Introduction

When it comes to high-quality materials for various applications, Nitinol Sheet and Foil stand out as top choices. With their exceptional properties, they offer unparalleled flexibility, durability, and shape memory characteristics. Understanding the importance of Nitinol Sheet and Foil is crucial for unlocking their potential in different industries.

Why Choose High-Quality Nitinol Sheet and Foil?

High-quality Nitinol Sheet and Foil are preferred for their superior mechanical properties, including shape memory characteristics and biocompatibility. These materials offer unmatched performance in a wide range of applications, making them a valuable investment for businesses seeking reliable solutions.

Applications of Nitinol Sheet and Foil

Nitinol Sheets find extensive use in shape setting medical components, industrial manufacturing, aerospace engineering, and consumer products. Their unique properties make them ideal for precision engineering in medical devices, while also offering innovative design possibilities in other industries.

Understanding the Importance of Nitinol Sheet and Foil

Recognizing the significance of Nitinol Sheets is essential for harnessing their potential across diverse sectors such as healthcare, automotive, and electronics. Choosing high-quality Nitinol suppliers is crucial for advancing technologies with these exceptional materials.

The Advantages of Nitinol Sheet

Nitinol Sheet is highly regarded for its exceptional flexibility and durability, making it an ideal choice for a wide range of applications. Its unique combination of properties allows it to withstand repeated bending and twisting without losing its shape or structural integrity.

Flexibility and Durability

Nitinol Sheet exhibits remarkable flexibility, allowing it to be bent and shaped without damage. This makes it an excellent material for intricate designs and complex components that require precise shaping. Its durability ensures that it can withstand the rigors of demanding environments, making it a reliable choice for critical applications.

Shape Memory Properties

One of the most distinctive features of Nitinol Sheet is its shape memory properties, which enable it to return to a predetermined shape when subjected to heat or mechanical stress. This characteristic makes it an invaluable material for components that require precise positioning or movement, such as stents, orthodontic wires, and actuators.

Biocompatibility in Medical Devices

In the medical field, biocompatibility is crucial for ensuring the safety and effectiveness of devices used in the human body. Nitinol Sheet's excellent biocompatibility makes it an ideal material for medical implants, surgical instruments, and other medical devices where direct contact with bodily tissues is necessary.

Nitinol Sheets for Shape Setting Medical Components

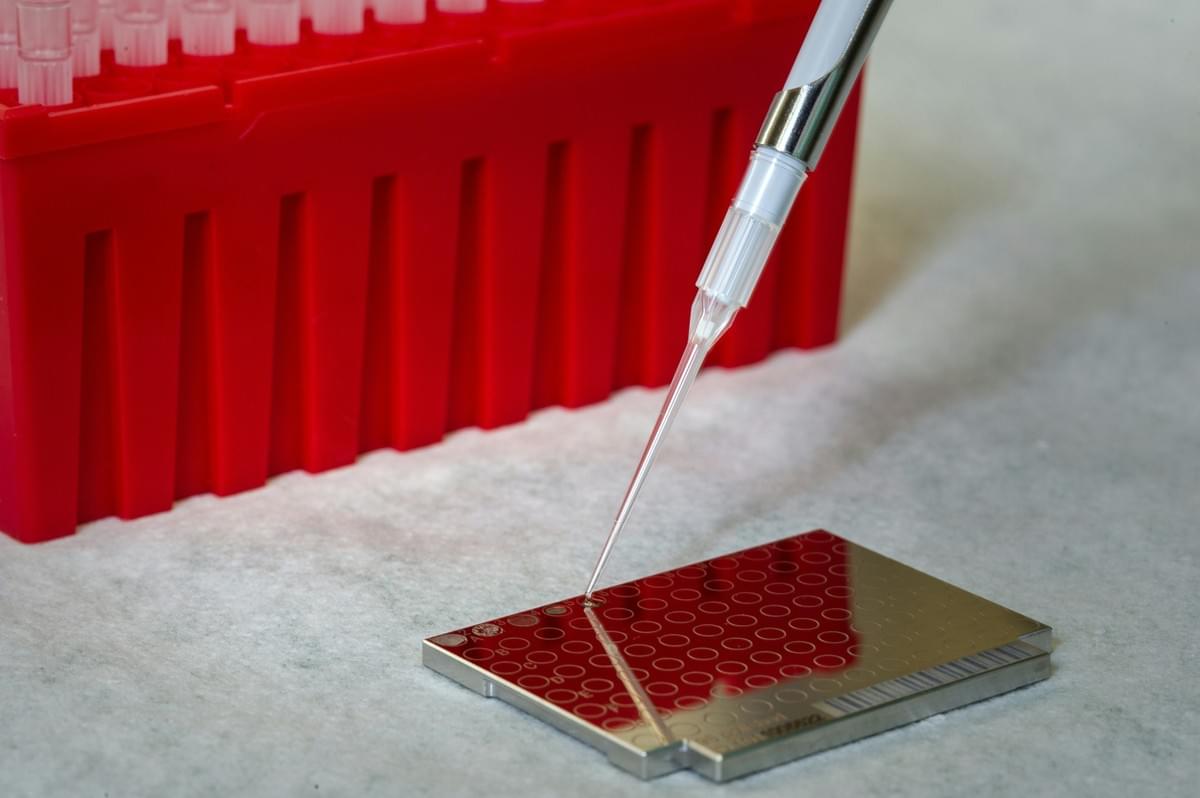

Precision Engineering for Medical Devices

Nitinol sheets are crucial in the precision engineering of medical devices due to their exceptional flexibility and shape memory properties. This allows for intricate designs and accurate shaping, ensuring that medical components can be tailored to specific patient needs with utmost precision.

Nitinol sheets are not only crucial for their flexibility and shape memory properties, but they also offer enhanced biocompatibility, making them ideal for medical applications. This means that medical devices incorporating Nitinol components are less likely to cause adverse reactions or tissue irritation in patients, leading to improved overall performance and patient outcomes. In addition, the high fatigue resistance of Nitinol ensures that medical devices can withstand repeated use without compromising their structural integrity, providing long-lasting reliability for patients and healthcare providers.

Enhanced Performance in Medical Applications

The use of Nitinol sheets in medical applications offers enhanced performance, as they provide superior biocompatibility and durability. This ensures that medical devices made from Nitinol sheets are safe for use within the human body and can withstand the demanding conditions of medical procedures.

Furthermore, Nitinol sheets offer the advantage of shape memory and superelasticity, allowing medical devices to return to their original shape after being subjected to external forces. This property is particularly useful in applications such as stents, where the device needs to expand and contract within the body without losing its structural integrity. Additionally, Nitinol's high fatigue resistance makes it an ideal material for long-term implantable devices, ensuring that they can withstand the rigors of continuous use within the body.

GEE SMA's Expertise in Custom Medical Components

GEE SMA specializes in custom medical components made from Nitinol sheets, offering expertise in designing and manufacturing tailored solutions for various medical applications. With a focus on innovation and quality, GEE SMA ensures that their custom medical components meet the highest standards of performance and reliability.

Now you have a well-crafted section on the importance of Nitinol Sheets for Shape Setting Medical Components, highlighting precision engineering, enhanced performance, and GEE SMA's expertise in custom medical components. The addition of an image message further enhances the visual appeal of your content while reinforcing the key points discussed.

NT0403 Nitinol Sheet

NT0403 Nitinol Sheet is a high-quality material composed of nickel and titanium, offering exceptional mechanical properties and shape memory characteristics. This unique alloy is widely recognized for its versatility and reliability, making it an ideal choice for various industries.

High-Quality Material Composition

The NT0403 Nitinol Sheet is meticulously crafted using a precise combination of nickel and titanium, ensuring superior quality and performance. This composition allows for exceptional flexibility, durability, and shape memory properties, making it suitable for a wide range of applications.

Furthermore, the precise combination of nickel and titanium in the NT0403 Nitinol Sheet results in excellent corrosion resistance, making it ideal for use in harsh environments. This high-quality material composition also provides exceptional biocompatibility, making it suitable for medical applications such as stents and surgical tools. Additionally, the uniformity of the composition ensures consistent performance across various temperatures and conditions, making it a reliable choice for critical applications.

Superior Mechanical Properties

With its remarkable resilience and shape memory capabilities, the NT0403 Nitinol Sheet exhibits superior mechanical properties that enable it to withstand extensive use without compromising its integrity. This makes it an excellent choice for demanding industrial environments where reliability is paramount.

Additionally, the NT0403 Nitinol Sheet's exceptional resistance to corrosion and fatigue further enhances its suitability for a wide range of industrial applications. This makes it an ideal material for components in aerospace, automotive, and medical devices, where long-term performance and durability are essential. Its ability to maintain its shape under extreme conditions also makes it a top choice for critical applications in harsh environments.

Versatile Applications in Various Industries

The NT0403 Nitinol Sheet's adaptability lends itself to diverse applications across multiple industries, including aerospace, automotive, medical devices, and consumer electronics. Its ability to retain its original shape after deformation makes it an invaluable material for innovative design possibilities.

By choosing the NT0403 Nitinol Sheet as your material of choice, you can benefit from its high-quality composition, superior mechanical properties, and versatile applications across various industries. Whether you require precision engineering in medical devices or innovative design possibilities in aerospace and automotive components, this exceptional material is sure to meet your needs with excellence.

Nitinol Shape Memory Alloy Sheet

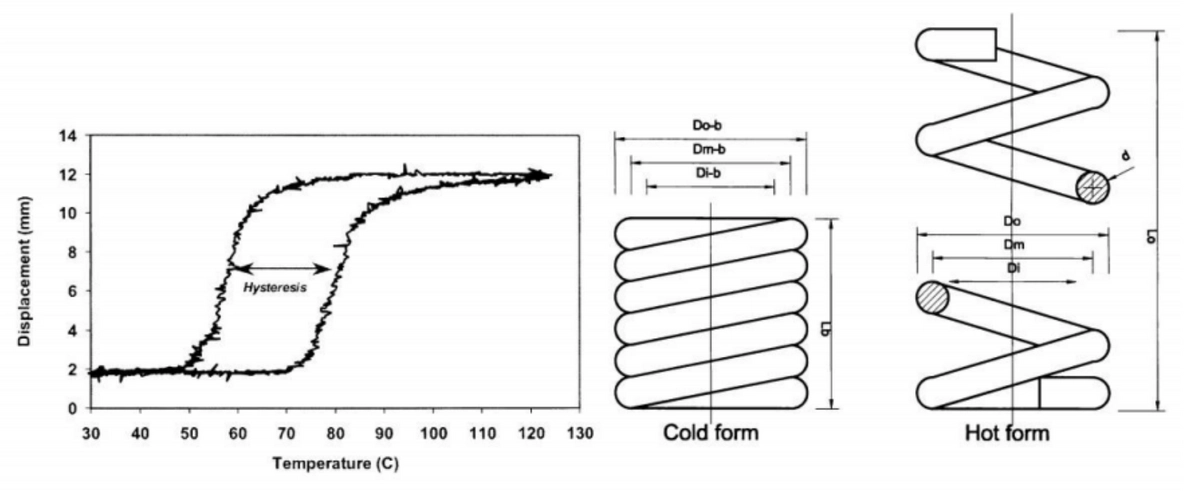

Nitinol Shape Memory Alloy Sheet offers remarkable shape memory characteristics, allowing it to return to its original shape after deformation. This unique property makes it ideal for applications where precise and reliable shape recovery is crucial, such as in medical devices and aerospace components.

Shape Memory Characteristics

Nitinol Shape Memory Alloy Sheet exhibits the ability to remember its original shape and return to it when subjected to heat or mechanical stress. This exceptional characteristic enables the material to be used in a wide range of innovative applications, from self-expanding stents in medical devices to actuators in robotics.

Nitinol Shape Memory Alloy Sheet's thermal and mechanical induced recovery also allows for precise control and manipulation, making it an ideal material for applications that require intricate movements and adjustments. This unique property has led to the development of advanced surgical tools with enhanced dexterity, as well as adaptive components in aerospace engineering that can respond to changing environmental conditions. The versatility of Nitinol Shape Memory Alloy Sheet opens up endless possibilities for creating cutting-edge technology that can adapt and perform with unparalleled precision.

Thermal and Mechanical Induced Recovery

When exposed to specific temperatures or mechanical forces, Nitinol Shape Memory Alloy Sheet undergoes a reversible phase transformation that allows it to recover its pre-deformed shape. This makes it an invaluable material for devices requiring controlled movement or precise positioning, such as guidewires and orthodontic archwires. In addition to these applications, Nitinol Shape Memory Alloy Sheets are also being used in minimally invasive medical devices, such as stents and catheters, due to their ability to adapt to the body's natural movements and maintain their original shape. This innovative material opens up new possibilities for the design of medical devices that can provide better patient outcomes and improved comfort during procedures.

Innovative Design Possibilities

The unique properties of Nitinol Shape Memory Alloy Sheet make it an ideal material for creating products that require precise and responsive movement. Its ability to remember and return to a specific shape after being deformed opens up new opportunities for designing innovative medical devices, such as stents and orthodontic wires, that can adapt to the body's movements. Additionally, in the field of robotics, Nitinol allows for the development of self-repairing and shape-changing components that can enhance the functionality and versatility of robotic systems.

Nickel Titanium Sheet Suppliers

Quality Assurance and Certification

When sourcing Nitinol sheet and foil, it's crucial to prioritize quality assurance and certification. Reputable suppliers like GEE SMA ensure that their materials meet stringent industry standards, providing peace of mind for your applications. By choosing certified suppliers, you can trust in the reliability and performance of your Nitinol materials. Additionally, working with certified suppliers can also streamline your procurement process by ensuring that you are meeting all necessary regulatory requirements without any hiccups.

Tailored Solutions for Industrial Applications

Nitinol sheet is used across a wide range of industries, each with unique requirements. The best suppliers understand this and offer tailored solutions for industrial applications. Whether it's aerospace, automotive, or consumer electronics, a reliable supplier will work closely with you to provide Nitinol sheet that meets your specific needs.

In addition to providing tailored solutions for industrial applications, a reliable supplier will also offer a collaborative approach for custom orders. This means that they will work closely with your team to understand your specific requirements and provide personalized recommendations for the use of Nitinol sheet in your industry. By fostering open communication and collaboration, the supplier can ensure that the Nitinol sheet meets your exact specifications and delivers optimal performance in your industrial application.

Collaborative Approach for Custom Orders

In many cases, standard Nitinol sheet sizes may not suffice for certain projects. This is where a collaborative approach from your supplier becomes invaluable. A trusted supplier will work with you to understand your custom requirements and provide tailored solutions that align with your project specifications.

In addition to providing tailored solutions, a collaborative supplier will also offer expertise and guidance throughout the custom order process. This can include recommendations on material selection, design considerations, and manufacturing techniques to ensure the final product meets your specific needs. By leveraging their knowledge and experience, you can benefit from a more efficient and cost-effective custom order experience.

Conclusion

When it comes to choosing quality Nitinol suppliers, it's crucial to prioritize reliability, expertise, and a proven track record. GEE SMA stands out as a trusted partner in providing high-quality Nitinol Sheet and Foil, offering tailored solutions for various industries and applications.

Choosing Quality Nitinol Suppliers

In the competitive market of Nitinol materials, selecting a supplier with a commitment to quality assurance and certification is paramount. With GEE SMA, you can be assured of superior products that meet stringent industry standards, ensuring the reliability and performance of your applications.

GEE SMA: Your Trusted Nitinol Partner

GEE SMA's expertise in providing Nitinol Sheets for Shape Setting Medical Components is unparalleled. Their precision engineering for medical devices and custom medical components showcases their dedication to enhancing performance in medical applications, making them the go-to partner for innovative design possibilities.

Advancing Technologies with High-Quality Nitinol Materials

As industries continue to evolve and demand advanced materials, the significance of high-quality Nitinol Sheet such as NT0403 cannot be overstated. With its superior mechanical properties and versatile applications across various industries, GEE SMA is at the forefront of advancing technologies with their top-notch Nickel Titanium Sheet offerings.