Introduction

In the realm of engineering, few innovations have garnered as much attention as the shape memory actuator. These remarkable devices leverage the unique properties of smart materials to produce motion and force in a way that traditional actuators simply cannot. But what exactly is a shape memory actuator, and how does it work? To answer these questions, we must delve into the fascinating world of smart materials with great forces, particularly focusing on Nitinol—the star player in this technology.

Understanding Shape Memory Actuators

At its core, a shape memory actuator (SMA actuator) is an ingenious device that can change its shape in response to external stimuli, typically temperature changes. This transformation is made possible by materials known as shape memory alloys (SMAs), which possess a unique ability to remember their original form after being deformed. So, what is an SMA actuator? It’s essentially a mechanism that utilizes this property for controlled movement and force generation in various applications.

Unpacking Smart Materials with Great Forces

Smart materials with great forces are revolutionizing multiple industries by enabling innovative solutions that were once thought impossible. SMA actuators stand out due to their lightweight design and high-performance capabilities, making them ideal for applications where weight reduction is crucial—like aerospace engineering or advanced robotics. Their ability to deliver significant actuation forces while remaining compact allows engineers to explore new possibilities across various sectors.

Nitinol: The Core of SMA Technology

Nitinol—a nickel-titanium alloy—is often hailed as the backbone of shape memory actuator technology due to its extraordinary properties and versatility. How is Nitinol used in actuators? When subjected to specific thermal cycles, it undergoes phase transformations that result in impressive mechanical performance and energy efficiency during operation. With such characteristics, Nitinol has become synonymous with cutting-edge applications; from medical devices to robotic systems, it’s clear that understanding how Nitinol works can open doors to countless innovations.

What is a Shape Memory Actuator?

When we dive into the world of smart materials, one standout technology is the shape memory actuator. So, what is a shape memory actuator? Essentially, it’s a device that utilizes shape memory alloys (SMAs) to convert thermal energy into mechanical work. This transformation allows these actuators to change their shape in response to temperature variations, making them incredibly versatile in various applications.

Definition and Working Principle

A shape memory actuator operates on the principle of phase transformation inherent in shape memory alloys. When heated above a certain temperature, these materials revert to their original pre-deformed shapes, exerting force in the process. This unique characteristic enables SMA actuators to perform tasks ranging from simple movements to complex operations in robotics and aerospace technologies.

The working principle behind what is an SMA actuator involves two key phases: the martensite phase at lower temperatures and the austenite phase at higher temperatures. In simpler terms, when cooled down, the material can be deformed easily; however, once it warms up again, it remembers its original form and springs back into action. This ability not only makes SMA actuators reliable but also opens doors for innovative applications across different industries.

Key Characteristics of SMA Actuators

SMA actuators are known for several distinguishing characteristics that make them appealing for numerous applications. One significant feature is their lightweight design combined with high force output—allowing engineers to create compact systems without sacrificing power or efficiency. Additionally, SMA actuators are energy-efficient since they only consume power during the heating phase; once activated, they maintain their position without continuous energy input.

Another essential characteristic worth noting is their ability to operate silently compared to traditional mechanical systems. This makes them particularly advantageous in environments where noise reduction is critical—such as medical devices or aerospace applications where stealth capabilities may be required. Furthermore, SMAs exhibit excellent durability and longevity due to their resistance to fatigue over time.

Nitinol’s Role in Actuation

Nitinol plays a pivotal role as one of the most popular materials used in shape memory actuators today. But how is Nitinol used in actuators? As an alloy primarily composed of nickel and titanium, Nitinol possesses remarkable properties like biocompatibility and corrosion resistance—making it ideal for medical device applications such as stents or surgical tools.

In addition to its practical benefits, Nitinol's unique ability for phase transformation enhances the functionality of SMA actuators significantly. By leveraging this material's characteristics within smart materials with great forces framework, engineers can develop sophisticated systems that respond dynamically under different conditions—opening up exciting possibilities across various sectors including robotics and aerospace innovations.

Moreover, understanding what are the applications of SMA actuators highlights just how integral Nitinol has become within this field; from precision robotics that require delicate movements to larger-scale machinery needing reliable actuation solutions—Nitinol-equipped SMAs are leading the charge toward smarter technologies.

The Science Behind Nitinol in Actuators

Nitinol, a unique shape memory alloy, is fundamental to the functionality of shape memory actuators. Its ability to remember specific shapes and return to them when heated makes it a game-changer in various applications. Understanding the science behind Nitinol helps us appreciate how it powers these smart materials with great forces.

Unique Properties of Nitinol

Nitinol exhibits remarkable properties that set it apart from traditional materials used in actuators. One of its most notable features is its ability to undergo phase transformation, allowing it to switch between two distinct crystalline structures: martensite and austenite. This transformation enables the shape memory actuator to exert significant force while remaining lightweight and compact, making Nitinol an ideal choice for various applications.

Additionally, Nitinol boasts excellent fatigue resistance and corrosion resistance, which enhances the longevity of SMA actuators in demanding environments. The combination of these unique properties allows for innovative designs that can withstand rigorous operational demands without compromising performance. As we delve deeper into how Nitinol is used in actuators, it's clear that its exceptional characteristics are pivotal for advancing technology.

Phase Transformation and Its Benefits

The phase transformation process in Nitinol is fascinating and critical for understanding what an SMA actuator is capable of achieving. When heated above a certain temperature, the material transitions from its low-temperature martensitic phase—where it can be easily deformed—to its high-temperature austenitic phase—where it returns to its original shape with tremendous force. This property allows SMA actuators to perform tasks ranging from simple movements to complex mechanical functions seamlessly.

The benefits of this phase transformation extend beyond just movement; they also include energy efficiency during operation. Unlike conventional motors that consume constant power regardless of their position, SMA actuators only require energy during the transition phases, leading to significant savings over time. This efficiency makes them particularly attractive for applications where battery life or energy conservation is crucial.

Applications of Nitinol in Modern Technology

Nitinol's unique properties and phase transformation capabilities have led to numerous applications across various industries—truly showcasing what are the applications of SMA actuators? In aerospace engineering, for example, they are used in deployable structures such as antennas and control surfaces that need precise actuation with minimal weight addition.

In the medical field, Nitinol's biocompatibility has paved the way for advancements in stents and guidewires that adapt dynamically within the human body—a perfect illustration of how is Nitinol used in actuators? Moreover, robotics has embraced SMA technology by integrating these smart materials into soft robotic systems where flexibility and adaptability are paramount.

Nitinol’s versatility exemplifies why it's at the forefront of modern technological innovations involving shape memory alloy actuators (SMA). As industries continue exploring new frontiers with smart materials powered by this incredible alloy, we can expect even more groundbreaking developments on the horizon.

Applications of SMA Actuators in Industry

Shape memory actuators (SMAs) are revolutionizing various industries by harnessing the unique properties of shape memory alloys, particularly Nitinol. These smart materials with great forces have found applications in aerospace, medical devices, and robotics, showcasing their versatility and effectiveness. Let’s dive deeper into how these remarkable materials are making waves across different sectors.

Aerospace Innovations Using SMA

In the aerospace industry, the use of shape memory actuators is nothing short of groundbreaking. What is a shape memory actuator? It’s a device that can change its shape in response to temperature changes, making it ideal for applications where space and weight are critical factors. From morphing wing structures that enhance aerodynamic efficiency to deployable satellite systems that minimize launch mass, SMA actuators are at the forefront of aerospace innovations.

These SMA actuators not only contribute to lighter designs but also improve performance through precise control mechanisms. Engineers can rely on Nitinol's unique properties for applications such as adaptive flight control surfaces and active vibration suppression systems. The ability to effectively manage forces while maintaining structural integrity makes SMAs a game-changer in modern aviation technology.

Medical Devices That Rely on SMAs

The medical field has embraced shape memory alloys with open arms, as they provide solutions that were previously thought impossible. What is an SMA actuator? In medicine, these devices are used in stents that expand within blood vessels or surgical tools that require minimal invasiveness yet maximum precision. The adaptability and responsiveness of Nitinol make it an excellent choice for creating life-saving medical devices.

Moreover, SMAs offer significant advantages over traditional materials due to their biocompatibility and ability to operate without external power sources once activated by body heat or other stimuli. This leads to longer-lasting implants and devices that can function effectively over time without requiring maintenance or replacement. The applications of SMA actuators extend from orthopedic implants to minimally invasive surgical instruments—transforming patient care one innovation at a time.

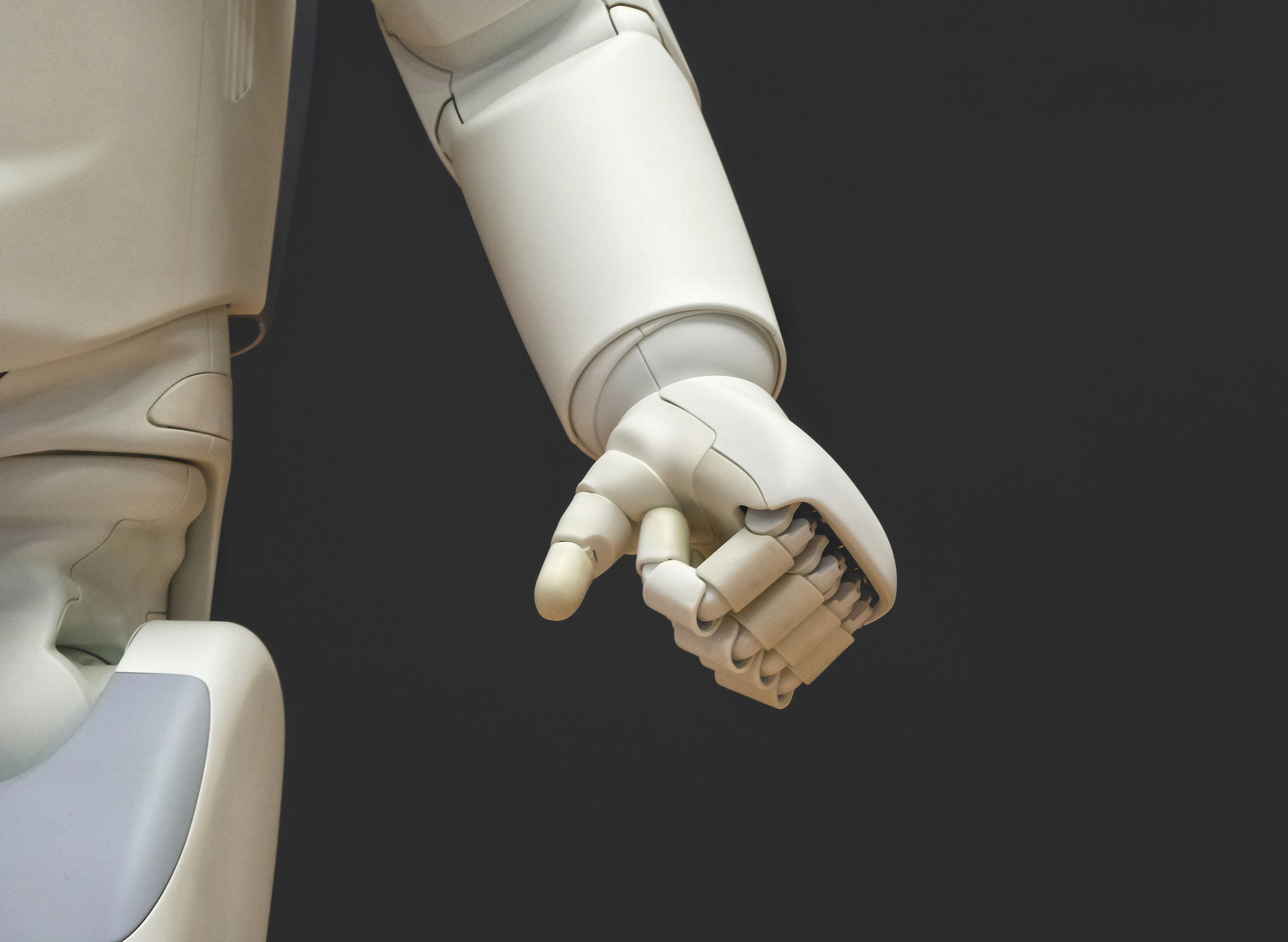

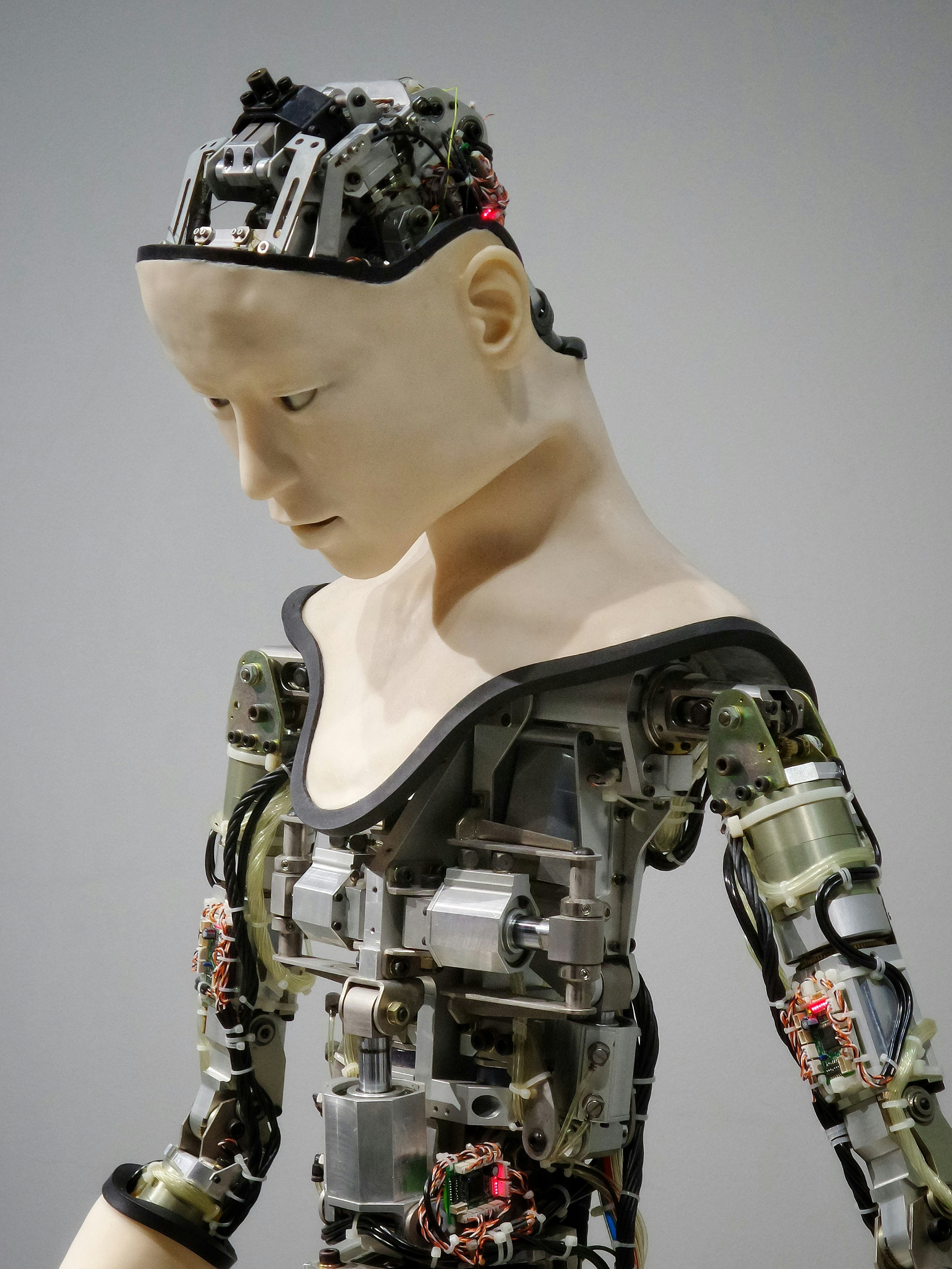

Robotics and Automation Powered by SMAs

In the realm of robotics and automation, what is a shape memory actuator? It’s essentially the secret sauce behind many robotic movements—enabling machines not only to perform tasks but also adapt dynamically to their environments. Shape memory alloy actuators allow robots to achieve complex motions with minimal energy consumption while maintaining high precision and reliability.

From soft robotics utilizing SMAs for gentle manipulation tasks in delicate environments like hospitals or homes to industrial automation where speed and efficiency matter most—SMA technology is proving invaluable across various robotic applications. Furthermore, the lightweight design associated with Nitinol enables robots equipped with these smart materials with great forces to navigate challenging terrains effortlessly while conserving energy during operation.

Advantages of Using Shape Memory Alloys

Shape memory alloys (SMAs) offer a unique blend of properties that make them highly advantageous in various applications. One of the most notable benefits is their lightweight design coupled with impressive performance capabilities. This combination allows for the creation of shape memory actuators that are not only efficient but also versatile in their use across different industries.

Lightweight Design and High Performance

When we talk about what is a shape memory actuator, it's essential to highlight how SMAs contribute to a lightweight design without compromising on strength. These materials, particularly Nitinol, enable devices to perform complex movements while maintaining minimal weight, which is crucial in sectors like aerospace and robotics. The high performance of SMA actuators stems from their ability to generate significant forces relative to their size, making them ideal for applications where space and weight are at a premium.

Energy Efficiency in Operation

Energy efficiency is another hallmark of SMA technology; these smart materials with great forces can operate effectively while consuming less energy than traditional actuators. What is an SMA actuator? It’s one that harnesses the unique properties of shape memory alloys to convert thermal energy into mechanical work efficiently. This means that devices powered by shape memory actuators can maintain functionality over extended periods without draining resources, making them not just smart but also sustainable.

Maintenance and Longevity of SMA Actuators

One of the standout features when considering what are the applications of SMA actuators is their low maintenance requirements and longevity. Shape memory alloy actuators are known for their durability; they can withstand numerous cycles without significant wear or degradation in performance. This reliability translates into reduced downtime and lower operational costs, making SMAs an attractive option for industries looking to enhance productivity while minimizing maintenance efforts.

Future Trends in Shape Memory Actuator Technology

The future of shape memory actuator technology is brimming with potential, as innovations continue to emerge across various sectors. From aerospace to healthcare, the applications of SMA actuators are expanding rapidly, showcasing the versatility and effectiveness of smart materials with great forces. As industries seek more efficient and adaptable solutions, the role of shape memory alloys (SMAs) will undoubtedly become increasingly critical.

Emerging Applications Across Sectors

What is a shape memory actuator? It’s not just a fancy term; it’s a game-changer in multiple fields! In aerospace, for instance, SMA actuators are being integrated into wing morphing technologies that enhance fuel efficiency and performance. Meanwhile, in the medical sector, these actuators are revolutionizing minimally invasive procedures by enabling devices that can change shape inside the body.

Furthermore, robotics is another area where SMA actuators shine brightly. With their ability to provide precise movements and adjustments, they are paving the way for more advanced robotic systems capable of performing complex tasks. The applications of SMA actuators seem limitless as industries explore creative ways to harness their unique capabilities.

Innovations by GEE SMA in Nitinol Development

When it comes to advancements in Nitinol development, GEE SMA is leading the charge with groundbreaking innovations. By enhancing the properties of Nitinol used in actuators, they are pushing the boundaries of what is possible with shape memory alloys. This includes creating new alloy compositions that improve response times and increase operational efficiencies for various applications.

Moreover, GEE SMA has been focusing on integrating smart sensors within their SMA actuators to provide real-time feedback during operation. This means that users can monitor performance dynamically and make adjustments as necessary—an exciting leap forward! As we ask ourselves how Nitinol is used in actuators today and tomorrow, companies like GEE SMA are at the forefront of this evolution.

Sustainability in SMA Actuator Production

Sustainability is becoming a key focus across all industries—including those utilizing shape memory actuator technology. What are the implications for producing SMAs? Manufacturers are exploring eco-friendly materials and processes that reduce waste while maintaining high performance standards for their products.

Additionally, there’s an increasing emphasis on recycling old SMAs to create new components without compromising quality or functionality. This approach not only conserves resources but also aligns with global sustainability goals—making it a win-win situation! As we embrace these practices within shape memory actuator production, we move closer to a greener future while still enjoying all benefits these remarkable smart materials offer.

Conclusion

In wrapping up our exploration of shape memory actuators, it’s clear that these remarkable devices are not just a novelty but a significant advancement in modern technology. The impact of shape memory actuators extends across various industries, enhancing efficiency and functionality in ways we could only dream of a few decades ago. As we continue to innovate and discover new applications for these smart materials with great forces, the potential for shape memory alloy actuators seems limitless.

The Impact of Shape Memory Actuators

The impact of shape memory actuators is profound, transforming the landscape of engineering and design. These SMA actuators are redefining performance standards in sectors such as aerospace, medicine, and robotics by providing solutions that are both efficient and compact. With their ability to convert thermal energy into mechanical work, they enable innovations that were previously unattainable—truly a game changer for what is a shape memory actuator?

Exploring the Versatility of SMA Technology

Exploring the versatility of SMA technology reveals its adaptability across numerous applications, from intricate medical devices to robust aerospace components. What is an SMA actuator? It's not just about movement; it’s how these devices seamlessly integrate into existing systems while enhancing their capabilities. This flexibility allows engineers to leverage the unique properties of Nitinol in actuators, ensuring optimal performance tailored to specific needs.

Embracing the Future of Smart Materials

Embracing the future of smart materials means acknowledging that we are only scratching the surface with what is possible through shape memory alloys. As research progresses and new innovations emerge—such as advancements by companies like GEE SMA—the possibilities for Nitinol's application in various fields continue to expand exponentially. The future holds exciting prospects for SMA actuators as they pave the way for sustainable solutions while maintaining high performance and reliability.