in a small form factor is driving their adoption in the rapidly evolving consumer electronics market.

Advantages of Using Nitinol Linear Actuator

The use of Nitinol in linear actuators offers numerous advantages, including durability, responsiveness, and energy efficiency. Its ability to withstand repeated use without degradation makes it a cost-effective solution for complex engineering challenges.

Nitinol linear actuators also offer a high level of responsiveness, allowing for precise control and smooth operation. This makes them ideal for applications where accuracy and speed are essential, such as in medical devices or robotics. The ability of Nitinol to quickly and efficiently convert energy into motion makes it a valuable choice for engineers looking to optimize performance while minimizing energy consumption.

What is Nitinol Linear Actuator?

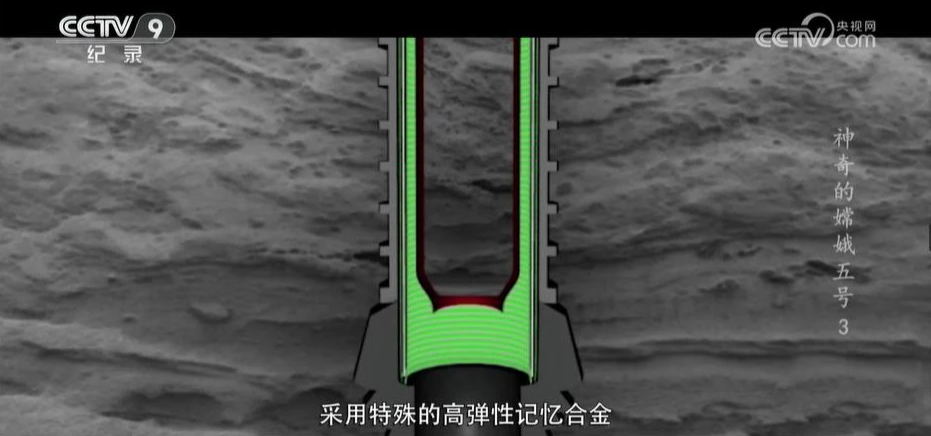

Nitinol linear actuators are advanced devices that utilize Nitinol Shape Memory Alloy Wire to convert thermal energy into mechanical motion. GEE SMA's expertise in crafting Nitinol shape memory alloys ensures the precise engineering and manufacturing of these high-performance actuators, guaranteeing exceptional quality and reliability.

GEE SMA's Expertise in Crafting Nitinol Shape Memory Alloys

GEE SMA's extensive experience in working with Nitinol allows for the production of superior quality linear actuators. The company's in-depth knowledge of the unique properties of Nitinol enables them to craft shape memory alloys with exceptional precision, ensuring optimal performance and durability for their linear actuators.

Furthermore, GEE SMA's expertise in working with Nitinol allows them to create linear actuators with a wide range of motion and precise control. This means that their shape memory alloys can be tailored to specific application requirements, providing flexibility and versatility for various industries. Additionally, the company's deep understanding of Nitinol's behavior under different conditions ensures that their linear actuators maintain consistent performance over time, making them a reliable choice for long-term use.

Key Features of Nitinol Linear Actuator

Nitinol linear actuators boast remarkable speed and responsiveness, making them ideal for applications requiring quick and accurate movements. These actuators are also known for their compact design, high force output, and silent operation, making them suitable for a wide range of industries and applications.

Furthermore, Nitinol linear actuators are highly durable and reliable, ensuring a long lifespan and minimal maintenance requirements. This makes them a cost-effective solution for industries looking to minimize downtime and maximize productivity. Additionally, their precise control and positioning capabilities make them an excellent choice for applications in robotics, medical devices, aerospace, and automotive industries.

Applications of Nitinol Linear Actuator in Various Industries

Nitinol linear actuators are particularly well-suited for use in medical devices, where precision and reliability are paramount. These actuators are used in surgical tools and equipment, allowing for precise control and movement in delicate procedures. In the robotics industry, Nitinol linear actuators play a crucial role in powering intricate robotic systems that require smooth and accurate motion control. Their ability to provide consistent and reliable performance makes them an ideal choice for use in aerospace applications, where safety and precision are of utmost importance.

The Technology Behind Nitinol Linear Actuator

How Nitinol Shape Memory Alloys Enable High Performance

Nitinol shape memory alloys enable high performance in linear actuators by exhibiting superelasticity and shape memory effects. This allows the nitinol wire to return to its original shape after being deformed, providing precise and reliable actuation in various applications.

Nitinol shape memory alloys are also highly durable, making them ideal for long-term use in linear actuators. This durability ensures that the nitinol wire can withstand repeated deformations and still maintain its original shape and performance, reducing the need for frequent maintenance or replacement. As a result, linear actuators incorporating nitinol shape memory alloys offer reliable and consistent operation over extended periods, making them a cost-effective and practical choice for various industrial and commercial applications.

Mechanism of Nitinol Linear Actuator

The mechanism of a nitinol linear actuator involves the use of Nitinol Linear Actuator (2 way) Shape Memory Alloy Wire, which is trained to remember a specific shape. When activated by an external stimulus such as heat, the nitinol wire undergoes a phase transformation, resulting in a significant change in length or force output.

In contrast to traditional linear actuators, which rely on mechanical components such as gears and motors to produce linear motion, nitinol linear actuators offer a more compact and efficient solution. The use of shape memory alloy wire eliminates the need for bulky components, making nitinol linear actuators ideal for applications where space is limited. Additionally, the ability of nitinol wire to undergo a reversible phase transformation allows for precise control over the length and force output, offering a level of flexibility not achievable with traditional linear actuators.

Comparison with Traditional Linear Actuators

In comparison with traditional linear actuators that rely on electric motors or hydraulic systems, nitinol actuators offer faster response times and higher energy efficiency. The use of nitinol also eliminates the need for bulky external power sources, making it ideal for compact and portable applications.

Benefits of Using Nitinol Linear Actuator

Precision and Control in Motion Systems

The Nitinol Linear Actuator offers exceptional precision and control in motion systems, allowing for smooth and accurate movements in various applications. Whether it's in medical devices, aerospace technology, or robotics, the high-performance capabilities of Nitinol Linear Actuators ensure reliable and precise motion control, enhancing overall operational efficiency.

Durability and Longevity of Nitinol Linear Actuator

One of the key advantages of utilizing Nitinol Linear Actuators is their remarkable durability and longevity. The unique properties of Nitinol Shape Memory Alloys enable these actuators to withstand extensive use without compromising performance, making them an ideal choice for demanding industrial environments where reliability is paramount.

Cost-Effective Solutions for Complex Engineering Challenges

Nitinol Linear Actuators provide cost-effective solutions for complex engineering challenges by offering a combination of high performance, durability, and efficiency. Their ability to deliver precise motion control while maintaining long-term reliability makes them a valuable investment for industries seeking innovative solutions to enhance their operational processes.

Customization and Integration of Nitinol Linear Actuator

When it comes to tailoring Nitinol functional materials to specific engineering requirements, GEE SMA's expertise shines through. With a deep understanding of the unique properties of Nitinol Shape Memory Alloys (SMAs), they are able to customize the material composition and fabrication process to meet the precise needs of different applications. Whether it's adjusting the transition temperature or fine-tuning the mechanical properties, GEE SMA's mastery allows for unparalleled customization.

Tailoring Nitinol Functional Materials to Specific Engineering Requirements

GEE SMA works closely with clients to understand their specific performance demands and environmental conditions, ensuring that the Nitinol linear actuator is tailored for optimal functionality. By customizing the material composition and processing parameters, they can create Nitinol SMAs with varying transformation temperatures, superelasticity, and fatigue resistance, providing tailored solutions for a wide range of engineering challenges.

Seamless Integration with Existing Systems

The adaptability of Nitinol linear actuators allows for seamless integration with existing systems across various industries. Whether it's in medical devices, aerospace applications, or industrial automation, GEE SMA ensures that their Nitinol actuators can be easily incorporated into different setups without requiring extensive modifications or overhauls.

Collaborative Approach to Design and Development with GEE SMA

GEE SMA takes a collaborative approach to design and development, working closely with engineers and innovators to bring their vision to life. By leveraging their expertise in Nitinol technology and shape memory alloys, they engage in a dynamic exchange of ideas and insights that ultimately leads to the creation of cutting-edge nitinol linear actuators that meet the most demanding performance criteria.

Future Potential and Innovations in Nitinol Linear Actuator

As the demand for advanced actuators continues to grow, ongoing research and development in nitinol technology is focused on enhancing the performance and efficiency of nitinol linear actuators. Engineers and scientists are exploring new methods to optimize the responsiveness and speed of nitinol actuators, paving the way for cutting-edge advancements in motion control systems.

Ongoing Research and Development in Nitinol Technology

Researchers are delving into innovative techniques to activate nitinol wire more rapidly, resulting in faster response times for nitinol linear actuators. Additionally, there is a concerted effort to refine the materials used in linear actuators, ensuring that they meet the highest standards of quality and durability.

Emerging Applications and Industries

The versatility of nitinol linear actuators has led to their adoption across a diverse range of industries, including aerospace, medical devices, robotics, and automotive engineering. As technology continues to evolve, new applications for nitinol actuator devices are constantly emerging, demonstrating their potential for revolutionizing various sectors. One exciting emerging application is in the field of renewable energy, where nitinol actuators show promise for improving the efficiency and reliability of solar panels and wind turbines. This could lead to significant advancements in sustainable energy production and contribute to the global shift towards cleaner power sources.

Sustainable and Environmentally-Friendly Aspects of Nitinol Actuators

In an era where sustainability is paramount, nitinol linear actuators offer a compelling advantage with their environmentally-friendly properties. The use of shape memory alloys like nitinol contributes to energy efficiency and reduced environmental impact, aligning with the global push towards sustainable engineering solutions.

In addition to their energy efficiency, nitinol linear actuators also offer durability and longevity, further contributing to their sustainable appeal. With a longer lifespan than traditional actuators, nitinol devices require less frequent replacement and maintenance, reducing overall material consumption and waste. This not only benefits the environment by conserving resources but also saves on costs for businesses and industries in the long run.

Conclusion

When it comes to versatility and promise, the Nitinol Linear Actuator truly shines. Its ability to seamlessly integrate into various systems and its unmatched precision and control make it a game-changer in the world of linear actuators. With GEE SMA's commitment to elevating Nitinol product quality, the future of Nitinol Linear Actuator looks brighter than ever.

The Versatility and Promise of Nitinol Linear Actuator

The Nitinol Linear Actuator's two-way shape memory alloy wire enables rapid and precise movements, making it a top choice for applications requiring quick response times. Its flexibility in design and customization options ensures that it can be tailored to fit specific engineering requirements, making it an incredibly versatile solution for a wide range of industries.

Strategic Advantages of Incorporating Nitinol Technology

Incorporating Nitinol technology into linear actuators offers strategic advantages such as cost-effective solutions for complex engineering challenges, durability, and longevity, as well as environmentally-friendly aspects that align with sustainable practices. These advantages position Nitinol Linear Actuators as a strategic investment for companies looking to enhance their motion systems.

GEE SMA's Commitment to Elevating Nitinol Product Quality

GEE SMA's expertise in crafting Nitinol Shape Memory Alloys ensures that their Nitinol Linear Actuators are at the forefront of innovation and quality. Their collaborative approach to design and development guarantees that each product is tailored to meet the highest standards, providing customers with reliable and high-performance solutions for their motion system needs.