Introduction

In the ever-evolving landscape of healthcare materials, Nitinol SE508 stands out as a revolutionary alloy that is transforming medical practices. This unique shape memory alloy (SMA) boasts remarkable properties that enable it to return to a predetermined shape when heated, making it invaluable in various applications. From stents to guidewires, Nitinol SE508 is not just a material; it's a game-changer in patient care.

Understanding Nitinol SE508 in Healthcare

Nitinol SE508 has garnered attention for its exceptional flexibility and resilience, which are critical in medical devices where precision and reliability are paramount. Its biocompatibility ensures that it can be safely used within the human body without adverse reactions, thus paving the way for innovative treatments. As healthcare continues to embrace advanced technologies, understanding the significance of Nitinol SE508 becomes essential for both practitioners and patients alike.

The Role of Shape Memory Alloys

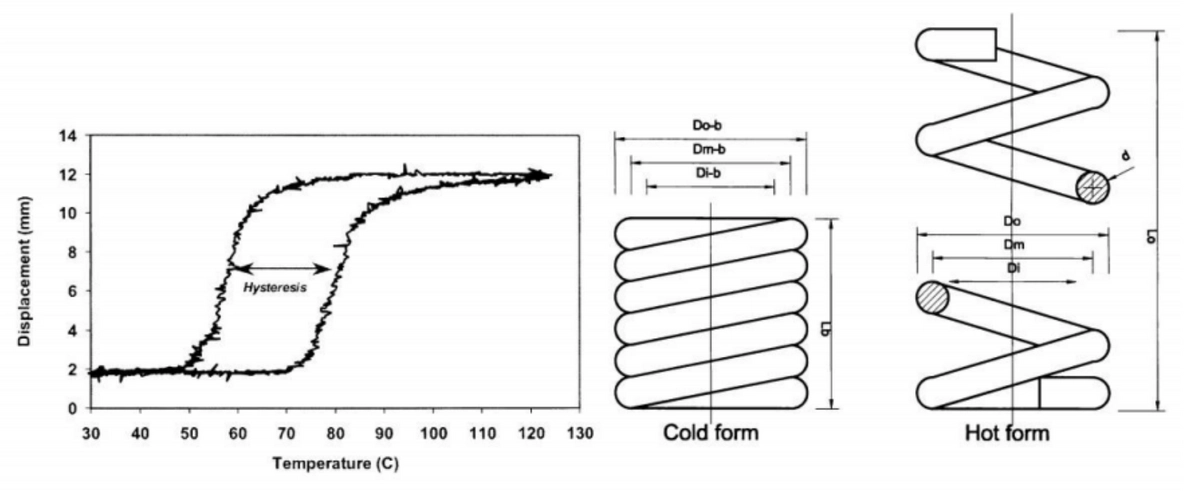

Shape memory alloys like Nitinol SE508 operate on fascinating principles of physics and materials science, allowing them to remember their original form after being deformed. This capability opens doors for minimally invasive procedures where traditional rigid materials may fall short due to their lack of adaptability. The versatility of shape memory alloys is not just theoretical; it's actively transforming surgical techniques and improving patient outcomes across various specialties.

Innovative Applications of Nitinol SE508

The potential applications for Nitinol SE508 are vast and varied, ranging from cardiovascular devices such as stents to orthopedic implants designed for precise alignment during healing processes. Tensile Nitinol SE508 wires play an integral role in multiple products by providing strength while maintaining flexibility—qualities that are crucial in dynamic environments like the human body. As we explore these innovative uses further, it becomes clear that this alloy is set to redefine standards in modern medicine.

Unique Properties of Nitinol SE508

Nitinol SE508 is a remarkable material that stands out in the realm of medical technology due to its unique properties. These characteristics, including exceptional flexibility and biocompatibility, make it an ideal choice for a variety of applications in healthcare. Moreover, the innovative use of Nitinol SE508 tubing has revolutionized how medical devices are designed and utilized.

Exceptional Flexibility and Shape Memory

One of the most fascinating features of Nitinol SE508 is its exceptional flexibility combined with shape memory capabilities. When subjected to specific temperature changes, this alloy can return to its original shape after being deformed, making it incredibly versatile for various medical applications. This property allows for the creation of devices that can adapt to complex anatomical structures within the human body, enhancing their effectiveness.

The ability of Nitinol SE508 to remember its original form means that it can be used in minimally invasive procedures where traditional materials might struggle. Imagine a stent that expands precisely when needed or a guidewire that navigates through intricate pathways without breaking—this is the magic of tensile Nitinol SE508 wires at work! Such flexibility not only improves patient outcomes but also minimizes recovery times.

Biocompatibility and Its Importance

Biocompatibility is crucial when it comes to materials used inside the human body, and Nitinol SE508 excels in this aspect as well. The alloy's composition ensures that it does not provoke adverse reactions when implanted or used in contact with bodily tissues. This characteristic makes it suitable for long-term applications such as stents, orthopedic implants, and other surgical devices.

Understanding what makes Nitinol biocompatible involves delving into its unique structure and chemical properties; it's engineered to integrate seamlessly with biological systems while maintaining mechanical integrity over time. The importance of biocompatibility cannot be overstated—it directly influences patient safety and device longevity! As healthcare continues to prioritize patient-centric solutions, materials like Nitinol SE508 will play an increasingly vital role.

Nitinol SE508 Tubing in Medical Devices

Nitinol SE508 tubing has opened up new avenues for innovation in medical device design due to its unique properties. This specialized tubing offers enhanced performance over traditional materials by providing both strength and flexibility—two critical factors when designing devices intended for delicate procedures or challenging environments within the body.

The application possibilities are vast: from catheters designed to navigate tight spaces effortlessly to advanced delivery systems capable of deploying drugs precisely where needed—Nitinol SE508 tubing is at the forefront! Furthermore, understanding what is the composition of Nitinol 55 helps manufacturers optimize their products according to ASTM standards tailored specifically for this alloy.

In summary, whether it's through exceptional flexibility or unmatched biocompatibility, Nitinol SE508 demonstrates why it's becoming a go-to material in modern medicine today.

Composition of Nitinol SE508

Understanding the composition of Nitinol SE508 is crucial for appreciating its unique properties and applications in healthcare. Nitinol, a nickel-titanium alloy, exhibits remarkable shape memory and superelasticity, making it a favorite in medical devices. But what exactly goes into making this extraordinary material?

What is the Composition of Nitinol 55?

Nitinol 55 specifically refers to a variant of Nitinol that contains approximately 55% nickel and 45% titanium. This precise composition allows for optimal performance characteristics, including enhanced flexibility and shape memory capabilities. The balance between nickel and titanium is critical; too much or too little can significantly alter its mechanical properties.

When considering applications such as Nitinol SE508 tubing, the specific ratios ensure that the material can withstand various stresses while still returning to its original shape after deformation. This exceptional quality makes it highly sought after for use in stents and other medical implants where reliability is paramount. Ultimately, understanding What is the composition of Nitinol 55? helps clarify why it's favored in innovative healthcare solutions.

Comparison of Nitinol and Other Alloys

When comparing Nitinol to other alloys like stainless steel or titanium, several key differences emerge that highlight its advantages. For instance, while titanium is known for its strength, many wonder: Is Nitinol stronger than titanium? The answer often lies in context; while pure strength might favor titanium, when you factor in elasticity and shape recovery under stress, Nitinol SE508 shines.

Moreover, unlike conventional materials that may experience fatigue over time with repeated stress cycles, tensile Nitinol SE508 wires maintain their integrity far better due to their unique superelastic properties. This characteristic enables them to be used effectively in minimally invasive procedures where flexibility without compromising strength is essential. In summary, comparing these alloys reveals why many medical professionals are turning to nitinol for advanced applications.

The ASTM Standards for Nitinol

The American Society for Testing and Materials (ASTM) has established various standards governing materials used in medical devices—including nitinol—ensuring safety and efficacy across products made from this alloy. Specifically relevant here are questions like What is the ASTM for nitinol? which leads us to ASTM F2063—a standard that outlines requirements specifically tailored for nitinol wire used in medical devices.

This standard addresses aspects such as mechanical properties, chemical composition limits, and surface finish requirements necessary for ensuring biocompatibility—an essential factor when considering materials implanted within the human body like those found in Nitinol SE508 tubing applications. Compliance with these standards not only fosters trust among manufacturers but also assures patients that they are receiving safe and effective treatments.

As we delve deeper into understanding these components—the composition of nitinol 55 alongside comparisons with other alloys—and regulatory standards like ASTM F2063—we gain a clearer picture of why nitinol continues to be a game-changer within modern medicine.

Performance Benefits Over Traditional Materials

When it comes to comparing materials used in medical devices, Nitinol SE508 stands out for its unique performance benefits over traditional materials like titanium. While titanium has long been a staple in the industry due to its strength and biocompatibility, Nitinol SE508 offers additional advantages that can enhance patient outcomes. Its remarkable shape memory and flexibility make it a game-changer in various applications, particularly when it comes to minimizing invasiveness during procedures.

Is Nitinol Stronger Than Titanium?

The question of whether Nitinol is stronger than titanium often arises in discussions about material selection for medical devices. While both materials have impressive strength characteristics, the answer depends on the specific application and design requirements. For instance, tensile Nitinol SE508 wires exhibit superior elasticity and fatigue resistance compared to conventional titanium alloys, making them ideal for dynamic applications where flexibility is crucial.

Moreover, it's essential to consider what is the composition of Nitinol 55? This specific alloy contains nickel and titanium in a precise ratio that allows it to return to its original shape after deformation—a property not found in titanium alone. Thus, while titanium may have higher tensile strength under certain conditions, the unique properties of Nitinol SE508 often make it more suitable for applications requiring repeated flexing or bending.

The Advantages of Tensile Nitinol SE508 Wires

Tensile Nitinol SE508 wires bring several advantages that set them apart from traditional materials used in medical devices. One significant benefit is their ability to undergo large deformations without permanent damage, which enhances their longevity and reliability in various applications. This characteristic makes tensile nitinol SE508 wires particularly valuable for devices like stents and guidewires that need to navigate complex anatomical structures with precision.

Another advantage lies in their biocompatibility—Nitinol SE508 Tubing can be safely implanted within the human body without adverse reactions. This aspect is critical when considering what is the ASTM for Nitinol? Compliance with ASTM standards ensures that these materials meet rigorous safety and performance criteria required by regulatory bodies. Thus, healthcare providers can trust that devices made from tensile nitinol will perform reliably while maintaining patient safety.

Applications in Minimally Invasive Procedures

Minimally invasive procedures are revolutionizing how healthcare professionals approach surgical interventions, and Nitinol SE508 plays a pivotal role in this transformation. The exceptional flexibility of nitinol tubing enables surgeons to navigate through tight spaces with ease while minimizing trauma to surrounding tissues—something traditional rigid materials struggle with effectively. As such, applications involving stents or embolization coils benefit significantly from using this innovative material.

Furthermore, understanding what is nitinol per ASTM F2063 helps ensure that products meet stringent quality standards necessary for medical use. By adhering to these guidelines, manufacturers can produce reliable devices designed specifically for minimally invasive techniques using nitinol tubing or other forms of this versatile alloy. The result? Enhanced patient care through reduced recovery times and improved surgical outcomes—truly a win-win scenario!

Regulatory Standards and Compliance

In the world of medical devices, adhering to regulatory standards is not just a box to check; it’s a lifeline for patient safety and product efficacy. Nitinol SE508, particularly in its various forms like Nitinol SE508 Tubing, must comply with stringent regulations that ensure its reliability in healthcare applications. Understanding these regulations helps manufacturers navigate the complex landscape of medical device compliance while ensuring that their products meet the necessary safety standards.

What is Nitinol Per ASTM F2063?

Nitinol per ASTM F2063 refers to a specific standard that outlines the requirements for nickel-titanium shape memory alloys used in medical applications. This standard ensures that Nitinol SE508 maintains its unique properties, such as exceptional flexibility and shape memory characteristics, which are crucial for effective performance in medical devices. By adhering to this standard, manufacturers can guarantee that their products meet industry expectations for quality and performance, making it an essential reference point in discussions about What is the ASTM for Nitinol?

Navigating Medical Device Regulations

Navigating the maze of medical device regulations can feel like trying to solve a Rubik's Cube blindfolded—complicated and daunting! For products made from materials like Nitinol SE508, understanding regulatory pathways is vital for market entry and compliance with health authorities such as the FDA or EMA. Companies must be well-versed in guidelines concerning biocompatibility, manufacturing processes, and clinical evaluations to ensure that their offerings—like tensile Nitinol SE508 wires—are safe and effective.

Importance of Quality Control in Nitinol Products

Quality control isn't merely an afterthought; it's at the heart of producing reliable Nitinol products for healthcare applications. Rigorous quality assurance processes ensure that every batch of Nitinol SE508 meets predefined specifications regarding mechanical properties and biocompatibility. This attention to detail is especially important when considering questions like Is Nitinol stronger than titanium? because only through stringent quality control can manufacturers confidently assert their materials' superiority.

GEE SMA: Leading the Way in Nitinol

In the ever-evolving world of medical technology, GEE SMA stands out as a pioneer in the development and application of Nitinol SE508. Their commitment to quality and innovation ensures that healthcare providers have access to cutting-edge materials that improve patient outcomes. With a focus on Nitinol SE508 Tubing and its unique properties, GEE SMA is redefining standards in medical device manufacturing.

Commitment to Quality and Innovation

GEE SMA's dedication to quality is evident in their rigorous testing processes, which ensure that every batch of Nitinol SE508 meets or exceeds industry standards. By adhering to ASTM regulations, such as those outlined for Nitinol per ASTM F2063, they guarantee the reliability and safety of their products. Furthermore, their innovative approach means they are constantly exploring new applications for Nitinol SE508 Tubing, pushing the boundaries of what's possible in healthcare.

Innovation at GEE SMA isn't just about creating new products; it's also about enhancing existing ones. They leverage advanced technologies to refine the composition of their materials, including what is the composition of Nitinol 55?, ensuring optimal performance in various medical applications. This commitment translates into stronger and more flexible solutions that outperform traditional materials like titanium—prompting many to ask: is Nitinol stronger than titanium?

Tailoring Solutions for Unique Medical Needs

Recognizing that each medical application has its own set of requirements, GEE SMA excels at tailoring solutions specifically designed for unique medical needs. Their expertise allows them to customize tensile nitinol SE508 wires for multiple products ranging from stents to guidewires, making them an invaluable partner in healthcare innovation. This adaptability not only meets but anticipates market demands, ensuring healthcare professionals have exactly what they need when they need it.

By engaging closely with clinicians and engineers during product development, GEE SMA can address specific challenges faced by end-users effectively. This collaborative approach fosters trust and ensures that every solution is practical and user-friendly while maintaining high performance standards inherent in nitinol SE508 Tubing. The result? A suite of products engineered with precision for diverse applications.

Addressing Customer Requirements Swiftly

In today's fast-paced medical landscape, responsiveness is key—and GEE SMA delivers just that! Their streamlined processes enable quick turnaround times on orders without sacrificing quality or compliance with regulatory standards like those established by ASTM for Nitinol products. Whether a client requires customized tensile nitinol SE508 wires or specialized tubing designs, GEE SMA prides itself on being able to meet customer requirements swiftly.

Moreover, their dedicated customer service team ensures clear communication throughout the entire process—from initial inquiry through delivery—making it easy for customers to navigate complex regulations such as what is Nitinol per ASTM F2063? This level of support not only enhances customer satisfaction but also reinforces GEE SMA's reputation as a leader in the nitinol market.

With a robust infrastructure designed around quality control measures and rapid response capabilities, GEE SMA continues to set benchmarks within the industry while solidifying its position as a go-to source for all things related to nitinol SE508.

Conclusion

In the ever-evolving landscape of medical technology, Nitinol SE508 stands out as a transformative material that promises to enhance patient outcomes and revolutionize treatment methodologies. As we look toward the future, the potential applications of Nitinol SE508 in medicine appear limitless, from advanced surgical tools to innovative implant designs. This alloy not only embodies cutting-edge engineering but also addresses critical healthcare needs with its unique properties and performance benefits.

The Future of Nitinol SE508 in Medicine

The future of Nitinol SE508 in medicine is bright, with ongoing research exploring its capabilities beyond current applications. Innovations such as Nitinol SE508 tubing are paving the way for more efficient delivery systems and minimally invasive procedures that can significantly reduce recovery times for patients. As we delve deeper into questions like “What is the composition of Nitinol 55?” or “What is the ASTM for Nitinol?”, it becomes clear that understanding these materials will be crucial in harnessing their full potential.

Transforming Patient Care with Nitinol

Nitinol SE508 has already begun transforming patient care by enabling less invasive surgical techniques and improving device functionality. With features like exceptional flexibility and shape memory, devices made from tensile nitinol SE508 wires are not only easier to use but also provide better outcomes for patients undergoing complex procedures. This shift towards utilizing advanced materials leads to quicker recoveries and enhances overall patient satisfaction, proving that innovation in material science directly correlates with improved healthcare experiences.

Why Nitinol SE508 is a Game-Changer

Nitinol SE508 is undeniably a game-changer in the realm of medical devices due to its unique combination of strength and biocompatibility—qualities that raise important questions like “Is Nitinol stronger than titanium?” The answer often leans toward yes, especially when considering specific applications where flexibility matters most. Moreover, compliance with standards such as “What is Nitinol per ASTM F2063?” ensures that products made from this alloy meet rigorous quality benchmarks, further solidifying its place at the forefront of medical innovations.