Introduction

Nitinol shape memory alloys, also known as memory wire or memory metal, have revolutionized various industries with their unique properties. Understanding the basics of nitinol shape memory alloys is crucial for harnessing their potential in engineering and design. Exploring nitinol memory wire properties and what makes nitinol wire a unique material will shed light on the incredible capabilities of this innovative material.

Understanding the Basics of Nitinol Shape Memory Alloys

Nitinol shape memory alloys, often called memory wire or memory metal, are a type of smart material that can remember its original shape and return to it when subjected to certain stimuli. This remarkable property makes nitinol a highly sought-after material in various industries, from medical devices to aerospace engineering.

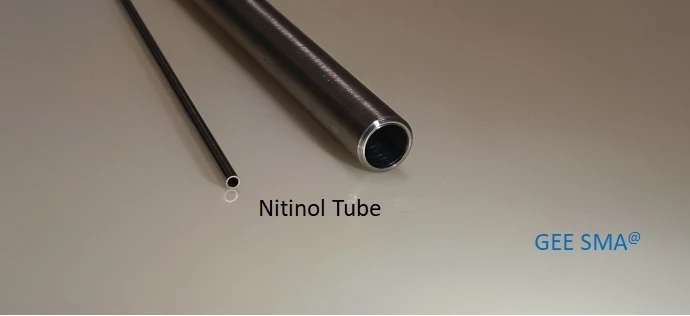

Nitinol shape memory alloys are composed of nearly equal parts nickel and titanium, which give them their unique properties. When nitinol is deformed at a low temperature, it retains that shape until it is heated above its transformation temperature, returning to its original form. This ability to "remember" and revert to a specific shape makes nitinol an ideal material for applications such as stents, braces, and other medical devices requiring precise movement or positioning.

Exploring Nitinol Memory Wire Properties

The unique properties of nitinol memory wire make it an incredibly versatile material for innovative applications. When exposed to heat or stress, nitinol alloy shape memory allows it to return to its predetermined shape, offering unparalleled flexibility and durability in various environments. Additionally, nitinol wire exhibits superelasticity, meaning it can undergo significant deformation and return to its original shape when the stress is removed. This makes it ideal for medical devices such as stents and braces, where the material must withstand repeated bending and flexing without losing its functionality.

What Makes Nitinol Wire a Unique Material

Nitinol wire stands out in the world of materials due to its remarkable combination of two distinct properties: shape memory and superelasticity. Let's explore what makes Nitinol so unique:

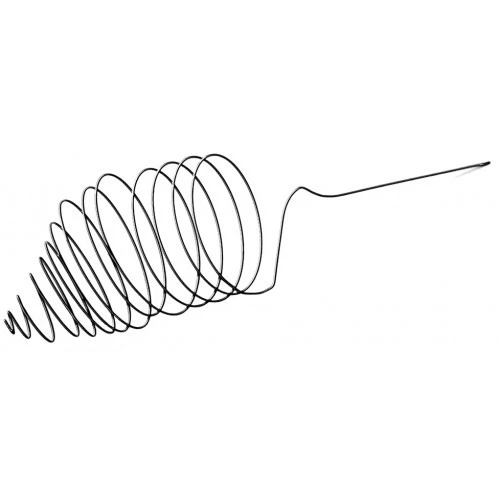

- Shape Memory: Nitinol can be "trained" to remember a specific shape. When deformed, it can apply a force to return to its original form upon exposure to a certain temperature. This allows for creating components that can be manipulated for easy insertion (like stents in minimally invasive surgery) and then regain their functional shape within the body.

- Superelasticity: Unlike most materials that deform permanently under stress, Nitinol exhibits superelasticity. It can bend and flex significantly without breaking, then return to its original shape once the stress is released. This makes it ideal for applications requiring flexibility and resilience, such as orthodontic wires or robotic grippers.

The Synergy of Properties:

The true wonder of Nitinol lies in the synergy between these two properties. Shape memory allows the material to be manipulated into a temporary form, while superelasticity ensures it can withstand significant deformation without permanent damage. This unique combination unlocks a vast range of possibilities:

- Minimally Invasive Medical Devices: Nitinol instruments can be compressed for insertion and then utilize shape memory to expand to their functional form within the body, minimizing patient trauma.

- Durable Robotics Components: Nitinol's superelasticity allows robots to handle delicate tasks and withstand accidental impacts without compromising functionality.

- Reliable Aerospace Parts: Nitinol components can function reliably in the harsh space environment due to their shape memory and ability to withstand extreme temperature fluctuations.

- Beyond the Examples:

The potential applications of Nitinol wire are constantly expanding as research and development delve deeper into its properties. Its unique combination of shape memory and superelasticity makes it a truly innovative material that revolutionizes various industries.

How Nitinol Shape Memory Alloy Works

Nitinol shape memory alloy, also known as memory metal nitinol, is a unique material that can return to a predetermined shape after being deformed. This remarkable property is due to the alloy’s phase transformation behavior at specific temperatures, allowing it to remember and recover its original form. The memory shape alloy nitinol wire comprises nearly equal parts of nickel and titanium, enabling it to undergo reversible martensitic phase transformation.

The Science Behind Nitinol’s Shape Memory Properties

Nitinol's memory wire properties result from its crystal structure and ability to transition between two different phases: austenite and martensite. When heated above its transition temperature, the nitinol alloy shape memory reverts to its original austenitic phase, causing it to return to its pre-set shape. This unique behavior makes nitinol an ideal material for applications requiring precise and reliable actuation.

The unique properties of nitinol alloy shape memory make it an ideal material for medical devices. Its ability to return to a pre-set shape when heated above its transition temperature allows for creating minimally invasive medical tools that can be inserted into the body in a compact form and then expand to their functional shape once inside. This has revolutionized procedures such as stent placement and minimally invasive surgery, providing patients with less invasive treatment options and faster recovery times.

Applications of Nitinol Alloy Shape Memory in Various Industries

The remarkable properties of nitinol shape memory alloy have led to its widespread use in various industries, including medical devices, aerospace engineering, and robotics. In the medical field, nitinol memory wire is employed in minimally invasive surgical tools such as stents and guidewires due to its flexibility and biocompatibility. Additionally, the aerospace industry utilizes nitinol for applications such as actuators in aircraft components.

Shape Memory Effect in Nitinol Wire

The unique shape memory effect in nitinol wire allows it to be deformed at low temperatures and recover its original shape when exposed to higher temperatures. This property has revolutionized engineering design by enabling the creation of self-expanding structures and adaptive mechanisms that respond to changes in environmental conditions. As a result, nitinol has become an essential material for developing innovative solutions across various industries.

Now, let's explore how GEE SMA leverages its expertise in producing high-quality nitinol materials tailored to customer needs.

Crafting High-Quality Nitinol Materials

Nitinol shape memory alloy, also known as memory metal nitinol, is a remarkable material with unique properties that make it ideal for various applications. GEE SMA has established expertise in producing high-quality nitinol shape memory alloys, ensuring that the material meets the highest performance and reliability standards.

GEE SMA’s Expertise in Producing Nitinol Shape Memory Alloys

GEE SMA has extensive knowledge and experience working with nitinol shape memory alloys, allowing us to consistently produce materials with exceptional shape memory properties. Our team of experts utilizes advanced technologies and precise manufacturing processes to create nitinol materials that exhibit superior functionality and durability.

Tailoring Nitinol Functional Materials to Meet Customer Needs

At GEE SMA, we understand that each customer may have specific application requirements. Therefore, we specialize in tailoring nitinol functional materials to meet our clients' unique needs. Whether it's a specific size, shape, or performance characteristic, we can customize nitinol alloys to ensure they align perfectly with customer specifications.

Swiftly Addressing Customer Requirements

We take pride in our ability to swiftly address customer requirements regarding nitinol shape memory alloys. Our responsive approach allows us to communicate efficiently with clients, understand their needs, and deliver tailored solutions quickly. This ensures that our customers receive the exact nitinol materials they need without unnecessary delays.

Practical Applications of Nitinol Memory Wire

Advancements in Medical Devices Using Nitinol Shape Memory Alloys

Nitinol shape memory alloys have revolutionized the medical industry with their unique ability to return to a predetermined shape when heated. From stents that expand in blood vessels to orthodontic wires that apply constant pressure for teeth alignment, nitinol memory wire has become indispensable in medical device manufacturing. This remarkable material ensures precision, durability, and patient comfort, making it essential in modern healthcare technology.

Nitinol shape memory alloys have also found significant applications in the aerospace industry, where their unique properties are leveraged for various purposes. For instance, nitinol is used in actuators and sensors for aircraft components, where its ability to return to a predetermined shape allows for precise control and adjustment. Additionally, nitinol wires are utilized in deployable structures such as antennas and solar panels, as they can be compactly stored and then expand to their intended shape once deployed. This versatility and reliability make nitinol an invaluable material in aerospace engineering, contributing to advancing aviation technology.

Nitinol’s Role in Aerospace Industry

In the aerospace industry, nitinol alloy shape memory plays a crucial role in various applications, such as actuators for aircraft wing flaps and landing gear components. Nitinol wire's ability to withstand extreme temperatures and return to its original shape makes it ideal for aerospace engineering. Its lightweight yet resilient nature makes it a top choice for enhancing safety and efficiency in aircraft design.

Nitinol wire's unique properties also make it an ideal material for use in robotics and automation. Its ability to return to its original shape after deforming allows for precise and reliable movement in robotic applications. This makes nitinol wire a valuable component in developing advanced robotic systems, where accuracy and repeatability are crucial. Additionally, its lightweight nature contributes to the overall efficiency of robotic and automated systems, making it a preferred choice for engineers and designers in this field.

Nitinol Wire in Robotics and Automation

Nitinol memory wire is also making significant strides in robotics and automation, where precise movement and control are paramount. Its unique properties make it perfect for creating artificial muscles that mimic human motion, leading to advancements in prosthetics and robotic exoskeletons. As technology continues to evolve, the versatility of nitinol wire opens up endless possibilities for innovation in automation and robotics.

Benefits and Limitations of Nitinol Memory Metal

Advantages of Using Nitinol in Engineering and Design

Nitinol, a nickel-titanium alloy, is more than just a metal; it's a game-changer for engineers and designers due to its remarkable combination of properties:

- Shape Memory: Nitinol can be "programmed" to remember a specific shape. When deformed, it forces it to return to its original form upon exposure to a certain temperature. This allows engineers to create intricate components that can be manipulated for easier insertion or positioning (like stents) and regain functionality within a system.

- Superelasticity: Unlike traditional materials that break under stress, Nitinol exhibits superelasticity. It can bend and flex significantly without permanent deformation, returning to its original shape once the stress is released. This unique property opens doors for designing exceptional flexibility and resilience components, ideal for applications like springs, actuators, or grippers.

Benefits for Designers and Engineers

- Design Freedom: Shape memory allows designers to create complex shapes that can be manipulated temporarily, giving them greater freedom to explore innovative functionalities.

- Durability and Reliability: Superelasticity translates to components that can withstand significant stress and repeated bending without breaking, leading to longer-lasting designs and reduced maintenance needs.

- Corrosion Resistance: Nitinol's exceptional resistance to corrosion makes it suitable for harsh environments where other materials might degrade. This translates to reliable performance over extended periods, minimizing the need for replacements.

- Biocompatibility: For medical device design, Nitinol's biocompatibility allows for safe interaction with the human body, opening doors for innovative medical implants and instruments.

Beyond the Advantages

Nitinol's potential extends far beyond these initial advantages. As research continues, we can expect even more exciting applications to emerge in various engineering and design fields. This unique material's ability to combine shape memory, superelasticity, and other valuable properties positions it as a key player in shaping the future of innovation.

Challenges in Working with Nitinol Shape Memory Alloy

One of the main challenges in working with nitinol memory wire is its high sensitivity to temperature changes, which can affect its shape memory properties. Additionally, the unique behavior of nitinol alloy shape memory requires careful consideration during the design and manufacturing process to ensure precise functionality.

One way to overcome nitinol's limitations is to carefully control the temperature environment in which the alloy is used. This can be achieved through the use of specialized coatings or insulation to shield the nitinol from rapid temperature changes. Additionally, incorporating temperature sensors and feedback control systems into the design can help maintain a stable environment for the nitinol shape memory alloy, ensuring consistent performance.

How to Overcome Nitinol’s Limitations

To overcome the limitations of nitinol shape memory alloy, engineers and designers can employ advanced heat treatment processes to optimize the material’s transformation temperatures and enhance its performance stability. Additionally, thorough testing and validation procedures are essential to ensure the reliability and consistency of nitinol materials in real-world applications.

By carefully considering the advantages and challenges associated with nitinol memory metal, engineers and designers can harness its unique properties to create innovative solutions while addressing potential limitations through strategic approaches.

Leverage the Unique Properties of Nitinol for Innovative Solutions

Nitinol wire has revolutionized various industries with its unique memory shape alloy properties. From medical devices to aerospace technology, the potential of nitinol memory wire is boundless. As the demand for innovative solutions grows, the future of nitinol shape memory alloys looks promising, paving the way for groundbreaking advancements in engineering and design.

Harnessing the Potential of Nitinol Wire in Various Industries

The versatility of nitinol memory wire has opened doors for groundbreaking applications across various industries. Its ability to remember and return to a predetermined shape makes it an invaluable material in medical devices, robotics, and aerospace technology. As manufacturers continue to harness the potential of nitinol alloy shape memory, we expect to see further advancements pushing the boundaries of what is possible in engineering and design.

Exploring the Future of Nitinol Shape Memory Alloys

The future of nitinol shape memory alloys holds immense promise as researchers and engineers uncover new ways to leverage their unique properties. With ongoing developments in material science and manufacturing techniques, we can anticipate even more sophisticated applications for nitinol memory metal. The possibilities for this remarkable material are endless, from nanotechnology to renewable energy systems.

As industries seek innovative solutions that deliver exceptional performance, leveraging nitinol's unique properties becomes increasingly crucial. Memory wire nitinol's ability to withstand repeated deformations while retaining its original shape offers unparalleled opportunities for creative problem-solving in diverse fields. By embracing this extraordinary material, engineers and designers can unlock a world of possibilities that lead to transformative innovations.