Introduction

In advanced medical technology, nitinol actuators have emerged as a game-changer in high-field MRI control. These innovative devices are revolutionizing how we manipulate magnetic resonance imaging systems, offering unmatched precision and efficiency. As we delve deeper into the significance of high-field MRI control, it becomes evident that nitinol actuators play a pivotal role in shaping the future of medical diagnostics. Introducing GEE SMA, a leading provider of cutting-edge nitinol actuator technology, poised to elevate MRI control to new heights.

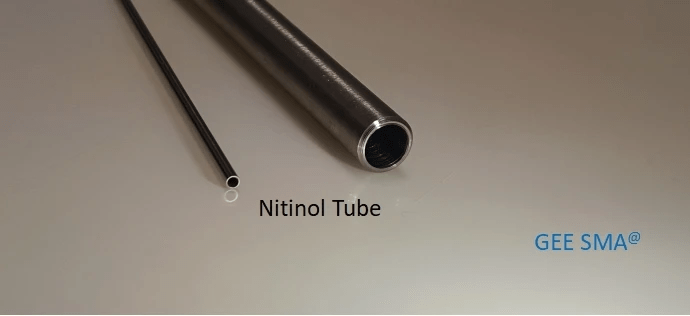

Understanding Nitinol Actuators

Nitinol actuators are sophisticated devices that leverage shape memory alloys to achieve remarkable flexibility and responsiveness in controlling high-field MRI systems. These advanced components are engineered to deliver precise movements and adjustments, enabling healthcare professionals to optimize imaging processes with unparalleled accuracy and reliability. The versatility and adaptability of nitinol actuators make them indispensable tools for enhancing the performance of MRI equipment.

The Importance of High-Field MRI Control

High-field MRI scans are revolutionizing medical diagnostics by offering unparalleled image detail. However, achieving optimal results requires precise control over the powerful magnetic fields. Here's how advanced control systems, particularly those utilizing Nitinol actuators, are making a significant difference:

- Enhanced Image Quality: Precise field manipulation minimizes artifacts and distortions, leading to clearer images for better diagnoses.

- Reduced Scan Time: Optimized control allows faster data acquisition, minimizing patient discomfort and improving workflow efficiency.

- Improved Patient Comfort: Advanced control systems can help mitigate noise and vibrations often associated with high-field MRI scans, leading to a more comfortable experience.

- Advanced Applications: Precise field control unlocks the potential for novel imaging techniques, further expanding diagnostic capabilities.

High-field MRI control is no longer a luxury but necessary for achieving the best possible diagnostic outcomes. With innovative solutions like Nitinol actuators, the future of medical imaging promises even greater precision and patient comfort.

Introducing GEE SMA

GEE SMA is at the forefront of innovation in nitinol actuator technology, providing state-of-the-art solutions tailored to meet the evolving demands of high-field MRI control. Focusing on quality craftsmanship and cutting-edge materials, GEE SMA is dedicated to delivering superior performance and reliability in every aspect of its products. As industry leaders in this specialized field, GEE SMA continues to drive advancements that shape the future of MRI technology.

The Power of Nitinol Actuators in MRI Control

Nitinol actuators are revolutionizing MRI control with their efficient precision and reliability. These advanced actuators provide seamless control over high-field MRI systems, allowing for accurate and consistent performance. The power of nitinol actuators lies in their ability to deliver precise movements and adjustments, ensuring optimal imaging results for healthcare professionals and patients.

Efficient Control and Precision

Nitinol actuators offer efficient control and precision, allowing seamless adjustments in high-field MRI systems. Their shape memory properties enable them to respond quickly to commands, ensuring accurate positioning and movement within the MRI environment. This level of precision is crucial for obtaining clear and detailed imaging results, making nitinol actuators a game-changer in MRI technology.

Nitinol actuators are also known for their durability and reliability, providing consistent performance even in the demanding environment of high-field MRI systems. Medical professionals can rely on them to deliver precise movements and adjustments without the risk of malfunction or breakdown. As a result, this technology enhances imaging quality and contributes to the overall efficiency and productivity of MRI procedures, ultimately benefiting both healthcare providers and patients.

Nitinol Actuators for High-Field MRI Systems

High-field MRI systems require robust control mechanisms to navigate complex imaging processes effectively. Nitinol actuators are designed to meet high-field environments' demands, offering unparalleled performance and reliability. Their ability to withstand strong magnetic fields while maintaining precise control makes them ideal for advanced MRI systems used in medical diagnostics and research.

In addition to their resilience in high magnetic fields, Nitinol actuators offer compact and lightweight design advantages. They can be integrated into existing MRI systems easily without adding significant bulk or weight. Their streamlined nature also contributes to improved efficiency and reduced energy consumption, making them a cost-effective choice for high-field MRI applications.

Advantages of Nitinol Spring Actuators

Nitinol spring actuators offer several advantages that make them ideal for demanding applications, particularly in medicine. Here are some key benefits:

- Exceptional Durability and Longevity: Unlike traditional springs, nitinol springs can withstand repeated use without wearing down. This translates to cost-effective, long-term performance in high-use environments like MRI control systems. Consistent operation ensures reliable imaging procedures for healthcare professionals.

- High Energy Density: Nitinol springs deliver powerful and precise movements despite their compact size. This makes them perfect for space-constrained medical devices like robotic surgery tools and implants. The ability to provide strong, consistent motion within the human body enhances the accuracy and success of medical procedures.

Nitinol spring actuators combine impressive durability, high energy density, and compact size, making them valuable technology for various medical applications. Their ability to deliver precise and powerful movements within tight spaces will lead to advancements in minimally invasive surgeries and other medical procedures.

Exploring the Applications of Nitinol Linear Actuators

Nitinol linear actuators are revolutionizing MRI control systems, offering unparalleled precision and efficiency. These advanced actuators can be customized to meet the specific needs of MRI technology, providing seamless integration and superior performance. With nitinol linear actuators, MRI control systems can be tailored to deliver optimal results for medical professionals and patients.

Customizing MRI Control Systems

By incorporating nitinol linear actuators into MRI control systems, medical professionals can customize the functionality and performance of these critical devices. Whether it's enhancing imaging capabilities or improving patient comfort during scans, nitinol actuators offer a versatile solution for tailoring MRI control systems to meet specific requirements. The flexibility and adaptability of nitinol linear actuators enable seamless integration into existing MRI technology, providing a customizable solution for healthcare providers.

Nitinol Wire Actuators for Advanced MRI Technology

Nitinol wire actuators are crucial in advancing MRI technology, offering unparalleled precision and reliability. These advanced actuators enable the development of high-performance MRI systems that push the boundaries of imaging capabilities. By harnessing the power of nitinol wire actuators, medical professionals can access cutting-edge MRI technology that delivers exceptional results with unmatched efficiency.

Nitinol wire actuators are designed to be flexible and durable, making them ideal for the unique demands of MRI technology. Their ability to withstand high magnetic fields and extreme temperatures ensures reliable performance in an MRI system's challenging environment. This durability reduces maintenance and downtime, allowing medical professionals to focus on delivering exceptional patient care without worrying about equipment failure.

Tailoring Nitinol Actuators to Unique MRI Needs

One of the key benefits of nitinol actuators is their ability to be tailored to unique MRI requirements. Whether it's designing specialized imaging protocols or optimizing scan parameters, nitinol actuators provide a customizable solution for addressing specific needs within the field of medical imaging. By leveraging the versatility of nitinol actuators, healthcare providers can create tailored solutions that elevate the standard of care in diagnostic imaging.

The Science Behind Nitinol Actuators

Understanding Nitinol Shape Memory Alloys

Nitinol actuators are made from a unique material called shape memory alloys (SMA). These alloys can remember their original shape and return to it when heated. This remarkable property allows nitinol actuators to flex and move precisely, making them ideal for high-precision applications such as MRI control systems.

Nitinol actuators are highly sought for their ability to provide precise and reliable movement in high-precision applications. The unique properties of shape memory alloys (SMA) allow nitinol actuators to flex and bend accurately, making them ideal for applications such as MRI control systems. This level of precision is crucial in medical settings where accuracy and reliability are paramount, showcasing the value of nitinol materials in advancing technology.

Crafting High-Quality Nitinol Materials

Crafting high-quality nitinol materials involves a complex process of alloying nickel and titanium in precise proportions to achieve the desired shape memory effect. The resulting nitinol wire is then carefully treated to ensure optimal flexibility, durability, and performance in demanding MRI environments. This meticulous treatment process is essential for enhancing the product quality, as it ensures that the nitinol materials can withstand the rigors of medical procedures without compromising their shape memory properties. Additionally, the attention to detail in crafting these materials allows for greater precision and reliability in medical devices, ultimately benefiting patients and healthcare professionals.

Enhancing Product Quality with GEE SMA

GEE SMA takes the science of nitinol actuators to the next level by incorporating cutting-edge manufacturing techniques and quality control measures. This ensures that every nitinol actuator produced meets the highest performance, reliability, and safety standards for use in advanced MRI control systems.

Addressing Safety Concerns: Is Nitinol Toxic?

Debunking Myths about Nitinol Safety

There is a common misconception that nitinol actuators are toxic, but this is not true. Nitinol is biocompatible, making it safe for medical devices such as MRI control systems. It has been extensively tested and proven to be non-toxic, ensuring the safety of patients and healthcare professionals.

Ensuring Safe and Reliable MRI Control

Safety is paramount when it comes to MRI control, and nitinol actuators provide the reliability needed in high-stakes medical settings. These actuators are designed to withstand the demanding environment of an MRI system, ensuring precise and safe control without compromising patient safety. With nitinol actuators, healthcare providers can have peace of mind knowing that they are using safe and reliable technology.

Meeting Regulatory Standards with Nitinol Actuators

Compliance with regulatory standards is crucial in the medical industry, and nitinol actuators meet these requirements with flying colors. They undergo rigorous testing to ensure they meet all safety and performance standards set forth by regulatory bodies. By choosing nitinol actuators for MRI control systems, healthcare providers can rest assured that they are using a technology that meets the highest regulatory standards for safety and efficacy.

The Future of High-Field MRI Control

As high-field MRI technology advances, the demand for innovative nitinol actuator technology is on the rise. Manufacturers are constantly pushing the boundaries of what nitinol actuators can achieve, focusing on enhancing efficiency, precision, and reliability in high-field MRI control systems. These innovations drive the future of MRI technology, offering exciting possibilities for improved patient care and diagnostic accuracy.

Innovations in Nitinol Actuator Technology

Innovations in nitinol actuator technology pave the way for more efficient and precise control of high-field MRI systems. With materials science and engineering advancements, manufacturers are developing nitinol actuators that offer enhanced performance and durability. These next-generation actuators are designed to meet the demanding requirements of modern MRI technology, providing clinicians with greater control and flexibility during imaging procedures.

Meeting Customer Requirements with GEE SMA

As customer demands for high-field MRI control become increasingly sophisticated, manufacturers must adapt to meet these evolving requirements. Global Engineering & Excellence (GEE) Shape Memory Alloys (SMA) is at the forefront of this evolution, offering tailored solutions to address specific customer needs in the field of MRI control. By leveraging GEE SMA expertise, manufacturers can ensure that their nitinol actuators are custom-designed to deliver optimal performance in high-field MRI applications.

Tailoring Nitinol Functional Materials for Future MRI Needs

The future of high-field MRI control hinges on developing advanced nitinol functional materials that adapt to evolving technological demands. Manufacturers can create actuators that offer unparalleled performance and reliability by tailoring nitinol alloys and composites to specific MRI requirements. This approach allows for greater customization and innovation in high-field MRI systems, ultimately improving patient outcomes and diagnostic capabilities.

Embrace the Future of MRI Control

Nitinol actuators have revolutionized the field of MRI control, offering efficient and precise solutions for high-field systems. With the introduction of GEE SMA, the future of MRI technology looks brighter than ever. By embracing the potential of nitinol actuators, we can advance MRI technology to new heights and ensure safe and reliable control for years to come.

Harnessing the Potential of Nitinol Actuators

Nitinol actuators are a game-changer in MRI control, providing customizable and high-quality solutions for advanced systems. By harnessing their potential, we can unlock new possibilities in precision control and enhance patient experiences during imaging procedures.

Nitinol actuators have revolutionized the field of MRI control by offering unparalleled flexibility and precision. Their customizable nature allows for tailored solutions that meet the unique needs of advanced imaging systems, ensuring high-quality performance. By leveraging the potential of Nitinol actuators, we can push the boundaries of precision control in MRI technology, ultimately enhancing the overall patient experience and improving diagnostic accuracy.

Advancing MRI Technology with GEE SMA

GEE SMA's nitinol spring actuators offer unparalleled performance and reliability, paving the way for advancements in MRI technology. With their expertise and innovative solutions, GEE SMA is driving the evolution of high-field MRI control and setting new standards for industry excellence.

GEE SMA's nitinol spring actuators have revolutionized the field of MRI technology, providing unmatched performance and reliability. This breakthrough has opened the door for new possibilities in high-field MRI control, allowing for more precise imaging and diagnosis. As a result, GEE SMA is at the forefront of driving innovation and setting the bar for excellence in the industry.

Looking ahead, it's clear that nitinol linear actuators and wire actuators will continue to play a vital role in shaping the future of MRI control. By embracing these cutting-edge technologies, we can ensure that patients receive the best possible care while pushing the boundaries of what's possible in medical imaging.

By leveraging the power of nitinol actuators and GEE SMA's expertise, we're not just advancing MRI technology – we're transforming it into something extraordinary. The future is bright for high-field MRI control, thanks to these remarkable innovations!