Introduction

When it comes to advanced materials, nitinol wire is a game-changer. This unique alloy, also known as nitinol nickel titanium, is a shape memory alloy (SMA) with remarkable properties that make it ideal for various applications. From medical devices to aerospace engineering, the versatility of nitinol wire has made it an indispensable material in various industries. However, the key to unlocking its full potential lies in sourcing high-quality nitinol wire from reliable suppliers.

Understanding Nitinol Wire and Its Applications

Nitinol wire is a type of titanium wire that exhibits shape memory properties, allowing it to return to its original shape after deformation. This remarkable feature makes it perfect for applications such as nitinol springs and other components that require precise and repeatable movements. In addition to its shape memory capabilities, nitinol alloys also offer excellent biocompatibility, making them an ideal choice for medical implants and devices.

The Importance of High-Quality Nitinol Wire

Nitinol, a nickel-titanium alloy, is prized for its unique shape memory and superelastic properties. These characteristics make it a valuable material for various applications, particularly in demanding fields like medicine and aerospace. However, the performance and safety of these applications hinge on the quality of the Nitinol wire used.

Risks of Low-Grade Nitinol

- Compromised Functionality: Inferior Nitinol might not exhibit the expected shape memory or superelastic behavior to the desired degree. This can lead to malfunctions or reduced effectiveness in the final product.

- Premature Failure: Low-quality Nitinol may be more susceptible to fatigue or breakage under stress, potentially causing component failure and compromising the integrity of the entire system.

- Safety Concerns: In critical applications like medical implants or aerospace components, failure due to low-grade Nitinol can have serious safety consequences.

Benefits of High-Quality Nitinol Wire

- Reliable Performance: High-grade Nitinol ensures consistent and predictable shape memory and superelastic properties, guaranteeing the functionality of the final product.

- Enhanced Durability: Superior Nitinol offers greater resistance to fatigue and stress, leading to longer-lasting components and reliable performance over time.

- Safety and Trust: Using high-quality Nitinol minimizes the risk of unexpected failures, promoting safety and reliability in critical applications.

Investing in Quality

While a higher initial investment might be associated with high-quality Nitinol, the benefits outweigh the costs. Reliable performance, extended product life, and minimized safety risks translate to significant long-term value. Choosing high-grade Nitinol wire is an essential decision for applications with peak performance and unwavering reliability.

Where to Find Reliable Nitinol Suppliers

Finding a trustworthy source for nitinol wire for sale can be challenging, but it's essential for obtaining premium materials that meet stringent quality standards. Whether you're looking for standard sizes or custom shapes and specifications, partnering with a reputable supplier like GEE SMA can assure you of top-notch products backed by technical expertise and exceptional customer support.

Now, let's explore the unique properties and features of nitinol wire that make it such a valuable material across various industries!

Exploring Nitinol Wire Properties and Features

Nitinol wire, nickel titanium, is a type of shape memory alloy (SMA) that exhibits unique properties such as superelasticity and the ability to return to its original shape after deformation. This makes it an ideal material for applications requiring precise and controlled movement.

Shape Memory Alloys (SMA) Explained

Shape memory alloys like nitinol are capable of remembering their original shape and returning to it when subjected to heat or stress. This property allows nitinol wire to be used in various applications, from medical devices like stents and guidewires to actuators and robotics. The versatility of nitinol alloys makes them an ideal choice for industries that require materials with high durability and flexibility. In addition to medical and robotics applications, nitinol is used in eyeglass frames, dental braces, and even in the aerospace industry for components such as couplings and connectors.

Nitinol Alloys and Their Versatility

Nitinol alloys are composed primarily of nickel and titanium, with a small amount of other elements. This composition gives nitinol its unique properties, including high strength, corrosion resistance, and biocompatibility. Nitinol's versatility makes it suitable for use in various industries, such as healthcare, aerospace, automotive, and consumer electronics.

Nitinol alloys are known for their shape memory and superelasticity, making them ideal for applications in the healthcare industry. From stents and guidewires to orthodontic wires and surgical instruments, nitinol's unique properties allow for the creation of innovative medical devices that can adapt to the body's movements and withstand the harsh conditions within the human body. Its biocompatibility further enhances its appeal in medical applications, as it minimizes the risk of adverse reactions when implanted or used in direct contact with bodily tissues.

Applications of Nitinol Wire in Various Industries

Nitinol wire, a nickel-titanium alloy known for its shape memory and superelastic properties, has revolutionized numerous industries due to its unique combination of functionality and performance. Here's a glimpse into the diverse applications of Nitinol wire:

In the Medical Field

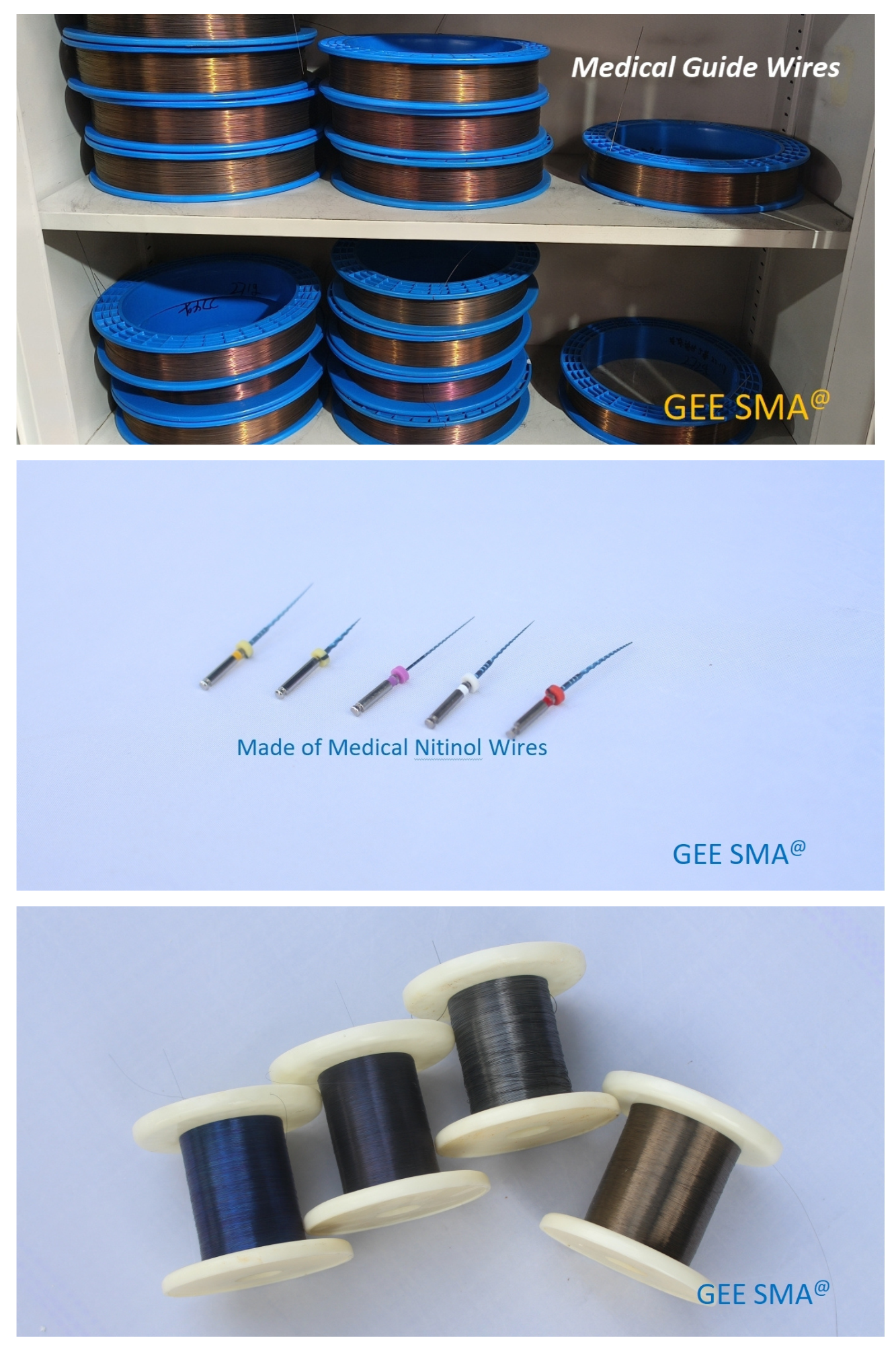

- Minimally Invasive Surgery: Nitinol's flexibility and biocompatibility make it ideal for instruments like stents, guidewires, and catheters used in minimally invasive procedures. These instruments can be collapsed for easy insertion and then regain their shape once inside the body, minimizing patient trauma and recovery time.

- Orthopedics: Nitinol's shape memory allows for the creation of self-expanding implants, such as braces and bone plates, that conform to the patient's anatomy, providing a snug fit and promoting healing.

Beyond Medicine

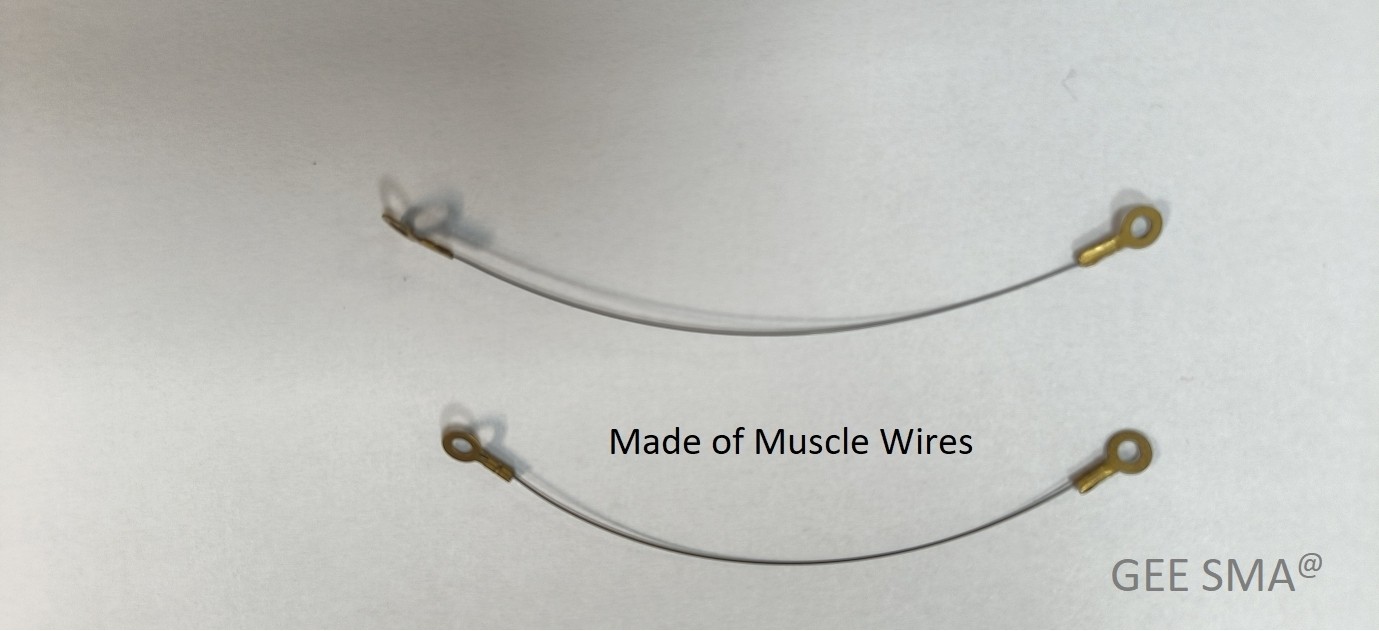

- Robotics: Nitinol's shape memory allows for the creation of actuators that can perform specific movements when exposed to heat. This makes it valuable for robots requiring precise and controlled motions.

- Consumer Products: Nitinol's combination of flexibility and durability makes it ideal for eyeglass frames that can withstand bending without breaking. Its shape memory can also be used in features like self-adjusting temple pieces.

- Aerospace: Nitinol's ability to withstand extreme temperature fluctuations and maintain its shape memory makes it a valuable component in aircraft and spacecraft. For example, it can be used in deployable antennas, landing gear components, and pipe couplings that remain functional in harsh environments.

- Automotive Industry: Nitinol's durability and corrosion resistance make it suitable for engine components like valve springs and fuel injection systems, where it can handle high stresses and maintain performance over time.

This is just a sampling of the diverse applications for Nitinol wire. As research and development continue, we can see Nitinol play an even greater role in various industries, pushing the boundaries of innovation and functionality.

Factors to Consider When Choosing a Nitinol Supplier

1. Quality Assurance and Certification

When searching for nitinol wire for sale, it's crucial to prioritize suppliers that offer quality assurance and certification for their products. Look for suppliers who adhere to strict industry standards and have certifications that guarantee the reliability and performance of their nitinol nickel titanium products.

2. Customization Options for Nitinol Wire

The versatility of nitinol alloys makes customization an important factor when choosing a supplier. Whether you require nitinol wire in specific sizes or shapes or with unique properties, finding a supplier that offers customization options will ensure that you get the perfect nitinol spring or wire titanium for your application needs.

3. Customer Support and Technical Expertise

A reputable nitinol supplier should provide excellent customer support and technical expertise to assist you throughout purchasing. Look for a supplier who can offer guidance on selecting the right nitinol alloys for your project and provide ongoing support to address any technical questions or concerns.

Remember, when choosing a nitinol supplier, prioritize quality assurance, customization options, and reliable customer support to ensure you find the best materials for your specific needs.

Finding High-Quality Nitinol Wire for Sale

When sourcing top-notch nitinol wire for sale, GEE SMA stands out as a trusted supplier with a stellar reputation in the industry. With years of experience and expertise in providing high-quality nitinol nickel titanium products, GEE SMA is the go-to choice for businesses and manufacturers seeking reliable solutions for their projects.

GEE SMA: A Trusted Supplier for Nitinol Wire

GEE SMA offers an extensive range of nitinol alloys, including nitinol wire, wire titanium, and nitinol springs, all crafted with precision and excellence. Their commitment to quality and customer satisfaction has earned them a loyal customer base who rely on their consistent delivery of top-grade nitinol materials.

GEE SMA's nitinol wire is known for its high tensile strength and superelasticity, making it an ideal choice for medical devices such as stents and guidewires. The wire titanium offered by GEE SMA is also highly sought after for its exceptional corrosion resistance and biocompatibility, making it a top choice for surgical implants. In addition, their nitinol springs are meticulously engineered to provide precise and reliable performance in various applications, from aerospace to automotive industries.

Product Range and Specifications

GEE SMA's product range encompasses a wide variety of nitinol wire options, catering to diverse industrial needs. From shape memory alloys to specialized nitinol alloys, their offerings are backed by stringent quality control measures and adhere to international standards for performance and reliability.

GEE SMA's nitinol wire options are designed to meet the specific needs of various industries, ensuring that customers can find the perfect solution for their applications. Whether it's shape memory alloys for medical devices or specialized nitinol alloys for aerospace components, GEE SMA has a comprehensive range to choose from. With a focus on quality control and adherence to international standards, customers can have confidence in the performance and reliability of these nitinol wire options.

Testimonials from Satisfied Customers

Customers who have procured nitinol wire from GEE SMA have expressed high satisfaction with the materials' quality, durability, and performance. Testimonials from satisfied clients underscore the trustworthiness of GEE SMA as a supplier that consistently delivers on its promises.

With GEE SMA's unwavering commitment to excellence and customer satisfaction, businesses can confidently invest in premium nitinol materials that offer long-term value and performance.

The Benefits of Investing in Premium Nitinol Wire

Investing in premium nitinol wire for sale offers a range of benefits for various applications. Nitinol nickel titanium is renowned for its reliability and durability, making it an ideal choice for critical components. Whether used in medical devices, aerospace engineering, or consumer electronics, nitinol wire provides long-term performance and peace of mind.

1. Reliability and Durability of Nitinol Materials

Nitinol alloys are known for their exceptional resilience and ability to withstand repeated use without compromising their shape memory properties. This makes nitinol wire titanium an excellent choice for applications that require consistent performance under challenging conditions. From surgical tools to industrial actuators, nitinol spring and wire are reliable for mission-critical operations.

Nitinol materials not only offer exceptional resilience and durability but also provide cost-effectiveness and long-term performance. This makes them a practical choice for applications that require consistent performance under challenging conditions, without breaking the bank. Whether it's in the medical field or industrial settings, nitinol wire and spring stand out as reliable and durable options that can withstand the test of time, providing value for money in the long run.

2. Cost-Effectiveness and Long-Term Performance

While the initial investment in nitinol wire may be higher than traditional materials, its longevity and high performance make it a cost-effective choice in the long run. With minimal maintenance and replacement requirements, nitinol alloys offer a compelling value proposition for businesses seeking durable solutions that stand the test of time.

In addition to its cost-effectiveness and long-term performance, nitinol wire is also highly versatile. Its unique shape memory and superelasticity properties allow for various applications across various industries, from medical devices to automotive components. This versatility further enhances the value proposition of nitinol alloys, making them an attractive choice for businesses looking for adaptable solutions that can meet diverse needs.

3. Potential Applications and Advantages for End Users

The versatility of nitinol wire opens up a world of possibilities for end users across various industries. Its shape memory properties allow it to be used in innovative ways, such as self-expanding stents in medical devices or precise actuators in robotics. The unique advantages of nitinol alloys make them an attractive option for designers and engineers looking to push the boundaries of what's possible.

By choosing premium nitinol wire from a trusted supplier like GEE SMA, businesses can unlock the full potential of this remarkable material while ensuring reliability, cost-effectiveness, and long-term performance across a wide range of applications.

Making the Right Choice for Your Nitinol Needs

When choosing the right nitinol supplier, it's essential to compare different options to ensure you're getting the best quality and value for your investment. Look for suppliers with a proven track record of providing high-quality nitinol wire for sale and a wide range of customization options to meet your specific needs.

Comparing Different Nitinol Suppliers

Take the time to research and compare different nitinol suppliers, paying close attention to their certifications, quality assurance processes, and customer reviews. Look for suppliers like GEE SMA that offer a comprehensive range of nitinol alloys and shapes, backed by industry-leading expertise and support.

Tips for Evaluating Nitinol Wire Options

Nitinol wire's unique properties make it a valuable material for various applications. However, selecting the right wire for your project requires careful consideration of several factors:

Material Properties

- Shape Memory (SM) Response: Evaluate the Nitinol's transition temperature and the force required to induce shape change. Does it align with your application's needs for actuation temperature and recovery force?

- Superelasticity: Consider the wire's ability to recover from elastic deformation without permanent damage. How much stress or strain does your application require the Nitinol to handle?

Mechanical Properties

- Tensile Strength: This determines the maximum pulling force the Nitinol wire can withstand before breaking. Match the tensile strength to the stress requirements of your application.

- Fatigue Strength: Evaluate the Nitinol's ability to endure repeated stress cycles without failure. This is crucial for applications involving constant movement or vibration.

- Surface Finish: A smooth surface finish minimizes friction and wear, which can be important for smooth operation in some applications.

- Biocompatibility: For medical applications, ensure the Nitinol meets biocompatibility standards to minimize tissue irritation or rejection.

Supplier Capabilities

- Customizable Options: Does the supplier offer Nitinol wire in various diameters, lengths, and surface finishes? Can they provide pre-shaped springs or Nitinol wire formed to your specifications?

- Quality Control: Reputable suppliers prioritize strict quality control measures to ensure consistent material properties and reliable performance in the Nitinol wire.

- Certifications: Look for suppliers with relevant certifications for Nitinol production, such as ASTM International standards.

By carefully evaluating these factors and considering your specific project requirements, you can make an informed decision and select Nitinol wire that delivers your application's optimal performance and functionality.

Ensuring the Best Value for Your Investment

To ensure the best value for your investment in nitinol wire, prioritize suppliers that offer competitive pricing without compromising on quality. Seek out suppliers like GEE SMA that provide high-quality materials and offer technical support and expertise to help you make informed decisions for your projects.

Empower Your Projects with Reliable Nitinol Materials

When making informed decisions about nitinol purchases, it's crucial to consider the quality, reliability, and long-term performance of the materials. GEE SMA stands out as your go-to partner for high-quality nitinol solutions, offering a wide range of nitinol wire for sale to meet your specific project needs. With GEE SMA, you can empower your projects with reliable nitinol materials that deliver exceptional results.

Making Informed Decisions for Nitinol Purchases

When investing in nitinol wire, it's important to make informed decisions based on your project's specific requirements. By carefully evaluating the properties and features of nitinol nickel-titanium alloys, you can ensure you get the best value for your investment. With a trusted supplier like GEE SMA, you can have confidence in the quality and performance of the chosen nitinol materials.

GEE SMA: Your Partner for High-Quality Nitinol Solutions

GEE SMA is dedicated to providing high-quality nitinol wire for sale that meets industry standards. As a leading supplier of shape memory alloy products, GEE SMA offers various options and customization capabilities to cater to various applications across different industries. With a focus on quality assurance and customer satisfaction, GEE SMA is committed to being your reliable partner for all your nitinol needs.

By choosing GEE SMA as your supplier for nitinol alloys and nitinol spring products, you empower your projects with durable and versatile materials that offer exceptional performance and cost-effectiveness. Whether it's for medical devices, automotive components, or consumer electronics, GEE SMA provides tailored solutions that enable you to achieve superior results in your applications. Trust in GEE SMA to deliver the reliable nitinol materials you need to bring your projects to life.