Introduction

In the realm of advanced materials, few substances capture the imagination quite like Nitinol alloy foil. Known for its remarkable properties, Nitinol is a unique blend of nickel and titanium that exhibits both shape memory and superelasticity. This fascinating material, often referred to as Nitinol Shape Memory Alloy Foil, has revolutionized various industries by enabling designs that were once thought impossible.

Understanding Nitinol Alloy Foil

So, what is nitinol alloy? Essentially, it's a nickel-titanium alloy distinguished by its ability to return to a predetermined shape when heated above a certain temperature. One popular variant is the NT0402 Nitinol foil, which showcases these extraordinary characteristics in a thin and flexible form. This lightweight material has garnered attention not just for its unique properties but also for its potential applications across diverse fields.

The Science Behind Shape Memory Alloys

At the core of Nitinol's appeal lies the science of shape memory alloys (SMAs). These materials can remember their original shapes and revert back to them when subjected to specific thermal conditions. This intriguing phenomenon raises questions like: why is nitinol so expensive? The answer lies in its complex manufacturing process and the precise control required to harness its unique properties effectively.

Applications of Nitinol in Modern Design

The versatility of nitinol alloy foil extends far beyond scientific curiosity; it has found practical applications in modern design that span from medical devices to aerospace engineering. Its ability to adapt under varying temperatures makes it ideal for creating innovative solutions such as self-expanding stents or flexible actuators in aircraft systems. With advantages like enhanced strength and durability—leading many to wonder if nitinol is stronger than titanium—this alloy continues to push boundaries across multiple industries while shaping our future technologies.

Medical Innovations with Nitinol Alloy Foil

The medical field has seen remarkable advancements thanks to the unique properties of nitinol alloy foil. This versatile material, known for its shape memory and superelasticity, has revolutionized various medical devices and tools. From enhancing patient care to improving surgical outcomes, nitinol is at the forefront of medical innovation.

Nitinol in Stents and Catheters

Nitinol's ability to return to a predetermined shape after deformation makes it an ideal material for stents and catheters. When deployed in the body, devices made from Nitinol Shape Memory Alloy Foil can navigate complex vascular paths and expand precisely where needed. This capability significantly reduces complications during procedures, making it a favorite among surgeons.

Stents crafted from NT0402 Nitinol Foil are particularly effective because they maintain their structure under physiological conditions while also exhibiting flexibility. This combination allows them to accommodate the natural movement of blood vessels without causing damage or discomfort. With enhanced biocompatibility, nitinol stents have a lower risk of thrombosis compared to traditional materials, leading to better long-term outcomes for patients.

Moreover, using nitinol in catheters provides additional benefits such as increased maneuverability and reduced trauma during insertion. The lightweight nature of nitinol alloy foil means that these devices can be both durable and easy to handle, ensuring that healthcare providers can perform procedures with greater precision and confidence. As we explore further applications of this remarkable material, it becomes clear why so many are asking: what is nitinol alloy?

Shape Memory Alloys in Orthopedic Devices

In orthopedics, Nitinol Shape Memory Alloy Foil is transforming how we approach bone fixation and joint stabilization. The unique properties of shape memory alloys allow orthopedic devices to adapt dynamically to patients' movements while providing necessary support during recovery periods. Surgeons now have access to tools that not only respond effectively but also enhance patient comfort.

For instance, plates and screws made from NT0402 Nitinol Foil can change shape based on temperature or stress levels within the body—a feature that promotes healing by mimicking natural bone behavior more closely than traditional materials could achieve. This adaptability leads many healthcare professionals to ask: why is nitinol so expensive? The answer lies in its advanced manufacturing processes and exceptional performance characteristics that justify the cost when compared with alternatives like titanium.

Additionally, using nitinol in orthopedic implants has proven advantageous due to its fatigue resistance—an essential factor for long-term success in load-bearing applications like joint replacements. Patients benefit from reduced complications associated with implant failure or loosening over time since these devices maintain their integrity under repeated stress conditions better than conventional materials might allow.

Custom Surgical Tools Made from Nitinol

Custom surgical tools made from nitinol represent another exciting frontier in medical innovations powered by this extraordinary alloy. Surgeons can now utilize instruments crafted specifically for their techniques—tools that combine flexibility with strength thanks to the properties inherent in Nitinol Shape Memory Alloy Foil. These bespoke solutions streamline procedures while minimizing tissue damage.

One notable benefit of using NT0402 Nitinol Foil in surgical instruments is its lightweight nature combined with high tensile strength; this ensures durability without sacrificing maneuverability during delicate operations where precision matters most! As hospitals increasingly embrace personalized medicine approaches tailored specifically around individual patient needs (and surgeon preferences), custom tools made from this innovative material become indispensable assets within operating rooms worldwide.

Furthermore, integrating smart technology into these custom surgical tools enhances their functionality even further—imagine instruments equipped with sensors that provide real-time feedback on performance metrics or tissue interaction! Such advancements underscore what are the advantages of nitinol? Ultimately highlighting its potential not just as a tool but as an integral component driving forward-thinking solutions across diverse fields within medicine today!

Aerospace Advancements Utilizing Nitinol

The aerospace industry is constantly on the lookout for materials that can enhance performance while reducing weight. Enter Nitinol, a remarkable alloy known for its unique properties, including shape memory and superelasticity. By utilizing Nitinol alloy foil in various applications, aerospace engineers are pushing the boundaries of what's possible in aircraft design.

Nitinol's Role in Lightweight Structures

One of the most significant advantages of using Nitinol is its lightweight nature, which is crucial in aerospace applications where every gram counts. The NT0402 Nitinol foil, for instance, provides strength without adding unnecessary weight to aircraft structures. This reduction in mass not only enhances fuel efficiency but also allows for increased payload capacity—an essential factor for commercial and military aviation.

Beyond mere weight savings, what is nitinol alloy? It’s an innovative material that combines the benefits of metals with unique properties that traditional alloys simply can't match. When integrated into lightweight structures, Nitinol contributes to enhanced performance and durability while maintaining structural integrity under extreme conditions.

Shape Memory Alloys for Actuation Systems

Shape memory alloys (SMAs) like Nitinol are revolutionizing actuation systems within aircraft by providing reliable movement without heavy mechanical components. When heated above a certain temperature, Nitinol can return to its original shape after being deformed—this property makes it ideal for actuators used in flight control surfaces and landing gear systems. The ability to replace bulky hydraulic systems with compact SMA solutions leads to significant weight reductions and improved responsiveness.

What are the advantages of nitinol in these applications? Besides being lightweight and responsive, it allows engineers to design more streamlined systems that require less maintenance over time. As a result, incorporating this technology into actuation systems can lead to safer and more efficient flight operations.

Benefits of Nitinol in Flight Technology

Nitinol's unique characteristics offer numerous benefits when applied to flight technology beyond just structural components or actuation systems. Its resistance to fatigue makes it an excellent candidate for parts exposed to repeated stress cycles during takeoff and landing phases—think about how many times those flaps move! Additionally, because nitinol alloy foil can operate effectively at varying temperatures without losing performance characteristics, it's perfect for the diverse thermal environments experienced during flights.

Is nitinol stronger than titanium? While both materials boast impressive strength-to-weight ratios, each has its own set of advantages depending on the application context; however, when it comes to flexibility and adaptability under different conditions—Nitinol often takes the cake! As we continue exploring new horizons in aerospace technology with this versatile material at our side, we’re bound to see even more groundbreaking innovations emerge.

Consumer Electronics and Nitinol

Nitinol alloy foil is making waves in the consumer electronics sector, offering innovative solutions that blend functionality with cutting-edge design. As technology evolves, the demand for adaptable materials grows, and Nitinol Shape Memory Alloy Foil stands out due to its unique properties. From flexible displays to smart wearables, Nitinol's versatility is revolutionizing how we interact with our devices.

Flexible Displays with Nitinol Alloy Foil

One of the most exciting applications of nitinol alloy foil is in the development of flexible displays. These displays leverage the unique properties of Nitinol Shape Memory Alloy Foil, allowing screens to bend and twist without losing functionality or clarity. Imagine a smartphone that can roll up like a piece of paper—thanks to nitinol foil, this futuristic vision is inching closer to reality.

Flexible displays made from NT0402 Nitinol Foil not only enhance portability but also open new avenues for creative designs in consumer electronics. The ability to create lightweight yet durable screens means manufacturers can produce devices that are both stylish and practical. This innovation raises an intriguing question: what is nitinol alloy? It’s a nickel-titanium blend that possesses remarkable shape memory characteristics, making it ideal for various applications.

Smart Wearables Featuring Nitinol Components

The rise of smart wearables has been nothing short of phenomenal, and nitinol components are at the forefront of this trend. By integrating Nitinol Shape Memory Alloy Foil into fitness trackers and smartwatches, manufacturers can create devices that adapt seamlessly to user needs while maintaining comfort and style. The flexibility offered by nitinol allows these wearables to be more than just functional; they can also be fashion statements.

Moreover, with features such as adjustable straps made from NT0402 Nitinol Foil, wearables can conform perfectly to any wrist size or shape without compromising performance or durability. This adaptability raises questions about durability—specifically: is nitinol stronger than titanium? While both materials have their strengths, nitinol's unique properties offer distinct advantages in specific applications like wearables where flexibility and resilience are key.

Heat-Responsive Nitinol in Home Gadgets

In addition to flexible displays and smart wearables, heat-responsive nitinol plays a significant role in modern home gadgets. These innovative products utilize the unique thermal properties of nitinol alloy foil to create responsive mechanisms that activate based on temperature changes. For instance, imagine curtains that automatically close when sunlight heats them up—a reality made possible through the clever use of shape memory alloys.

This technology not only enhances convenience but also improves energy efficiency within homes by regulating temperature naturally using NT0402 Nitinol Foil components. As consumers become more environmentally conscious, gadgets featuring heat-responsive nitinol will likely gain traction due to their sustainable approach toward home automation systems—addressing concerns such as why is nitinol so expensive? The answer lies in its intricate manufacturing process and exceptional capabilities compared to traditional materials.

The Automotive Industry's Nitinol Applications

The automotive industry has been quick to embrace the unique properties of Nitinol alloy foil, leveraging its shape memory capabilities to enhance vehicle performance and safety. With a growing emphasis on lightweight materials and innovative designs, Nitinol Shape Memory Alloy Foil is becoming a staple in modern automotive engineering. As manufacturers continue to explore its potential, the impact of this remarkable alloy is expected to grow significantly.

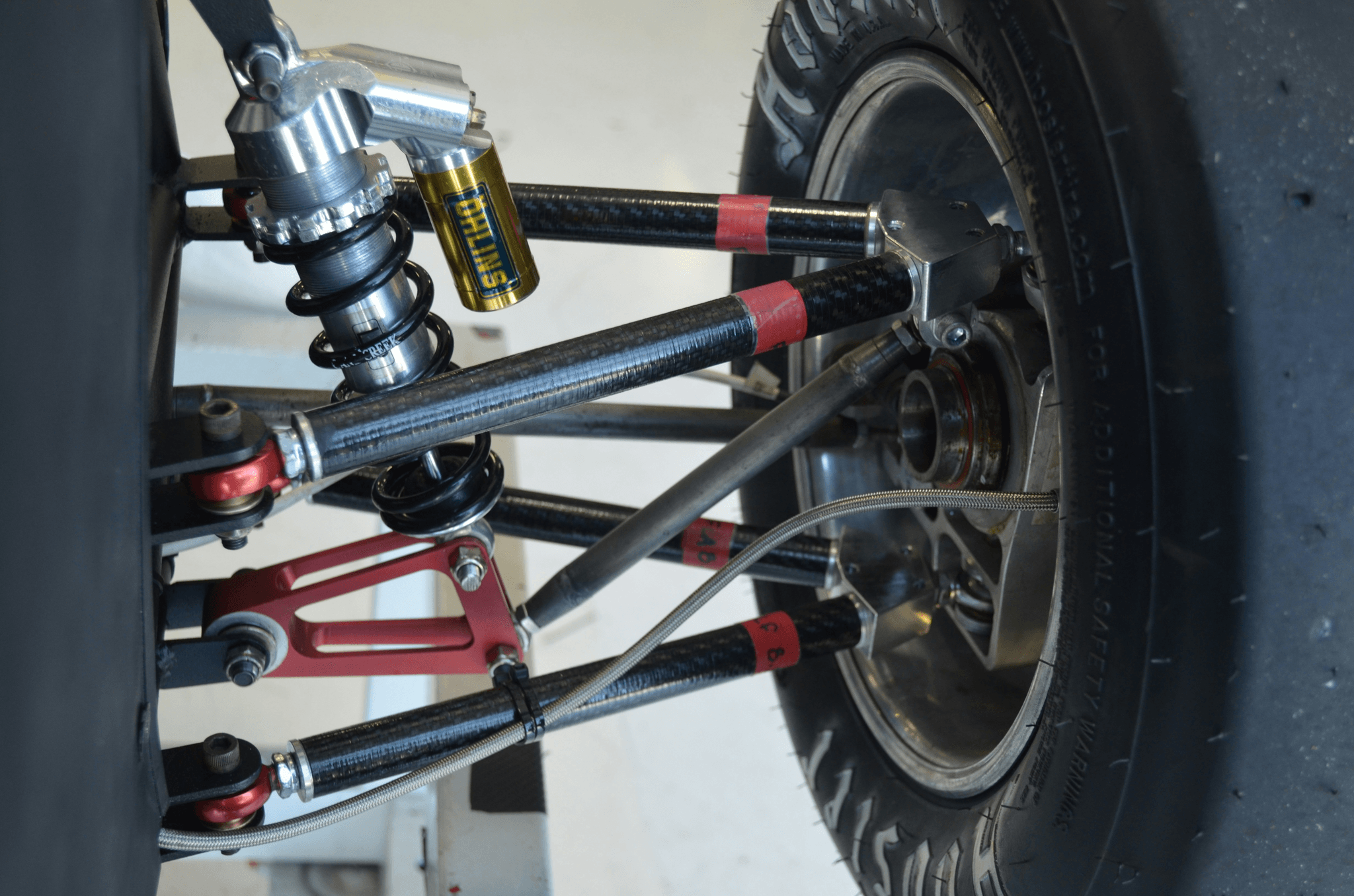

Nitinol in Active Suspension Systems

Active suspension systems are revolutionizing how vehicles handle road conditions, and Nitinol plays a pivotal role in this transformation. By utilizing NT0402 Nitinol Foil, these systems can adjust automatically to varying terrains, providing superior comfort and stability for passengers. The ability of nitinol to change shape in response to temperature makes it an ideal candidate for dynamic adjustments that traditional materials simply cannot match.

Moreover, incorporating nitinol alloy foil into suspension systems not only enhances ride quality but also reduces weight compared to conventional solutions. This weight reduction contributes further to fuel efficiency—a key concern for modern automotive design. When asking What is nitinol alloy? one must consider its applications in active suspension as a prime example of innovation at work.

Enhancing Safety Features with Nitinol Foil

Safety features in vehicles are paramount, and the integration of nitinol foil is pushing the boundaries of what’s possible. For instance, seatbelt mechanisms equipped with shape memory alloys can adapt their tension based on crash dynamics, offering improved protection during accidents. This adaptability not only enhances passenger safety but also reflects why many engineers are curious about Why is nitinol so expensive?—its unique properties come at a premium.

Additionally, crumple zones designed with nitinol allow for more efficient energy absorption upon impact due to their ability to revert back after deformation. This capability provides an extra layer of security that traditional materials lack while maintaining vehicle integrity post-collision. As we explore “What are the advantages of nitinol?” it becomes clear that enhanced safety features stand out prominently.

Fuel Efficiency Improvements Using Nitinol

Fuel efficiency remains a hot topic among auto manufacturers and consumers alike—enter nitinol! By reducing overall vehicle weight through the use of lightweight components made from Nitinol Shape Memory Alloy Foil, cars can achieve better mileage without sacrificing performance or safety standards. In fact, many engineers wonder: Is nitinol stronger than titanium?—the answer lies in its unique combination of strength-to-weight ratio and flexibility.

Moreover, using NT0402 Nitinol Foil allows for innovative designs such as adjustable exhaust systems that optimize airflow depending on driving conditions; thus improving engine efficiency further still! Such advancements underscore how critical it is for automakers to consider new materials like nitinol when striving for sustainable practices within their production processes. As we look ahead at future trends within the automotive sector, it's clear that incorporating advanced materials like nitinol will be essential for achieving greater fuel efficiency.

Understanding Nitinol's Cost and Value

The cost of Nitinol alloy foil can be a significant barrier for many industries looking to adopt this innovative material. The intricate manufacturing process, combined with the unique properties of Nitinol Shape Memory Alloy Foil, contributes to its high price tag. Additionally, the demand for precision and quality in applications such as medical devices and aerospace components further drives up costs.

Why Is Nitinol So Expensive?

So, why is nitinol so expensive? The answer lies in its complex production methods and raw material sourcing. Creating NT0402 Nitinol Foil requires precise control over temperature and composition to achieve the desired shape memory effect, which increases manufacturing costs significantly.

Moreover, the limited number of suppliers who can produce high-quality Nitinol contributes to its elevated price. This scarcity not only affects availability but also enables suppliers to maintain higher profit margins on their products. As industries continue to explore the benefits of nitinol alloy foil, prices may fluctuate based on market demand and advancements in production techniques.

What Are the Advantages of Nitinol?

What are the advantages of nitinol? One standout feature is its unique ability to return to a predetermined shape upon heating, making it invaluable in various applications like stents and actuators. This shape memory effect allows for innovative designs that can adapt to different conditions without compromising structural integrity.

Nitinol also boasts excellent fatigue resistance and biocompatibility, particularly important in medical devices where patient safety is paramount. Its lightweight nature combined with strength makes it an attractive alternative for industries like aerospace and automotive as well. Overall, these advantages make nitinol alloy foil a game-changer across multiple sectors.

Comparing Nitinol to Other Alloys like Titanium

When comparing nitinol to other alloys like titanium, one might wonder: is nitinol stronger than titanium? While both materials have their strengths, they serve different purposes based on their unique properties. Titanium offers excellent tensile strength but lacks the shape memory characteristics that make nitinol so versatile.

In terms of weight-to-strength ratio, both materials excel; however, nitinol's ability to undergo deformation while maintaining functionality gives it a competitive edge in specific applications such as flexible electronics or adaptive structures. Furthermore, when considering cost-effectiveness over time—factoring in maintenance and performance—nitirol may provide better long-term value despite its upfront costs compared to titanium alloys used in similar contexts.

Conclusion

As we draw our exploration of Nitinol alloy foil to a close, it’s clear that this remarkable material has reshaped multiple industries. The future of Nitinol Shape Memory Alloy Foil is bright, with innovations on the horizon that promise to revolutionize how we think about materials in design and engineering. Whether it's in medicine, aerospace, or consumer electronics, the potential applications for Nitinol seem limitless.

Future Trends in Nitinol Alloy Applications

Looking ahead, we can expect to see significant advancements in the use of Nitinol alloy foil across various sectors. For instance, the medical field is likely to embrace even more sophisticated uses for Nitinol Shape Memory Alloy Foil in minimally invasive surgeries and personalized implants. Moreover, as technology continues to evolve, integrating NT0402 Nitinol Foil into smart devices could lead to new functionalities that enhance user experience while maintaining lightweight and durable design.

GEE SMA's Role in Nitinol Innovation

GEE SMA is at the forefront of driving innovation within the realm of nitinol alloys. Their commitment to research and development ensures that they are continually improving the properties and applications of materials like NT0402 Nitinol Foil. By focusing on what makes nitinol so expensive—its unique properties such as shape memory and superelasticity—GEE SMA is pushing boundaries that could redefine standards across industries.

The Lasting Impact of Nitinol on Industries

The lasting impact of nitinol on various industries cannot be overstated; it has become a game changer for many applications where traditional materials fall short. With advantages like flexibility, resilience, and lightweight characteristics—questions like Is nitinol stronger than titanium? often arise as comparisons are made between these two powerful materials. As businesses continue to explore what are the advantages of nitinol beyond its cost considerations, it’s evident that this alloy will remain an integral part of technological advancement for years to come.