Introduction

Welcome to the fascinating world of Nitinol Alloy, a remarkable material that has revolutionized various industries with its unique properties. From the wonders of Nitinol wire to exploring its wide range of metal applications, this incredible nickel titanium alloy continues to amaze and inspire innovation.

Understanding Nitinol Alloy

Nitinol alloy, nickel titanium, is a special type of metal that exhibits extraordinary shape memory and superelasticity properties. Composed of nearly equal parts nickel and titanium, this alloy has gained popularity for its ability to return to its original shape after deforming, making it highly versatile for numerous applications.

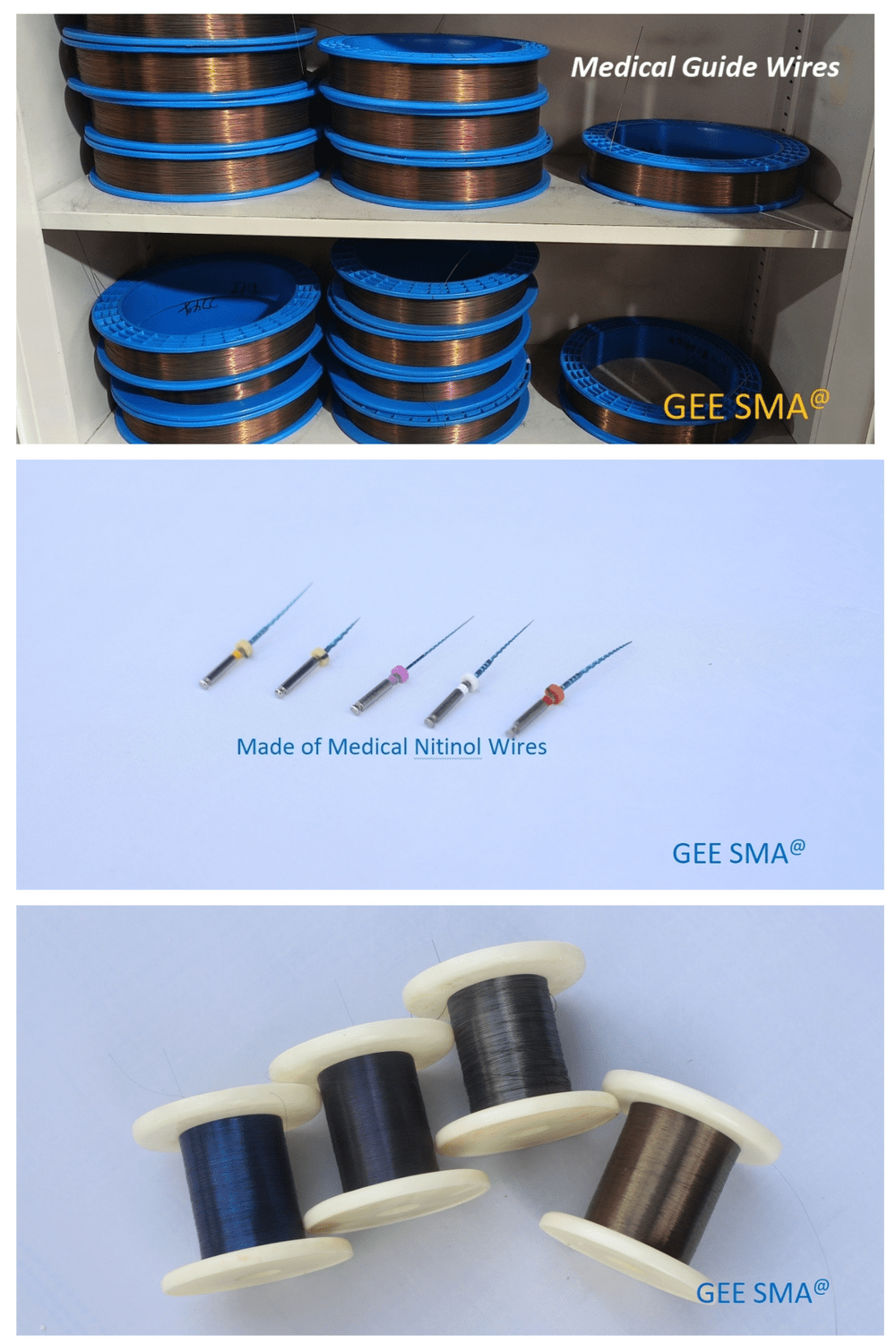

The Wonders of Nitinol Wire

Nitinol wire is a marvel in itself, known for its remarkable flexibility and resilience. Its unique ability to remember and recover its original shape after undergoing significant deformation makes it an ideal material for various medical devices, engineering applications, and consumer products.

Nitinol wire's incredible properties have led to its use in various applications. In the medical field, Nitinol is commonly used in stents, orthodontic wires, and guidewires due to its biocompatibility and shape memory. Additionally, in engineering, Nitinol wire is utilized in actuators, sensors, and robotics to exert substantial force while maintaining flexibility. Furthermore, consumer products such as eyeglass frames and mobile phone antennas benefit from the durability and resilience of Nitinol wire.

Exploring Nitinol Metal Applications

Nitinol metal has vast and diverse applications, ranging from medical implants and orthodontic treatment to actuators in robotics and aerospace engineering. Its ability to withstand extreme conditions while maintaining its shape makes it an invaluable resource across different industries.

The Fascinating Nickel Titanium

Nickel titanium alloy is truly a wonder material that continues to push the boundaries of modern technology. With its impressive capabilities and innovation potential, the possibilities for nitinol applications are limitless.

Nickel titanium alloy, also known as nitinol, is a shape-memory alloy that exhibits superelasticity and can return to its original shape after deforming. This unique property makes it ideal for various applications, from medical devices like stents and orthodontic wires to actuators and robotics. Nitinol's versatility allows for the development of innovative products that can adapt to changing conditions, making it an exciting material for future technological advancements.

What is Nitinol Alloy?

Nitinol alloy, also known as nickel titanium or NiTi, is a remarkable material with unique properties that make it a game-changer in various industries. Composed of nearly equal parts nickel and titanium, nitinol exhibits shape memory and superelasticity, making it highly versatile for a wide range of applications.

Definition and Composition

Nitinol alloy combines approximately 50% nickel and 50% titanium. This precise composition gives nitinol exceptional properties, allowing it to return to its original shape after deforming. The alloy's ability to remember and recover its shape makes it invaluable in medicine, engineering, and consumer products.

Nitinol's shape memory properties result from its unique crystalline structure, which allows it to undergo reversible martensitic phase transformations. This means that when nitinol is deformed at low temperatures, it can return to its original shape when heated above a certain temperature. This remarkable behavior has led to the development of medical devices such as stents and orthodontic wires that can be easily inserted into the body in a compact form and then expand to their original shape once in place.

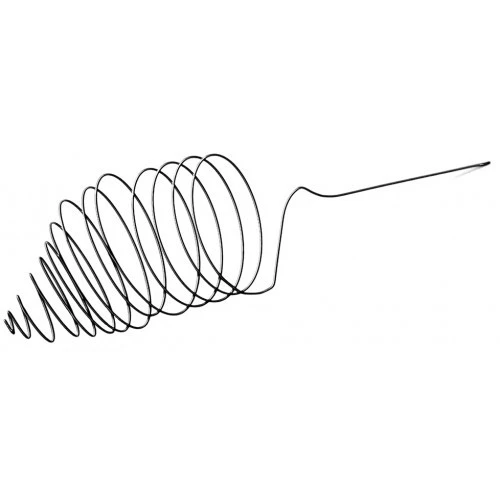

Shape Memory Properties

One of the most fascinating aspects of nitinol alloy is its shape memory effect. This means that the material can remember its original shape and return to it when subjected to heat or stress. Whether used in medical devices or aerospace components, this unique property allows nitinol to adapt to various conditions without losing its structural integrity. Additionally, nitinol exhibits superelasticity, meaning it can undergo large deformations and still return to its original shape without permanent damage. This makes it an ideal material for applications where flexibility and resilience are crucial, such as in minimally invasive medical implants or high-performance actuators.

Superelasticity

In addition to its shape memory properties, nitinol alloy exhibits superelasticity, enabling it to undergo substantial deformation without permanent damage. This makes it ideal for applications where flexibility and resilience are essential, such as in orthodontic wires or stents used in medical procedures. The ability of nitinol to withstand significant deformation and return to its original shape is a game-changer in the medical field, allowing for the creation of innovative devices that can adapt to the body's movements without causing harm. Furthermore, the superelasticity of nitinol opens up possibilities for advanced engineering solutions in other industries, such as aerospace and automotive, where durable and flexible materials are highly sought.

By understanding the definition and composition of nitinol alloy, its remarkable shape memory properties and superelasticity, we can begin to appreciate the endless possibilities this extraordinary material offers in various industries.

How Nitinol Alloy Works

Nitinol alloy, nickel titanium, is a remarkable material with unique shape memory and superelastic properties. When discussing how nitinol alloy works, it's essential to understand its transformation temperatures, which refer to the points at which the material changes shape. At lower temperatures, nitinol is in its martensitic phase and can be deformed. However, when heated above its transition temperature, it reverts to its original shape, showcasing its remarkable memory capabilities.

A key aspect of nitinol alloy is its ability to undergo deformation and recover its original shape when subjected to heat. This property makes it ideal for various applications requiring precise movements, such as medical devices and actuators. Whether used in stents or robotic actuators, nitinol's ability to recover from deformation sets it apart from other materials.

GEE SMA has been at the forefront of developing innovative nitinol technology that further enhances the material's capabilities. Their advancements in shaping and processing nitinol wire have led to more intricate designs and improved performance in various applications. From medical devices to aerospace components, GEE SMA's innovative approach has expanded the possibilities for utilizing nitinol alloy in new and exciting ways.

With an understanding of how nitinol alloy works and GEE SMA's commitment to pushing the boundaries of what this incredible material can achieve, it's clear that we are only scratching the surface of its potential. As more industries recognize the benefits of using nickel titanium in their products and designs, we can expect to see even more groundbreaking applications emerge shortly. The future of nitinol alloy is undoubtedly bright as we continue unlocking its full potential for innovation and advancement across various fields.

Nitinol Alloy in Medicine

Nitinol alloy has revolutionized medicine with its remarkable properties and versatility. Medical devices and implants made from nitinol offer superior biocompatibility and corrosion resistance, making them ideal for a wide range of medical applications. From surgical tools to bone fixation devices, nitinol has become indispensable in modern healthcare.

1. Medical Devices and Implants

Nitinol alloy is widely used in producing various medical devices and implants due to its exceptional biocompatibility and shape memory properties. This unique combination allows for the creation of intricate designs that can conform to the body's natural contours, providing patients with improved comfort and better outcomes. From cardiovascular to orthopedic applications, nitinol is pivotal in advancing medical technology.

2. Stents and Guidewires

One of the most well-known applications of nitinol in medicine is in the manufacture of stents and guidewires. Nitinol stents treat narrow or weakened arteries by providing structural support and maintaining blood flow, while nitinol guidewires enable precise navigation during minimally invasive procedures. Nitinol's flexibility, durability, and resilience make it an ideal material for these critical medical interventions.

3. Orthodontic Treatment

In orthodontics, nitinol wire has transformed traditional braces by offering patients a more comfortable and efficient treatment option. Nitinol's unique shape memory properties allow orthodontic wires to return to their original shape after being bent, exerting continuous gentle force on teeth for effective realignment. This innovative use of nitinol has significantly improved the orthodontic experience for both patients and practitioners.

With its groundbreaking applications in medicine, nitinol alloy continues to drive innovation across various healthcare disciplines. As researchers explore new ways to harness its potential, we can expect even more exciting developments to improve patient care and treatment outcomes.

Nitinol Alloy in Engineering

Nitinol alloy has revolutionized engineering with its remarkable properties and versatility. This incredible material has opened up a world of possibilities for engineers and designers, from actuators to eyeglass frames and aerospace applications.

1. Actuators and Robotics

Nitinol wire is widely used in actuators and robotics due to its unique shape memory properties. This allows for precise control of movement and positioning, making it ideal for robotic surgery, prosthetics, and industrial automation applications. The flexibility and durability of nitinol wire make it a top choice for engineers looking to create innovative solutions in these fields.

2. Eyeglass Frames

Nitinol metal's flexibility has made it a game-changer in the eyewear industry. Nitinol frames are lightweight and incredibly resilient, allowing for greater comfort and durability compared to traditional materials like plastic or metal. The material's shape-memory properties also ensure that eyeglass frames retain their shape even after being bent or twisted, making them an ideal choice for everyday use.

3. Aerospace Applications

In the aerospace industry, where reliability and performance are paramount, nitinol alloy has numerous applications. From components in aircraft engines to deployable structures in space exploration missions, the superelasticity and high fatigue resistance of nickel titanium make it an invaluable material for engineering solutions that require precision, strength, and resilience.

With its unparalleled combination of properties, including shape memory and superelasticity, nitinol alloy continues to push the boundaries of what is possible in engineering applications. Its widespread use in actuators, eyeglass frames, and aerospace technologies is a testament to its enduring impact on the field. As engineers continue to unlock the potential of this remarkable material, the future looks bright for nitinol alloy innovations!

Where Nitinol Alloy is Used

Nitinol alloy, known for its remarkable shape memory and superelasticity, has found diverse applications across various industries. Its unique properties make it an ideal material for use in the automotive industry, consumer electronics, and sports and recreation.

1. Automotive Industry

In the automotive industry, nitinol alloy is utilized in various components such as actuators, sensors, and brake systems. Its ability to withstand high temperatures and return to its original shape makes it an excellent choice for critical applications within vehicles. From engine components to safety features, nitinol wire enhances performance and reliability.

2. Consumer Electronics

Nitinol alloy has made significant contributions to the consumer electronics sector, where it is used in mobile phone antennas, headphone wires, and camera shutters. Its flexibility and durability enable the creation of innovative designs that enhance user experience while ensuring the longevity of electronic devices. Additionally, its resistance to corrosion makes it a preferred choice for various electronic components.

3. Sports and Recreation

In sports and recreation, nitinol alloy produces lightweight yet sturdy equipment such as archery bows, fishing rods, and bicycle frames. Its ability to withstand repeated deformation without permanent damage makes it an ideal material for high-performance sports gear. Furthermore, the unique properties of nickel titanium wire contribute to improved efficiency and durability in recreational equipment.

By leveraging the exceptional qualities of nitinol alloy across these industries, manufacturers can create products that offer superior performance and durability while pushing the boundaries of innovation.

Unlock the Potential of Nitinol Alloys

Nitinol alloy has revolutionized various industries with its remarkable properties, and the future of its applications looks incredibly promising. From medical devices to aerospace engineering, the potential for nitinol's versatility knows no bounds.

The Future of Nitinol Applications

As technology advances, the demand for nitinol alloy is expected to soar. With its shape memory and superelasticity, we can anticipate more innovative uses in robotics, smart materials, and even wearable tech. As industries seek to improve efficiency and performance, nitinol's unique properties make it an ideal material for creating advanced actuators and sensors in robotics. Additionally, the use of nitinol in smart materials will revolutionize the way we interact with our environment, from self-healing structures to adaptive optics. Furthermore, integrating nitinol into wearable tech will lead to the development of more comfortable and responsive devices that seamlessly integrate into our daily lives.

GEE SMA's Commitment to Quality

GEE SMA is dedicated to delivering top-notch nitinol products at competitive prices without compromising quality. Their expertise in nickel-titanium alloys ensures that customers receive reliable, high-performance materials for their specific applications.

GEE SMA's dedication to delivering top-notch nitinol products at competitive prices without compromising on quality is evident in its dedication to continuous improvement and innovation. By investing in cutting-edge technology and processes, GEE SMA ensures that its nickel titanium alloys meet the highest industry standards, providing customers with materials that exceed expectations. This commitment to excellence sets GEE SMA apart as a reliable and trusted partner for all nitinol alloy needs.

As researchers delve deeper into understanding nitinol's behavior at different temperatures and stress levels, we can look forward to unlocking even more potential uses for this incredible material. The possibilities are endless with this shape-shifting wonder!

Remember that our current knowledge does not limit the wonders of nitinol alloy; there is still much to discover and explore in this fascinating field!