Introduction

Nitinol composition is a fascinating blend of nickel and titanium, renowned for its remarkable properties and versatility. This unique alloy, also known as nitinol nickel titanium, has captured the imagination of scientists and engineers worldwide. Its ability to remember its original shape, known as shape memory alloy, has revolutionized industries from healthcare to aerospace. Let's delve into the power of nitinol alloys and explore their unparalleled strength and flexibility.

Understanding Nitinol Composition

Nitinol is primarily composed of nickel and titanium, with precise proportions that give it its extraordinary properties. This combination creates a material that exhibits a shape memory effect, allowing it to return to its original shape after being deformed. Nitinol wire is a key component in shaping this alloy into various forms used across different industries.

The Power of Nitinol Alloys

Nitinol titanium is a remarkable alloy possessing unique properties that make it invaluable across various industries.

- Shape memory effect: Nitinol alloys can return to their original shape after being deformed, thanks to a process called shape memory effect.

- Superelasticity: This property allows nitinol to undergo significant deformation without permanent damage, making it highly resilient.

- Titanium enhancement: Adding titanium to nitinol significantly improves its strength and durability, expanding its potential applications.

These exceptional characteristics make nitinol titanium an ideal material for medical devices, aerospace components, and robotic systems, among other fields.

Exploring Nitinol's Versatility and Strength

Nitinol alloys are versatile and incredibly strong, making them ideal for demanding applications in various fields. Nickel silver is often added to nitinol compositions to enhance their durability and resistance to corrosion. The resulting material is both malleable and robust, opening up new possibilities for innovation in engineering design.

Furthermore, the unique properties of nitinol alloys allow for shape memory and superelasticity, making them suitable for a wide range of applications. From medical devices like stents and guidewires to intricate components in aerospace engineering, nitinol's versatility and strength make it an attractive choice for demanding environments. The ability to return to a predetermined shape after deformation, along with its high fatigue resistance, sets nitinol apart as a material that can withstand the rigors of real-world use.

The Basics of Nitinol Composition

Nitinol composition comprises nitinol nickel titanium, a unique alloy that exhibits shape memory and superelasticity. This remarkable combination of properties makes it a popular choice in various industries. Nitinol nickel-titanium, also known as NiTi, is the foundation of nitinol alloys and is responsible for their exceptional performance.

Nitinol Nickel Titanium: The Foundation of Nitinol Alloys

Nitinol nickel titanium, or NiTi, is a smart material that can remember its original shape and return to it when heated—a property known as the shape memory effect. This makes it ideal for applications requiring precise movement or positioning, such as in medical devices and actuators. Additionally, nitinol nickel titanium exhibits superelasticity, allowing it to recover its original shape after undergoing significant deformation.

Nitinol nickel-titanium is also highly biocompatible, making it suitable for medical implants and devices without causing adverse reactions in the body. Its corrosion resistance and ability to withstand harsh physiological environments enhance its utility in medical applications. In addition, the unique combination of shape memory effect and superelasticity makes nitinol nickel titanium a versatile material tailored to meet specific design requirements, opening up new possibilities for innovative product development in various industries.

Titanium Metal: Enhancing Nitinol's Properties

The addition of titanium to nitinol alloys not only enhances their strength and corrosion resistance but also significantly improves their biocompatibility. This makes nitinol-titanium alloys an ideal choice for medical implants and devices, as they are well-suited for long-term use within the human body. The biocompatibility of these alloys reduces the risk of adverse reactions and ensures better patient outcomes, making them a valuable material in medical technology.

Nitinol Wire: A Key Component in Shape Memory Alloy

Nitinol wire plays a crucial role in creating shape memory alloy (SMA), which is at the heart of many innovative applications. This wire is meticulously engineered to exhibit the desired shape memory effect and superelasticity, allowing it to perform intricate functions in medical devices, robotics, and consumer products. The unique properties of nitinol wire make it an essential component in shaping the future of various industries.

Nitinol wire's unique properties make it an ideal material for minimally invasive medical devices. Its shape memory effect allows for the creation of self-expanding stents that can be inserted into blood vessels and then return to their original shape once in place. This capability reduces the need for invasive surgical procedures and promotes faster patient recovery times. Additionally, nitinol wire's superelasticity enables the development of flexible surgical tools to navigate through delicate anatomical structures with precision and ease.

The Advantages of Nitinol Alloys

Shape Memory Alloy: Nitinol's Unique Ability

Nitinol alloys are renowned for their shape memory properties, allowing them to return to their original shape after deforming. This unique ability makes nitinol ideal for applications such as orthodontic braces, stents, and eyeglass frames, where flexibility and resilience are essential.

Nitinol's shape memory properties are limited to returning to their original shape after being deformed and offer a unique combination of flexibility and strength. This makes nitinol titanium an ideal choice for applications that require both qualities, such as in the medical field for surgical tools and implants. The ability of nitinol to withstand deformation while maintaining its structural integrity is a testament to its exceptional material properties, making it a valuable asset in various industries.

Nitinol Titanium: Combining Flexibility and Strength

Nitinol titanium alloys offer remarkable flexibility and strength, making them suitable for various applications. From medical instruments to robotics, the versatility of nitinol titanium allows for the creation of innovative and durable products that can withstand demanding conditions.

Nitinol titanium alloys are also known for their shape memory and superelastic properties, allowing them to return to their original shape after deforming. This unique characteristic makes nitinol titanium ideal for applications such as stents in medical devices, where the material can expand and contract without losing its strength. Additionally, the biocompatibility of nitinol titanium further enhances its suitability for medical use, as it minimizes the risk of adverse reactions when implanted in the human body.

Nickel Silver Material: Adding Durability to Nitinol

Nickel silver is often incorporated into nitinol alloys to enhance their durability and resistance to corrosion. This addition further expands the potential applications of nitinol in industries such as aerospace, automotive engineering, and consumer electronics, where reliability is paramount.

Applications of Nitinol Composition

Nitinol composition has found groundbreaking applications in various industries, showcasing its remarkable versatility and strength. From revolutionizing healthcare to pushing the boundaries of innovation in aerospace and improving everyday life through consumer products, the impact of nitinol alloys is undeniable.

Nitinol in Medical Devices: Revolutionizing Healthcare

Nitinol nickel-titanium has become a game-changer in the medical industry. Its shape memory alloy properties allow for the creation of innovative devices such as stents, orthodontic wires, and surgical instruments. The flexibility and biocompatibility of nitinol titanium make it an ideal material for implants that adapt to the body's natural movements, leading to improved patient outcomes and recovery times. Its unique ability to return to its original shape after deformation ensures long-term durability and reliability in medical applications.

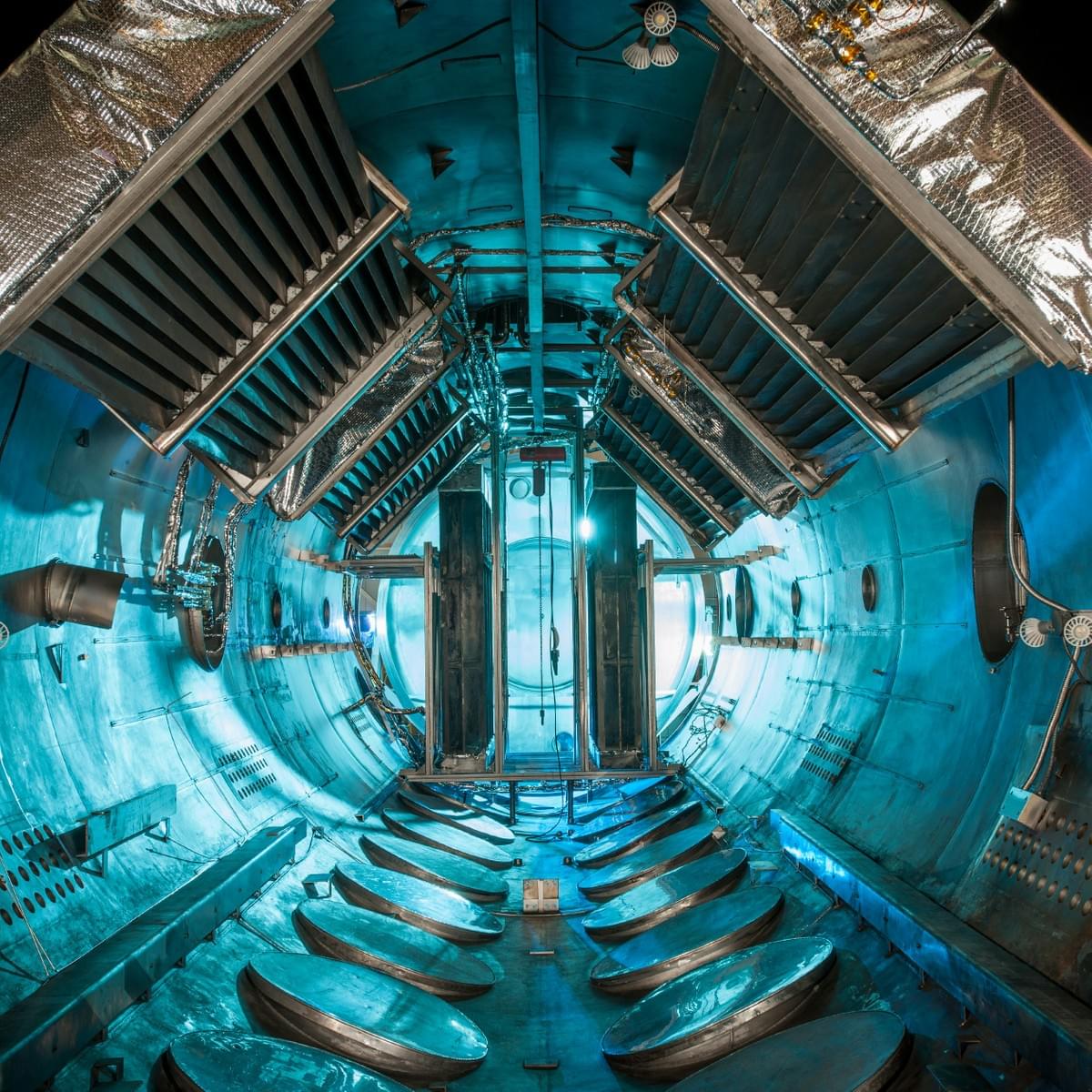

Nitinol in Aerospace: Pushing the Boundaries of Innovation

In aerospace, nitinol alloys are being utilized to develop cutting-edge technologies such as actuators and components for aircraft systems. The exceptional strength-to-weight ratio of titanium metal combined with the shape memory properties of nitinol wire allows for the creation of lightweight yet durable parts that contribute to improved fuel efficiency and enhanced performance in aviation. This remarkable combination is propelling the industry towards new frontiers of innovation.

Furthermore, nitinol in aerospace technology extends beyond just actuators and components. The shape memory properties of nitinol allow for the development of adaptive wing structures that can change shape in response to different flight conditions, leading to improved aerodynamics and fuel efficiency. This innovative application of nitinol is revolutionizing the design and performance of aircraft, pushing the boundaries of what was once thought possible in aviation engineering.

Nitinol in Consumer Products: Improving Everyday Life

Nitinol alloys offer a remarkable range of applications, extending beyond industrial use into our daily lives. This versatile material, combined with nickel silver, has found its way into consumer products, providing comfort, durability, and functionality benefits.

- Eyeglass frames: Flexible and resistant to damage.

- Dental braces: Comfortable and effective orthodontic treatment.

- Novelty items: Entertaining and unique products like self-bending spoons.

By incorporating nitinol into these everyday items, industries demonstrate the material's potential to revolutionize product design and enhance consumer experiences.

Manufacturing and Processing of Nitinol

Nitinol alloys are manufactured and processed by industry leaders like GEE SMA, who are at the forefront of nitinol manufacturing. With state-of-the-art facilities and cutting-edge technology, GEE SMA ensures the highest quality and precision in producing nitinol compositions that meet the most demanding specifications.

GEE SMA: Leading the Way in Nitinol Manufacturing

GEE SMA's expertise in nitinol composition has made it a leader in the industry, providing innovative solutions for various applications. Its commitment to research and development has allowed it to continuously improve its manufacturing processes, setting new standards for nitinol alloys worldwide.

Quality Control and Certification of Nitinol Alloys

Quality control is paramount in ensuring the reliability and performance of nitinol alloys. Rigorous testing and certification processes guarantee that each batch of nitinol composition meets the highest standards, providing customers with confidence in the material's consistency and durability.

Innovations in Nitinol Processing Techniques

Innovative processing techniques play a crucial role in shaping the properties of nitinol alloys. Advanced methods such as heat treatment, cold working, and shape setting manipulate the material's characteristics, allowing for customized solutions tailored to specific applications while maintaining the unique properties of nitinol compositions.

The Future of Nitinol

Advancements in Nitinol Technology

As the demand for innovative materials grows, so does the need for advancements in nitinol technology. Researchers and engineers are continuously exploring new ways to improve the properties of nitinol alloys, such as enhancing its shape memory capabilities and increasing its fatigue resistance. These advancements pave the way for exciting industrial developments, from healthcare to aerospace, where nitinol's unique properties can be harnessed for groundbreaking applications.

Nitinol's Role in Sustainable Development

Nitinol, a remarkable alloy, is emerging as a key player in sustainable development. This unique material offers several advantages that contribute to environmentally friendly practices:

- Recyclability: Nitinol alloys can be recycled multiple times without compromising their properties, reducing waste and conserving resources.

- Energy Efficiency: Nitinol's inherent properties, such as shape memory and superelasticity, enable energy-efficient applications across various industries.

- Durability: Nitinol's exceptional strength and resistance to corrosion contribute to longer product lifespans, minimizing the need for replacements and reducing environmental impact.

By harnessing the potential of nitinol, industries can make significant strides towards a more sustainable future.

The Growing Demand for Nitinol Alloys

As more industries recognize the benefits of nitinol composition, the demand for nitinol alloys continues to rise. From medical devices that improve patient outcomes to aerospace components that enhance performance and safety, nitinol's versatility and strength make it a sought-after material. With increasing applications across diverse sectors, the future looks bright for nitinol alloys as they become integral to technological advancements.

Embrace the Opportunities with Nitinol Technology

Mastering Nitinol Composition for Success

Nitinol composition is a complex yet powerful combination of nickel, titanium, and titanium metal, creating a shape memory alloy with incredible versatility and strength. Mastering the art of nitinol composition is essential for success in various industries, from healthcare to aerospace and consumer products.

Harnessing the Potential of Nitinol Alloys

The potential of nitinol alloys lies in their unique properties, such as shape memory and superelasticity. By harnessing these capabilities, industries can develop groundbreaking medical devices, innovative aerospace components, and high-performance consumer products that push the boundaries of what's possible.

As technology advances, embracing the opportunities presented by nitinol technology is crucial for staying ahead in the market. Whether through manufacturing breakthroughs or sustainable development initiatives, nitinol offers endless possibilities for innovation and growth.

Nitinol technology, with its shape memory and superelastic properties, has the potential to revolutionize the medical field. From minimally invasive surgical tools to stents and orthodontic wires, nitinol's unique characteristics allow for the development of innovative medical devices that improve patient outcomes and reduce recovery times. This opens up new opportunities for companies to tap into the growing healthcare market and positively impact people's lives.