Introduction

Nitinol, a unique alloy of nickel and titanium, has revolutionized the medical industry with its exceptional properties. From its flexibility to shape memory, Nitinol rods have become indispensable in various medical applications. As a leading material in medical devices, Nitinol wire offers unparalleled benefits that contribute to improved patient outcomes and enhanced medical procedures.

Understanding Nitinol Rods for Medical Applications

Nitinol rods are widely used in medical applications due to their superelasticity and biocompatibility. As a shape memory alloy, Nitinol allows for the creation of intricate devices such as guidewires that can navigate through the body's complex pathways with precision and resilience.

Exploring the Benefits of Nitinol in Medical Devices

The unique properties of Nitinol, including its ability to return to a predetermined shape when heated, make it ideal for medical devices like stents and orthopedic implants. This versatility has led to significant advancements in minimally invasive procedures and patient care.

Common Uses of Nitinol in the Medical Industry

Nitinol is commonly utilized in various medical applications such as cardiovascular intervention, neurovascular surgery, and orthodontic treatments. Its exceptional performance and reliability have positioned it as an indispensable material in modern healthcare.

What is Nitinol?

The unique properties of Nitinol wire and rod

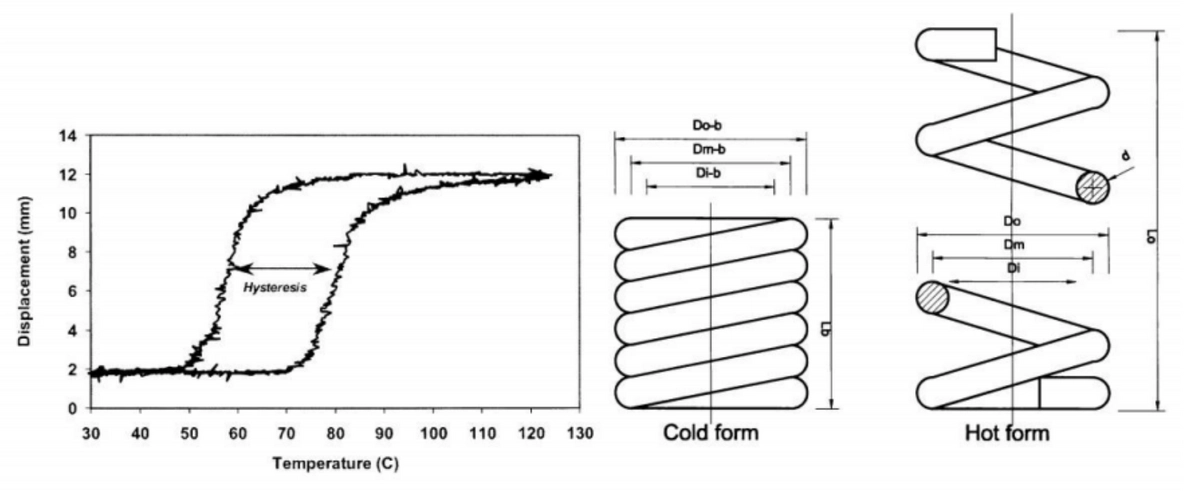

Nitinol, a nickel-titanium alloy, exhibits shape memory and superelasticity, making it ideal for medical applications. Its ability to return to a predetermined shape when heated and withstand large strains without permanent deformation makes it invaluable in medical devices.

Nitinol is manufactured through a process of carefully controlled heating and cooling, known as heat treatment, to achieve its unique properties. This involves precise manipulation of the alloy's crystalline structure to create the desired shape memory and superelasticity. The resulting wire and rod can then be used in a wide range of medical devices, from stents and guidewires to orthodontic braces and surgical instruments.

How Nitinol is manufactured

Nitinol is manufactured through a process of controlled heating and cooling that allows the material to exhibit its unique properties. Nickel titanium suppliers carefully control the composition and processing parameters to achieve the desired characteristics for medical-grade Nitinol.

Applications of Nitinol in medical devices

Nitinol's exceptional flexibility, kink resistance, and biocompatibility make it an excellent material for medical devices such as nitinol guidewires used in minimally invasive procedures. Its high fatigue resistance also makes it suitable for stents, orthopedic implants, and other critical applications. In addition to these uses, nitinol is also being explored for applications in dental braces and endodontic instruments due to its shape memory properties, allowing for customized fittings and improved patient comfort. The unique ability of nitinol to return to its original shape after deformation makes it an ideal material for devices that require precise positioning and constant force over time.

High-Quality Nitinol Rods for Medical Devices

Nitinol rods are essential components in various medical devices, making the quality of these materials crucial for patient safety and device performance. High-quality medical-grade Nitinol ensures superior mechanical properties, biocompatibility, and corrosion resistance, which are vital for long-term implantable devices.

The importance of quality in medical-grade Nitinol

The use of high-quality Nitinol is paramount in medical applications to ensure the reliability and durability of devices such as stents, guidewires, and orthopedic implants. Inferior quality Nitinol can lead to device failure, tissue damage, or adverse patient reactions. Therefore, stringent quality control measures and material testing are necessary to meet the rigorous standards of the medical industry.

High-quality Nitinol rods exhibit superior properties such as shape memory and superelasticity, making them ideal for medical device applications. These properties allow the material to return to its original shape after deformation, providing the necessary flexibility and resilience for devices used in the human body. Additionally, high-quality Nitinol rods have excellent biocompatibility, reducing the risk of adverse reactions when implanted in patients.

Examining the properties of high-quality Nitinol rods

High-quality Nitinol rods exhibit superelasticity and shape memory properties that allow them to withstand deformation and return to their original shape upon heating. They also possess excellent fatigue resistance, radiopacity for imaging purposes, and bio-inertness for compatibility with bodily tissues. These properties make them ideal for a wide range of medical applications.

The role of GEE SMA as a trusted supplier of Nitinol materials

GEE Superelastic Materials (GEE SMA) is a reputable manufacturer and supplier of high-quality Nitinol materials for medical devices. With a commitment to precision engineering and material excellence, GEE SMA ensures that its Nitinol products meet stringent regulatory requirements and industry standards. Their expertise in producing reliable Nitinol rods makes them a trusted partner for innovative medical device manufacturers.

GEE SMA's dedication to precision engineering and material excellence is evident in their commitment to meeting stringent regulatory requirements and industry standards. This ensures that their Nitinol products are not only of the highest quality but also compliant with all necessary guidelines for medical device manufacturing. As a result, GEE SMA has built a strong reputation as a reliable partner for innovative medical device manufacturers seeking top-notch Nitinol materials.

Nitinol in Medical Devices

Nitinol, a unique nickel-titanium alloy, has revolutionized the medical industry with its exceptional properties. Its superelasticity and shape memory make it ideal for minimally invasive procedures, such as stents and guidewires.

Advantages of using Nitinol in medical applications

The use of nitinol in medical devices offers several advantages. Its superelasticity allows for flexibility and kink resistance, making it perfect for guidewires used in navigating through tortuous anatomy during surgeries. Additionally, its shape memory properties enable stents to expand and contract as needed without compromising their structural integrity.

Furthermore, nitinol's biocompatibility makes it a suitable material for implants and surgical tools, reducing the risk of adverse reactions within the body. Its corrosion resistance also ensures that the medical devices made from nitinol have a longer lifespan, reducing the need for frequent replacements and lowering healthcare costs. With these advantages, nitinol has become an indispensable material in various medical applications, revolutionizing the way certain procedures are performed and improving patient outcomes.

Challenges and solutions in using Nitinol in medical devices

While nitinol's unique properties make it an excellent material for medical devices, there are challenges in working with it due to its high cost and difficulty in manufacturing. However, advancements in production techniques and the expertise of nickel titanium suppliers have addressed these challenges, making nitinol more accessible for medical applications.

Furthermore, the use of nitinol in medical devices has led to numerous success stories in the field of medical innovations. From shape memory stents that can expand and contract within the body to orthodontic wires that apply constant pressure for teeth realignment, nitinol has revolutionized the way certain medical conditions are treated. These success stories highlight the immense potential of nitinol in improving patient outcomes and quality of life.

Success stories of Nitinol in medical innovations

Nitinol has been instrumental in various successful medical innovations. From self-expanding stents that conform to vessel walls to shape memory orthopedic implants that adapt to bone structures, the use of nitinol has significantly improved patient outcomes and recovery times.

Nitinol's unique properties have also revolutionized the field of minimally invasive surgery, with the development of nitinol-based surgical instruments. These instruments are designed to navigate through small incisions and then expand once inside the body, allowing for precise and effective procedures with minimal trauma to surrounding tissues. As a result, patients experience reduced scarring, faster recovery times, and lower risk of post-operative complications, making nitinol an invaluable asset in modern surgical techniques.

By harnessing the potential of nitinol and addressing the challenges associated with its use, the future of medical devices looks promising with continued advancements and innovative solutions powered by this remarkable alloy.

Nitinol Manufacturing Process

Understanding the complex process of manufacturing Nitinol

Manufacturing Nitinol involves a precise combination of nickel and titanium in specific proportions, resulting in a shape memory alloy with unique properties. The process includes melting, casting, hot working, and cold working to achieve the desired shape and properties for medical applications.

Quality control measures in Nitinol production

To ensure the highest quality of Nitinol rods and wires, manufacturers implement stringent quality control measures at every stage of production. This includes rigorous testing for mechanical properties, dimensional accuracy, surface finish, and biocompatibility to meet the strict standards required for medical-grade materials.

Sustainable practices in Nitinol manufacturing

In response to growing environmental concerns, many Nickel Titanium suppliers have adopted sustainable practices in their manufacturing processes. This includes recycling scrap materials, reducing energy consumption, and implementing eco-friendly technologies to minimize the environmental impact of producing Nitinol materials.

By emphasizing understanding the complex manufacturing process of Nitinol, ensuring quality control measures are met at every stage of production, and adopting sustainable practices in manufacturing, we can continue to harness the potential of this remarkable shape memory alloy for innovative medical applications.

Addressing Common Concerns about Nitinol

Nitinol is a unique metal alloy that offers exceptional properties for medical applications, but many are concerned about its cost and value. However, the benefits of using Nitinol in medical devices far outweigh the initial investment. Its superelasticity and shape memory properties make it an invaluable material for creating innovative medical solutions.

Addressing the cost of Nitinol and its value in medical applications

Nitinol is often perceived as expensive due to its unique manufacturing process and specialized properties. However, its long-term benefits in medical applications, such as durability and biocompatibility, make it a valuable investment for healthcare providers. The high performance and reliability of Nitinol rods in medical devices justify their cost, ensuring optimal patient outcomes.

Exploring the unique characteristics of Nitinol metal

Nitinol is a nickel-titanium alloy known for its shape memory and superelasticity. These unique characteristics allow it to return to a predetermined shape when heated, making it ideal for applications requiring precise movements or adjustments within the body. This exceptional property sets Nitinol apart from traditional materials used in medical devices, making it indispensable for cutting-edge innovations.

The role of industry leaders in advancing Nitinol technology

Leading manufacturers play a crucial role in advancing Nitinol technology by continuously improving production processes and developing new applications for this remarkable material. Nickel titanium suppliers invest in research and development to enhance the performance of Nitinol rods, ensuring they meet the evolving needs of the medical industry. Their commitment to innovation drives the progress of Nitinol technology, paving the way for groundbreaking advancements in healthcare.

By addressing common concerns about Nitinol's cost and value while highlighting its unique characteristics and industry leaders' role in advancing its technology, we can foster a deeper understanding of this exceptional material's potential in revolutionizing medical innovations.

Conclusion

When selecting nickel titanium suppliers for your medical device needs, it's crucial to prioritize quality and reliability. Look for suppliers with a proven track record in producing high-quality Nitinol wire and rod. GEE SMA stands out as a trusted supplier of Nitinol materials, ensuring the highest standards for medical-grade Nitinol.

Key Considerations for Selecting Nitinol Suppliers

Consider the supplier's experience, certifications, and quality control measures to ensure that you are getting the best Nitinol materials for your medical devices. It's important to prioritize long-term partnerships with suppliers who are committed to excellence and innovation in the field of Nitinol manufacturing.

When selecting Nitinol suppliers, it's crucial to consider their track record of on-time delivery and customer service. A supplier who consistently meets deadlines and provides excellent support can help ensure the success of your medical device projects. Additionally, look for suppliers who offer customization options and are willing to work closely with you to meet your specific Nitinol material needs.

Harnessing the Potential of Nitinol in Medical Innovations

As technology continues to advance, there is tremendous potential for leveraging the unique properties of Nitinol in creating groundbreaking medical innovations. From nitinol guidewires to stents, the adaptability and biocompatibility of Nitinol make it an invaluable material for enhancing patient care and treatment outcomes.

The Future of Nitinol in Medical Applications

The future of nitinol rod in medical applications is bright, with ongoing research and development focused on expanding its capabilities even further. As industry leaders continue to push the boundaries of what is possible with this remarkable metal alloy, we can expect to see even more innovative uses that will revolutionize medical treatments.

With the ability to shape-shift and return to its original form, nitinol has already been used in medical devices such as stents and guidewires. However, ongoing research is exploring new ways to utilize nitinol's unique properties in areas such as orthopedics, neurology, and cardiology. By leveraging the biocompatibility and flexibility of nitinol, medical professionals may soon have access to advanced tools and implants that can improve patient outcomes and recovery times.