Introduction

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is a remarkable alloy known for its super-elasticity and shape memory effect. Nitinol sheets exhibit extraordinary flexibility and resilience, making them ideal for various medical applications. Understanding the nitinol transition temperature is crucial in harnessing its unique properties while unveiling the mechanical characteristics of nitinol sheets, which sheds light on their potential in healthcare.

Understanding the Super-Elasticity of Nitinol Sheets

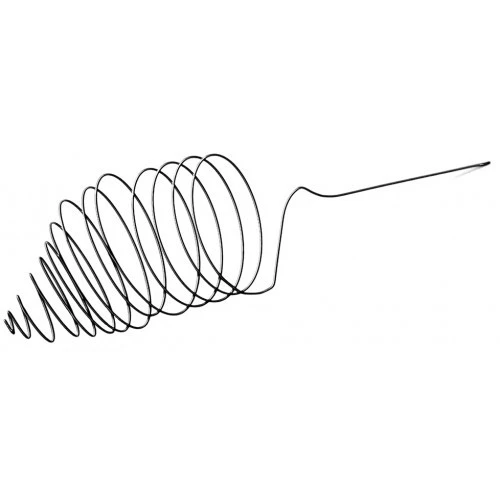

Nitinol sheets exhibit exceptional super-elasticity, meaning they can return to their original shape after significant deformation. This unique property makes nitinol ideal for medical devices requiring flexibility and durability, such as stents and guidewires.

Nitinol's super-elasticity stems from its distinctive phase transformation behavior, influenced by its transition temperature. This critical temperature, referred to as the austenite finish temperature, signifies the point at which nitinol undergoes a structural change from martensite to austenite when heated. This transformation empowers nitinol's remarkable shape memory and super-elasticity, making it an invaluable material for medical applications demanding adaptability and resilience.

Nitinol's properties offer several advantages for medical device applications:

- Super-elasticity: Enables devices to conform to complex anatomical structures and withstand significant stress.

- Shape memory: Allows pre-shaped devices to recover their original configuration after deployment.

- Biocompatibility: Generally well-tolerated by the human body.

- Corrosion resistance: Maintains integrity in the body's environment.

The combination of these properties positions nitinol as a leading material for innovative medical device development.

Exploring the Nitinol Transition Temperature

The nitinol transition temperature is the critical point at which this alloy undergoes a reversible phase transformation. By understanding this temperature, engineers and medical professionals can manipulate nitinol's shape memory effect to create innovative devices that adapt to specific conditions within the body.

Understanding the nitinol transition temperature is crucial for designing medical devices that can adapt to the body's specific conditions. By harnessing nitinol's shape memory effect, engineers can create stents that expand and contract in response to changes in blood flow or temperature. This ability to customize devices for individual patients can improve treatment outcomes and patient comfort.

Unveiling the Mechanical Properties of Nitinol Sheets

Nitinol sheets' mechanical properties include high tensile strength, fatigue resistance, and biocompatibility. These properties make nitinol an attractive material for medical implants and devices that require long-term performance within the human body.

Nitinol's high tensile strength allows it to withstand the rigors of the human body, making it an ideal material for implants such as stents, orthopedic devices, and dental braces. Its fatigue resistance ensures that these implants endure constant movement and pressure without succumbing to wear and tear over time. Additionally, nitinol's biocompatibility means it is well-tolerated by the body, minimizing the risk of adverse reactions or rejections commonly associated with other materials.

Let's now move on to explore the versatility of nitinol's material properties and its role in advancing medical technology.

The Versatility of Nitinol Material Properties

Nitinol, derived from nickel titanium naval ordnance laboratory, is renowned for its remarkable superelasticity and shape memory effect. Nitinol sheets exhibit the unique ability to return to their original shape after deformation, making them ideal for various medical applications. This exceptional property allows nitinol components to withstand significant stress and strain without permanent damage, ensuring reliability in medical devices.

A super-elastic nitinol sheet can be tailored to meet specific requirements in medical applications, offering versatility in design and functionality. With the ability to be shaped and manipulated at different temperatures, nitinol components can be customized for use in stents, guidewires, orthopedic implants, and other medical devices. This adaptability makes nitinol an invaluable material for creating innovative solutions in healthcare.

The biocompatibility of nitinol sheets is a crucial factor in their widespread use within the medical industry. Nitinol's inert nature and corrosion resistance make it compatible with the human body, reducing the risk of adverse reactions or complications when used in medical implants or devices. This biocompatibility ensures that nitinol components can seamlessly integrate with biological systems while maintaining their mechanical properties over time.

Advancements in Nitinol Manufacturing

Nitinol sheets have revolutionized the medical industry with their super-elasticity and shape memory effect. As the demand for these incredible properties grows, innovative production techniques for nitinol sheets have emerged. From advanced rolling and annealing methods to precise cutting and shaping processes, manufacturers constantly push the boundaries of what nitinol can achieve.

A key aspect of nitinol component manufacturing is ensuring quality assurance throughout production. This involves rigorous testing and inspection to guarantee that nitinol sheets meet the highest mechanical properties, shape memory, and biocompatibility standards. Quality assurance protocols are crucial in maintaining the reliability and safety of nitinol components used in medical devices.

Customizing nitinol sheets to suit specific medical needs has become a focal point of advancements in manufacturing. Whether it's tailoring the dimensions, surface finish, or mechanical characteristics, manufacturers are adept at creating bespoke nitinol components for various applications in cardiology, orthopedics, and minimally invasive surgery.

Applications of Nitinol Sheets in Medical Devices

Nitinol sheets, with their remarkable properties, have revolutionized the medical industry. These versatile materials, from super-elastic nitinol sheets to the nitinol transition temperature, have paved the way for innovative medical devices.

Nitinol Components in Stents and Guidewires

Nitinol's exceptional flexibility and resilience make it an ideal material for medical devices, particularly stents and guidewires used in minimally invasive procedures. This remarkable material offers several key advantages:

- Super-elasticity: Nitinol sheets can easily navigate complex anatomical structures, ensuring optimal patient outcomes.

- Biocompatibility: Being inert within the body, nitinol poses no risk of adverse reactions.

- Durability: Nitinol components are long-lasting, reducing the need for frequent replacements and minimizing patient discomfort.

These properties collectively position nitinol as a superior choice for medical devices, contributing to safer and more effective treatments.

Nitinol's Role in Endovascular Therapy

In endovascular therapy, nitinol is crucial in creating devices such as embolic protection and vena cava filters. The unique ability of nitinol sheets to return to their original shape after deformation ensures the effectiveness and safety of these life-saving medical tools.

Nitinol's unique properties also make it an ideal material for orthopedic implants. Its superelasticity and shape memory allow for the creation of stents, bone plates, and other implants that can withstand deformation and return to their original shape, providing stability and support to the injured or weakened bone. This versatility and reliability make nitinol a valuable asset in orthopedic surgery, offering patients a higher chance of successful recovery and improved quality of life.

Nitinol Sheets in Orthopedic Implants

Due to their biocompatibility and shape memory effect, orthopedic surgeons rely on nitinol sheets to fabricate implants. Whether used in bone plates, screws, or interventional orthopedic devices, nitinol's mechanical properties enhance patient comfort and promote faster recovery.

Nitinol's versatility extends beyond orthopedic implants, with its potential for use in various medical devices. Its unique properties make it suitable for cardiovascular stents, endovascular grafts, and neurovascular device applications. Nitinol's ability to adapt to the body's natural movements and maintain its structural integrity over time makes it an ideal material for these critical medical tools. As technology advances, we can expect to see even more innovative uses for nitinol in medical technology.

The Future of Nitinol in Medical Technology

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is poised to revolutionize minimally invasive procedures in the medical field. With its super-elasticity and shape memory effect, nitinol sheets offer the potential for advanced surgical tools that can navigate through intricate pathways within the body, minimizing trauma and recovery time.

Nitinol's Potential for Minimally Invasive Procedures

The unique properties of nitinol sheets make them ideal for developing minimally invasive medical devices such as catheters and endoscopes. These instruments can be designed to easily navigate through narrow blood vessels or delicate tissues, offering patients less invasive treatment options and faster recovery times. As medical technology advances, nitinol's potential for minimally invasive procedures will undoubtedly play a significant role in shaping the future of healthcare.

In addition to catheters and endoscopes, nitinol's unique properties make it an excellent material for developing stents and guidewires in various minimally invasive procedures. Stents made from nitinol are flexible and can be compressed for insertion into narrow arteries before expanding to provide structural support. Similarly, nitinol guidewires are known for their shape memory and superelasticity, allowing them to navigate tortuous blood vessels easily. These components not only improve patient comfort during procedures but also contribute to better treatment outcomes, making nitinol a valuable resource in the field of interventional medicine.

Emerging Trends in Nitinol Medical Components

As the demand for minimally invasive procedures grows, so does the need for innovative nitinol medical components. From advanced stents and guidewires to intricate surgical instruments, the emerging trend is to develop more complex and specialized nitinol devices that cater to specific patient needs. This trend reflects a shift towards personalized medicine and precision-based treatments that leverage nitinol's unique material properties.

The increasing demand for minimally invasive procedures has led to a greater emphasis on developing innovative nitinol medical components. This includes the creation of advanced stents, guidewires, and surgical instruments designed to be more intricate and specialized, catering to the specific needs of individual patients. As personalized medicine becomes more prevalent, a growing focus is on leveraging nitinol's unique material properties to provide precision-based treatments that can significantly impact patient care and outcomes.

Nitinol's Impact on Patient Care and Outcomes

Nitinol has the potential to significantly impact patient care and outcomes by enabling less invasive procedures and tailored medical devices. Patients can benefit from:

- Reduced pain

- Shorter hospital stays

- Improved recovery times

Moreover, as medical technology advances, the use of nitinol-based instruments in treatments can contribute to better overall health outcomes across various medical specialties.

Furthermore, nitinol has the potential to revolutionize treatment options for patients with chronic conditions. By allowing for more precise and customizable devices, nitinol can improve the effectiveness of therapies for cardiovascular disease, orthopedic issues, and neurovascular disorders. This level of tailored treatment can significantly enhance patient outcomes and quality of life, setting a new standard for personalized care in the medical field.

Integrating nitinol into medical devices holds immense promise for transforming patient care and elevating the overall standard of healthcare.

The Future of Nitinol Sheets in Healthcare

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, has become an indispensable material in the medical industry due to its super-elasticity and shape memory effect. The growing demand for nitinol components in medical devices such as stents, guidewires, and orthopedic implants highlights its crucial role in modern healthcare. As the advancements in nitinol manufacturing continue to unfold, the potential for tailored nitinol sheets to revolutionize minimally invasive procedures is becoming increasingly evident.

Exploring the Growing Demand for Nitinol Components

The increasing demand for nitinol components is a testament to the material's unique properties and versatility in various medical applications. From cardiovascular interventions to orthopedic surgeries, nitinol sheets have enhanced patient care and outcomes. As medical technology evolves, the demand for customized nitinol components is expected to soar, further solidifying its status as a game-changer in healthcare.

The versatility of nitinol components extends beyond traditional medical applications, with emerging uses in minimally invasive surgical procedures and implantable devices. This expanding range of potential applications drives the demand for customized nitinol components as healthcare providers seek to leverage the material's unique properties for innovative solutions. As the medical industry continues to explore new frontiers in patient care, nitinol is poised to play a pivotal role in shaping the future of healthcare technology.

Harnessing the Potential of Nitinol in Medicine

The potential of nitinol in medicine goes beyond its mechanical properties and biocompatibility; it lies in its ability to adapt and innovate with emerging trends. With ongoing research and development focusing on maximizing the benefits of nitinol material properties, there's a promising future for utilizing this shape memory alloy in groundbreaking medical technologies. Harnessing this potential will undoubtedly lead to more advanced treatment options and improved patient experiences.

As medical technology advances, the demand for innovative materials like nitinol will only increase. Nitinol's ability to adapt and innovate with emerging trends makes it a valuable asset in the development of cutting-edge medical devices. From minimally invasive surgical tools to implantable devices, nitinol's unique properties offer endless possibilities for improving patient outcomes and revolutionizing healthcare practices.

As we look ahead, the future of nitinol sheets holds immense promise for revolutionizing healthcare practices. The advancements in tailoring nitinol components for specific medical needs will pave the way for more precise and effective treatments. With an increased focus on patient-centric care and minimally invasive procedures, nitinol's impact on healthcare is set to expand significantly, opening doors to innovative approaches that prioritize both patient comfort and successful outcomes.

Furthermore, nitinol sheets in medical devices such as stents, guidewires, and orthodontic braces will continue to drive innovation in the healthcare industry. The unique properties of nitinol, including its shape memory and superelasticity, make it an ideal material for creating devices that can adapt to the body's natural movements and functions. This not only enhances patient comfort but also improves the overall effectiveness of these medical interventions. As research and development in nitinol technology progress, we can expect to see even more groundbreaking applications that address a wide range of medical conditions.