Introduction

Nitinol memory wire, also known as nitinol nickel titanium, is a revolutionary shape memory alloy that has transformed various industries with its unique properties. This metal nitinol is composed of nearly equal parts titanium and nickel, resulting in a wire titanium that exhibits remarkable shape memory and superelasticity. The discovery of nitinol wire in the 1960s by the U.S. Naval Ordnance Laboratory marked a pivotal moment in material science, leading to the development of numerous applications across different fields.

The History of Nitinol Memory Wire

The fascinating history of nitinol dates back to 1959 when researchers at the Naval Ordnance Laboratory stumbled upon this extraordinary titanium nickel alloy while investigating unusual properties in metal alloys. They discovered that this new material could remember its original shape and return to it after being deformed, thus coining the term shape memory alloy. This breakthrough led to the development of nitinol memory wire, which has since been widely used in various industries for its exceptional properties.

Understanding the Science Behind Nitinol

Nitinol's unique characteristics stem from its crystal structure, which undergoes a reversible phase transformation when subjected to temperature changes or mechanical stress. This phase transition allows nitinol to exhibit both superelasticity and shape memory effect, making it an incredibly versatile material for engineering applications. Understanding these underlying scientific principles is crucial for harnessing the full potential of nitinol wire in different projects and industries.

Benefits of Using Nitinol Memory Wire

The versatility and reliability of nitinol memory wire make it an ideal choice for a wide range of applications. Its remarkable flexibility, durability, and biocompatibility have made it indispensable in medical devices such as stents, braces, and surgical tools. Furthermore, its unique properties have also found applications in robotics, aerospace engineering, actuators, sensors, and many other cutting-edge technologies.

Getting Started with Nitinol Memory Wire

When it comes to working with nitinol memory wire, choosing the right nitinol alloy is crucial for achieving the desired results. Nitinol, also known as nickel titanium or TiNi, is a shape memory alloy that exhibits unique properties such as superelasticity and the ability to return to a predetermined shape when subjected to heat. Different compositions of nitinol offer varying levels of flexibility, stiffness, and transformation temperatures, so it's important to select the alloy that best suits your specific application.

Choosing the Right Nitinol Alloy

Understanding the properties of different nitinol alloys is essential for selecting the right one for your project. Whether you need a more flexible or rigid wire, or if you require a specific transformation temperature range, there's a nitinol composition that fits your needs. For instance, a higher nickel content in the alloy results in lower transition temperatures and increased flexibility, while higher titanium content leads to stiffer wires with higher transition temperatures.

Understanding the properties of different nitinol alloys is essential for selecting the right one for your project. Whether you need a more flexible or rigid wire, or if you require a specific transformation temperature range, there's a nitinol composition that fits your needs. For instance, a higher nickel content in the alloy results in lower transition temperatures and increased flexibility, while higher titanium content leads to stiffer wires with higher transition temperatures. It's important to consider not only the initial state of the wire but also its behavior under stress and strain, as well as its fatigue resistance over repeated use. This will ensure that you choose an alloy that not only meets your current needs but also has the durability to last over time.

Understanding Nitinol Wire Properties

Nitinol wire exhibits remarkable properties such as shape memory effect and superelasticity due to its unique crystal structure. When heated above its transformation temperature, nitinol undergoes a phase change from martensite to austenite and returns to its original shape. This ability makes it an ideal material for applications requiring precise movement and control.

Nitinol wire's unique properties also make it highly resistant to fatigue and corrosion, making it an excellent choice for long-term use in medical devices, aerospace components, and robotics. Its ability to withstand repeated bending and stretching without losing its shape or strength is a key advantage in these applications. This durability makes nitinol an attractive option for industries where reliability is crucial.

Basic Tools and Techniques for Working with Nitinol

Working with nitinol memory wire requires basic tools such as pliers, heat sources like torches or hot water baths, and fixtures for shaping and activating the wire. Techniques such as bending, twisting, and heat treatment are used to achieve desired shapes and activation states in nitinol components.

Now that you understand how crucial it is to choose the right nitinol alloy based on its properties and have an idea about basic tools and techniques required when working with this incredible material let's move on shaping and activating nitinol memory wire!

Shaping and Activating Nitinol Memory Wire

Nitinol memory wire, also known as nitinol nickel titanium, is a shape memory alloy that can remember its original shape and return to it when heated. This unique property makes it ideal for various applications in industries such as medical devices, robotics, and aerospace.

Heat Treatment Methods for Nitinol

When working with nitinol wire, heat treatment is a crucial step to activate its shape memory effect. By subjecting the metal nitinol to a specific temperature range, you can program it to remember a particular shape. This process involves carefully heating the nitinol wire to its transition temperature and then cooling it in the desired shape. Proper heat treatment ensures that the nitinol will exhibit the desired behavior when activated.

Creating Custom Shapes with Nitinol

One of the most fascinating aspects of working with nitinol memory wire is its ability to be easily shaped into custom forms. Whether you need intricate surgical tools for medical devices or precise components for robotics, nitinol's flexibility allows you to mold it into virtually any design. Using specialized tools and techniques, you can manipulate the titanium nickel alloy into complex shapes without sacrificing its unique properties.

Understanding the Shape Memory Effect in Nitinol

The shape memory effect in nitinol refers to its ability to return to a predetermined shape after being deformed at lower temperatures and then heated above its transformation temperature. This phenomenon is what gives nitinol wire titanium its remarkable resilience and adaptability in various applications. Understanding how this effect works is essential for harnessing the full potential of nitinol in your projects.

The shape memory effect in nitinol is a result of its unique crystalline structure, which allows it to "remember" a specific shape and return to it when heated. This property makes nitinol wire titanium an ideal material for applications such as medical devices, actuators, and eyeglass frames. By understanding the science behind this effect, engineers and designers can create innovative solutions that leverage nitinol's shape memory capabilities to their full potential.

By mastering heat treatment methods, shaping techniques, and understanding the science behind the shape memory effect in nitinol memory wire, you can unlock endless possibilities for innovation and advancement in your projects.

Applications of Nitinol Memory Wire

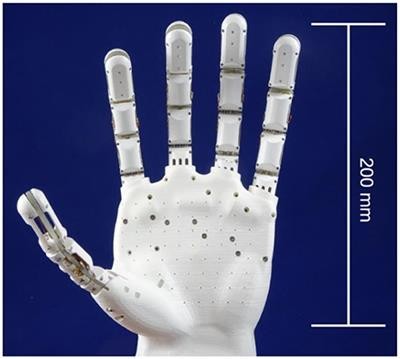

Medical Devices and Nitinol

Nitinol memory wire, also known as nitinol nickel titanium, has revolutionized the medical industry with its shape memory alloy properties. From stents that expand within the body to orthodontic wires that apply gentle pressure to straighten teeth, nitinol's flexibility and biocompatibility make it an ideal material for medical devices.

Robotics and Nitinol Components

In the world of robotics, nitinol wire titanium is used to create innovative components that mimic human muscle movement. These shape memory alloys are employed in robotics for their ability to return to a predetermined shape when heated, allowing for precise and controlled movements in robotic applications such as prosthetics and exoskeletons.

Aerospace and Nitinol's Unique Properties

The unique properties of metal nitinol make it an invaluable material in the aerospace industry. Its superelasticity and shape memory effect allow for the creation of lightweight components that can withstand extreme conditions. From actuators in aircraft wings to deployable structures in space exploration, titanium nickel alloy nitinol plays a crucial role in advancing aerospace technology.

Remember to incorporate these keywords throughout your content: nitinol memory wire, nitinol nickel titanium, shape memory alloy, nitinol wire, metal nitinol, titanium wire, wire titanium, titanium nickel alloy

Tips for Working with Nitinol Memory Wire

Handling and Safety Precautions

When handling nitinol memory wire, it's crucial to wear protective gloves to prevent any potential cuts or scratches from the sharp edges of the wire. Additionally, always work in a well-ventilated area when heating nitinol to avoid inhaling any fumes that may be produced during the shaping process. Proper eye protection should also be worn to shield against any flying debris or particles.

In addition to wearing protective gloves and working in a well-ventilated area, it's important to use appropriate tools when handling nitinol memory wire. Using pliers or tweezers with a non-slip grip can help provide better control and reduce the risk of accidental injury. It's also advisable to keep the work area organized and free of clutter to minimize the chance of tripping or knocking over equipment while working with the wire.

Troubleshooting Common Issues

If you encounter issues with nitinol memory wire not returning to its original shape after activation, it may be due to improper heat treatment or over-stressing the wire during shaping. To troubleshoot this, carefully reheat the wire using the appropriate method and allow it to cool naturally before attempting to reshape it. If there are kinks or bends in the wire, gently massage them out using your fingers or a soft cloth. Additionally, consider using a lower activation temperature for better shape memory effect and durability. This can help prevent over-stressing the wire and ensure it maintains its original shape over the long term. It's always best to err on the side of caution when working with nitinol memory wire to avoid potential issues down the line.

Best Practices for Long-Term Durability

To ensure the long-term durability of nitinol memory wire, store it in a cool, dry place away from direct sunlight and moisture. When not in use, coil the wire loosely rather than tightly winding it around a spool to prevent any unnecessary stress on the metal. Avoid exposing nitinol wire to extreme temperatures or rapid temperature changes, as this can affect its shape memory properties and lead to premature wear.

Additionally, it's important to handle nitinol memory wire with care to avoid kinking or bending it sharply, as this can cause permanent damage to the metal. When manipulating the wire, use smooth, gradual movements to maintain its shape memory and prevent any weakening of its structure over time. By being mindful of how you handle nitinol wire, you can ensure that it remains in optimal condition for your future projects.

Remember that safety is paramount when working with nitinol memory wire and always take precautions to protect yourself from potential hazards. By following these tips and best practices, you can effectively handle and shape nitinol while maximizing its longevity and performance in your projects.

Exploring the Future of Nitinol Memory Wire

Innovations in Nitinol Technology

As the demand for advanced materials grows, so does the need for continuous innovation in nitinol technology. Engineers and researchers are constantly pushing the boundaries of what is possible with nitinol nickel titanium, exploring new ways to enhance its shape memory alloy properties and improve its overall performance. From refining manufacturing processes to developing new compositions, the future of nitinol technology is filled with exciting possibilities.

With the growing interest in minimally invasive medical procedures, nitinol technology is being explored for potential new applications in the medical field. Its unique properties, such as superelasticity and shape memory, make it an ideal candidate for use in medical devices like stents, orthodontic wires, and surgical tools. As researchers continue to innovate and refine nitinol technology, we can expect to see even more groundbreaking advancements in the medical industry, improving patient outcomes and revolutionizing healthcare practices.

Potential New Applications for Nitinol

With its unique ability to remember and recover its original shape, nitinol memory wire has already found applications in various industries, including medical devices, robotics, and aerospace. Looking ahead, there is great potential for even more diverse uses of this remarkable material. From smart textiles to energy harvesting systems, the versatility of nitinol wire titanium opens up a world of possibilities for future applications.

As nitinol memory wire continues to revolutionize industries such as medical devices, robotics, and aerospace, the potential for new applications is virtually limitless. One exciting area of exploration is in the development of smart textiles that can adapt to changes in temperature or body movement. Imagine clothing that automatically adjusts to keep you comfortable in any environment, all thanks to the unique properties of nitinol wire.

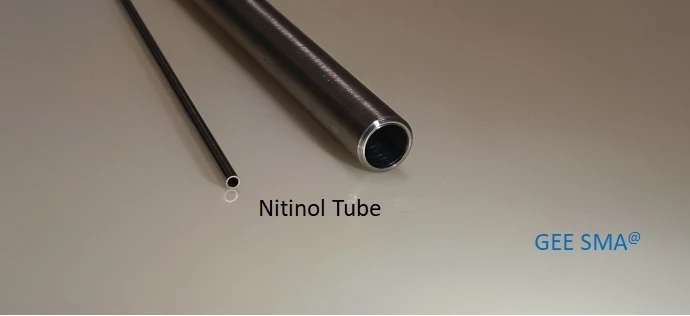

GEE SMA's Role in Advancing Nitinol Materials

As a leading manufacturer and supplier of metal nitinol products, GEE Shape Memory Alloys (SMA) plays a crucial role in advancing the field of nitinol materials. With a focus on research and development, GEE SMA is at the forefront of driving innovation in this space. By collaborating with industry partners and investing in cutting-edge technologies, GEE SMA is committed to unlocking the full potential of nitinol memory wire and shaping its future.

Furthermore, GEE SMA is dedicated to providing customized solutions for a wide range of industries, from medical devices to aerospace. The versatility of nitinol allows for endless possibilities in product design and functionality, and GEE SMA is committed to working closely with clients to bring their visions to life. By offering unparalleled expertise and support throughout the development process, GEE SMA ensures that the unique properties of nitinol are fully utilized in each application.

Remember that innovation never stops when it comes to nitinol nickel titanium! The potential for new applications is endless as we continue to push boundaries with this incredible shape memory alloy. And with pioneers like GEE SMA leading the charge, there's no telling what amazing advancements lie ahead for this remarkable material!

Conclusion

Nitinol memory wire is a game-changer in the world of materials science, offering unparalleled flexibility and resilience. Whether you're a medical professional, engineer, or hobbyist, mastering the potential of nitinol nickel titanium opens up a world of possibilities for innovation and creativity.

Mastering the Potential of Nitinol Memory Wire

By understanding the unique properties and shape memory effect of nitinol wire titanium nickel alloy, you can unlock its full potential in your projects. From intricate medical devices to cutting-edge robotics, nitinol offers a level of precision and performance that traditional materials simply can't match.

Incorporating Nitinol into Your Projects

Incorporating nitinol into your projects opens up a world of opportunities for creating custom shapes and activating its shape memory alloy properties. Whether you're looking to enhance the functionality of your designs or push the boundaries of what's possible, nitinol wire titanium nickel alloy is an invaluable tool for any innovator.

GEE SMA: Your Partner in Nitinol Innovation

As a leader in shape memory alloy technology, GEE SMA is committed to advancing the field of nitinol memory wire through cutting-edge research and development. With our expertise and industry-leading products, we're here to support your journey in harnessing the power of nitinol for your next breakthrough project.